Device and method for determining surface tenacity of material

A control device and humidity technology, applied in the direction of measuring devices, analyzing materials, adopting mechanical devices, etc., can solve the problems of coating film damage, peeling, affecting appearance and use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following embodiments, "material" includes the meaning of "paint" or "decorative paint used on walls or furniture".

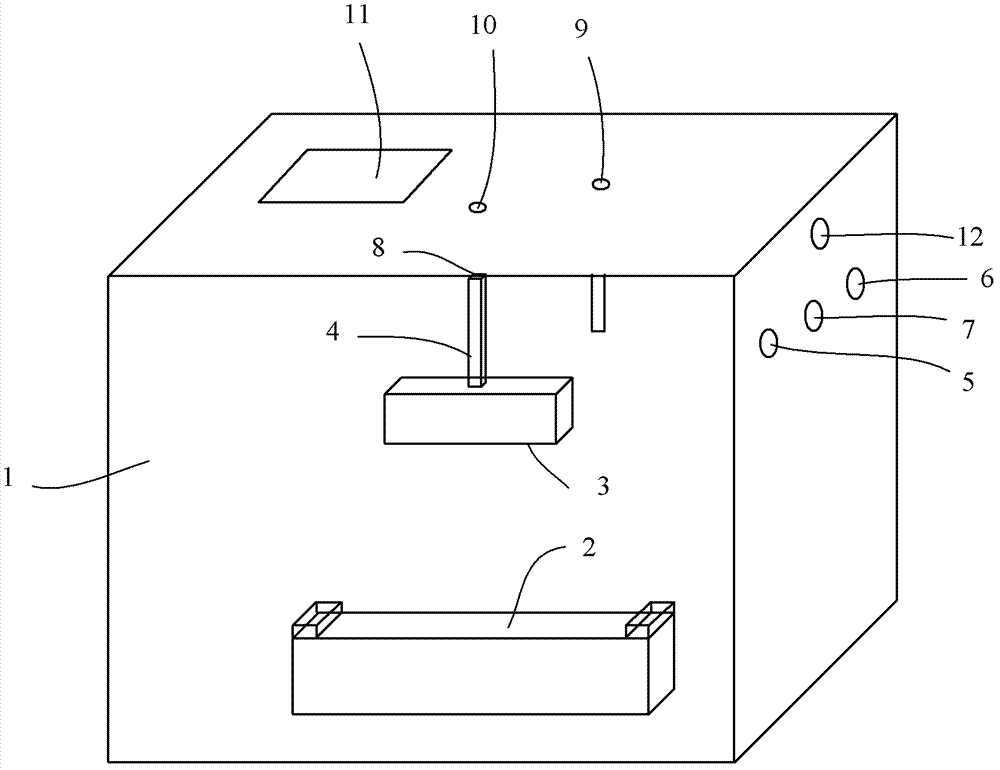

[0016] Such as figure 1 As shown, the device for measuring the surface adhesion of materials includes a test environment 1, a first sample fixing platform 2, a second sample fixing platform 3, a pressure controller 4, a temperature controller 5, a humidity controller 6, a pressure adjustment Device 7, pressure, bonding force sensor 8, temperature sensor 9, humidity sensor 10, display 11 and timer 12.

[0017] The test environment 1 is but not limited to a closed box. The first sample fixing table 2 and the second sample fixing table 3 are set in the testing environment 1, and the pressurization controller 4 is but not limited to a lifting device, such as a hydraulically driven lifting device. In one embodiment of the present invention, the first sample fixing table 2 is connected to the pressure output end (lower end in the figure) of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com