Patents

Literature

222 results about "Impulse detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

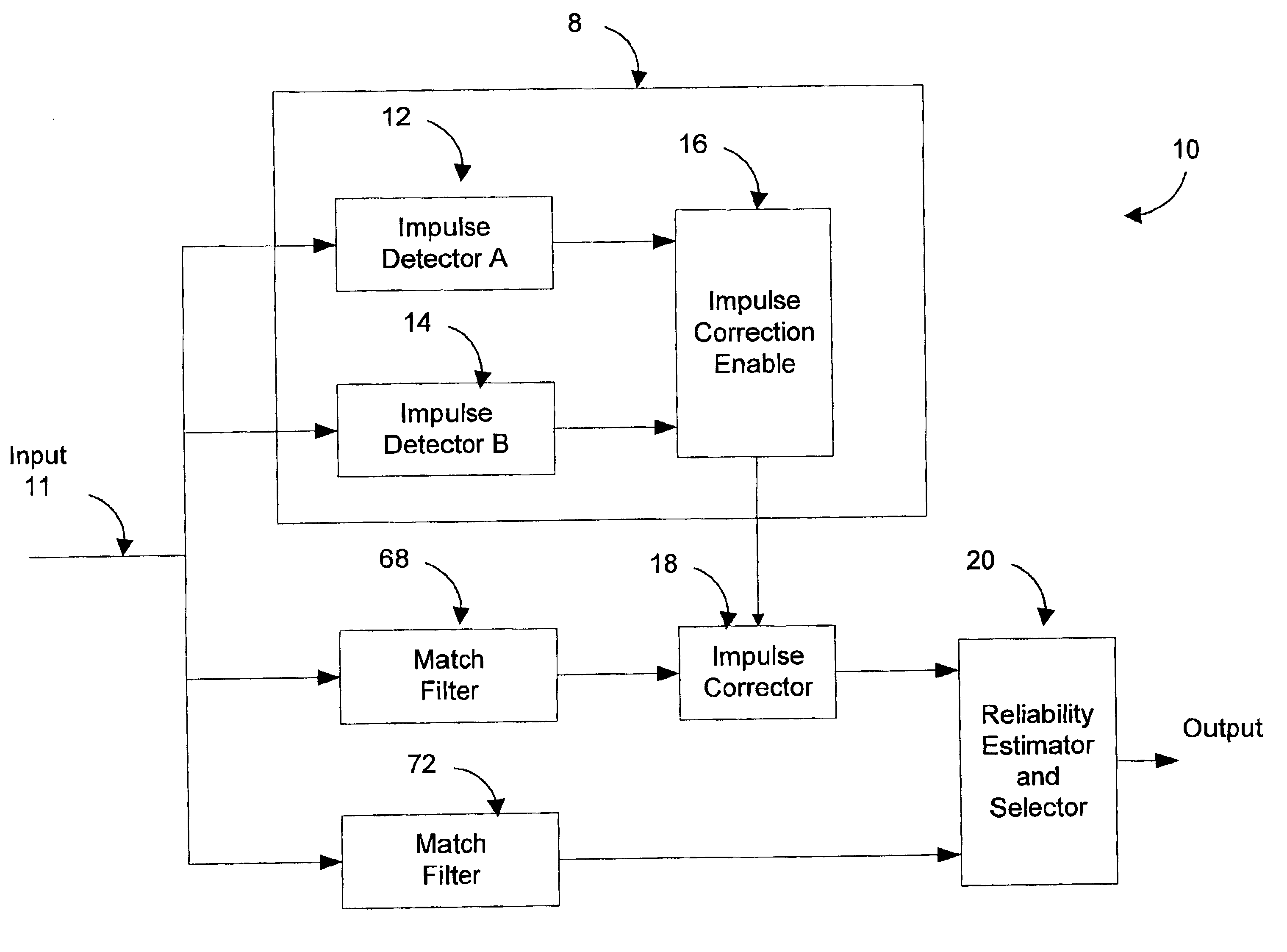

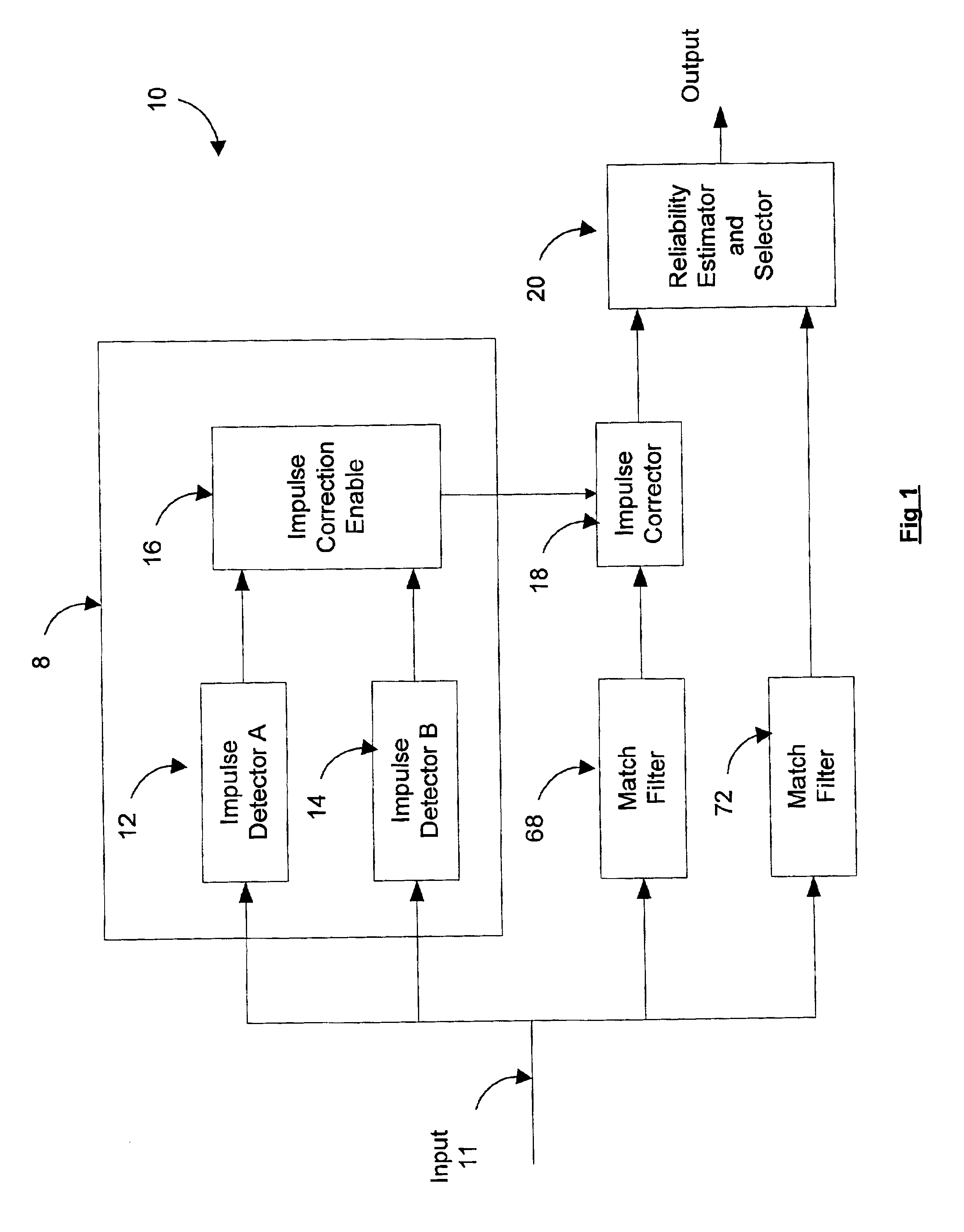

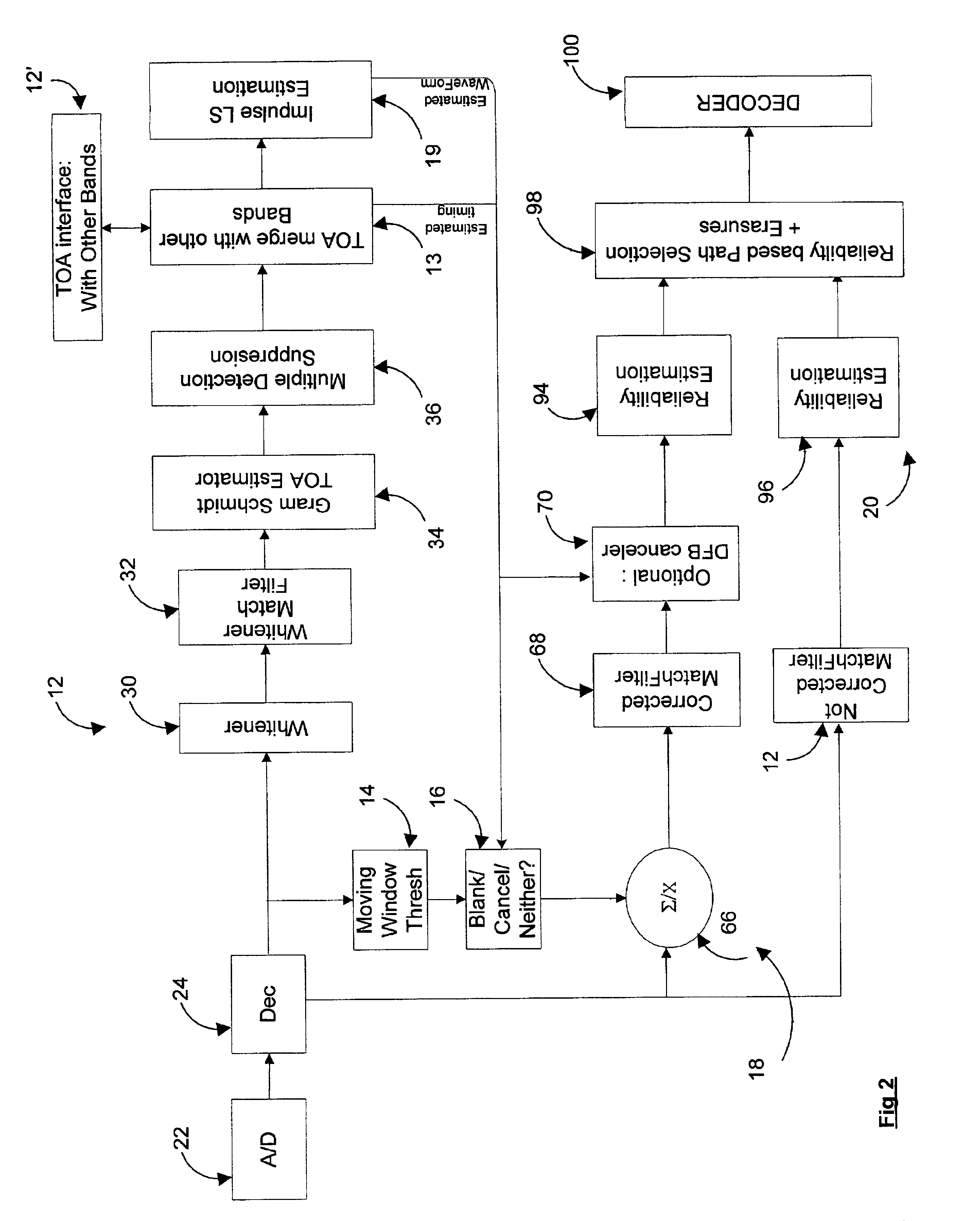

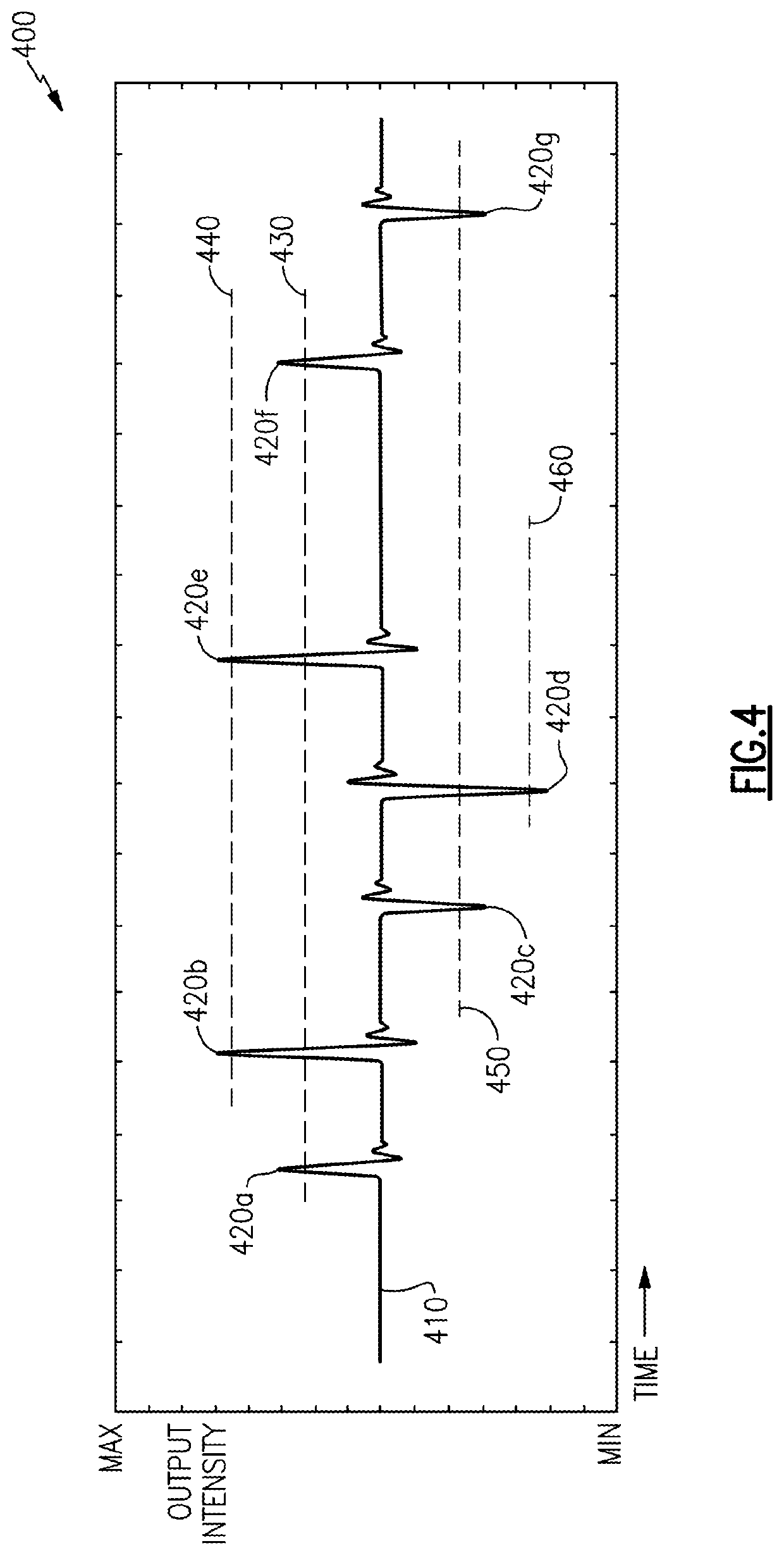

Method and system for detecting, timing, and correcting impulse noise

InactiveUS6920194B2Solve their vulnerability to impulse noiseLess complexDc level restoring means or bias distort correctionMulti-frequency code systemsData signalGram schmidt

A system for detecting and correcting impulse noise present on an input data signal includes an impulse detector module receiving an input data signal and producing as output an correction enable signal indicating when an impulse correction is required. An impulse corrector module receives the input data signal and a correction enable signal and produces a corrected data signal, e.g., having the impulse canceled or blanked, as output. A reliability estimator and selector module receives the corrected data signal and the input data signal and selects as output the input signal which is more reliable. In one embodiment, the impulse detector includes first and second complementary impulse detectors, the outputs of which are analyzed by an enable and correction module to produce an impulse detection signal with improved accuracy. Preferably, the enable and correction module also indicates the most appropriate type of impulse correction in accordance with the detection signals from the complementary detectors. A novel system and method of detecting impulses based on Gram Schmidt techniques is also presented. In this method, one or more channels of a multi-channel data signal are kept free of data. When a whitening filter is applied, impulses on these quiet channels are emphasized. The Gram Schmidt technique exploits this fact to provide for improved impulse detection. The system can be modified to detect other types of low dimensionality noise.

