Wholewheat quick-cooking noodles and processing method thereof

A processing method and noodle cooking technology, applied in applications, food preparation, food science, etc., can solve the problem of single nutrition, achieve the effect of smooth taste, improved quality, and strong wheat aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of whole wheat instant noodles, it is prepared from following raw materials:

[0049] Medium-strength wheat flour that has passed through a 70-mesh sieve: 80kg;

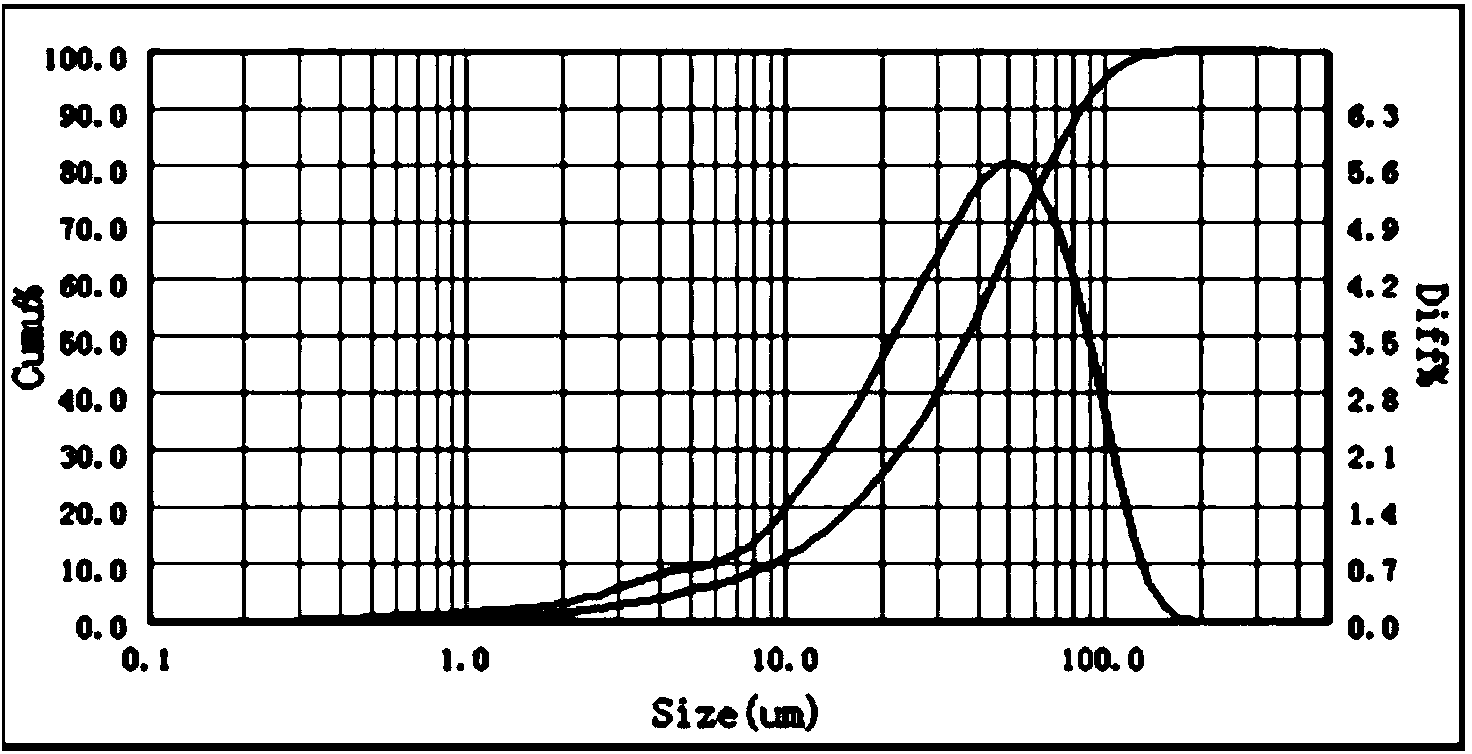

[0050] Bran powder with a particle size of 0.3-250μm: 18kg;

[0051] Wheat germ powder with a particle size of 70-200 mesh: 2kg;

[0052] Potato starch: 20kg;

[0053] Edible salt: 3kg;

[0054] The particle size distribution of bran powder is shown in Table 1.

