Self-cleaning polypropylene plastic barrel and preparation method thereof

A polypropylene plastic, self-cleaning technology, applied in the field of plastic packaging barrels, can solve the problems that affect the secondary use of plastic packaging barrels, waste, and easy adhesion to the wall, etc., to improve self-cleaning performance, increase molecular distance, The effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

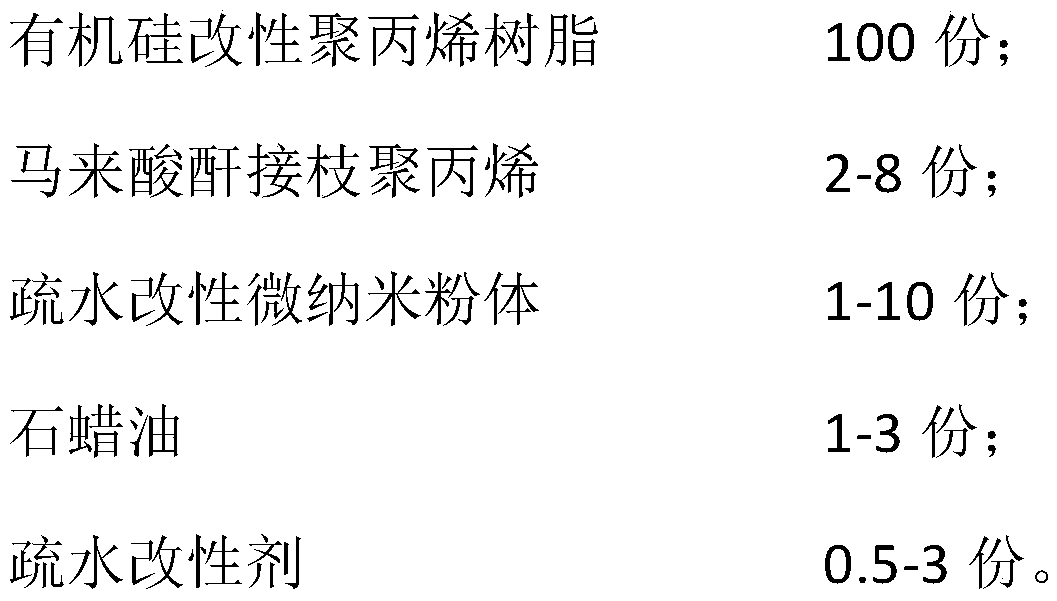

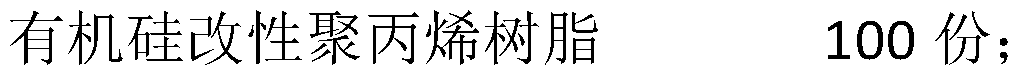

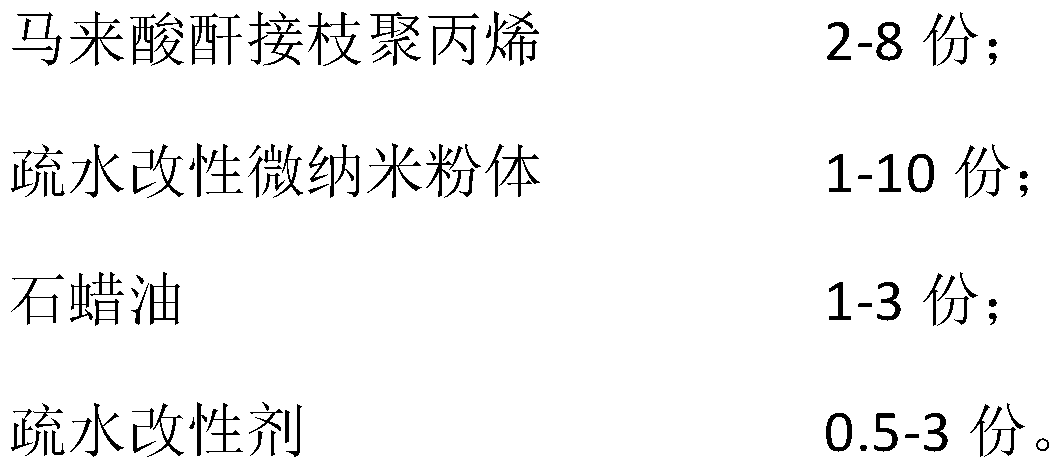

[0032] A self-cleaning polypropylene plastic bucket, its raw material composition and weight parts are:

[0033]

[0034]

[0035] A preparation method for a self-cleaning polypropylene plastic barrel, comprising the steps of:

[0036] (1) Preparation of silicone graft modified polypropylene (SMPP-1)

[0037] (1-a) Raw materials: 100 parts of polypropylene, 0.2 parts of BPO (benzoyl peroxide), 5 parts of silane coupling agent A-151 (vinyltriethoxysilane), and 2 parts of toluene.

[0038] (1-b) Preparation: Dissolve BPO (benzoyl peroxide) in toluene, stir until dissolved, then add silane coupling agent A-151, stir evenly, and make a mixed solution; add poly Propylene resin, then add the mixed liquid, mix at 105°C for 10 minutes; put the mixed material into a single-screw extruder for granulation, the temperature parameters of the extruder, from the feeding part to the die: 160°C, 180°C , 190°C, 195°C, 200°C to obtain silicone graft modified polypropylene (SMPP-1)

[00...

Embodiment 2

[0049] A self-cleaning polypropylene plastic bucket, its raw material composition and weight parts are:

[0050] A self-cleaning polypropylene plastic bucket, its raw material composition and weight parts are:

[0051]

[0052] Other preparation methods are the same as in Example 1.

Embodiment 3

[0054] A self-cleaning polypropylene plastic bucket, its raw material composition and weight parts are:

[0055]

[0056] A preparation method for a self-cleaning polypropylene plastic barrel, comprising the steps of:

[0057] (1) Preparation of silicone graft modified polypropylene (SMPP-2)

[0058] (1-a) raw material formula is different from embodiment 1, and concrete formula is as follows:

[0059] 100 parts of polypropylene, 0.4 parts of BPO (benzoyl peroxide), 10 parts of silane coupling agent A-151 (vinyltriethoxysilane) and 3 parts of toluene.

[0060] Other preparation methods are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com