Owner:RPX CORP

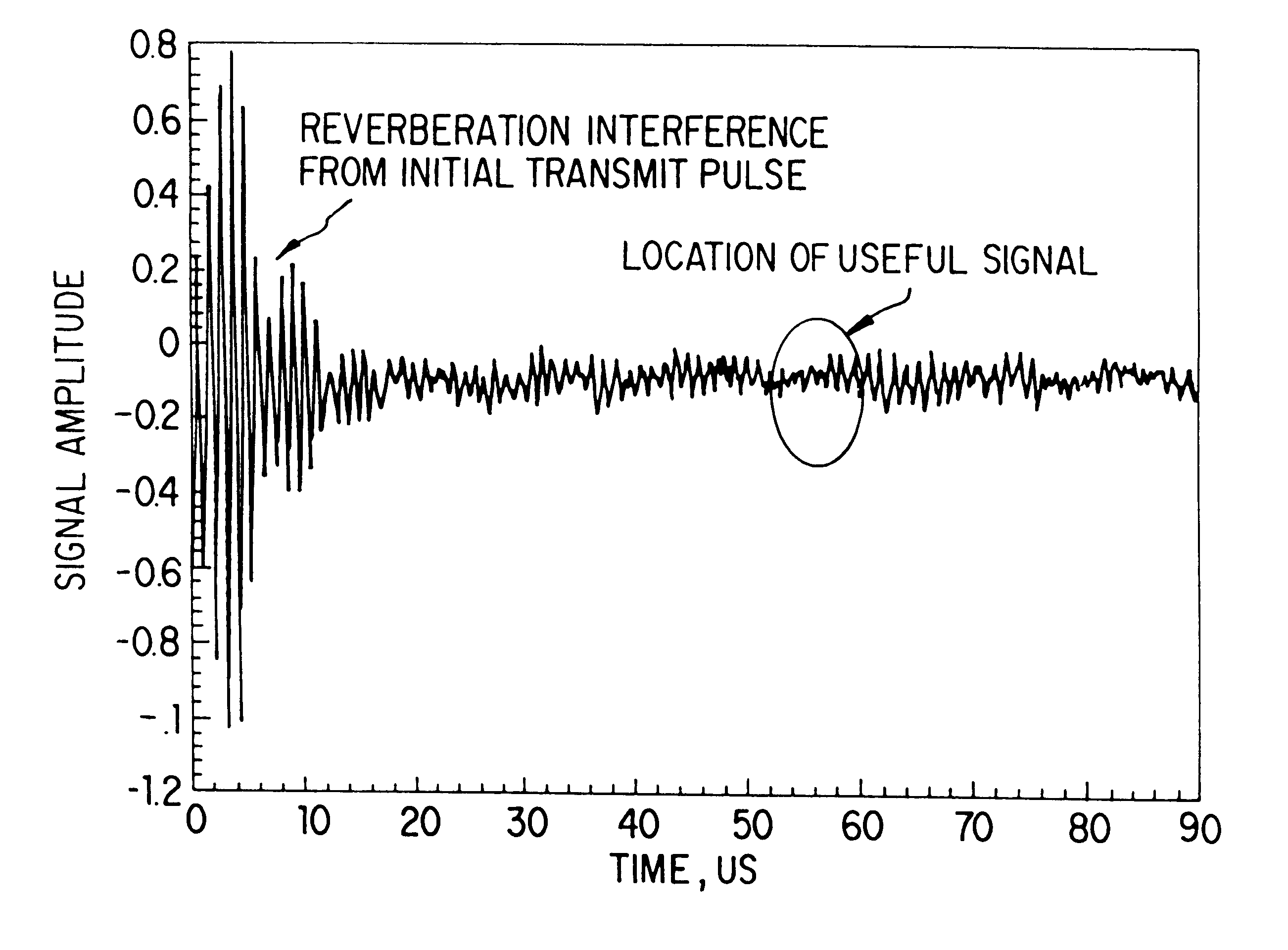

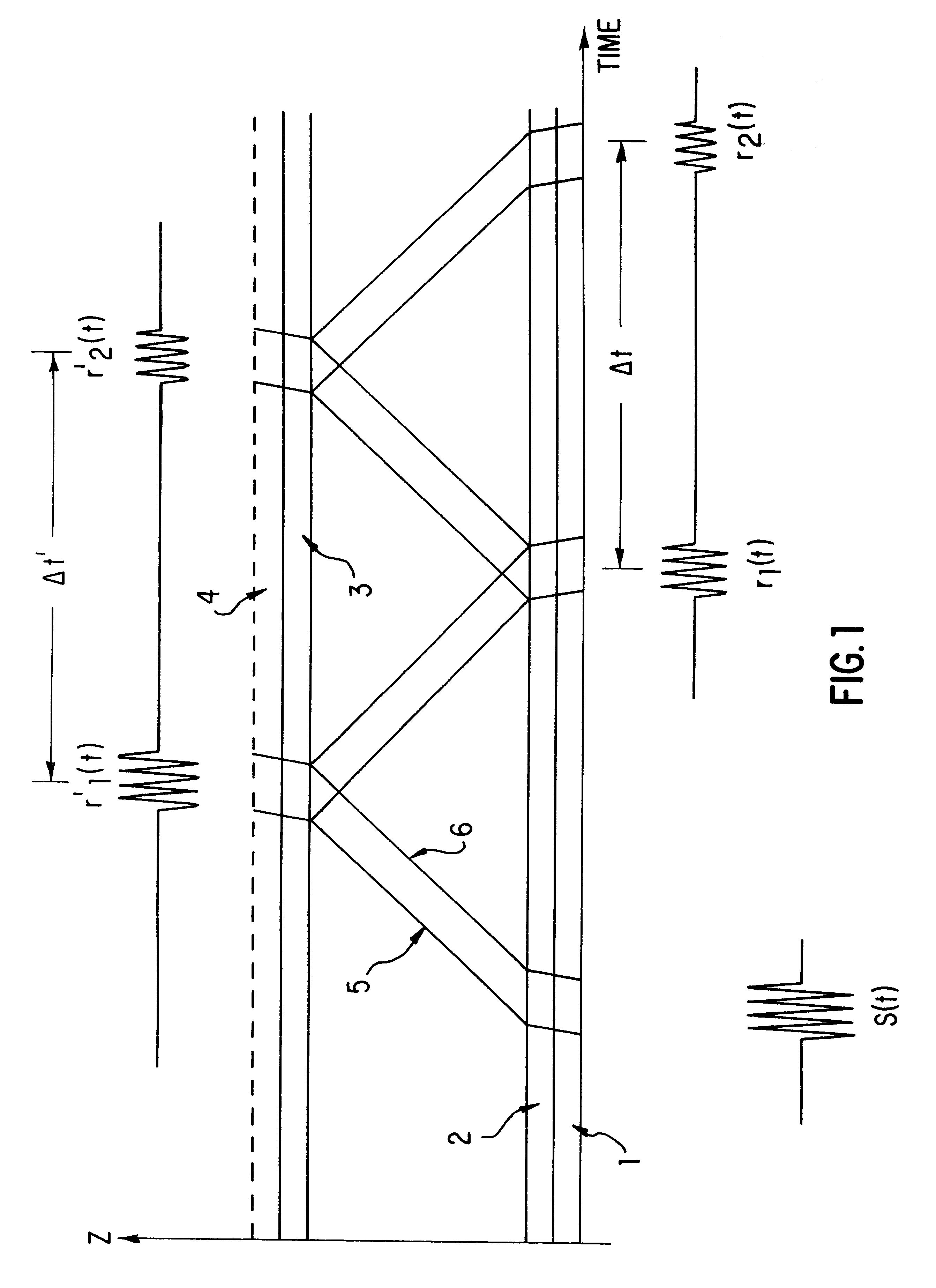

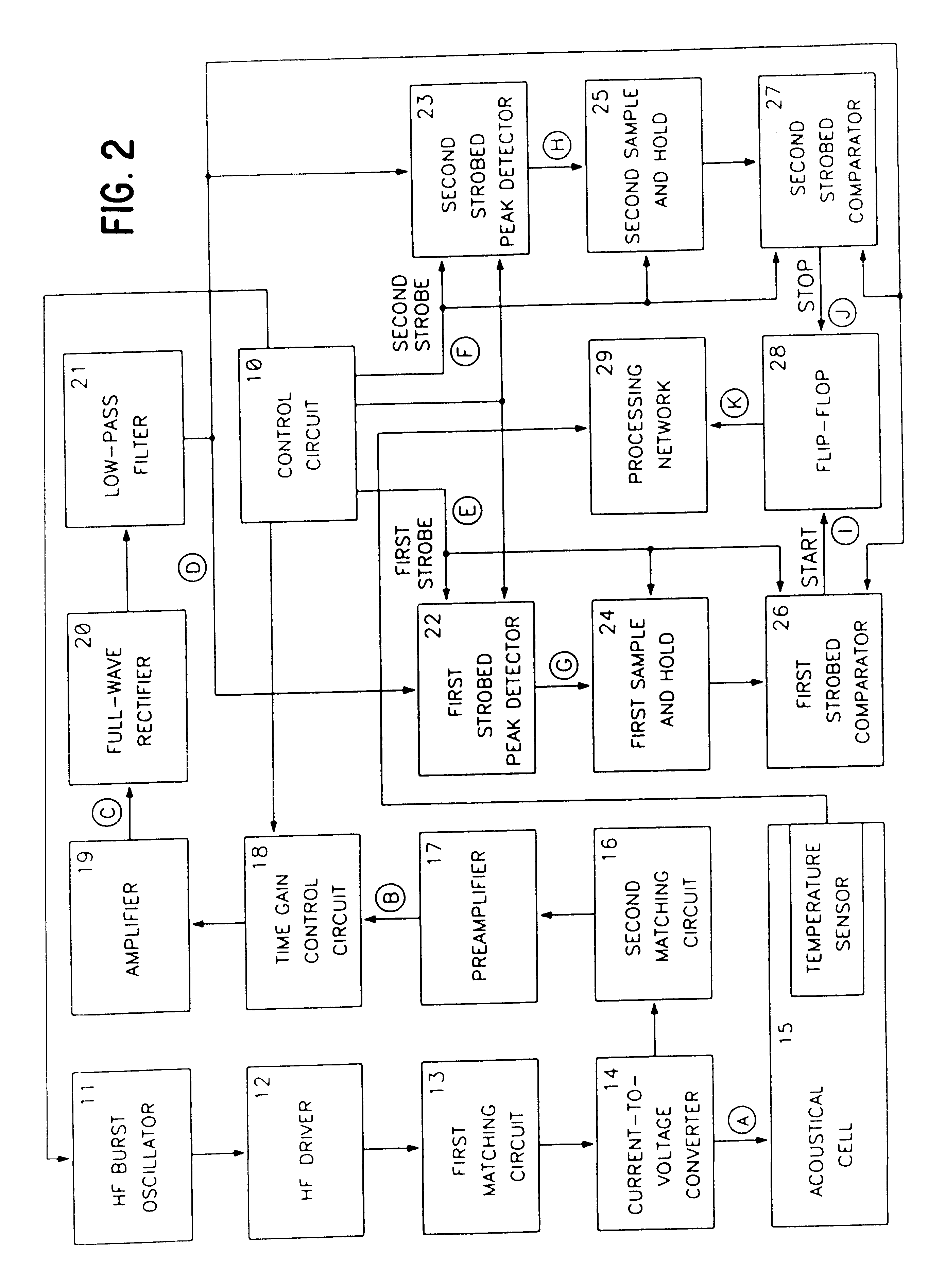

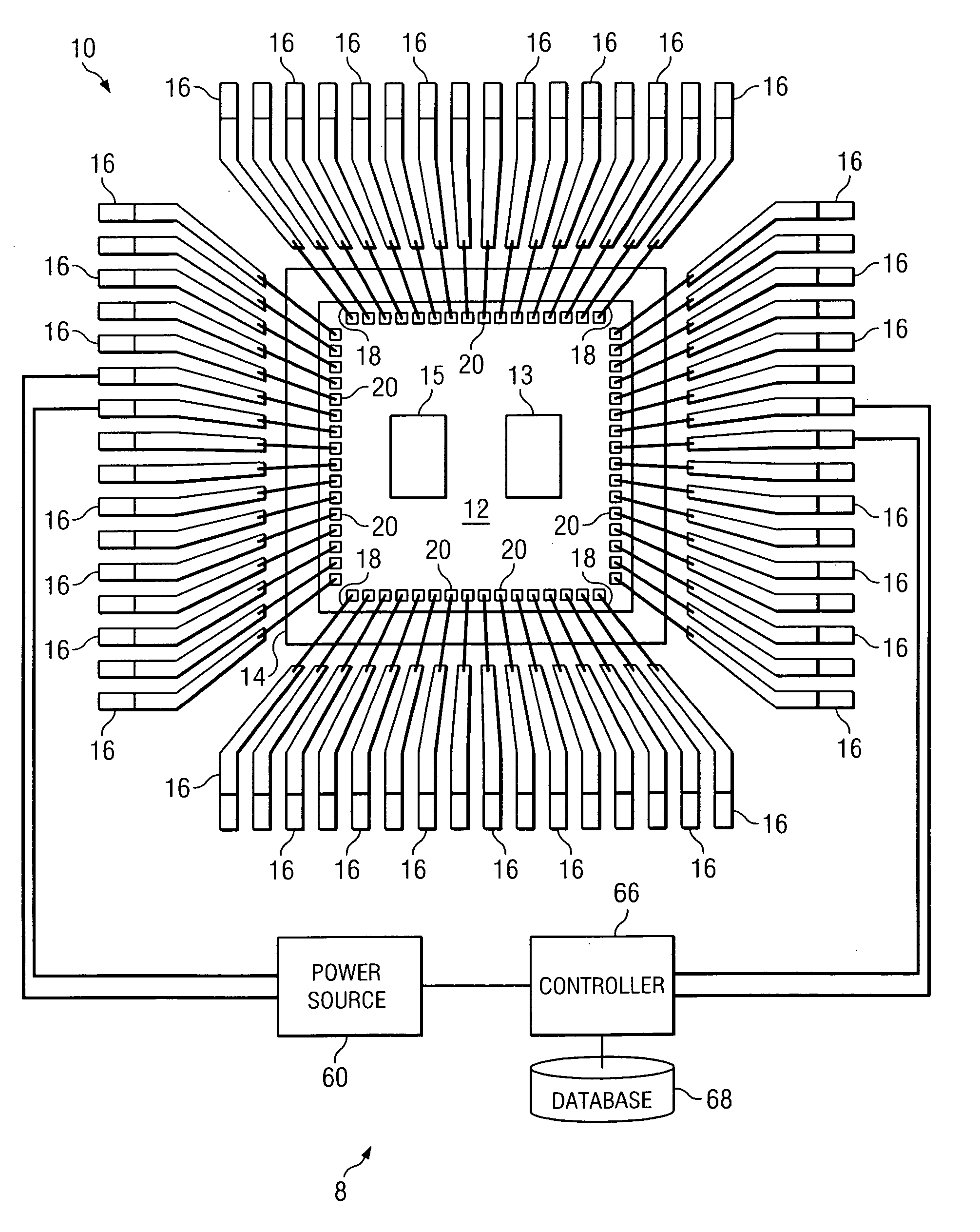

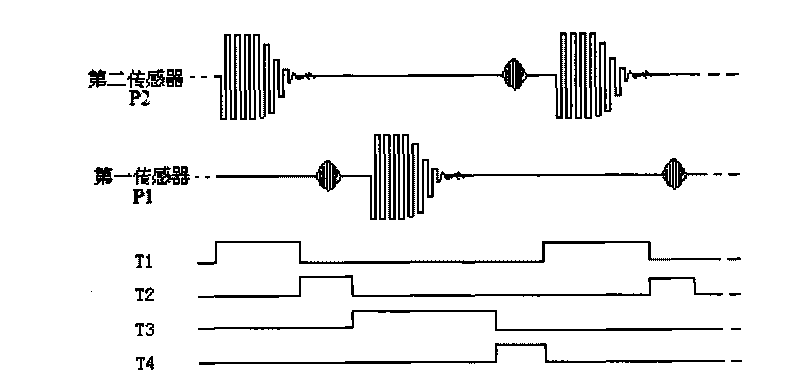

Apparatus and methods for performing acoustical measurements

InactiveUS6279379B1Good repeatabilityAbsenceVibration measurement in solidsSpectral/fourier analysisFast Fourier transformCorrelation function

Apparatus (15, 30) and methods for performing acoustical measurements are provided having some and preferably all of the following features: (A) the system (15, 30) is operated under near-field conditions; (B) the piezoelement (40) or piezoelements (40, 48) used in the system are (i) mechanically (41, 49) and electrically (13, 16) damped and (ii) efficiently electrically coupled to the signal processing components of the system; (C) each piezoelement (40, 48) used in the system includes an acoustical transformer (42, 50) for coupling the element to a gaseous test medium (9); (D) speed of sound is determined from the time difference between two detections of an acoustical pulse (81, 82) at a receiver (40, FIG. 3; 48, FIG. 7); (E) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (F) forward and inverse Fourier transforms employing fast Fourier transform techniques are used to implement the cross-correlation techniques; in such a mathematical manner that the peak of the cross-correlation function corresponds to the detection of a pulse at the receiver and (G) stray path signals through the body (31) of the acoustic sensor (15, 30) are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measured and on mixtures of compressible gases. Methods and apparatus (29) for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

