Waste rock throwing equipment suitable for fully mechanized coal mining face roadway

A fully-mechanized mining face and roadway technology, which is applied to mining equipment, earthwork drilling, filling, etc., can solve problems such as gap sizes, gangue rolling, and construction environment hazards, so as to increase relative density and support strength , clamping and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

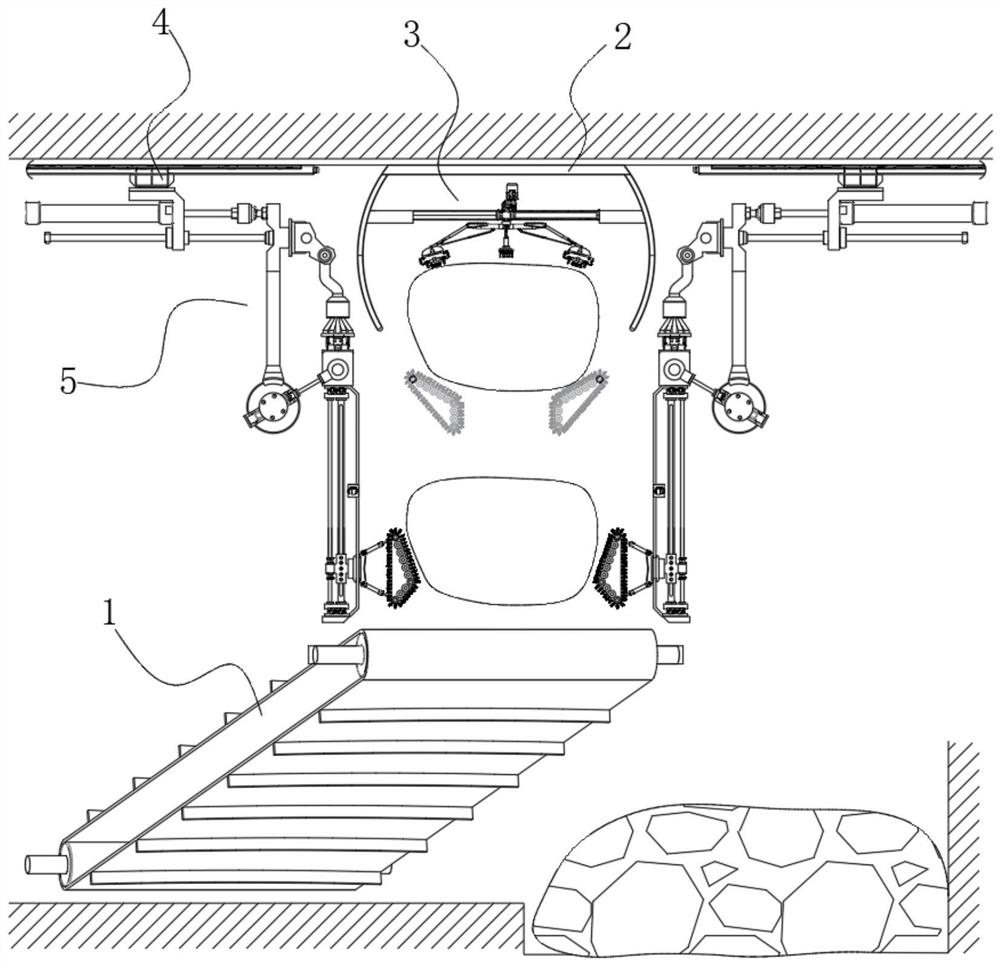

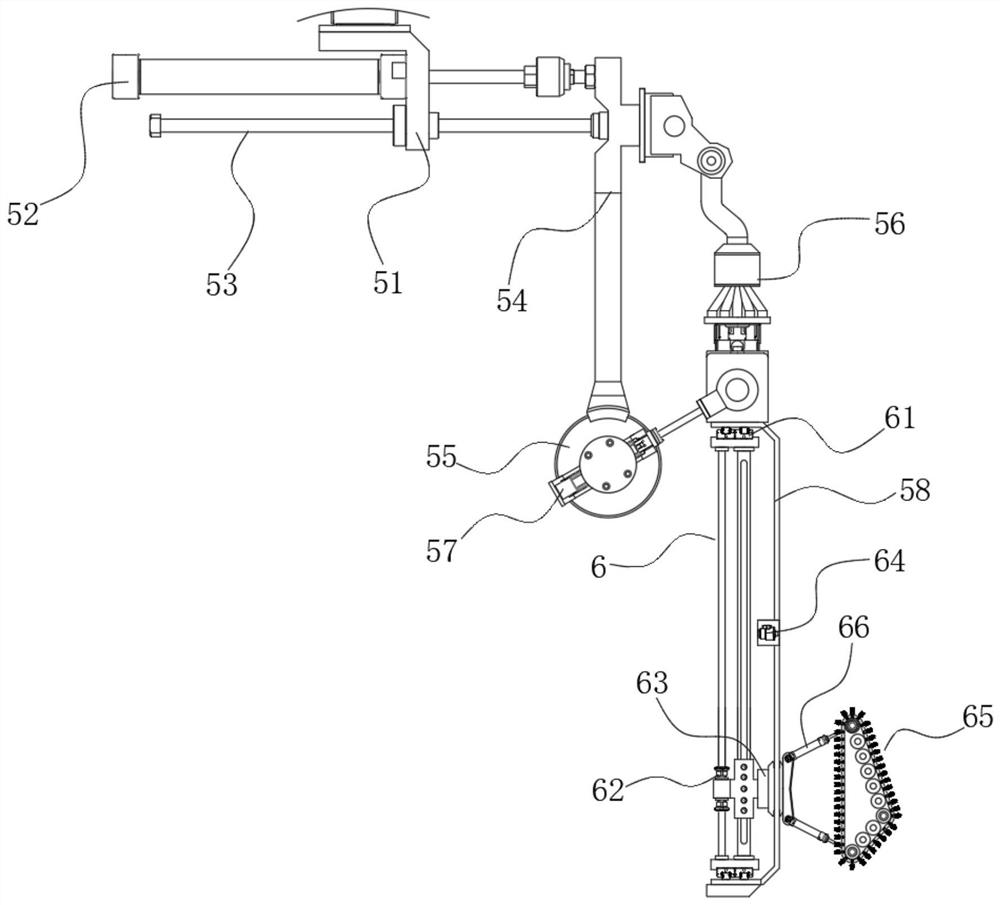

[0047] refer to Figure 1-4 , the present invention provides a technical solution: a kind of dumping equipment suitable for the roadway of fully mechanized mining face, which includes:

[0048] The gangue belt 1 is set obliquely towards the filling area;

