Lyocell fiber spinning solution waste recycling device and recycling method thereof

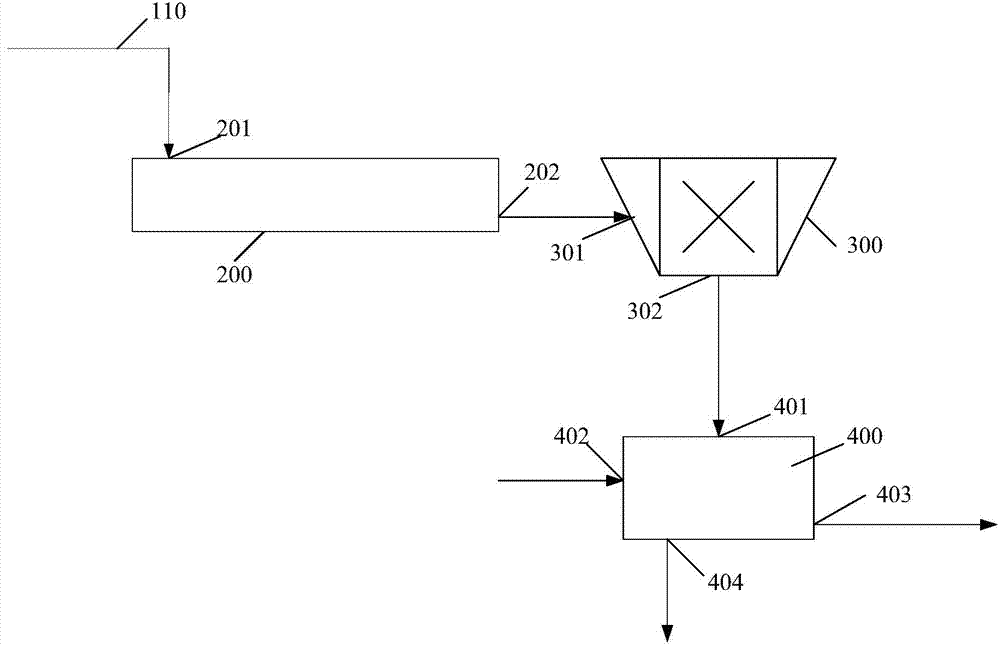

A spinning dope, recycling device technology, applied in rayon recycling, textiles and papermaking, fiber chemical characteristics, etc., can solve the problem that spinning dope waste cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The amount of waste generated is 150kg / h, and the discharge is 3h