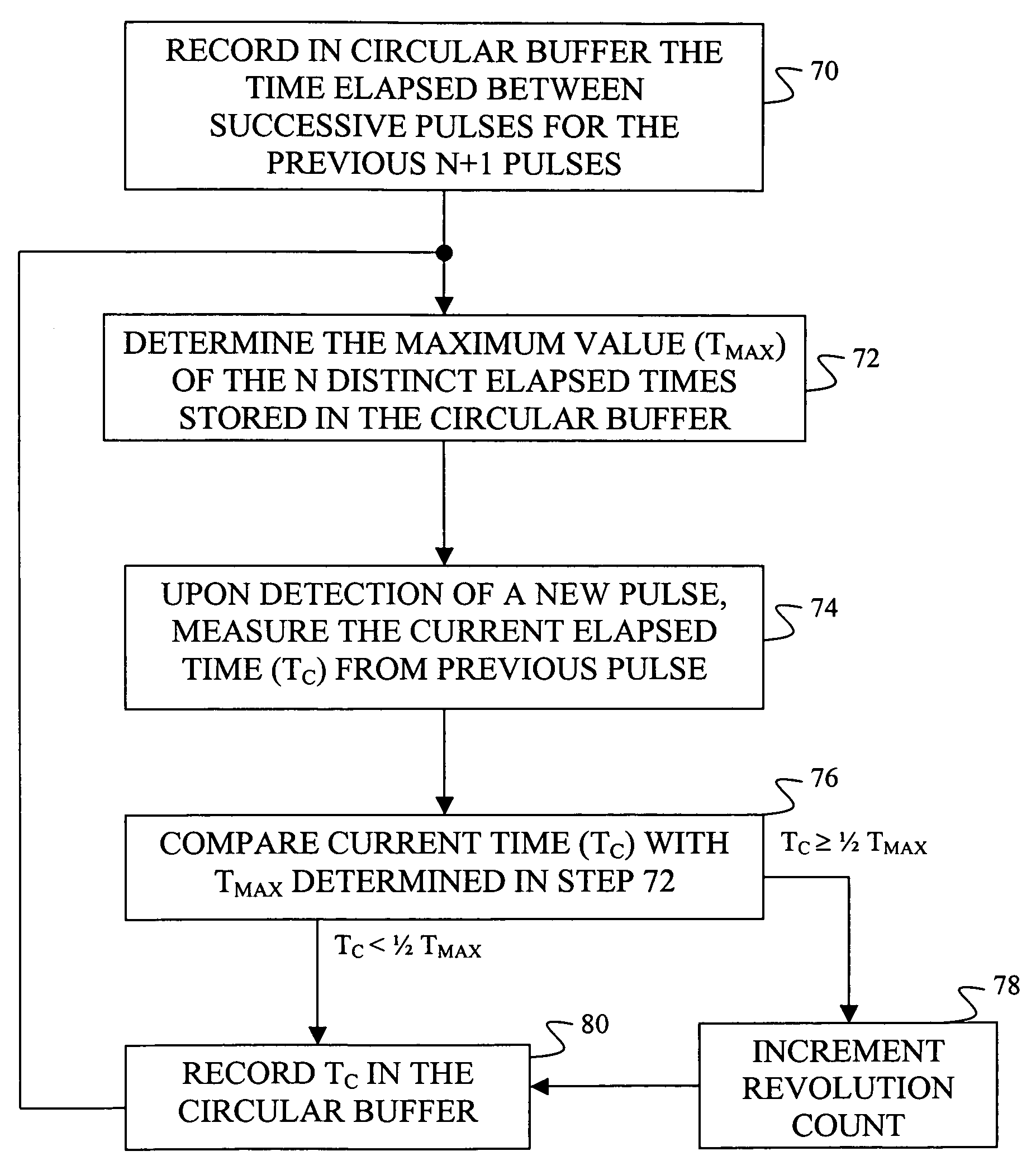

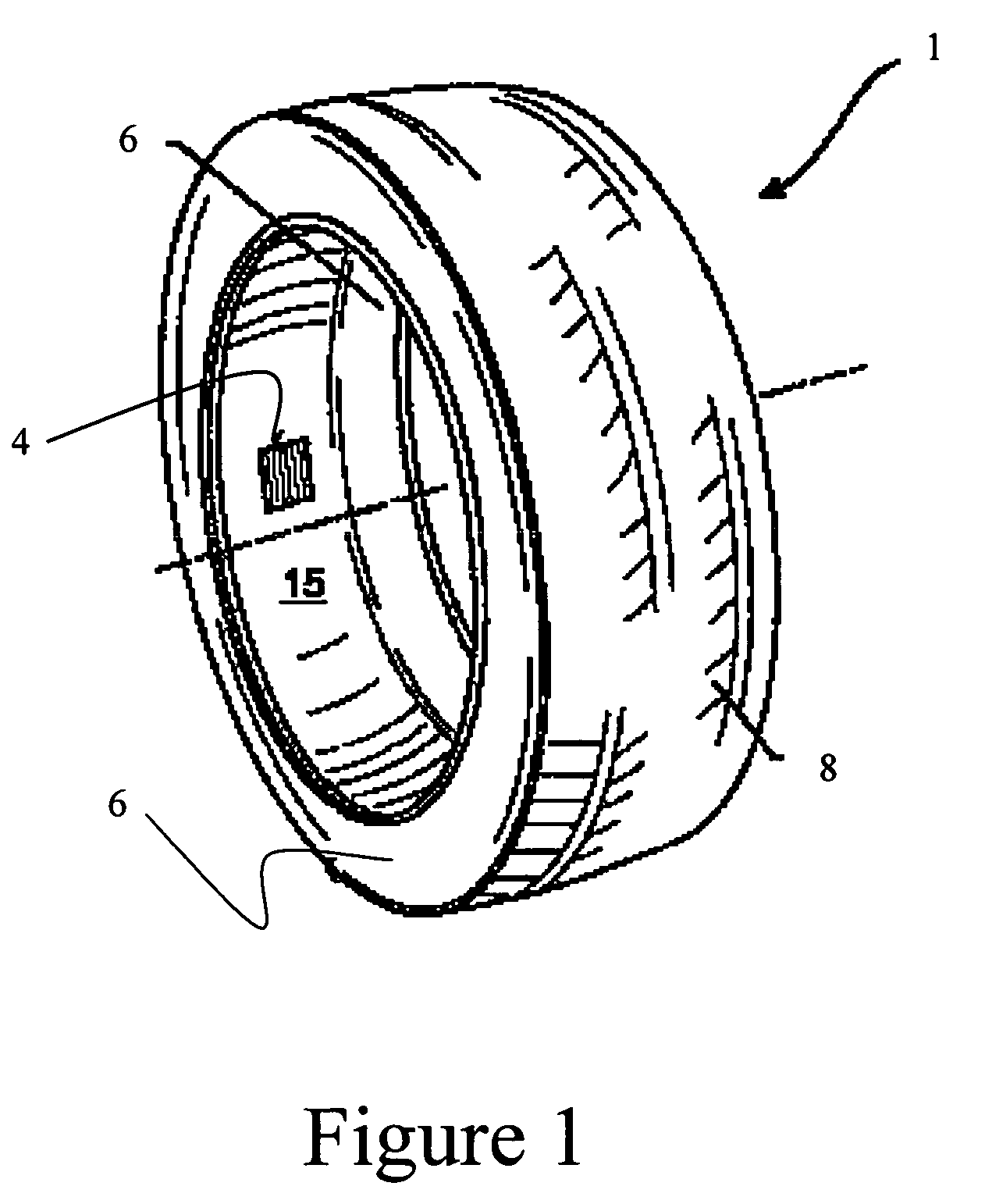

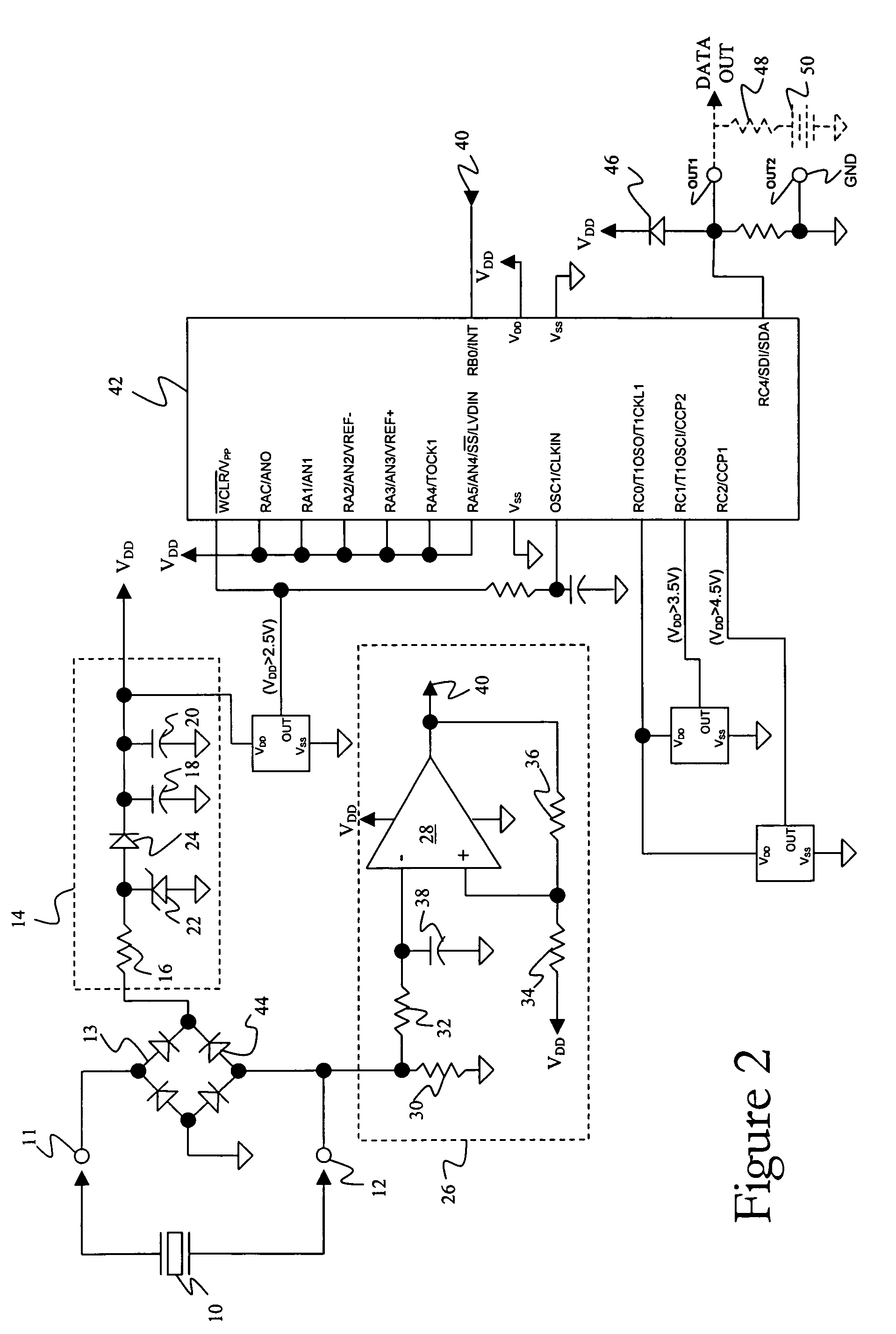

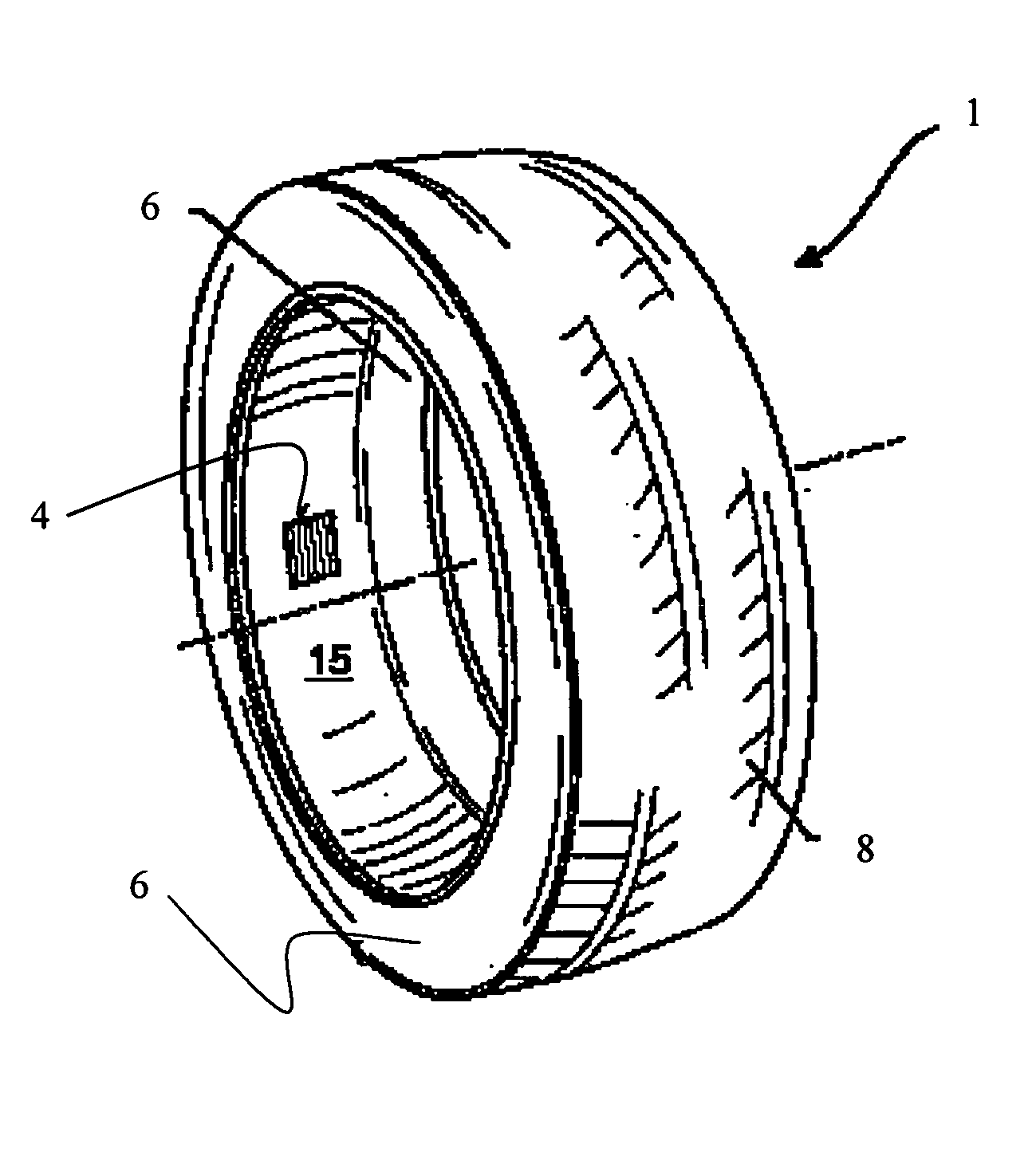

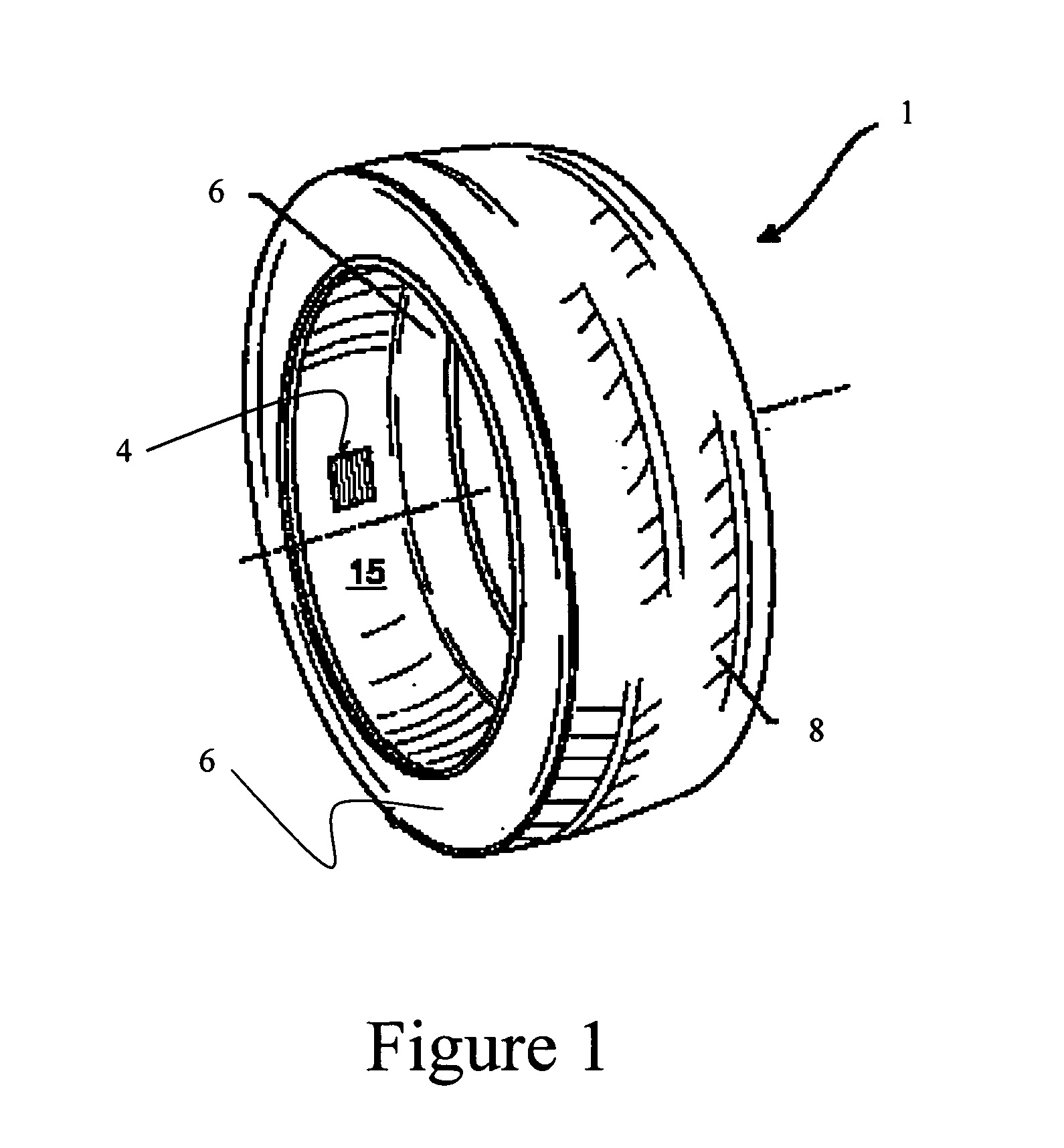

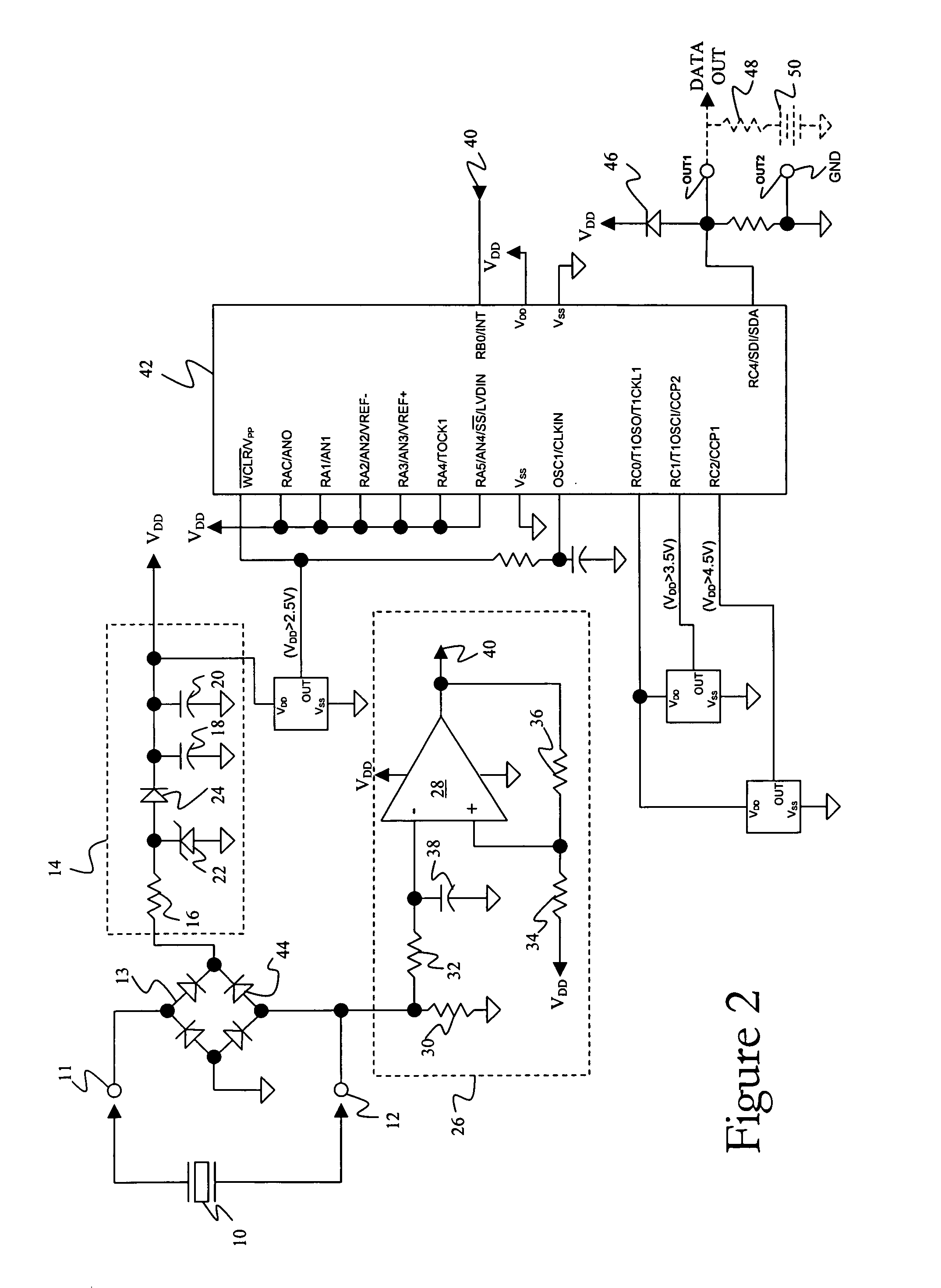

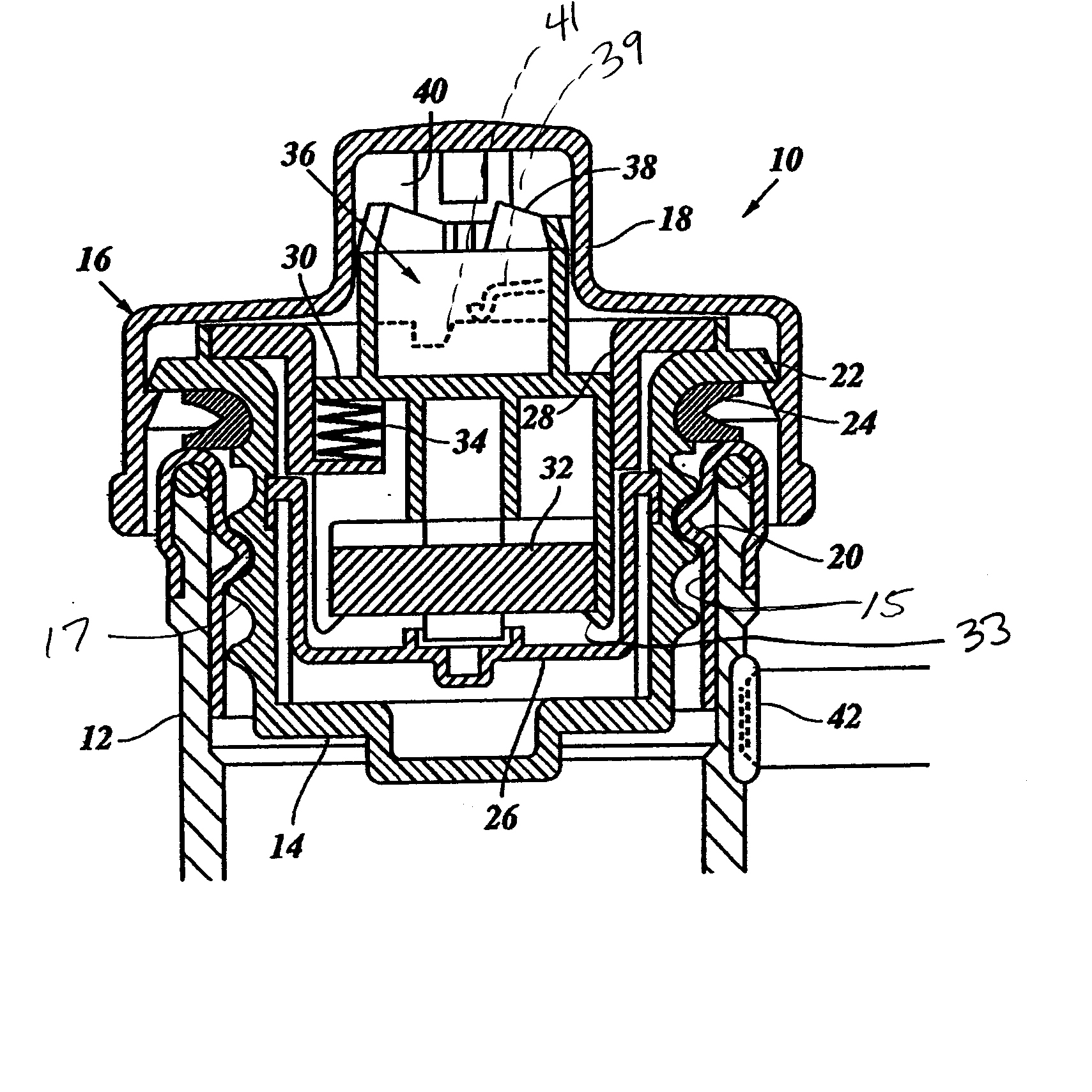

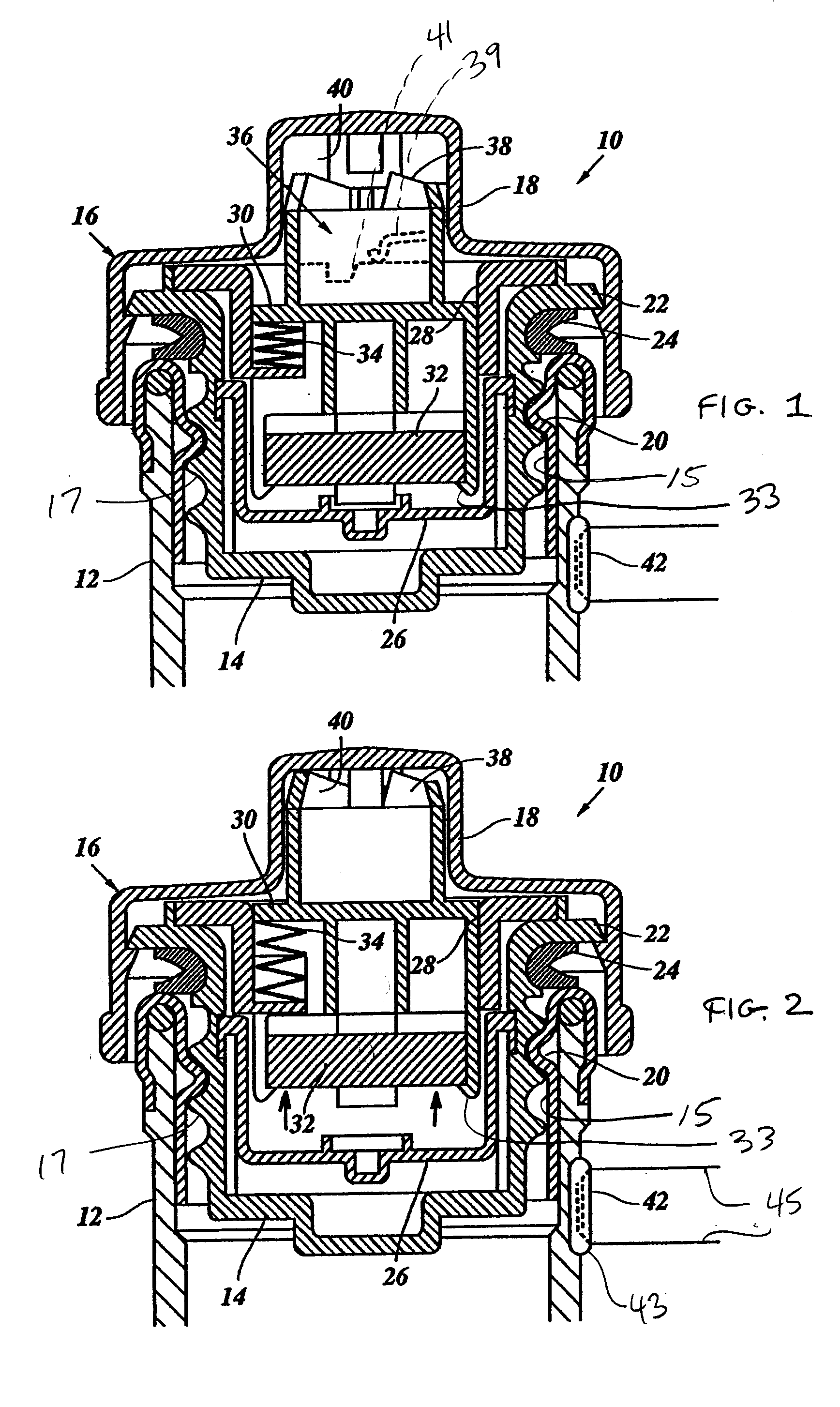

Integrated self-powered tire revolution counter

ActiveUS7132939B2Enhanced advantageAccurate countRegistering/indicating working of machinesNavigation instrumentsMicrocontrollerTire rotation

A self-powered tire revolution counter includes a motion sensitive power generation mechanism, a power conditioner, a pulse detector, a microcontroller, and, optionally, a radio frequency (RF) transmitting device. In one exemplary embodiment, the power generation mechanism corresponds to a piezoelectric patch that, during movement, provides both operating electrical power and pulsed signals indicative of tire rotation. The power conditioner receives a generator signal from the power generation mechanism and produces a conditioned output voltage that can be used to power associated electronic devices, including the microcontroller. The pulse detector receives the generator signal and produces a detection signal whenever the generator signal meets a predetermined condition. The microcontroller is programmed to determine current and lifetime-accumulated values of selected pulse indications in the detection signal that meet predetermined criteria. Data corresponding to tire environment related parameters such as temperature, pressure, tire deflection, and / or vehicle speed may be stored in the microcontroller at times during tire rotation as power is supplied from the power generation mechanism through the power conditioner. Additional data may be supplied to the microcontroller directly from an external source and read from the microcontroller either by direct electrical contact or via selective RF transmission.

Owner:MICHELIN RECH & TECH SA

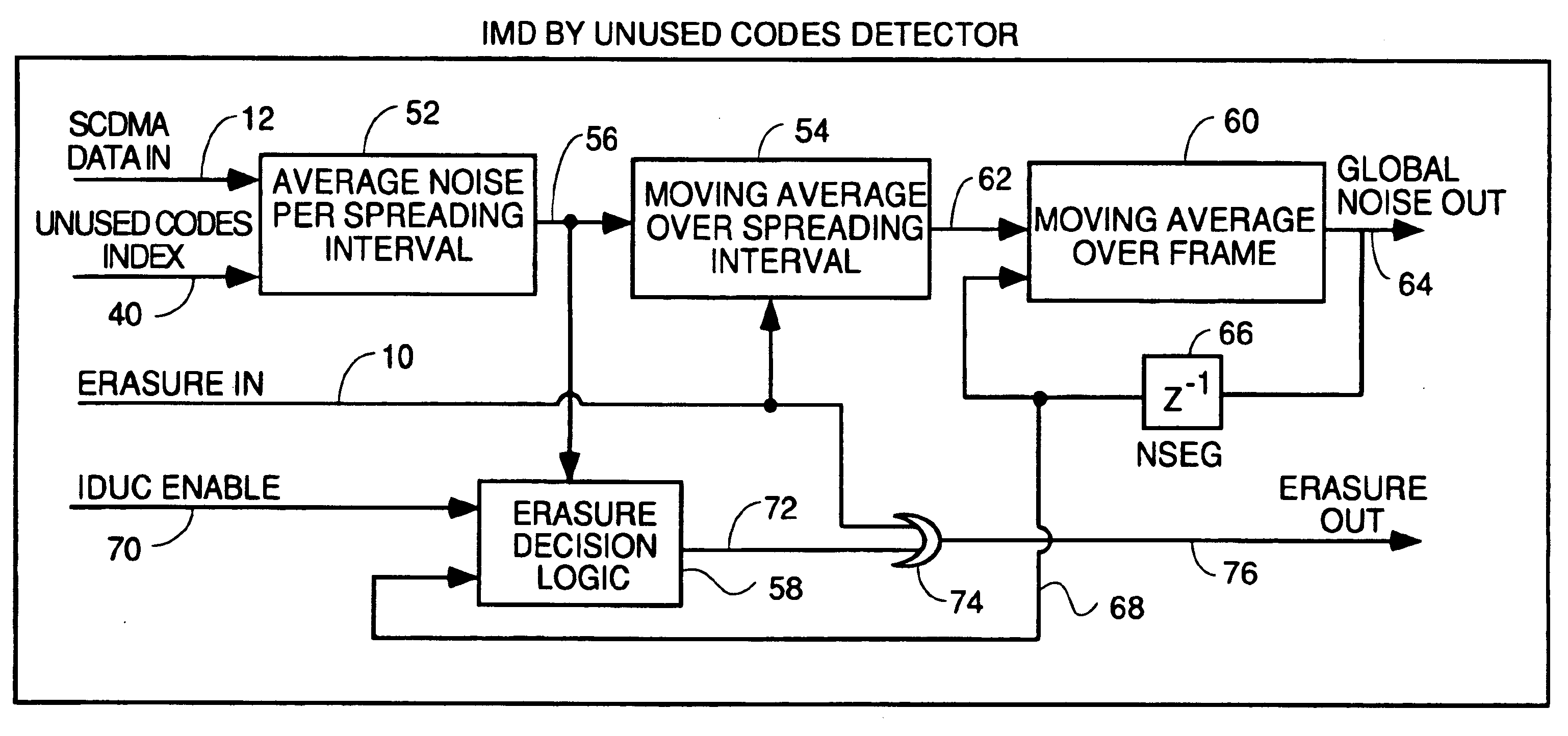

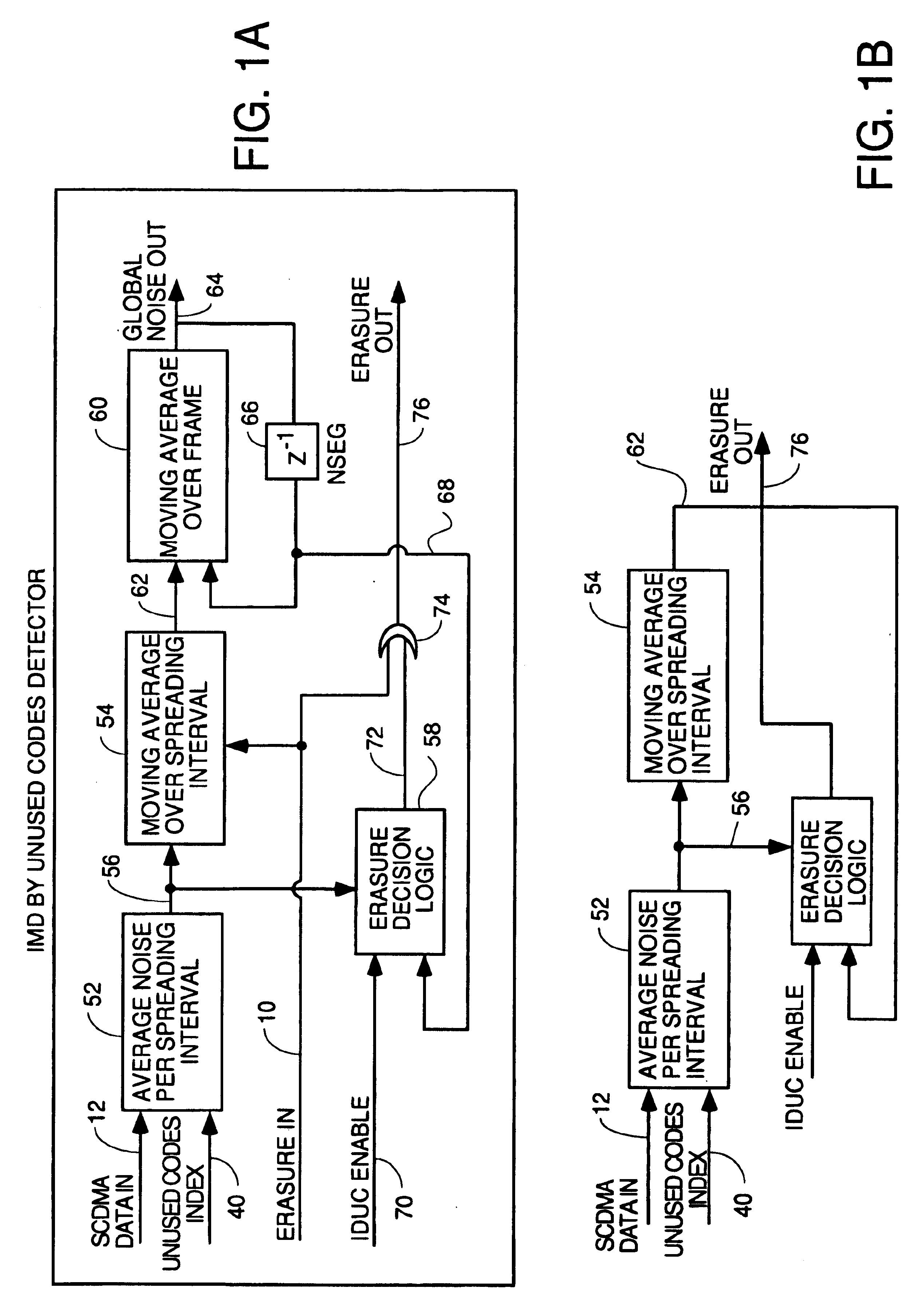

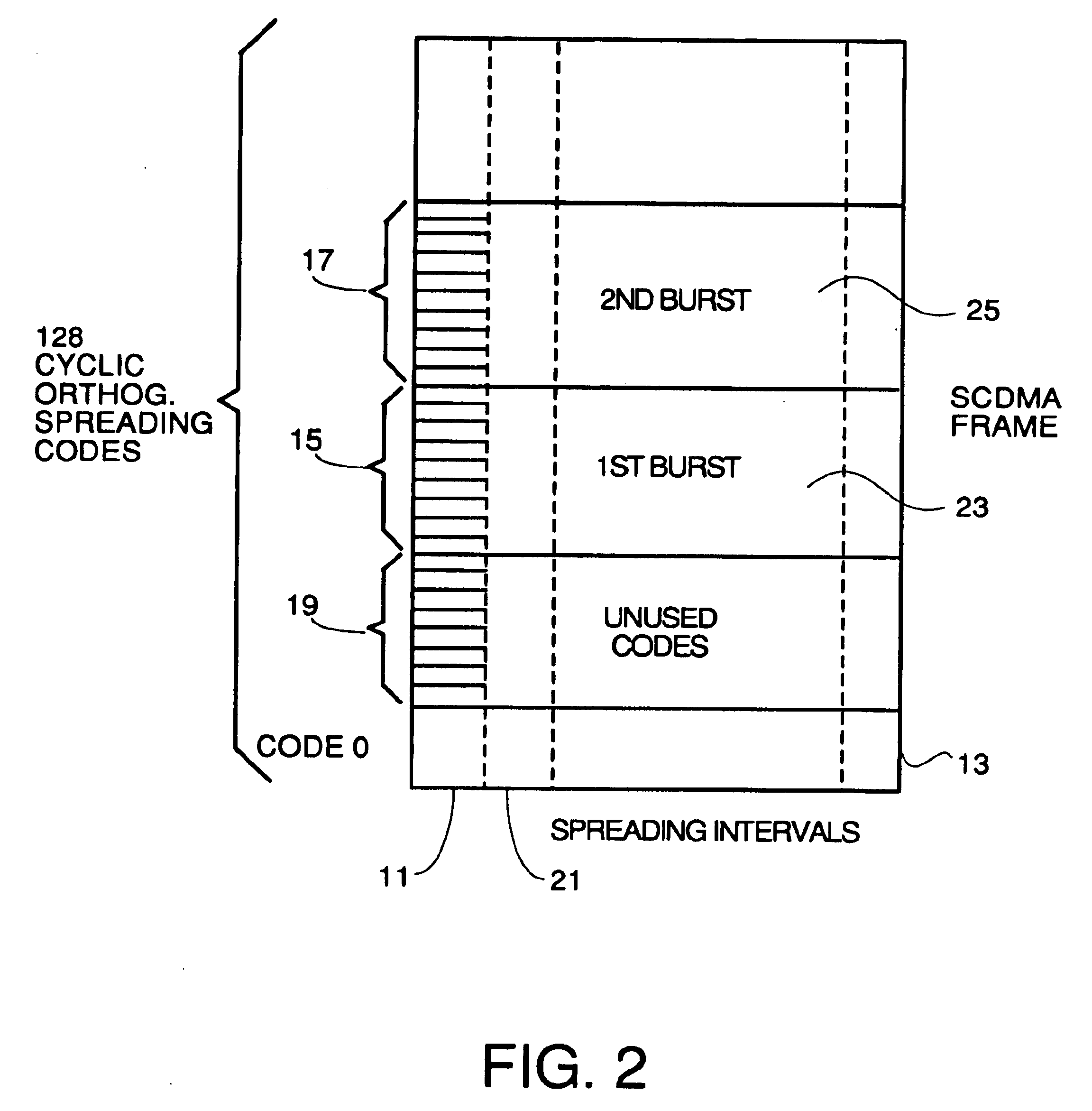

Detection of impulse noise using unused codes in CDMA systems

InactiveUS6859488B2Improving error correction capability of error correctionCancel noiseError preventionSpeech analysisDiscrimination thresholdEngineering

An impulse detector which can detect both low and high levels of impulse noise in a CDMA system is comprised of circuitry to calculate the background noise level in unused codes. Another circuit calculates the average noise power in the unused codes of each spreading interval to output the noise power per spreading interval. This average is continuously averaged over spreading intervals by another circuit which outputs the average background noise power. A comparator compares the noise power in the current spreading interval with the background noise power plus a programmable threshold and generates an erasure indication if the background noise power plus a discrimination threshold is exceeded.

