Detection device for precision hardware production

A detection device and hardware technology, which is applied to measurement devices, uses stable tension/pressure to test the strength of materials, and tests the hardness of materials. It can solve problems such as unsatisfactory detection results, avoid errors, improve detection results, avoid The effect of changing the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

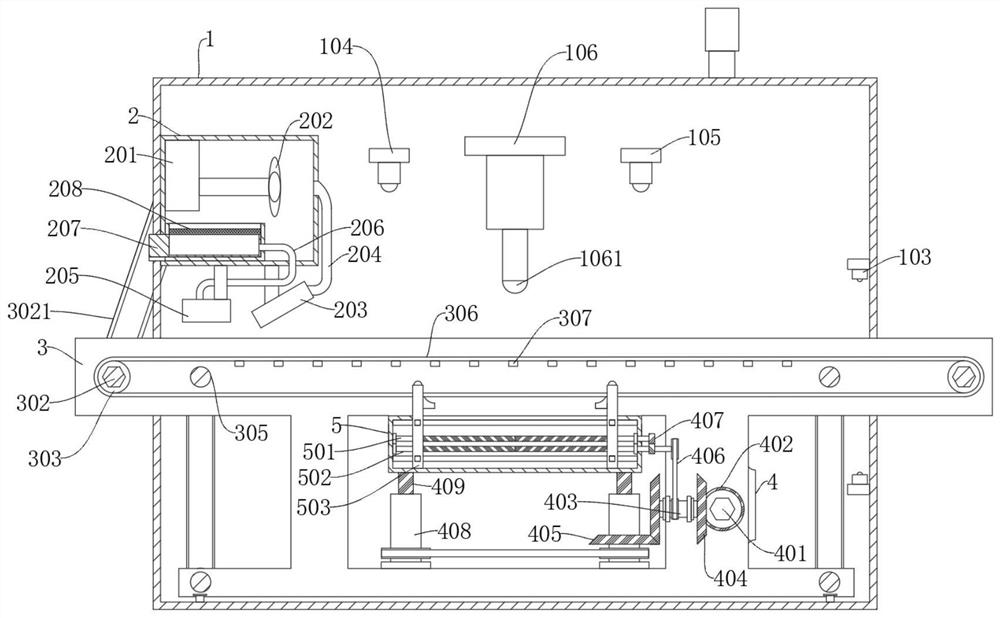

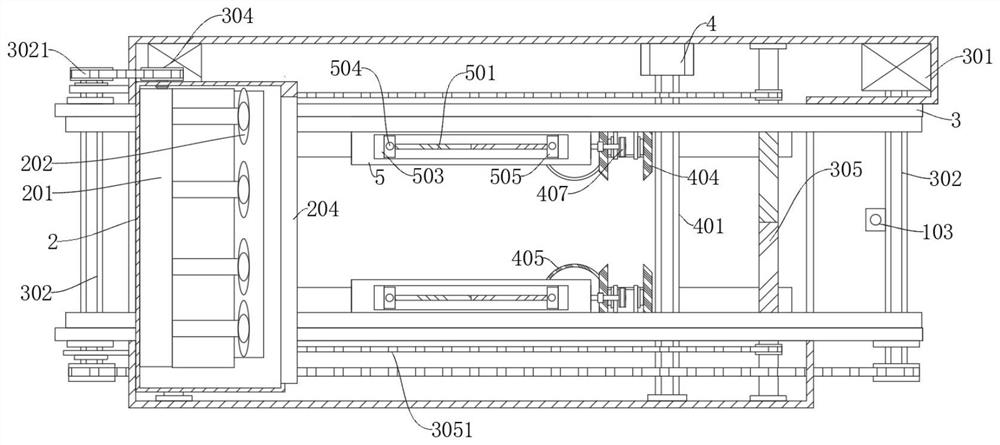

[0026] Example: refer to Figure 1-Figure 5 , a detection device for precision hardware production, comprising an installation box 1, also includes: a detection assembly arranged on the installation box 1; a dust removal assembly arranged on the installation box 1; an installation frame 3 slidingly connected in the installation box 1 ; the transportation assembly arranged on the mounting frame 3; the lifting assembly connected to the mounting frame 3 in rotation; the second two-way screw mandrel 501 and the third two-way screw mandrel 502 connected in rotation on the mounting table 5; fixedly connected to the output of the lifting assembly The mounting table 5 at the end, the mounting table 5 is slidingly connected with a clamping rod 503, the clamping rod 503 is provided with a chute 7, the chute 7 is rotationally connected with a fourth two-way screw rod 702, and two groups of threads of the fourth two-way screw rod 702 A first threaded block 703 and a second threaded block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com