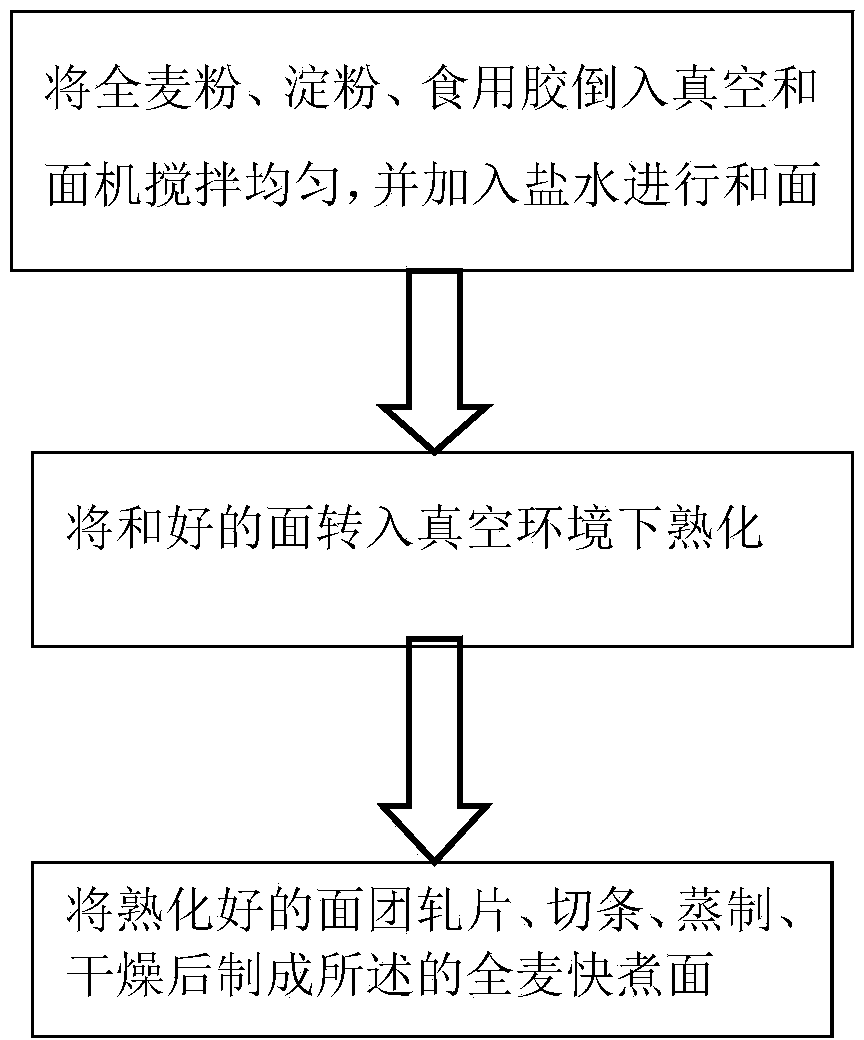

[0055] The above-mentioned whole wheat instant noodles processing method is as follows:

[0056] The step 1 is to pour the medium-strength gluten wheat flour, the bran powder and wheat germ powder obtained by superfine grinding into the vacuum dough mixing machine, and add 40.25kg of salt water to knead the dough, and the vacuum degree of the vacuum kneading machine It is: 0.08Mpa; the stirring time is 8 minutes, and the kneading time is 15 minutes after adding salt water.

[0057] Step 2, transfer the reconciled noodles to a vacuum noodl...

Embodiment 2

[0061] A kind of whole wheat instant noodles, it is prepared from following raw materials:

[0062]

[0063]

[0064] The particle size distribution of bran powder is shown in Table 1

[0065] The above-mentioned whole wheat instant noodles processing method is as follows:

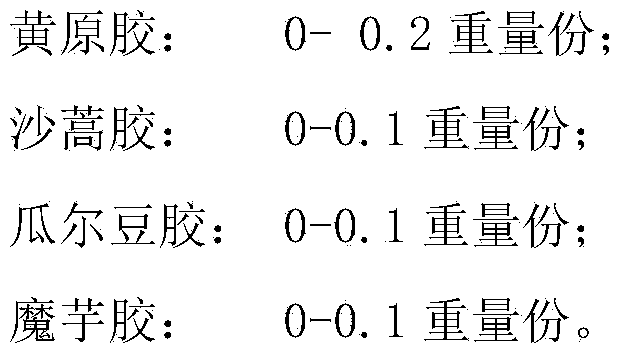

[0066] Step 1, the step 1 is to pour medium-strength gluten wheat flour, bran powder, wheat germ powder, and edible glue into the vacuum dough mixer, and add 29.44kg of salt water to knead the dough, and then vacuum The vacuum degree of the dough mixer is: 0.01Mpa; the stirring time is 10 minutes, and the dough mixing time is 20 minutes after adding salt water.

[0067] Step 2, transfer the reconciled noodles to a vacuum noodle belt with a vacuum degree of 0.08Mpa for curing, and the curing time is 15 minutes;

[0068] Step 3, after curing, the dough is rolled 5 times in an environment with a humidity of 65%, including 1 time at a rolling distance of 3mm, 2.5mm, 1.5mm, 1.25mm, and 1mm, and finally ...

Embodiment 3

[0071] A kind of whole wheat instant noodles, it is prepared from following raw materials:

[0072]

[0073] The particle size distribution of bran powder is shown in Table 1

[0074] The above-mentioned whole wheat instant noodles processing method is as follows:

[0075] Step 1, the step 1 is to pour medium-strength gluten wheat flour, bran powder, wheat germ powder, and edible glue into the vacuum dough mixer, and add 38.44kg of salt water to knead the dough, and then vacuum The vacuum degree of the dough mixer is: 0.05Mpa; the stirring time is 3 minutes, and the dough mixing time is 20 minutes after adding salt water.

[0076] Step 2, transfer the reconciled noodles to a vacuum noodle belt with a vacuum degree of 0.07Mpa for curing, and the curing time is 5 minutes;

[0077] Step 3, after aging, the sheet is rolled 9 times in an environment with a humidity of 65%, and rolled 4 times at a rolling distance of 2 mm, including direct rolling once, three folds twice, half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com