Owner:ARRIS ENTERPRISES LLC

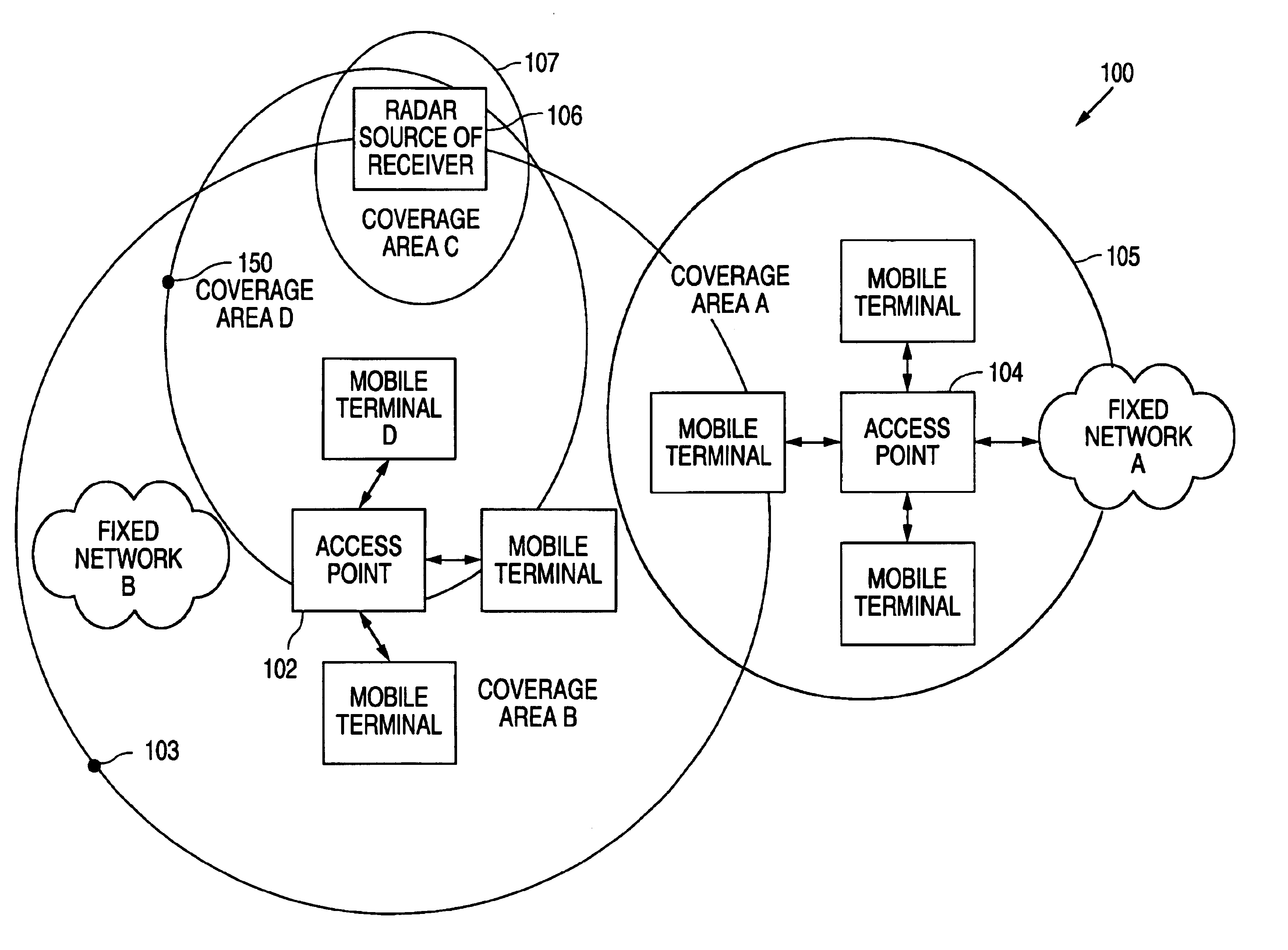

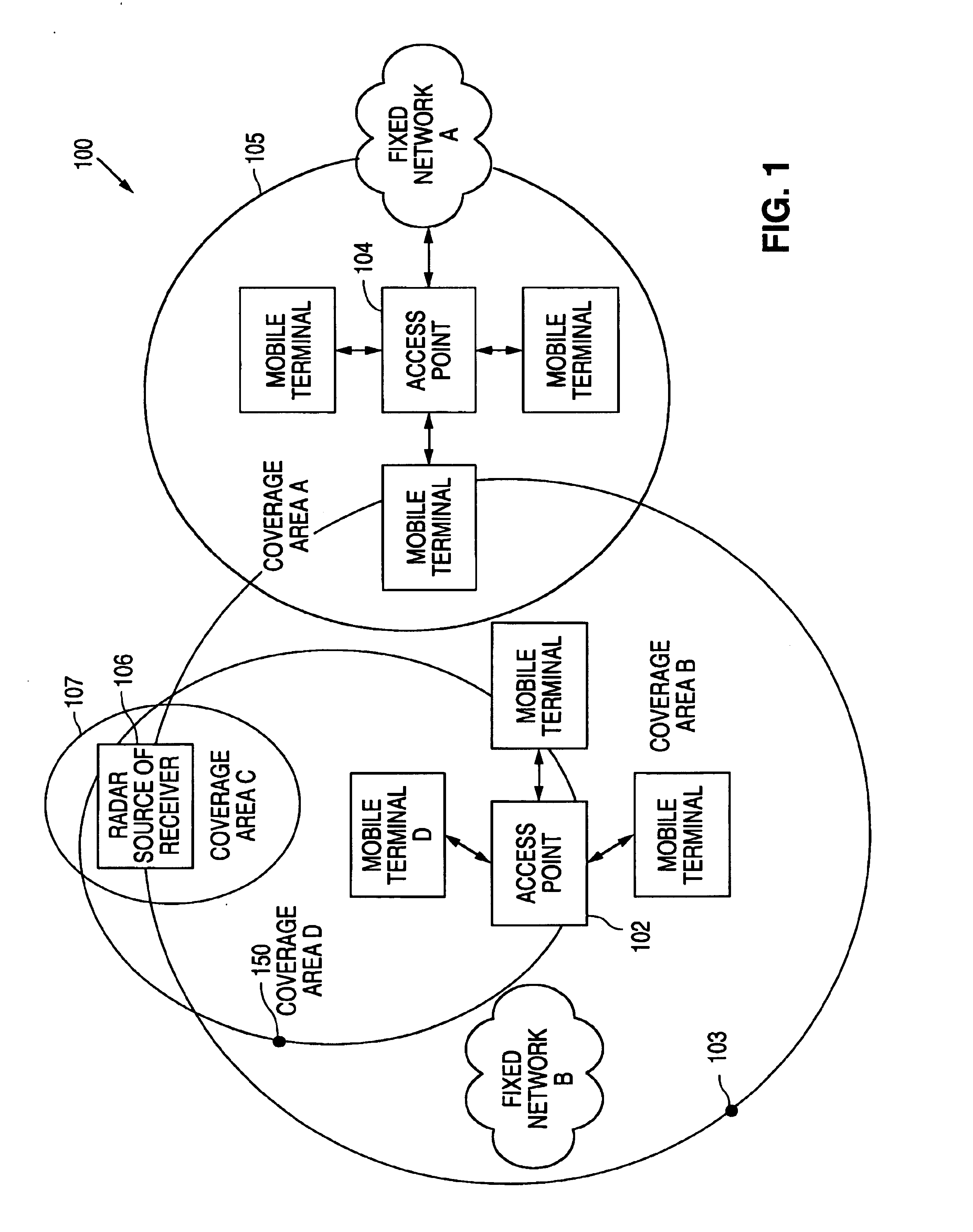

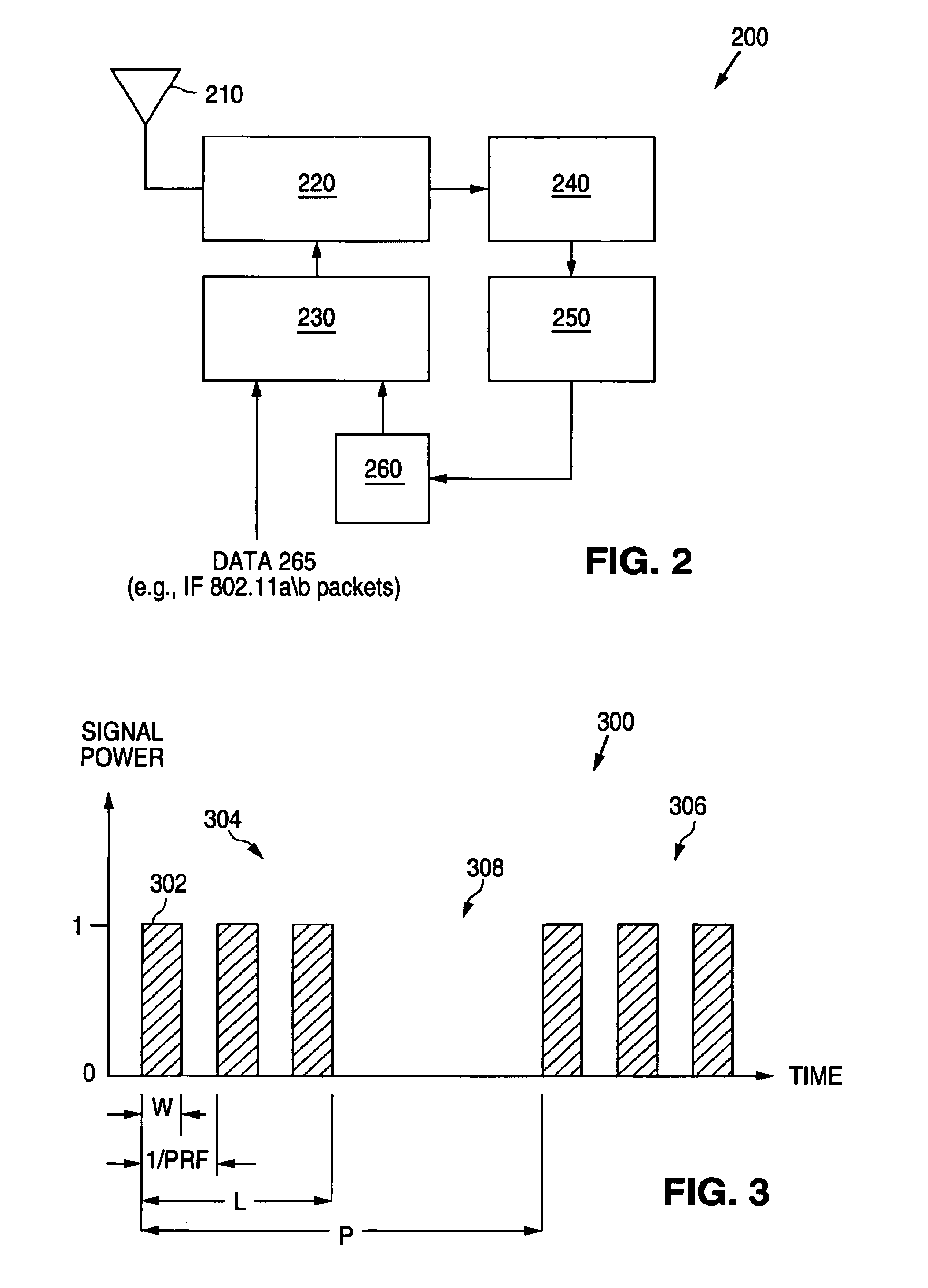

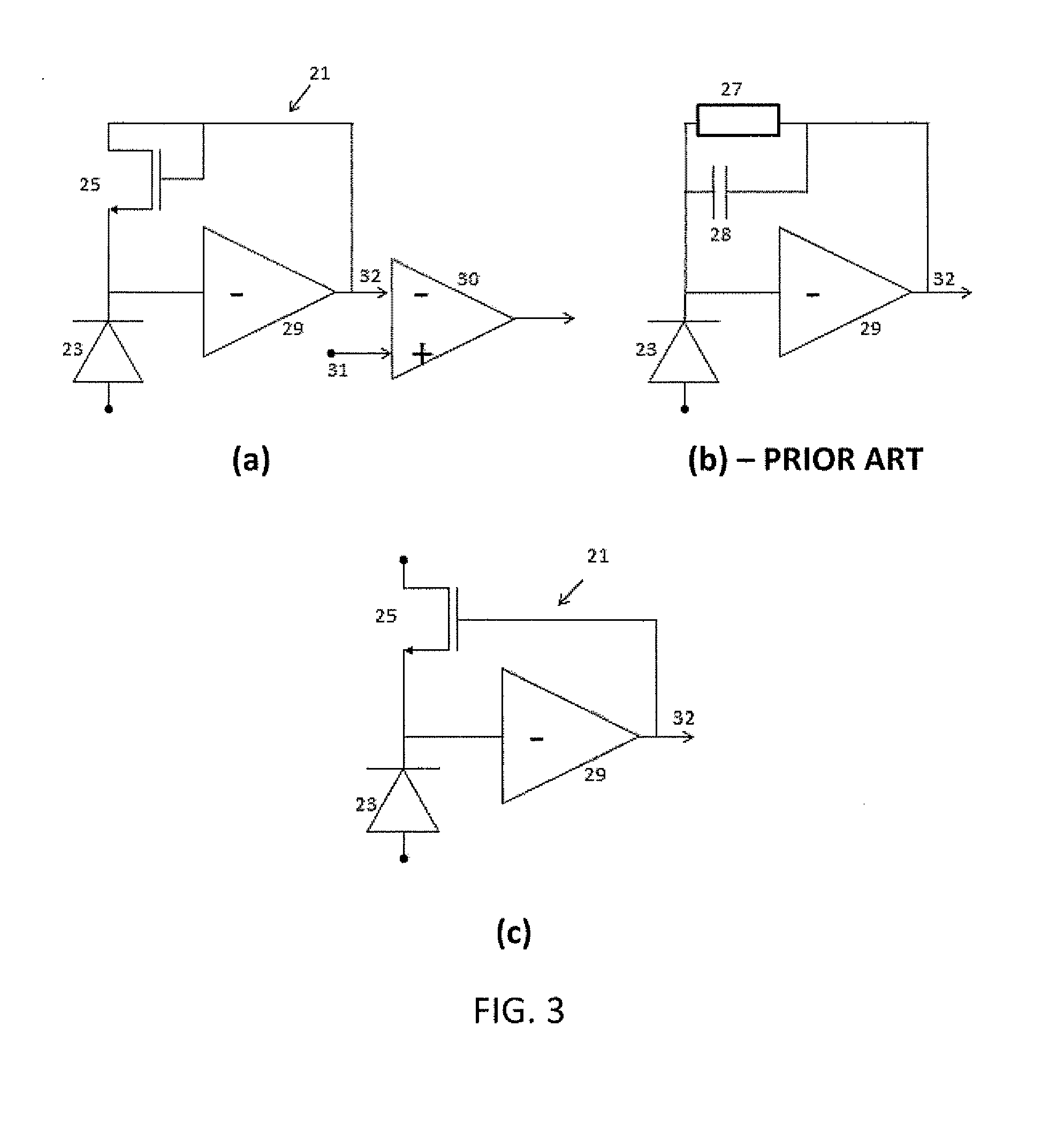

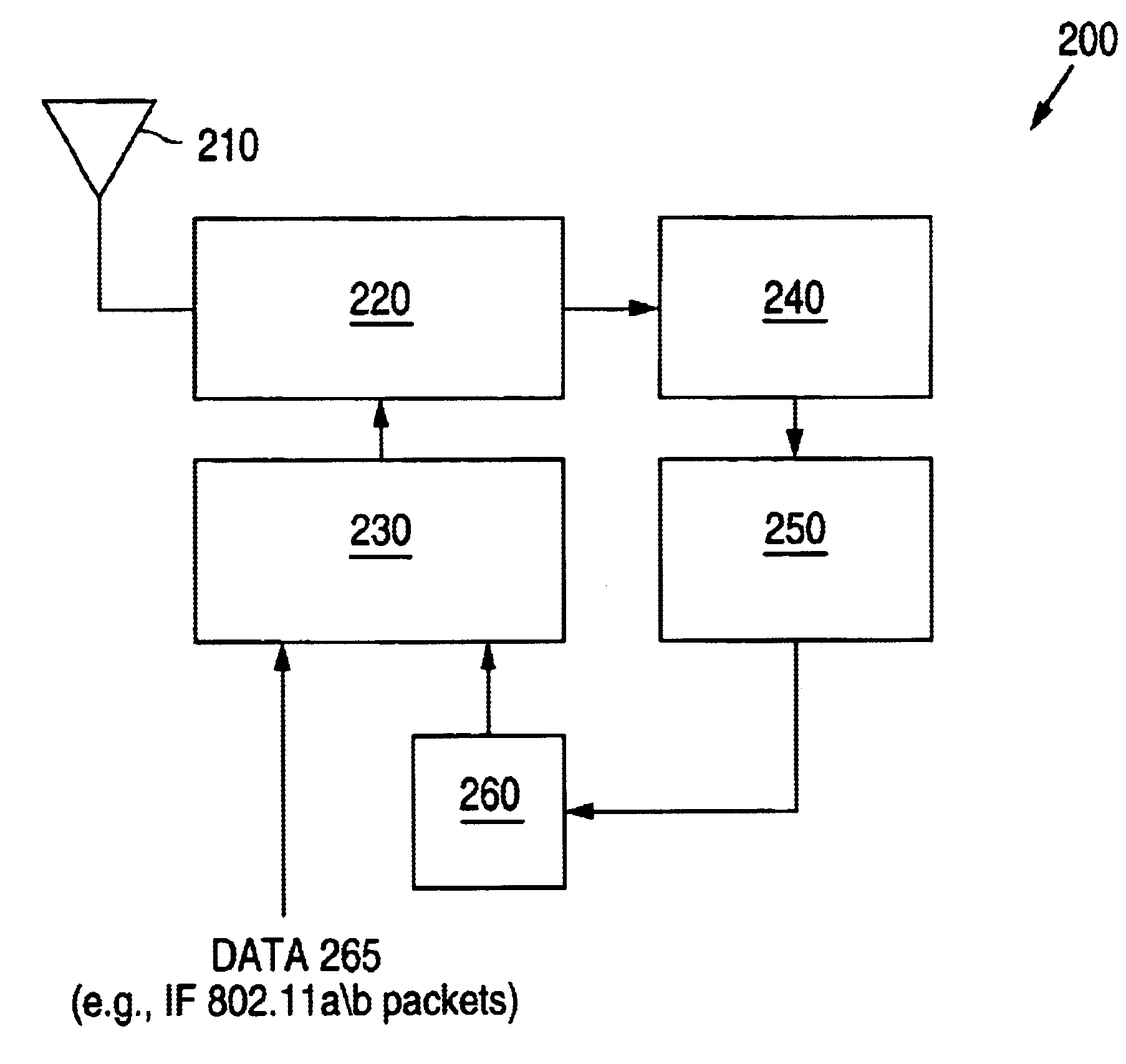

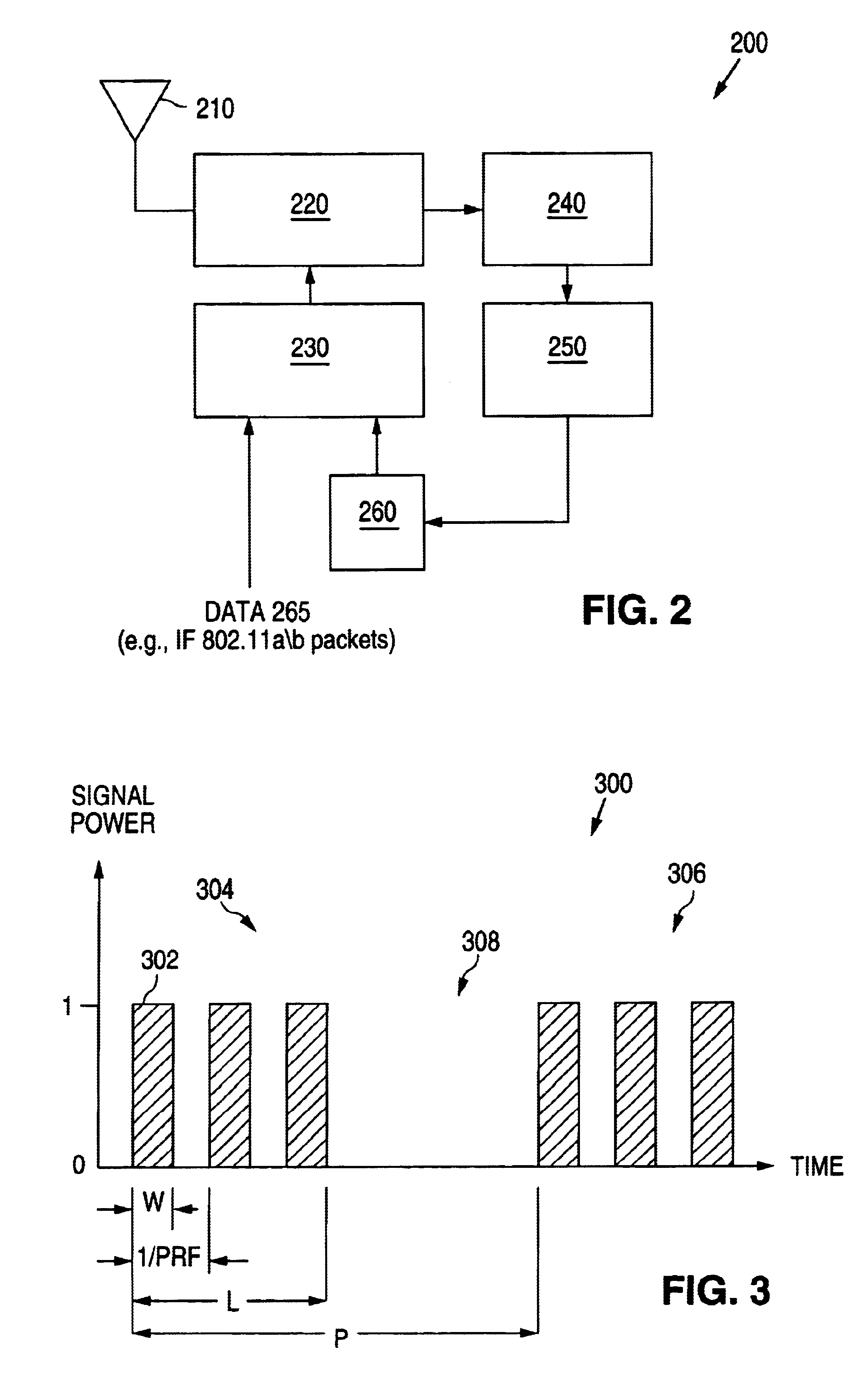

Method and apparatus for physical layer radar pulse detection and estimation

InactiveUS6954171B2Network traffic/resource managementData switching by path configurationDelayed timePhysical layer

Radar Pulse detection and radar signal length detection are used to detect and provide information for identifying radar signals. Pulse detection estimates a radar pulse size when it is too short for meaningful measurement. Pulse detection identifies a radar by identification of an in-band pulse without a communication or data packet encoded therein, or a communication error is detected with the in-band pulse. Signal length detection counts the length of a received signal after the received signal exceeds a radar threshold. The count identifies the received signal length upon drop of the power. The signal is identified as a radar when the power drops before a PHY error occurs, or when the power drop occurs after a PHY error and a delay time equivalent to the shortest radar signal. A radar signal is also identified upon a timeout wait for a power drop after a PHY error.