[0049] The blocking cover frame 2 is arranged directly above the cast-off belt 1;

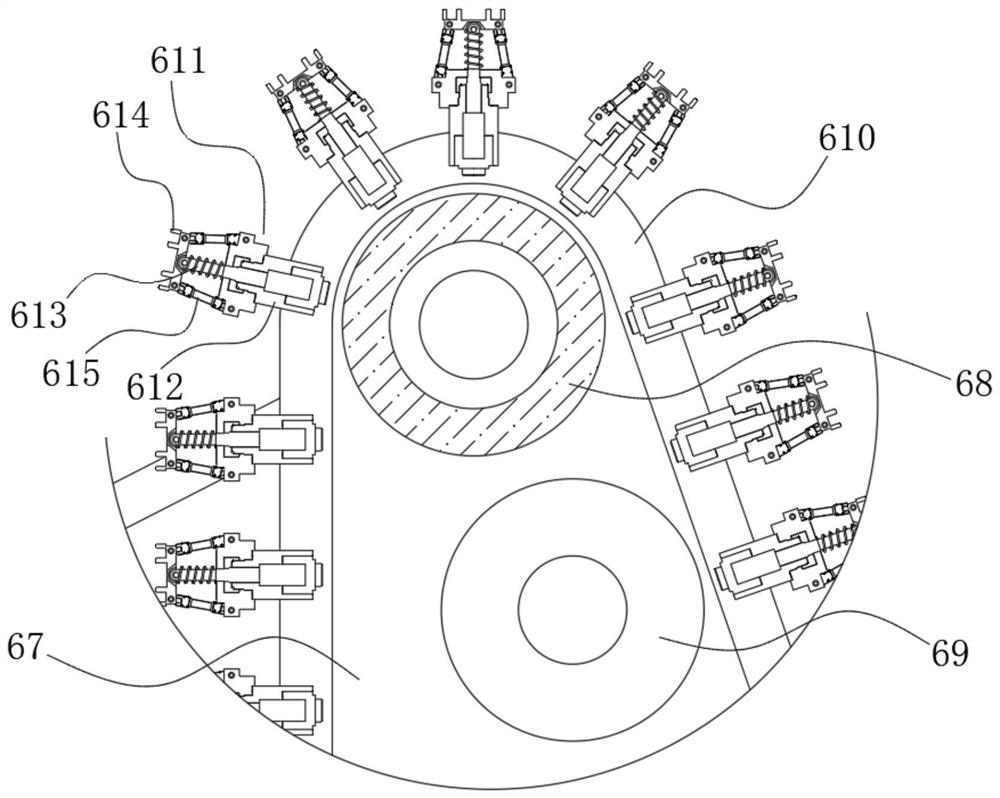

[0050] The crushing angle grinding device 3 is installed inside the barrier cover frame 2, and a plurality of groups are arranged along the conveying direction of the casting belt 1, and the distance between the lower end of the crushing and grinding device 3 of each group is from the upper surface of the casting belt 1 are equally spaced;

[0051] Guide rail one 4 is symmetrically arranged on the left and right sides of the shielding cover frame 2, and is longitudinally misaligned with the crushing angle grinding device 3, and a set of the crushing angle grinding device 3 is installed between each adjacent Said guide rail-4;

[0052] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com