Gas explosion impact force detecting device and method

A gas explosion and detection device technology, applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as damage, difficult explosion impact, difficulty in meeting actual needs, etc., and achieve accurate control of outburst time and exit opening time Short, the effect of improving the level of protection technology and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

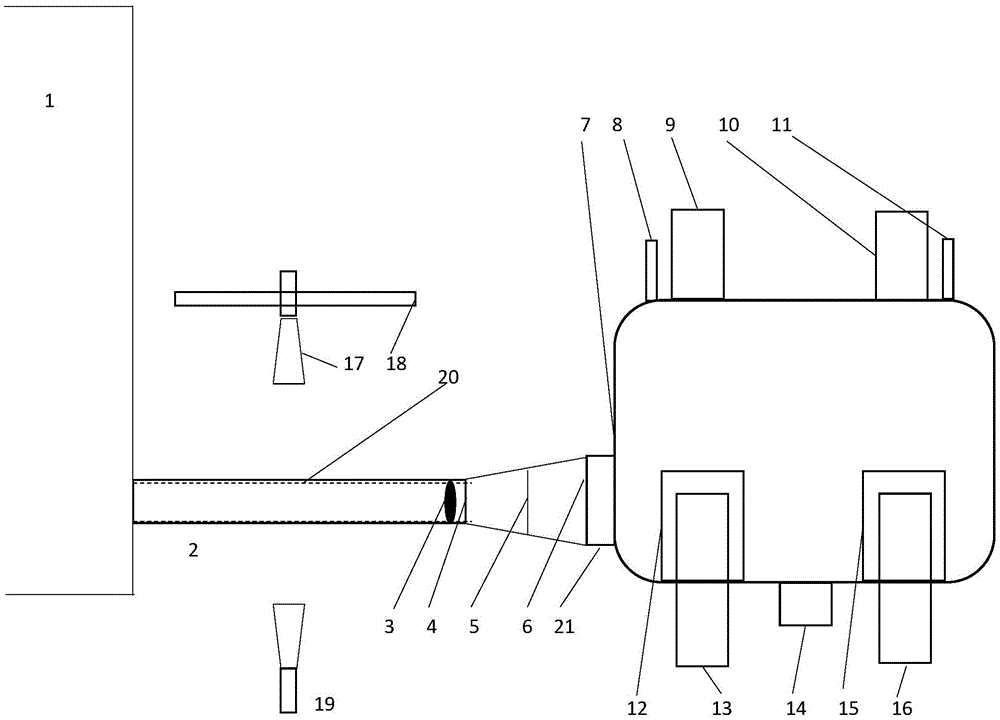

[0043] A gas explosion impulse detection device, characterized in that:

[0044] The detection device includes a buffer bin, a blast vent pipe, a pipeline, a blast bin, and a camera unit;

[0045] Among them, the volume of the buffer chamber is 30 times that of the blasting chamber, the material is made of steel, the interior is coated with flame-retardant materials, and the exterior is coated with anti-rust paint;

[0046] The explosion-venting pipe connects the pipeline and the blasting chamber, and the explosion-venting pipe is provided with a first explosion-venting membrane, a second explosion-venting membrane, The third explosion-venting membrane;

[0047] The pipeline is an explosion-proof material pipeline, and the explosion-proof material is transparent. A sliding vane chute and a sliding vane are arranged in the pipeline, and the sliding vanes are clamped in four sliding vane chutes arranged symmetrically on the inside parallel to the pipeline, and Under the shock ...

Embodiment 2

[0067] A gas explosion impulse detection device, characterized in that:

[0068] The detection device includes a buffer bin, a blast vent pipe, a pipeline, a blast bin, and a camera unit;

[0069] Among them, the volume of the buffer chamber is 20 times that of the blasting chamber, the material is made of stainless steel, the interior is coated with flame-retardant materials, and the exterior is coated with anti-rust paint;

[0070] The explosion-venting pipe connects the pipeline and the blasting chamber, and the explosion-venting pipe is provided with a first explosion-venting membrane, a second explosion-venting membrane, The third explosion-venting membrane;

[0071] The pipeline is an explosion-proof material pipeline, and the explosion-proof material is transparent. A sliding vane chute and a sliding vane are arranged in the pipeline, and the sliding vanes are clamped in four sliding vane chutes arranged symmetrically on the inside parallel to the pipeline, and Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com