Owner:QUALCOMM INC

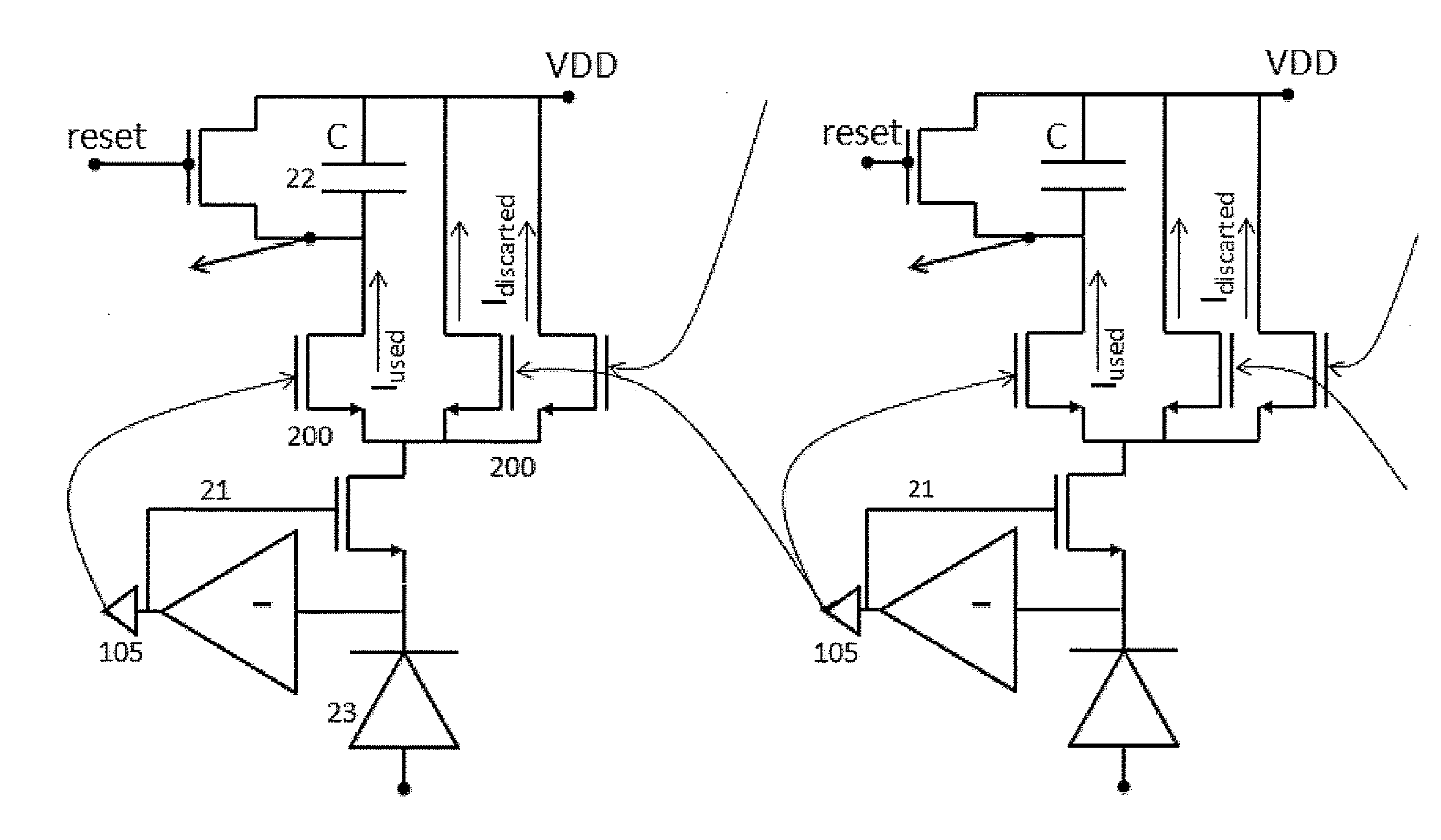

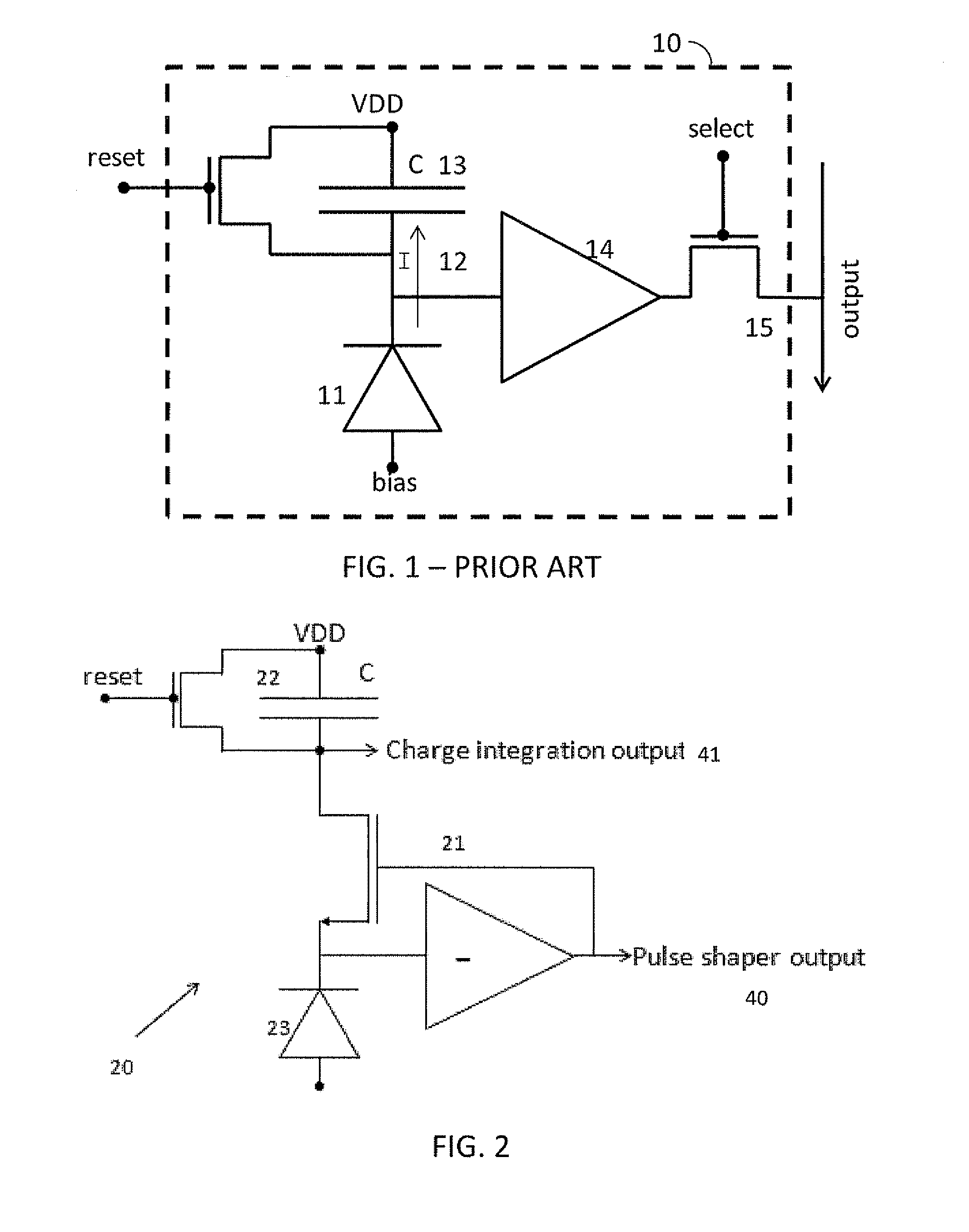

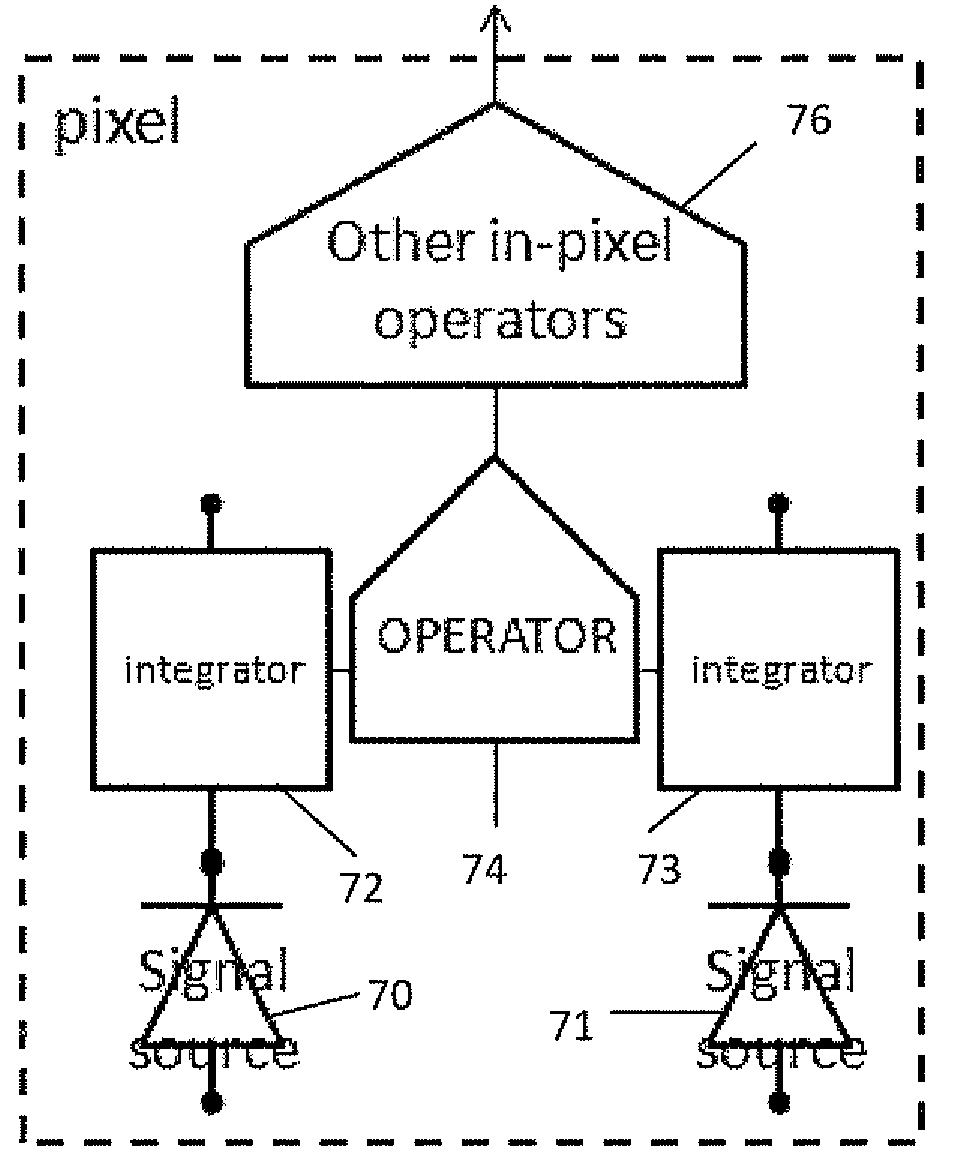

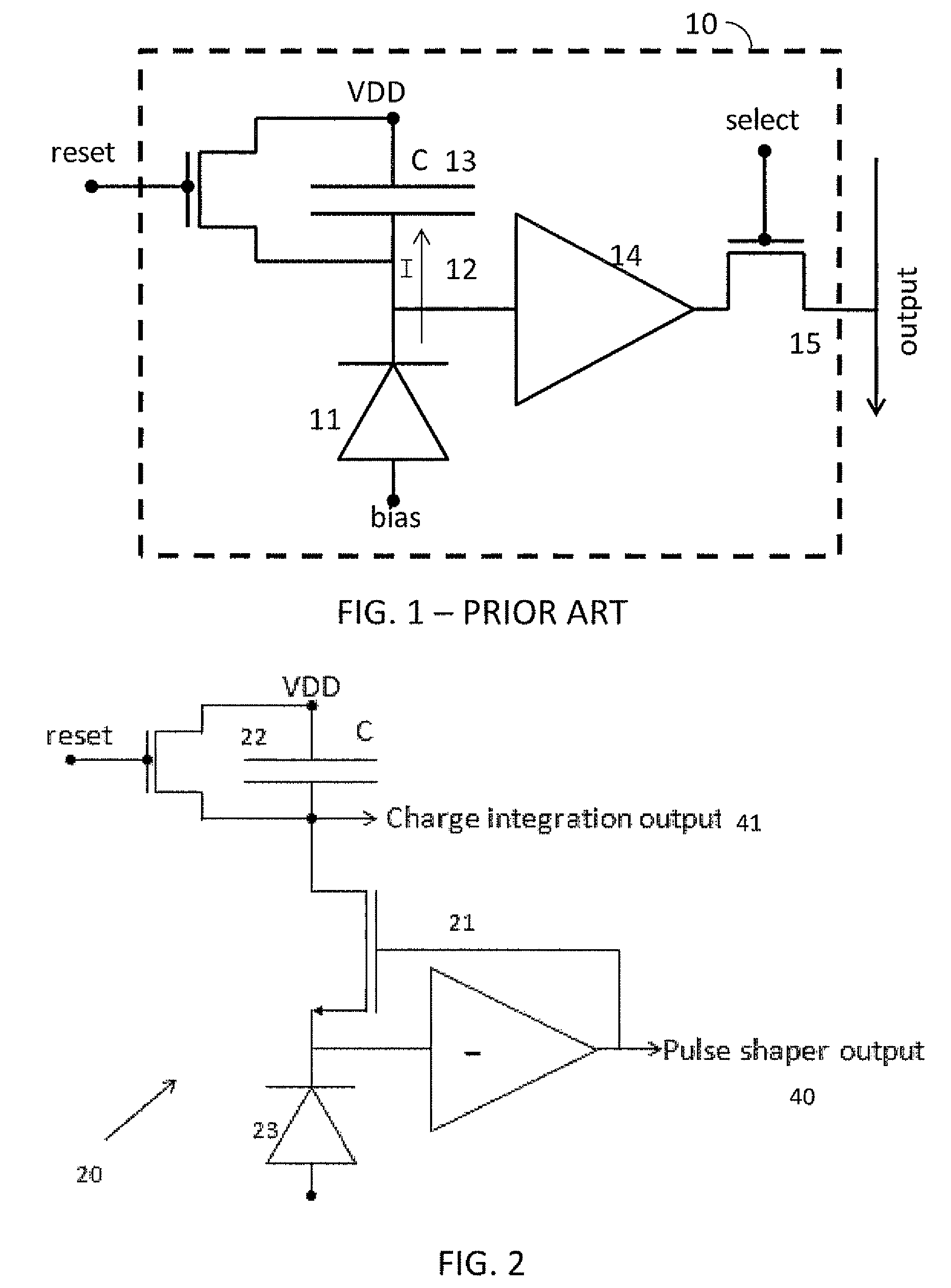

Combined integration and pulse detection

ActiveUS20120305786A1Solid-state devicesMaterial analysis by optical meansHigh energyElectromagnetic radiation

A pixel for the detection of electromagnetic radiation or high energy particles or charge packets, in particular for detecting X-ray photons, comprises a radiation receptor for converting the radiation into a sensing signal, the pixel being adapted for performing both pulse detection and integration of the same sensing signal.

Owner:CAELESTE CVBA +1

Method and apparatus for physical layer radar pulse detection and estimation

InactiveUS6891496B2Network traffic/resource managementData switching by path configurationDelayed timePhysical layer

Radar Pulse detection and radar signal length detection are used to detect and provide information for identifying radar signals. Pulse detection estimates a radar pulse size when it is too short for meaningful measurement. Pulse detection identifies a radar by identification of an in-band pulse without a communication or data packet encoded therein, or a communication error is detected with the in-band pulse. Signal length detection counts the length of a received signal after the received signal exceeds a radar threshold. The count identifies the received signal length upon drop of the power. The signal is identified as a radar when the power drops before a PHY error occurs, or when the power drop occurs after a PHY error and a delay time equivalent to the shortest radar signal. A radar signal is also identified upon a timeout wait for a power drop after a PHY error.

Owner:QUALCOMM INC

Integrated self-powered tire revolution counter

ActiveUS20060006991A1Enhanced advantageAccurate countRegistering/indicating working of machinesNavigation instrumentsMicrocontrollerElectricity

A self-powered tire revolution counter includes a motion sensitive power generation mechanism, a power conditioner, a pulse detector, a microcontroller, and, optionally, a radio frequency (RF) transmitting device. In one exemplary embodiment, the power generation mechanism corresponds to a piezoelectric patch that, during movement, provides both operating electrical power and pulsed signals indicative of tire rotation. The power conditioner receives a generator signal from the power generation mechanism and produces a conditioned output voltage that can be used to power associated electronic devices, including the microcontroller. The pulse detector receives the generator signal and produces a detection signal whenever the generator signal meets a predetermined condition. The microcontroller is programmed to determine current and lifetime-accumulated values of selected pulse indications in the detection signal that meet predetermined criteria. Data corresponding to tire environment related parameters such as temperature, pressure, tire deflection, and / or vehicle speed may be stored in the microcontroller at times during tire rotation as power is supplied from the power generation mechanism through the power conditioner. Additional data may be supplied to the microcontroller directly from an external source and read from the microcontroller either by direct electrical contact or via selective RF transmission.