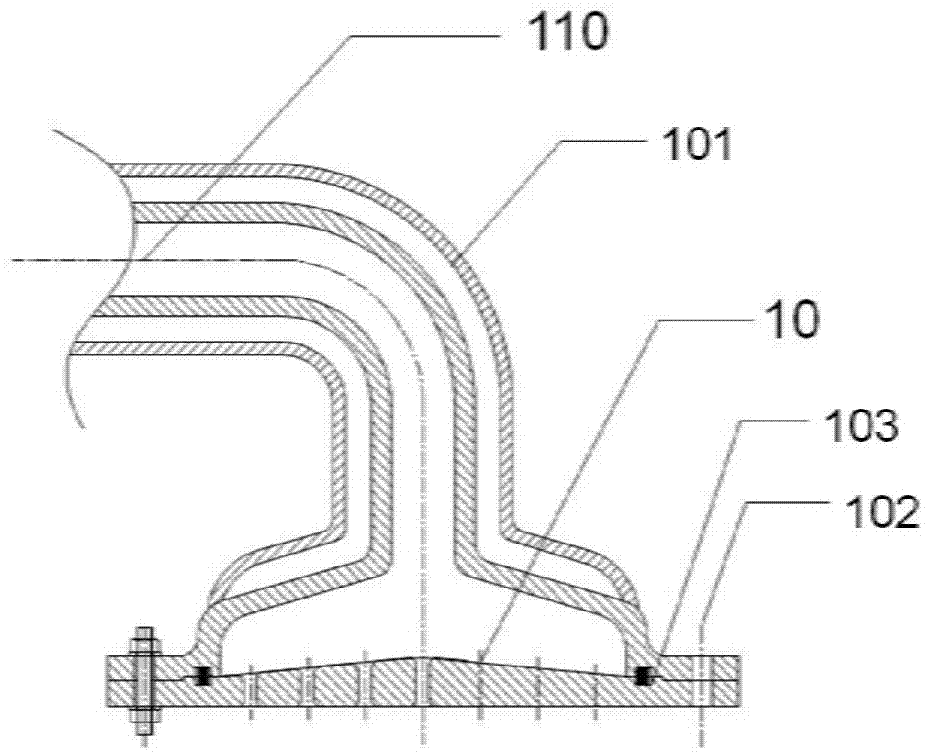

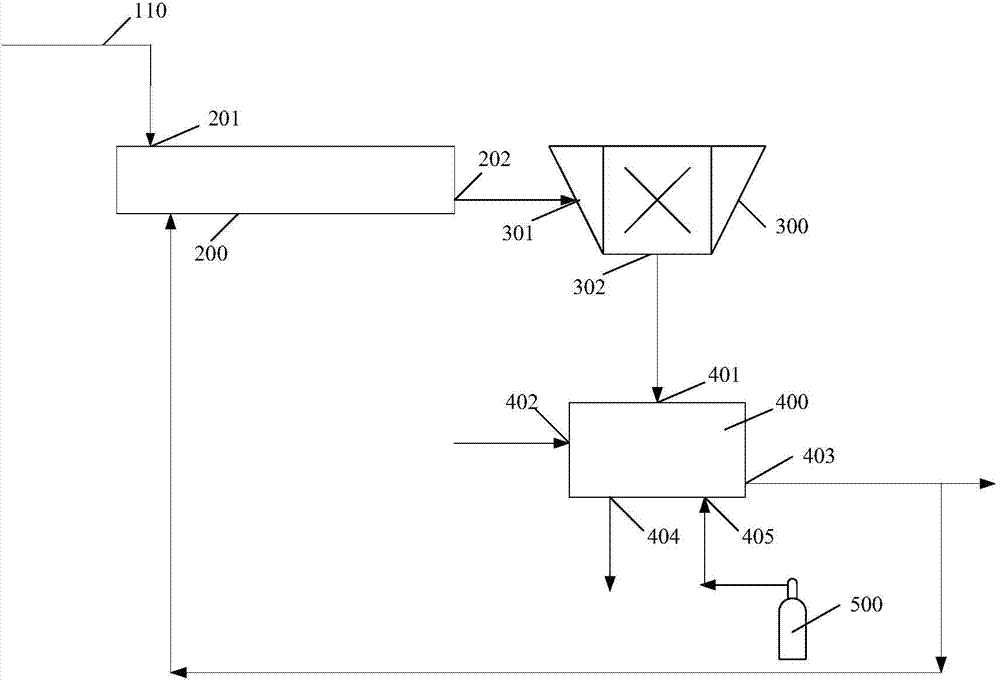

[0043] For discharge, use the pressure in the spinning dope pipeline to install an extrusion device with a small hole array at the discharge port. The diameter of the extrusion hole is 6mm, the number of holes is 20, the center distance of the holes is 18mm, and the area of the holes is 80cm 2 . The waste material is extruded into strips with a diameter of 8-10 mm through the device.

[0044] After cooling, the thin strips of waste material fall into the long water tank located under the extrusion device, adjust the circulating water flow to drive the waste material to the shredder inlet at the other end of the water tank, and the moving speed of the waste material in the water flow is 0.2m / s , the length of the tank is 2m.

[0045] Shredding, using a shredder to shred the strip waste into granules with a particle size of 8-15mm, the granules fall into the stainless steel mesh basket located below ...

Embodiment 2

[0048] The amount of waste generated is 2000kg / h, and the discharge is 3h

[0049] For discharge, use the pressure in the spinning dope pipeline to install an extrusion device with a small hole array at the discharge port. The diameter of the extrusion hole is 8mm, the number of holes is 133, the center distance of the holes is 24mm, and the area of the holes is 820cm 2 . The waste material is extruded into strips with a diameter of 10-12 mm through the device.

[0050] After cooling, the strip-shaped waste material falls into the long water tank located under the extrusion device, and the circulating water flow is adjusted to drive the waste material to move to the shredder inlet at the other end of the water tank. The moving speed of the waste material in the water flow is 0.3m / s , the length of the tank is 4m.

[0051] Shredding, using a shredder to shred the strip waste into 10-20mm granules, the granules fall into the stainless steel mesh basket located under the dis...

Embodiment 3

[0054] The amount of waste generated is 5000kg / h, and the discharge is 3h

[0055] For discharge, use the pressure in the spinning dope pipeline to install an extrusion device with a small hole array at the discharge port. The diameter of the extrusion hole is 10mm, the number of holes is 206, the center distance of the holes is 40mm, and the area of the holes is 3600cm 2 . The waste material is extruded into strips with a diameter of 12-16 mm through the device.

[0056] After cooling, the strip-shaped waste material falls into the long water tank located under the extrusion device, and the circulating water flow is adjusted so that it can drive the waste material to move to the shredder inlet at the other end of the water tank. The moving speed of the waste material in the water flow is 0.5m / s , the length of the tank is 5m.

[0057] Shredding, using a shredder to shred the strip waste into 12-30mm granules, the granules fall into the stainless steel mesh basket located...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com