Moringa oleifera rice noodles and production process thereof

A production process and rice noodle technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of rice noodle safety that cannot be ignored, illegal addition, single nutrient content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

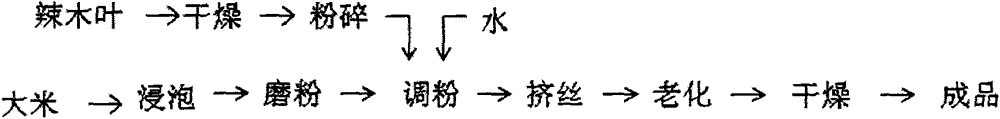

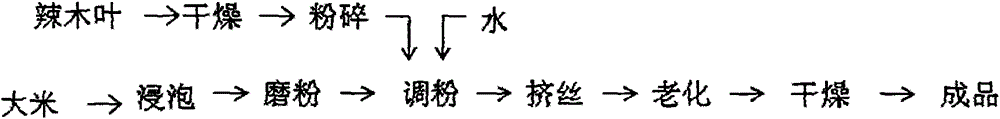

Method used

Image

Examples

Embodiment 2

[0024] Embodiment 2: According to the above technical process, fresh leaves of Moringa oleifera are picked, rinsed with water, drained, dried and pulverized, and passed through a 80-100 mesh sieve for later use. Weigh and take 25kg of japonica rice and 5kg of indica rice, and sieve them before entering the water to remove impurities such as yellow rice grains, rice grains and gravels as much as possible. Wash the cleaned rice twice, skim the floating rice bran and other impurities, then soak in water for 3.5 hours, drain for 50 minutes and then grind. Weigh 3kg moringa powder and mix evenly with the ground rice flour, add 11.5kg of water to adjust the powder, stir evenly and place it on the machine for 30min to extrude. Fix the bamboo strips on the powder receiving device to collect the powder. After the bamboo strips are filled with powder, they are placed in the aging room for aging. After aging for 14 hours, the powder can be collected. At this time, the Moringa rice noodl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com