Owner:MICHELIN RECH & TECH SA

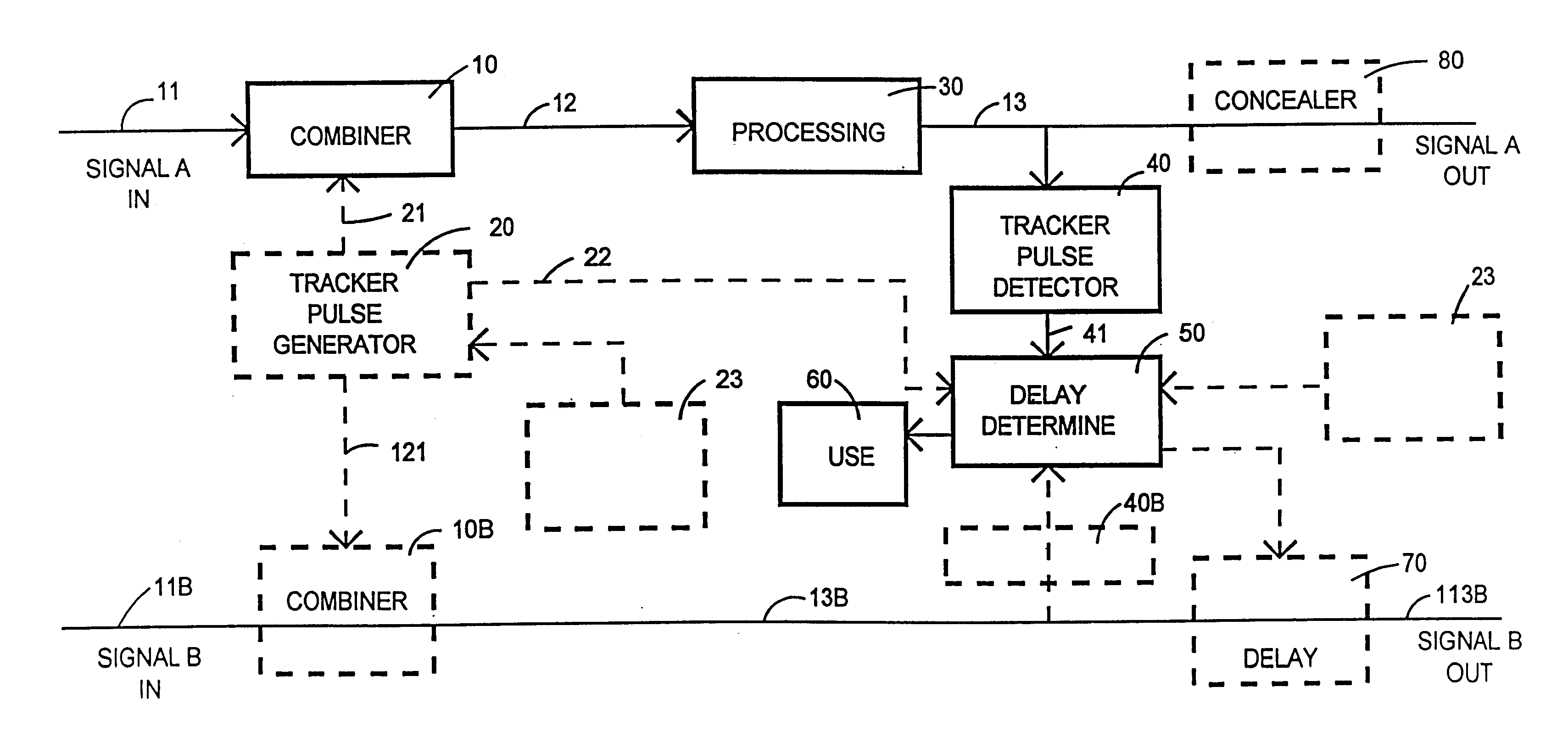

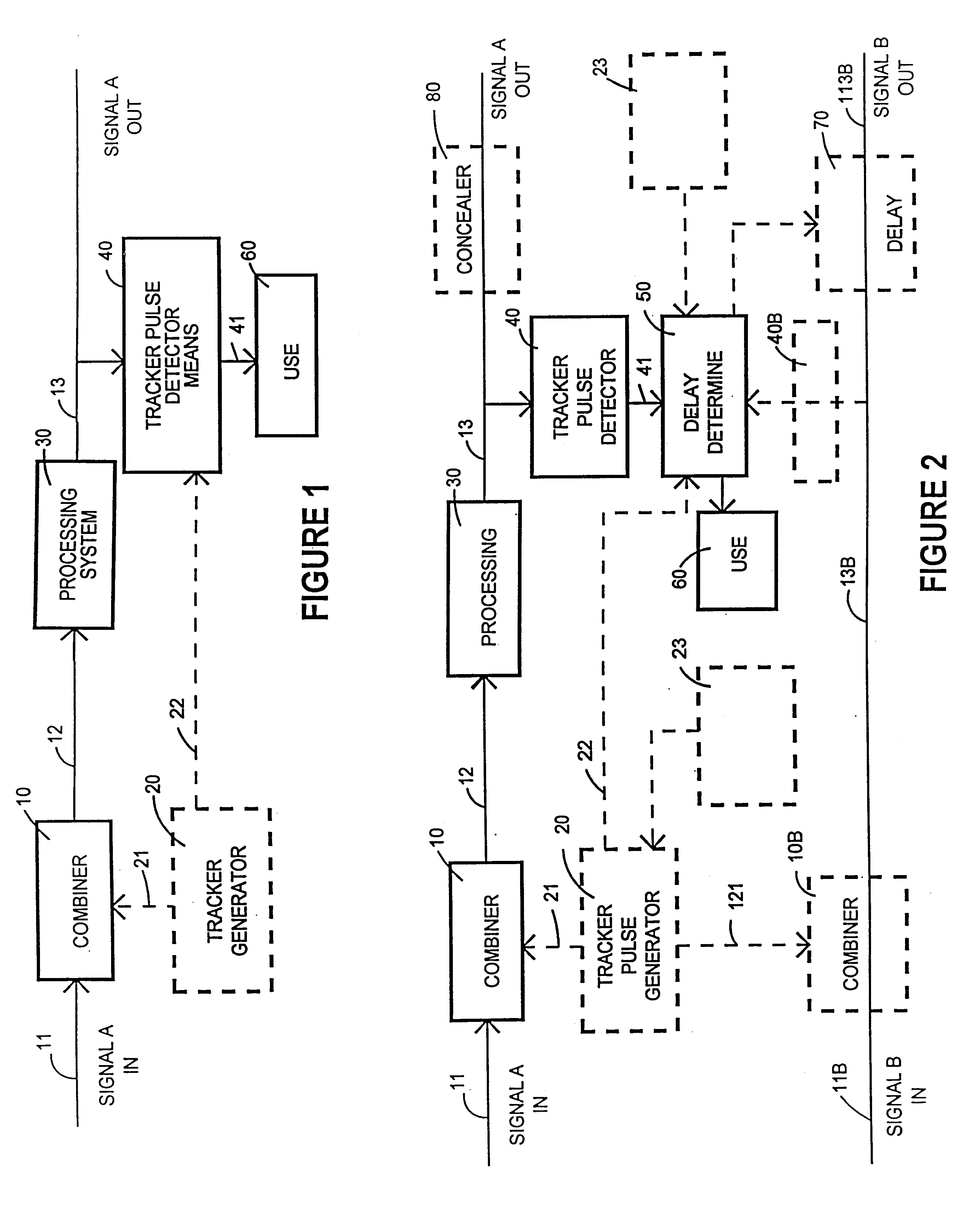

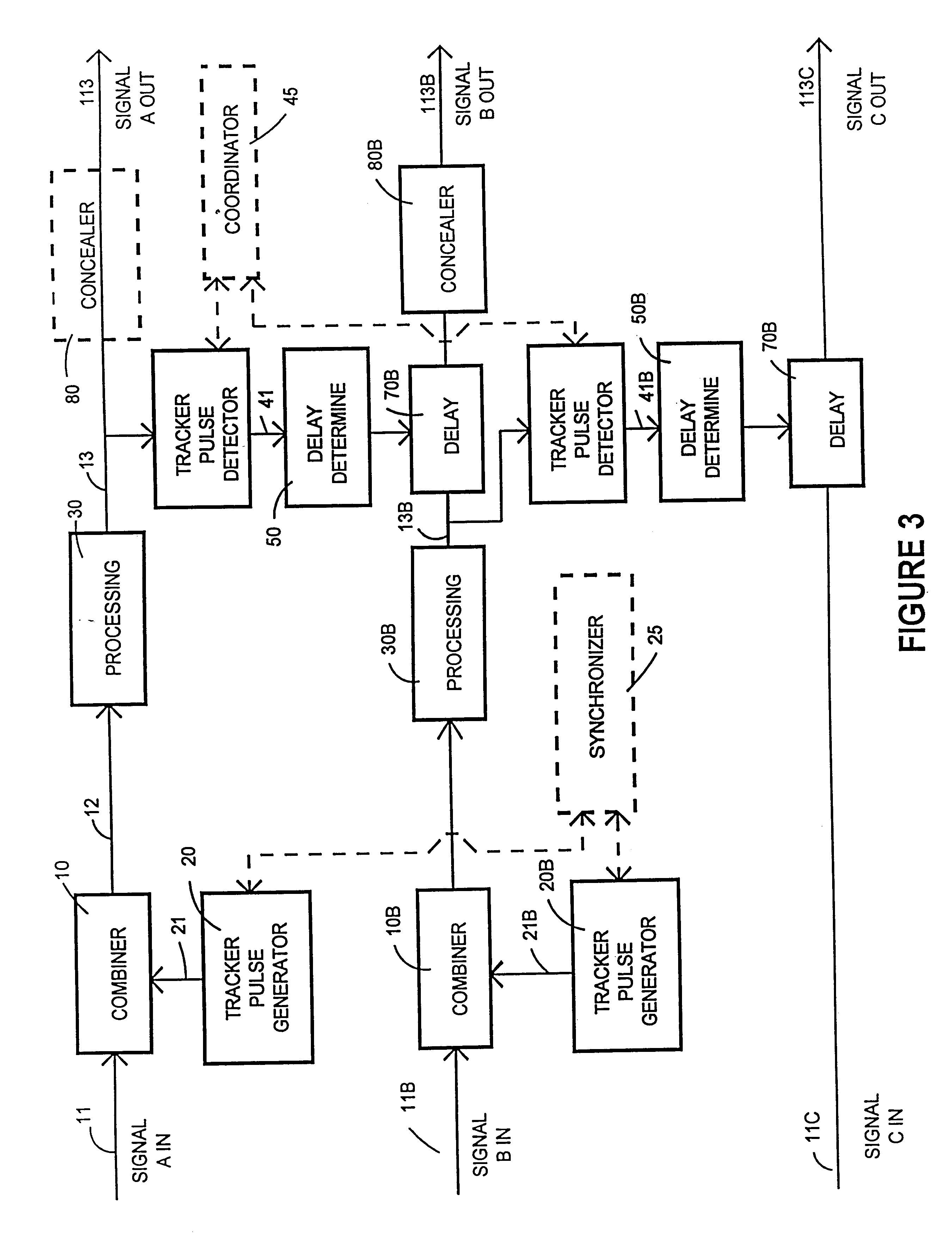

Pulse detector for ascertaining the processing delay of a signal

InactiveUS6330033B1Ensure processTelevision system detailsDifferential synchronisation source lockingSignal correlationSignal processing

A delay tracker for a signal processing system, which delay tracker utilizes a special code or pulse on the active portion of the tracked signal with the system including a pulse detector later in the system subsequently recognizing the special code or pulse in order to identify such signal and ascertain any delays associated with the signal for use by the system including possible resynchronization of the tracked signal with another signal associated therewith.

Owner:CASCADES AV

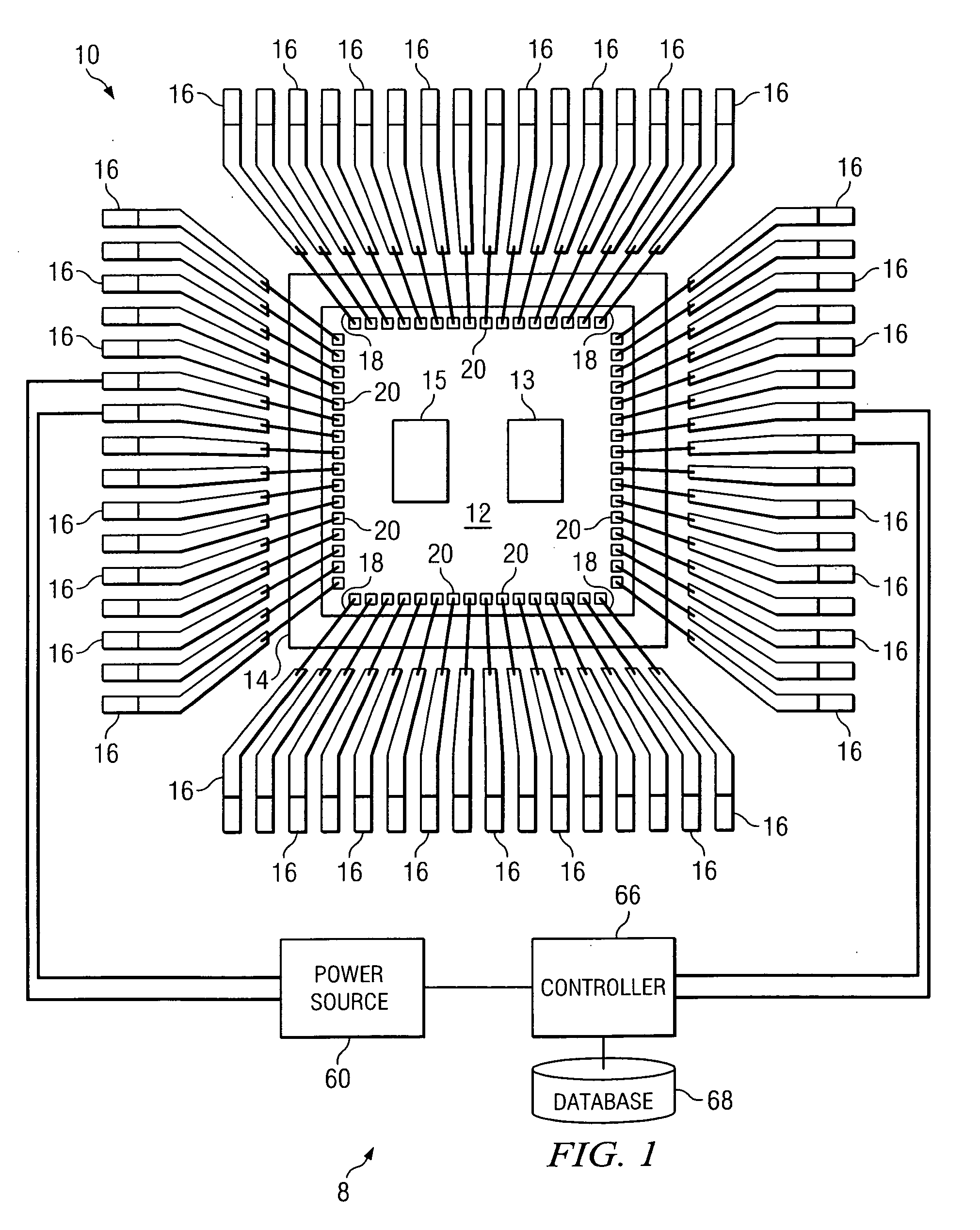

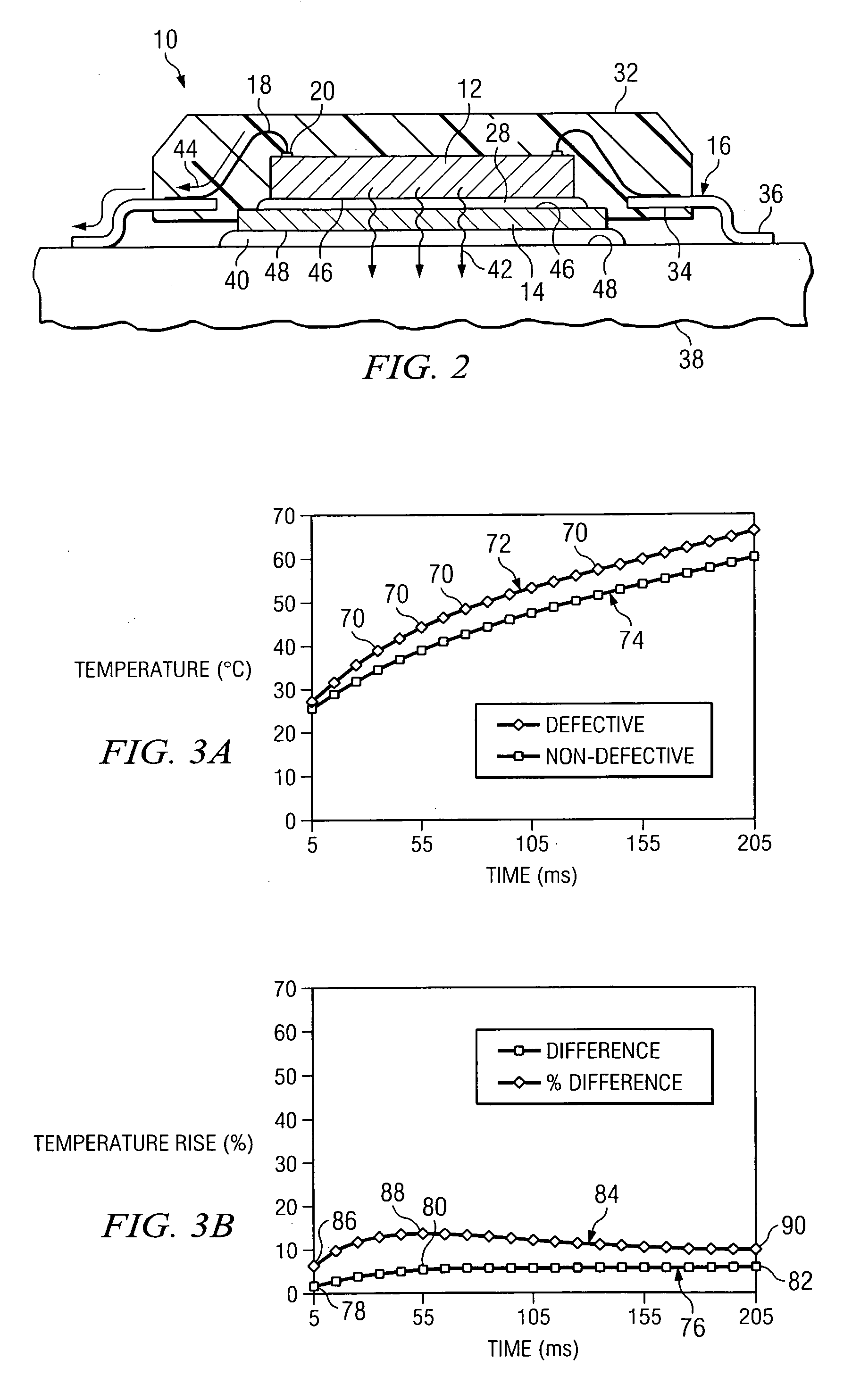

Method for the thermal testing of a thermal path to an integrated circuit

InactiveUS20060156080A1Eliminates and greatly reduces disadvantageEliminates and greatly reduces and problemSolid-state devicesElectrical testingPulse durationIntegrated circuit

According to one embodiment of the present invention, a method for detecting a defect in an integrated circuit using an optimized power pulse includes applying a first pulse of power to a first integrated circuit for an optimized pulse duration. The optimized pulse duration is determined as a function of a difference in temperature between a second, defective integrated circuit and a third, non-defective integrated circuit. The temperature of the first integrated circuit is measured after the first pulse of power is applied to the first integrated circuit for the optimized pulse duration, and a determination is made as to whether the first integrated circuit is defective based on the temperature of the first integrated circuit.

Owner:TEXAS INSTR INC

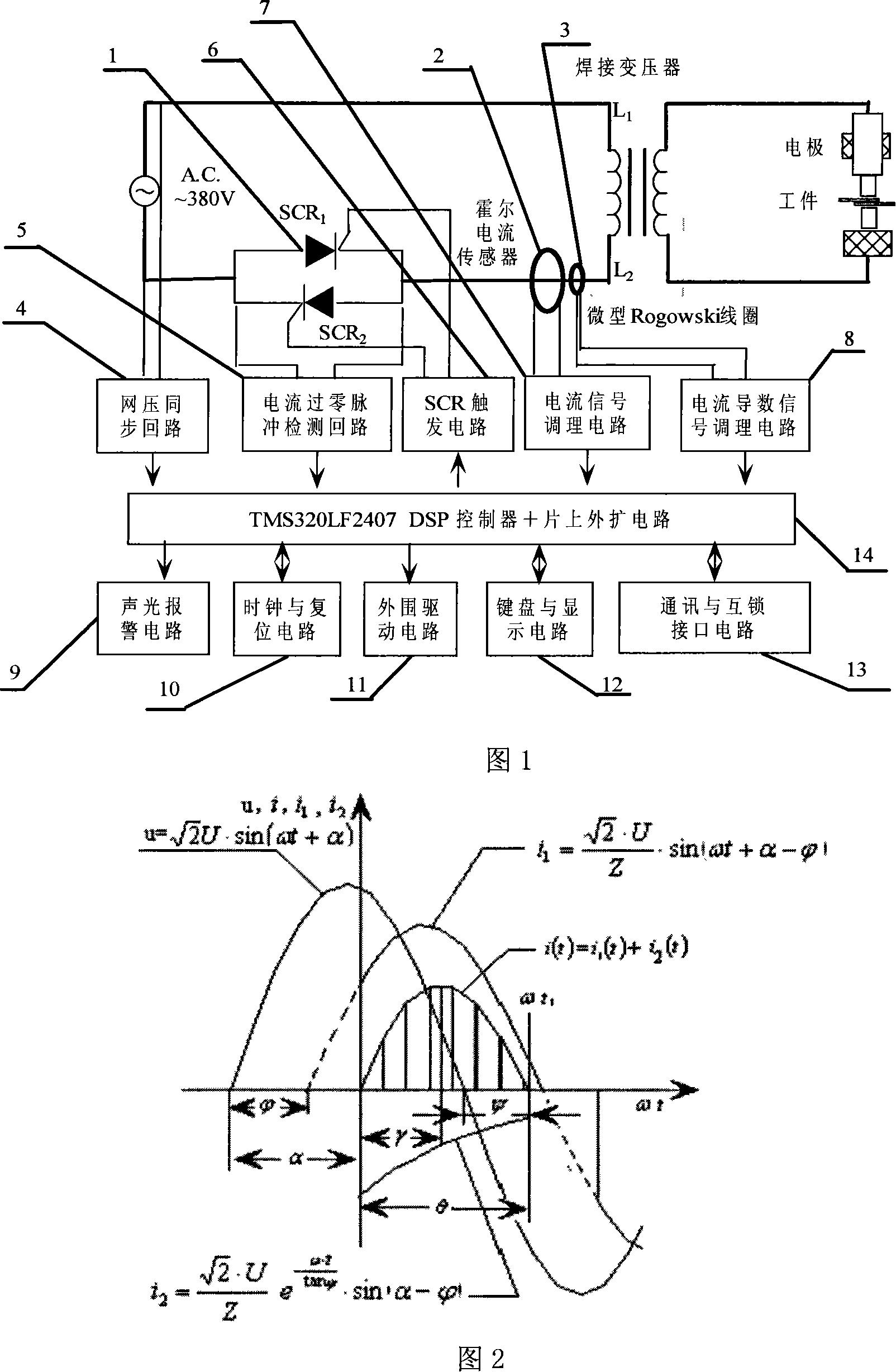

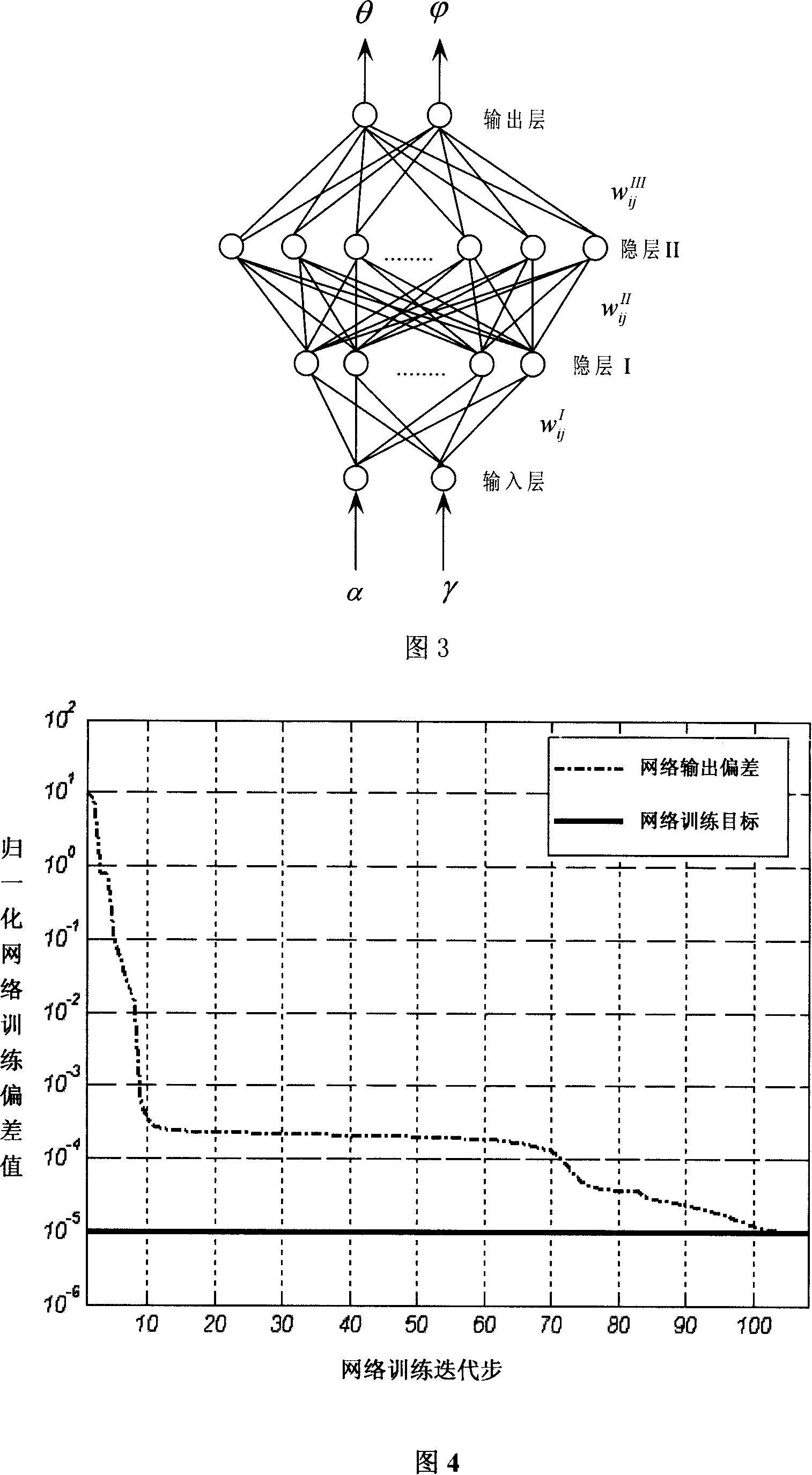

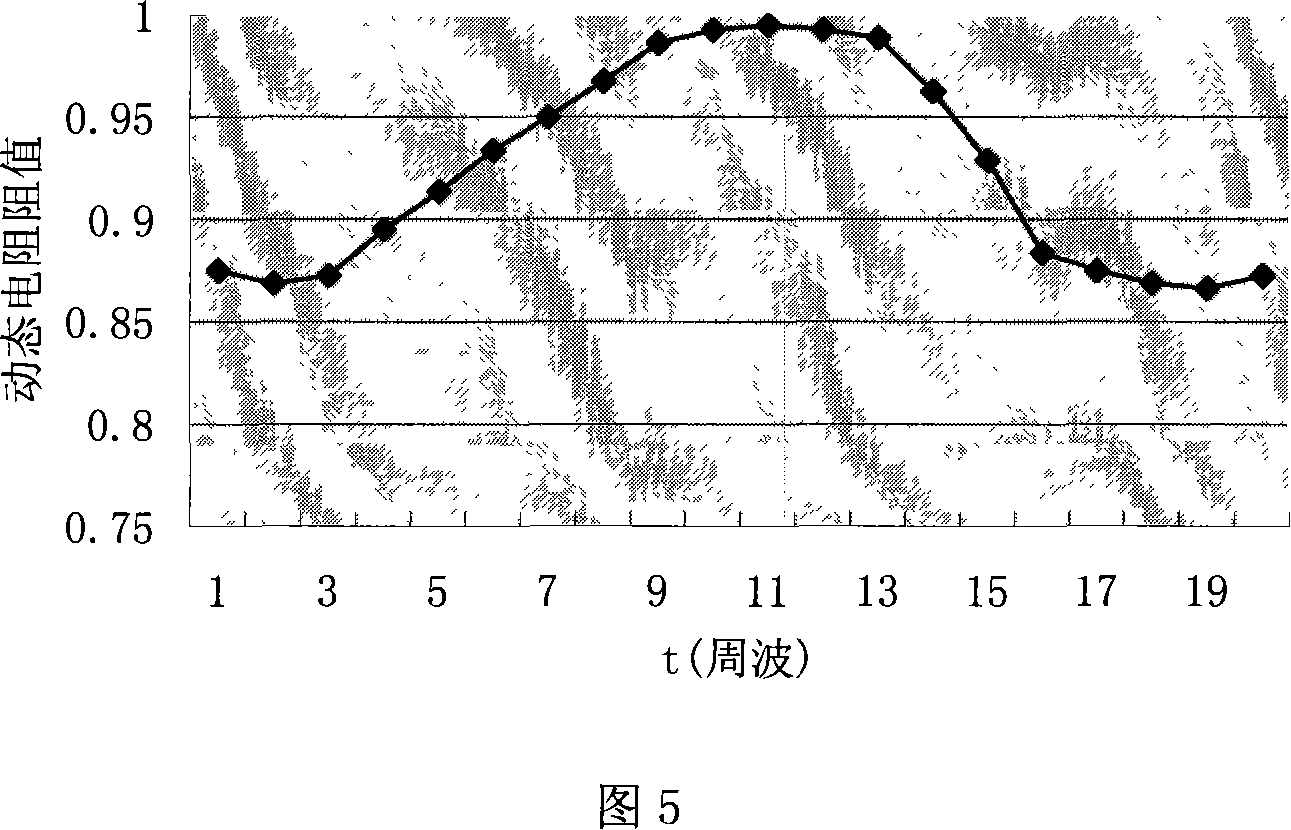

AC spot-welding dynamic electric resistance real-time measuring device and method

InactiveCN101149405AEasy to measureAccurate measurementResistance/reactance/impedenceWelding monitoring devicesDifferential coefficientMeasurement device

A kind of AC spot welding dynamic resistance real time measure instrument and method in the welding technology field, the said instrument includes: the welding transformer, a couple of inverse parallel silicon control, Holtz current sensor, minitype Lowe's loop, net pressure synchronization loop, current zero cross pulse detection loop, the silicon control starting circuit, welding current signal conditioning circuit, current differential coefficient signal conditioning circuit, sound-light alarm circuit, clock and replacement circuit, periphery drive circuit, keyboard and display circuit, communication and interlocked interface circuit, DSP control system. The method is that: uses embedded artificial NN calculate the angle of welding dynamic power factor and the current flow, then calculate the silicon control whole flow current virtual value, calculate the dynamic resistance in the spot welding process by using the ratio of the dynamic power factor and the whole flow current virtual value. This invention can detect the angle of welding dynamic power factor in quarter cycle, the instrument is simple, the real-time ability is good, the measurement precision is high.

Owner:SHANGHAI JIAO TONG UNIV

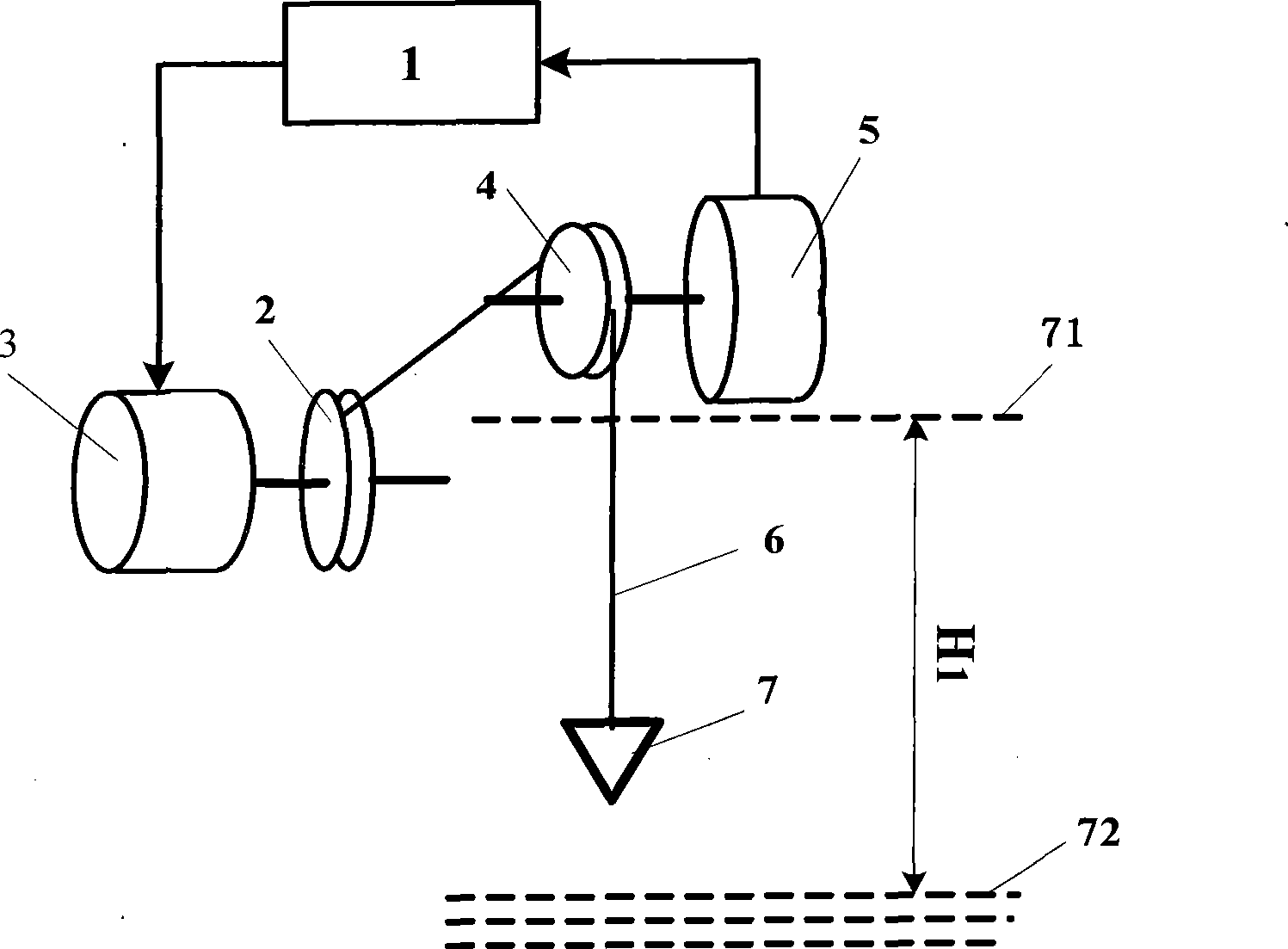

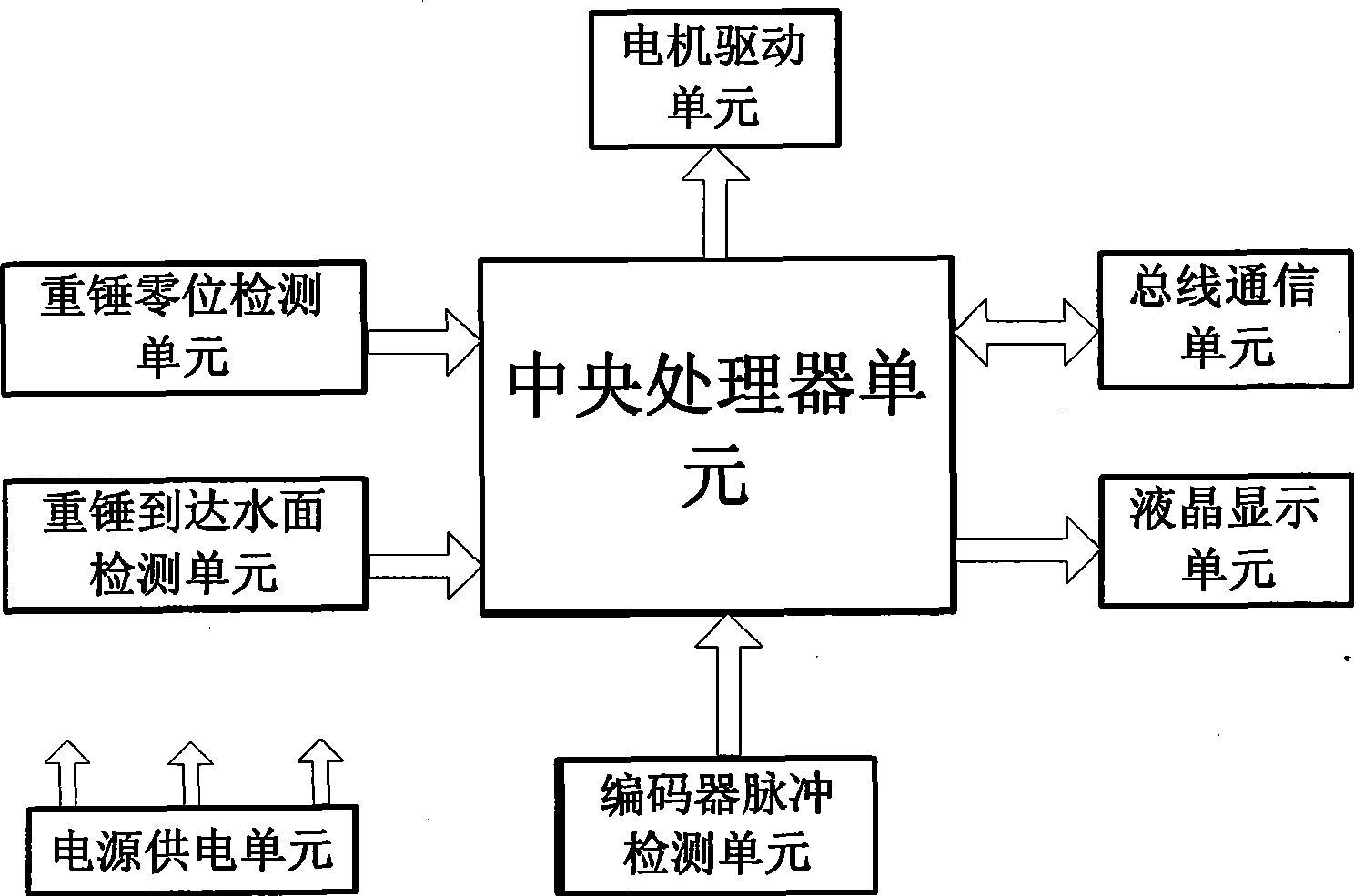

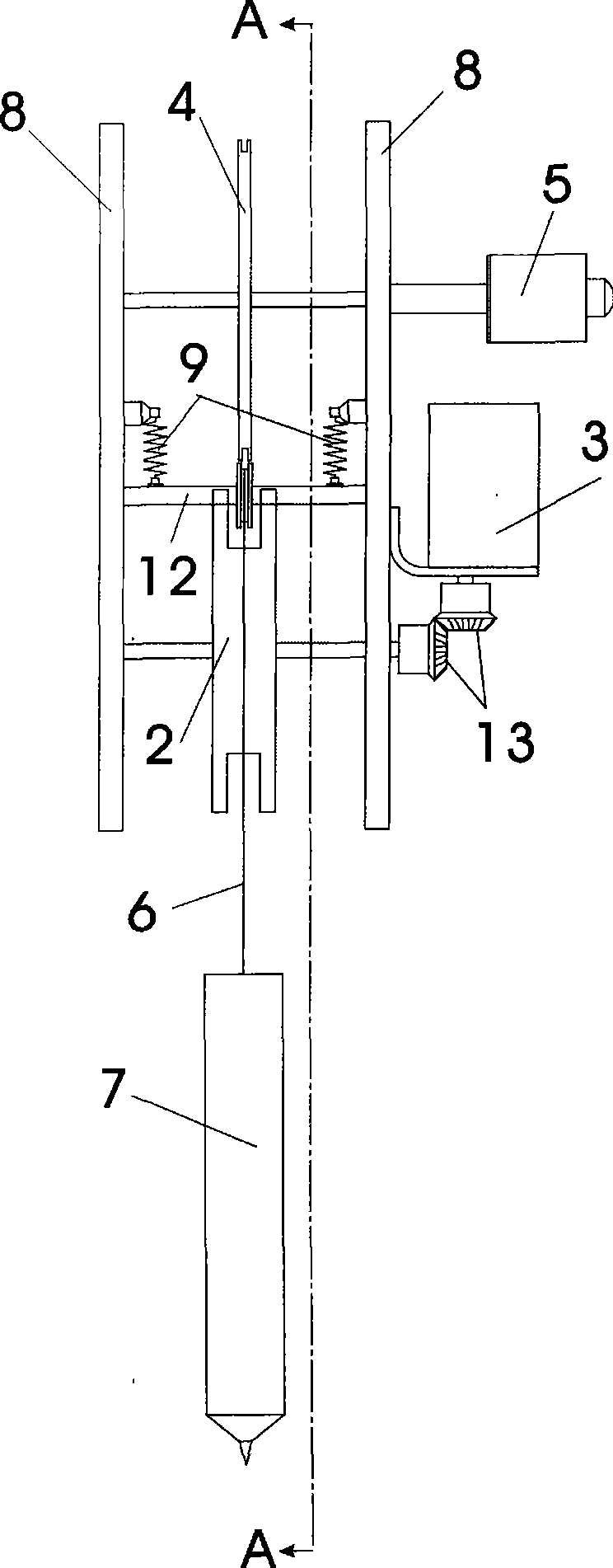

Liquid level detection type self-calibration high-precision water gauge

ActiveCN101464177AAvoid enteringAvoid Cumulative ErrorsMachines/enginesLevel indicatorsDrive wheelEngineering

A liquid level detection-type self-calibration high-precision water level gauge comprises a controller, a steel wire take-up pulley, a motor, a measurement driving wheel, a rotary encoder, a steel wire rope and a heavy hammer. A rotating shaft of the motor is connected with a rotating shaft of the steel wire take-up pulley; the steel wire take-up pulley is wound with one end of the steel wire rope, and the other end is connected with the heavy hammer through the measurement driving wheel; the rotary encoder is connected with a measurement driving wheel shaft; the controller includes a central processing unit which outputs a motor control signal to a motor driving unit to drive the motor to rotate; a zero position detection signal of a heavy hammer zero position detection unit, a water surface detection signal of the heavy hammer arriving at a water surface detection unit, and an encoding impulse signal of an encoder impulse detection unit are input to the central processing unit; and the data is processed by the central processing unit which also transfers the data to an external data processing unit. By adopting the active liquid level detection method and the zero position self-calibration method, the invention can prevent the heavy hammer from dropping into the water, and eliminate the accumulated error produced by the skidding of the steel wire rope and the impulse loss of the encoder, thereby ensuring high-precision and wide-range measurement of the water level.

Owner:GUANGZHOU SUNTRANS MEASUREMENT & CONTROL SYST

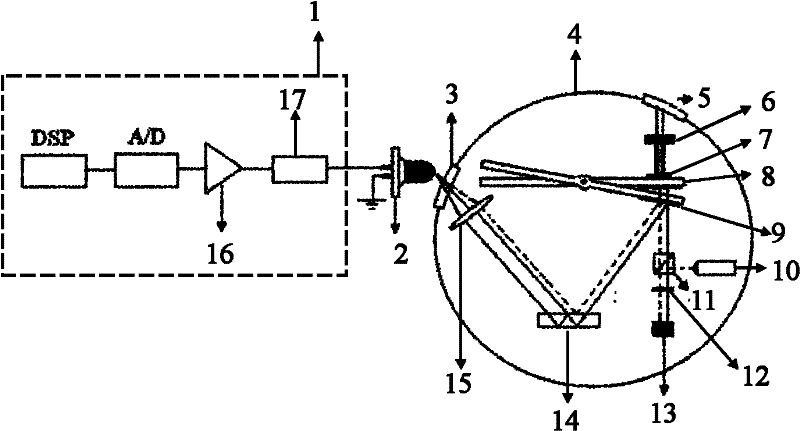

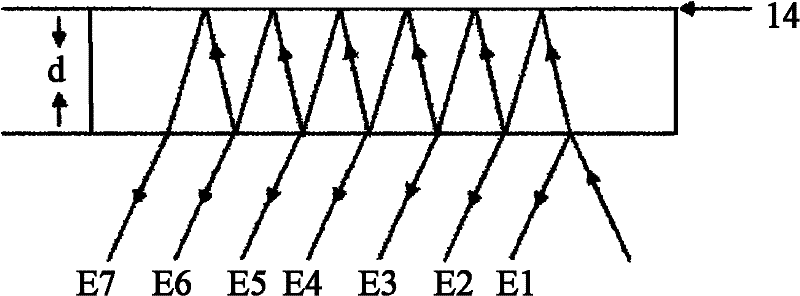

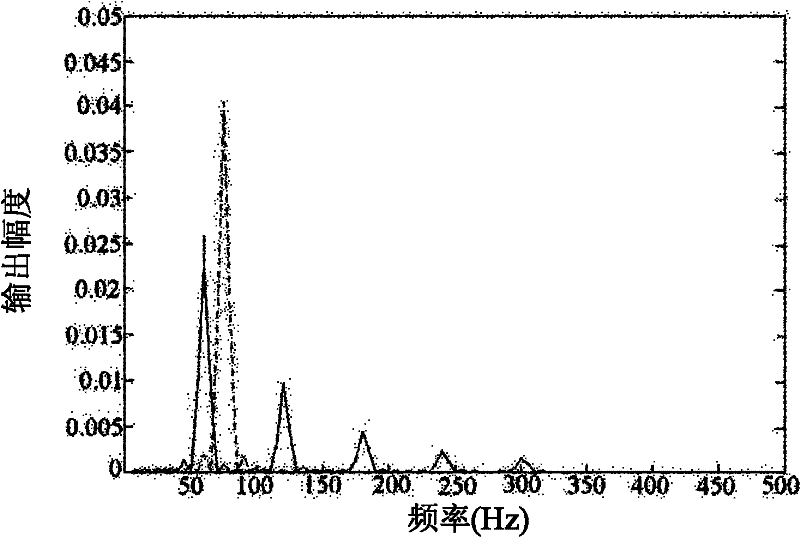

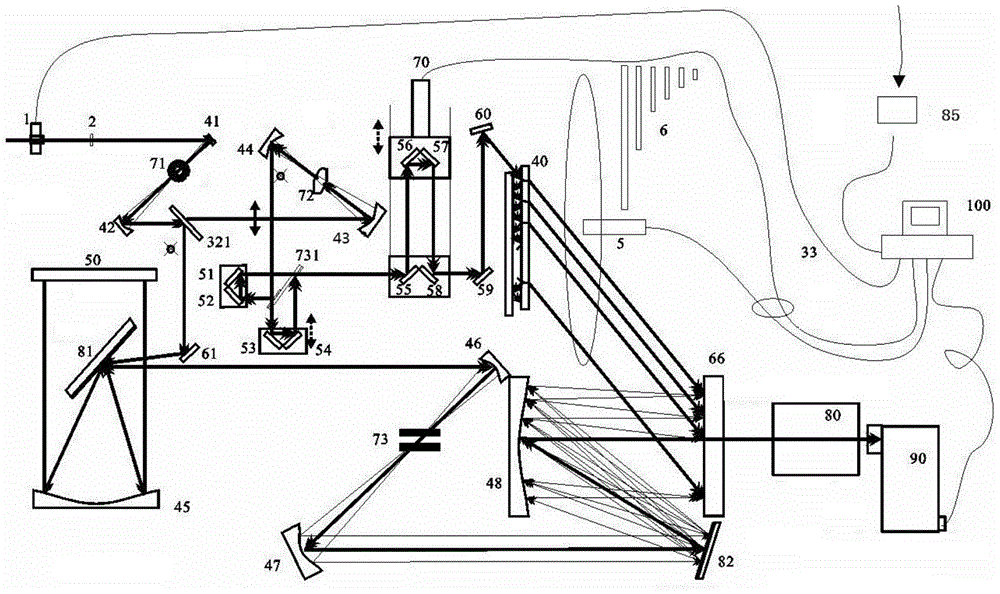

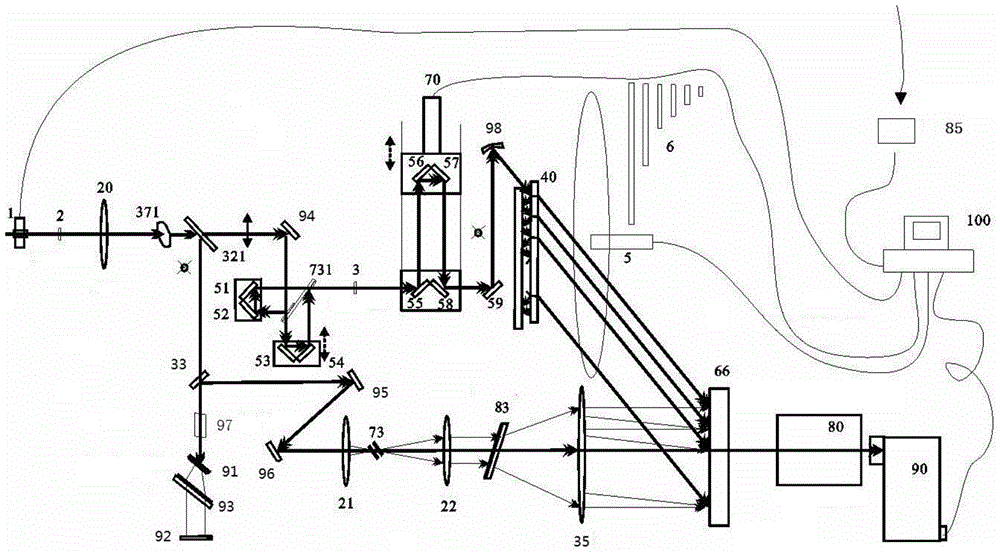

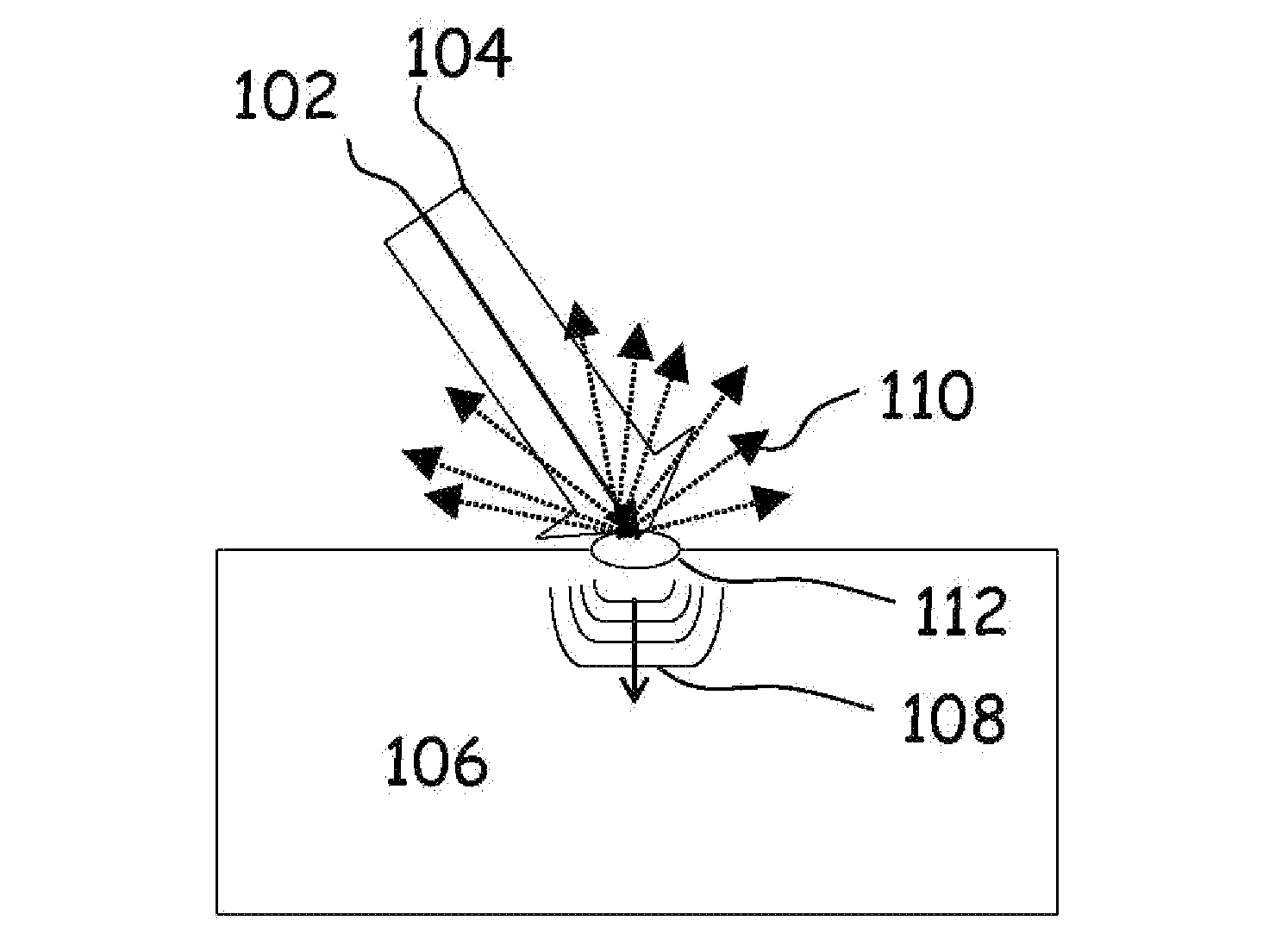

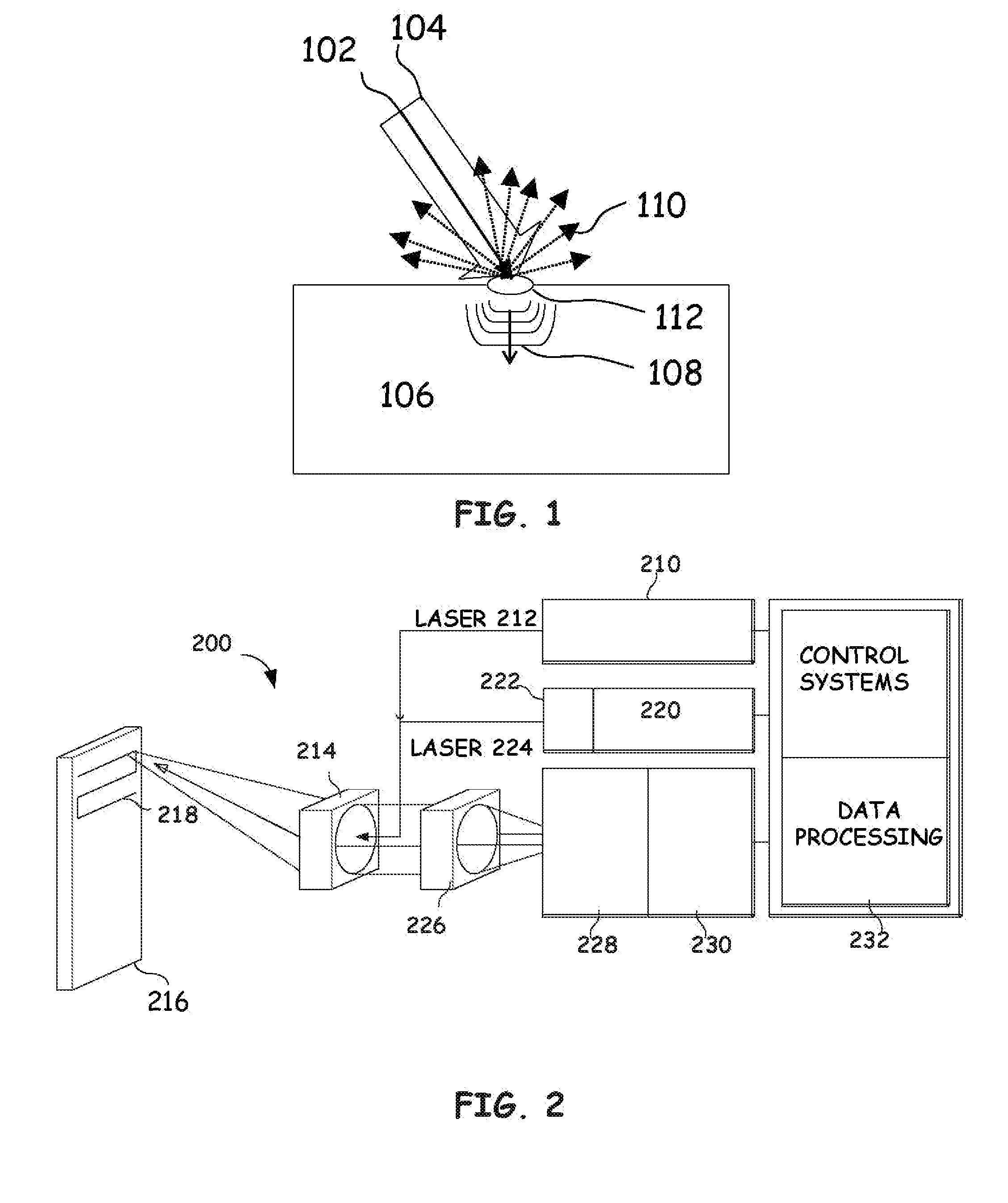

Multi-laser-beam heterodyne micro-impulse-measuring device and method

InactiveCN102175376ASolve efficiency problemsSolve the errorApparatus for force/torque/work measurementWorking fluidIntermediate frequency

The invention discloses a multi-laser-beam heterodyne micro-impulse-measuring device and a multi-laser-beam heterodyne micro-impulse-measuring method and relates to the technical field of micro impulse detection. By the device and the method, the problems of low energy coupling efficiency and big system error in the current small-impulse-measuring system are solved and the micro impulse measurement is carried out on the basis of a laser heterodyne technology and a Doppler effect. The method comprises the steps of: converting the micro impulse generated under the action of the laser and a target into a rotating angle of a torsional pendulum; then introducing a scanner into the measuring light path to attach an optical frequency to each of the light signals entering at different time points, so that a reflected light from the front surface of a planer standard lens and a transmitted light reflected by the front surface and the back surface of the planer standard lens for many times generate a multi-beam heterodyne interfering signal under an interfering condition; and thus modulating the change information of the rotating angle of a standard beam into the frequency difference of a medium-frequency heterodyne signal successfully. With polyvinyl chloride (PVC) and 2 percent of carbon (C) as working fluid, the micro impulse generated under the action of the laser and the working fluid is simulatively measured by using a torsional pendulum method and the measurement result shows that the maximum relative error of the measurement is less than 2.3 percent.

Owner:HARBIN INST OF TECH

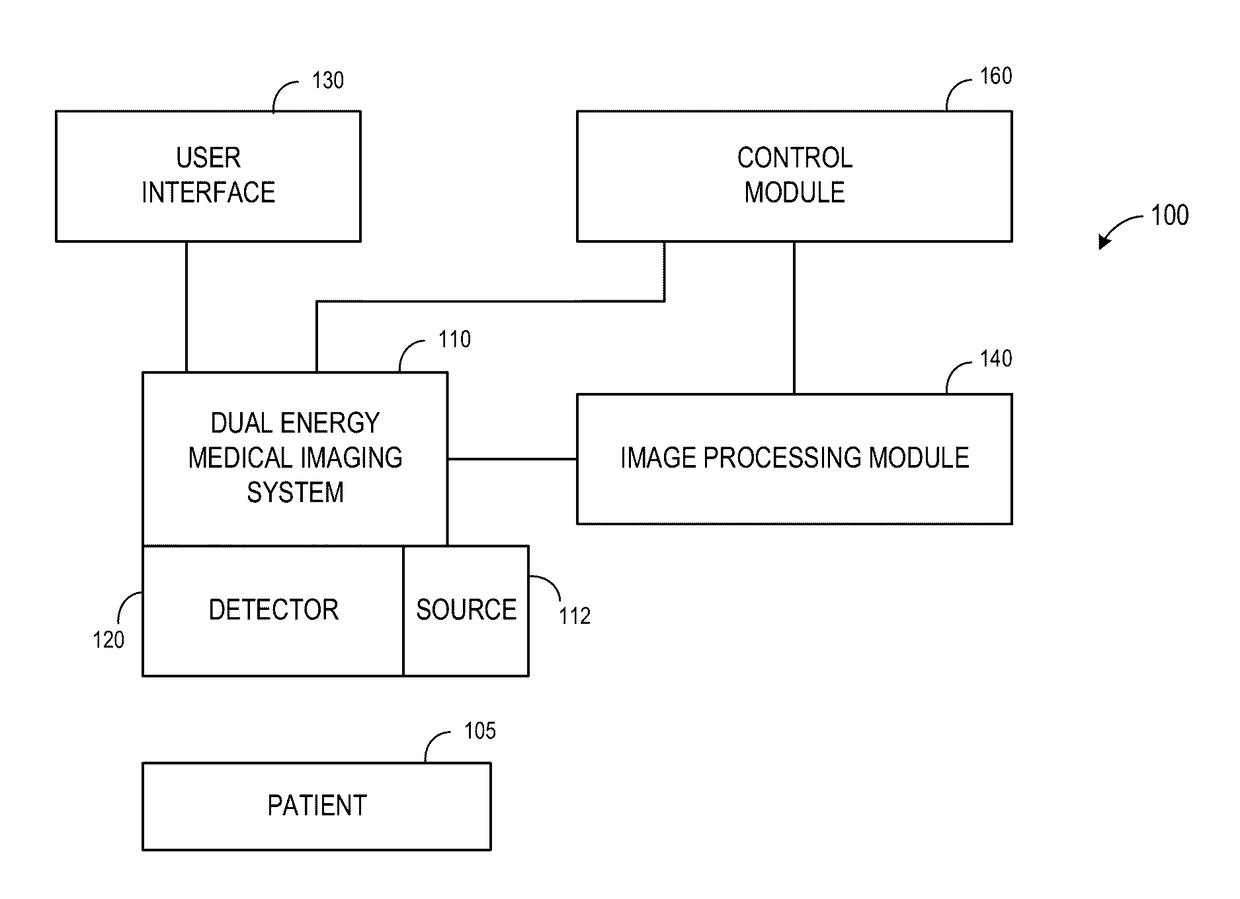

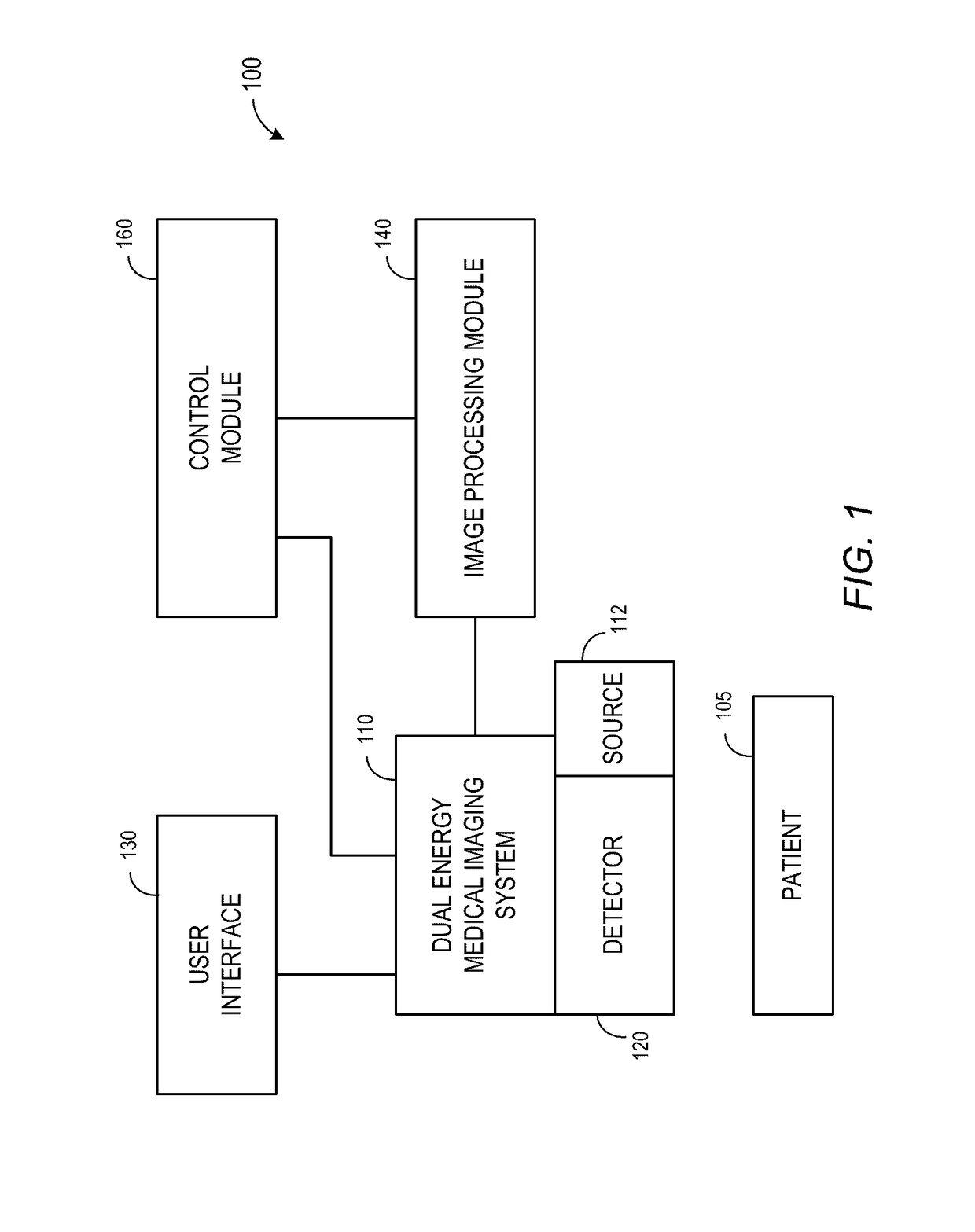

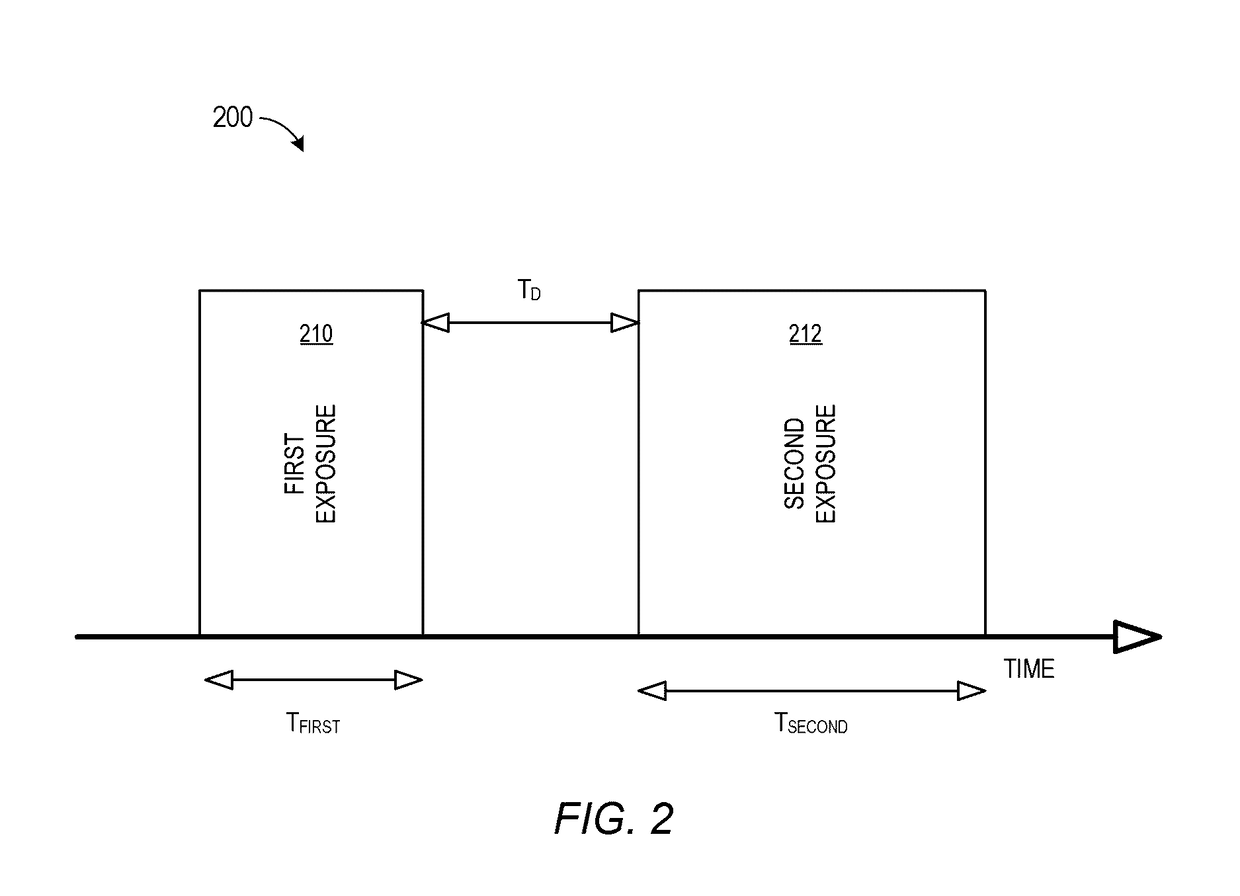

Fast dual energy for general radiography

ActiveUS20170065240A1Improved and accurate capturingMaterial analysis using wave/particle radiationRadiation diagnostic clinical applicationsKnee radiographyX-ray

Some embodiments are associated with an X-ray source configured to generate X-rays directed toward an object, wherein the X-ray source is to: (i) generate a first energy X-ray pulse, (ii) switch to generate a second energy X-ray pulse, and (iii) switch back to generate another first energy X-ray pulse. A detector may be associated with multiple image pixels, and the detector includes, for each pixel: an X-ray sensitive element to receive X-rays; a first storage element and associated switch to capture information associated with the first energy X-ray pulses; and a second storage element and associated switch to capture information associated with the second energy X-ray pulse. A controller may synchronize the X-ray source and detector.

Owner:GENERAL ELECTRIC CO

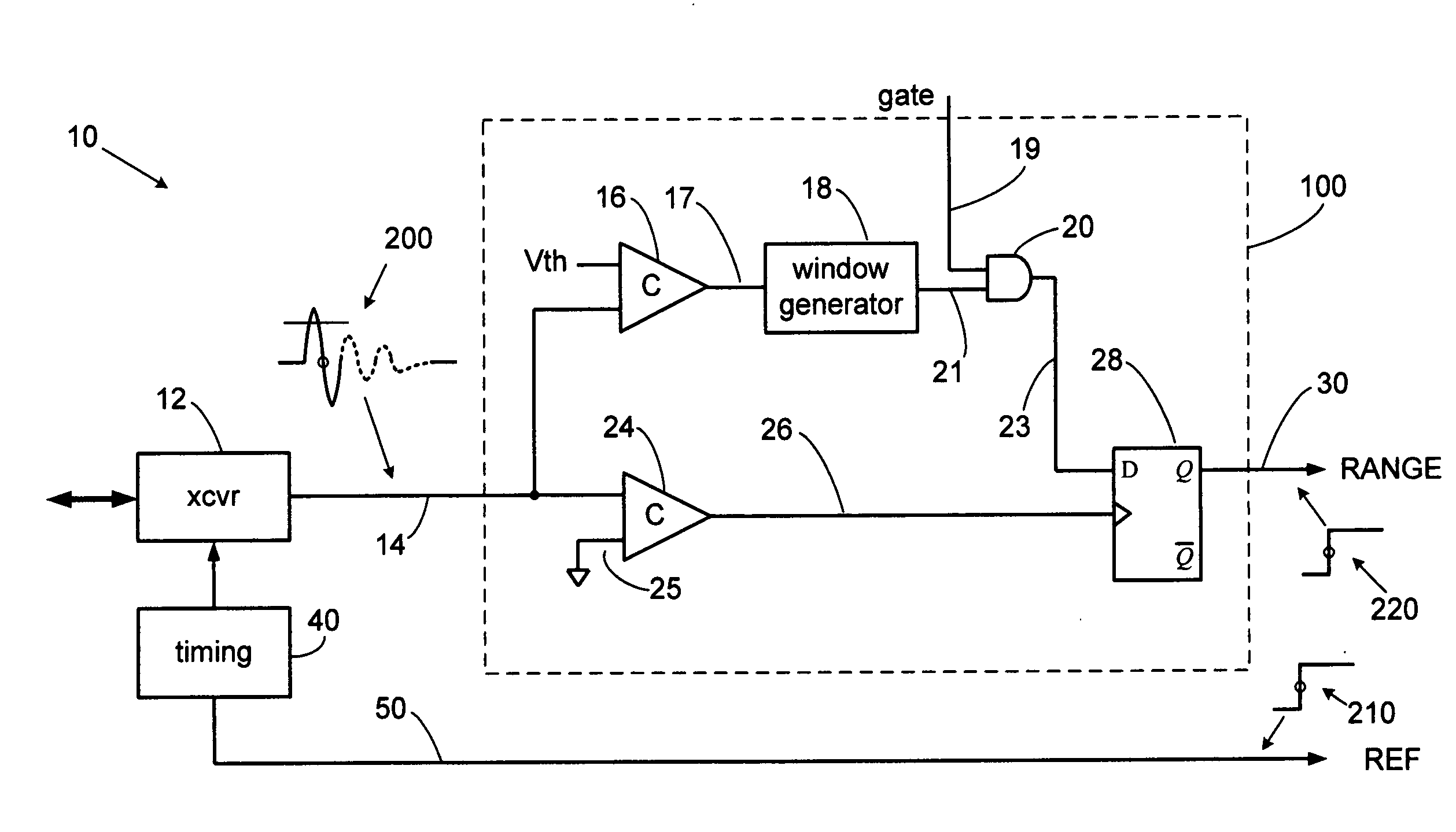

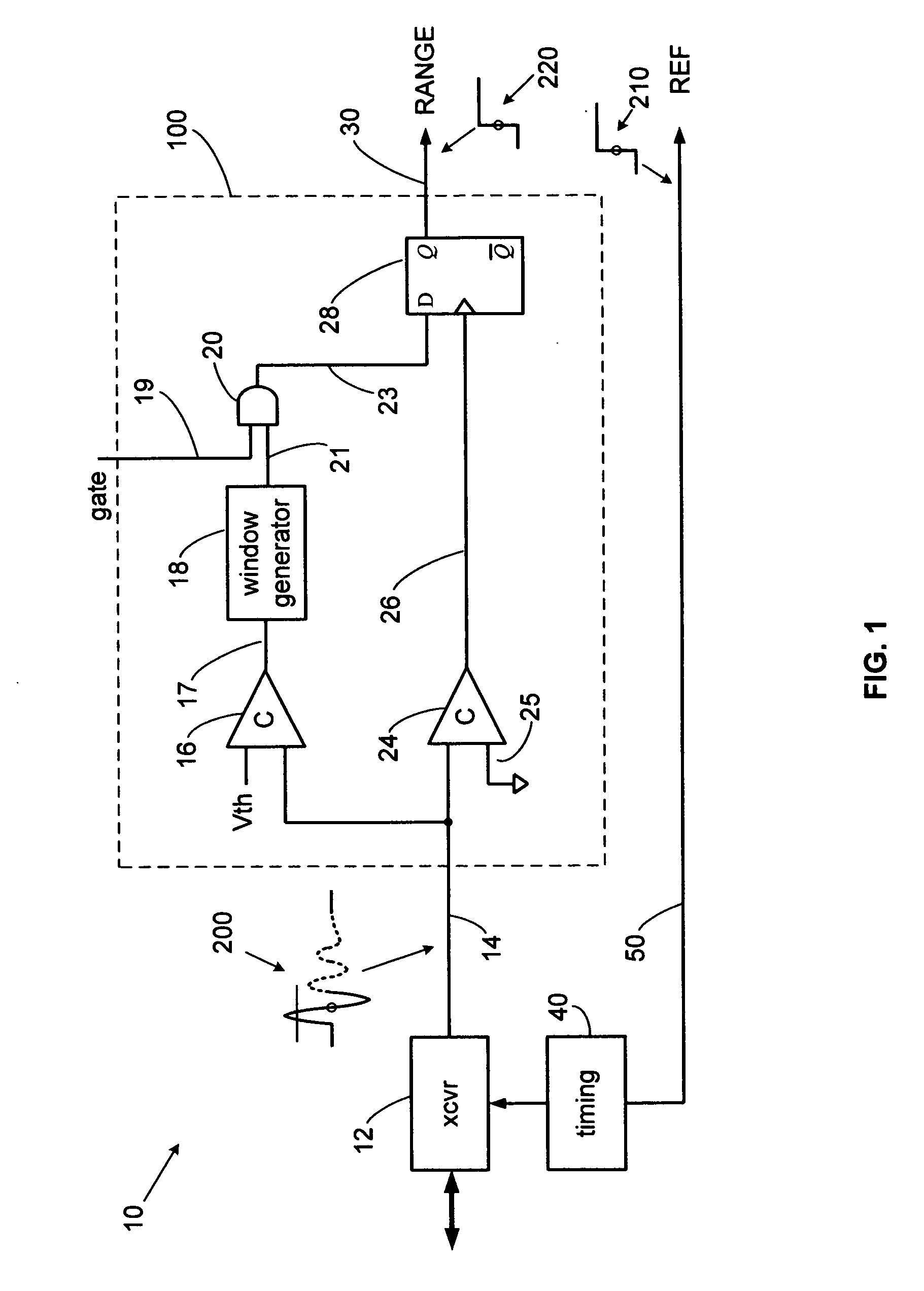

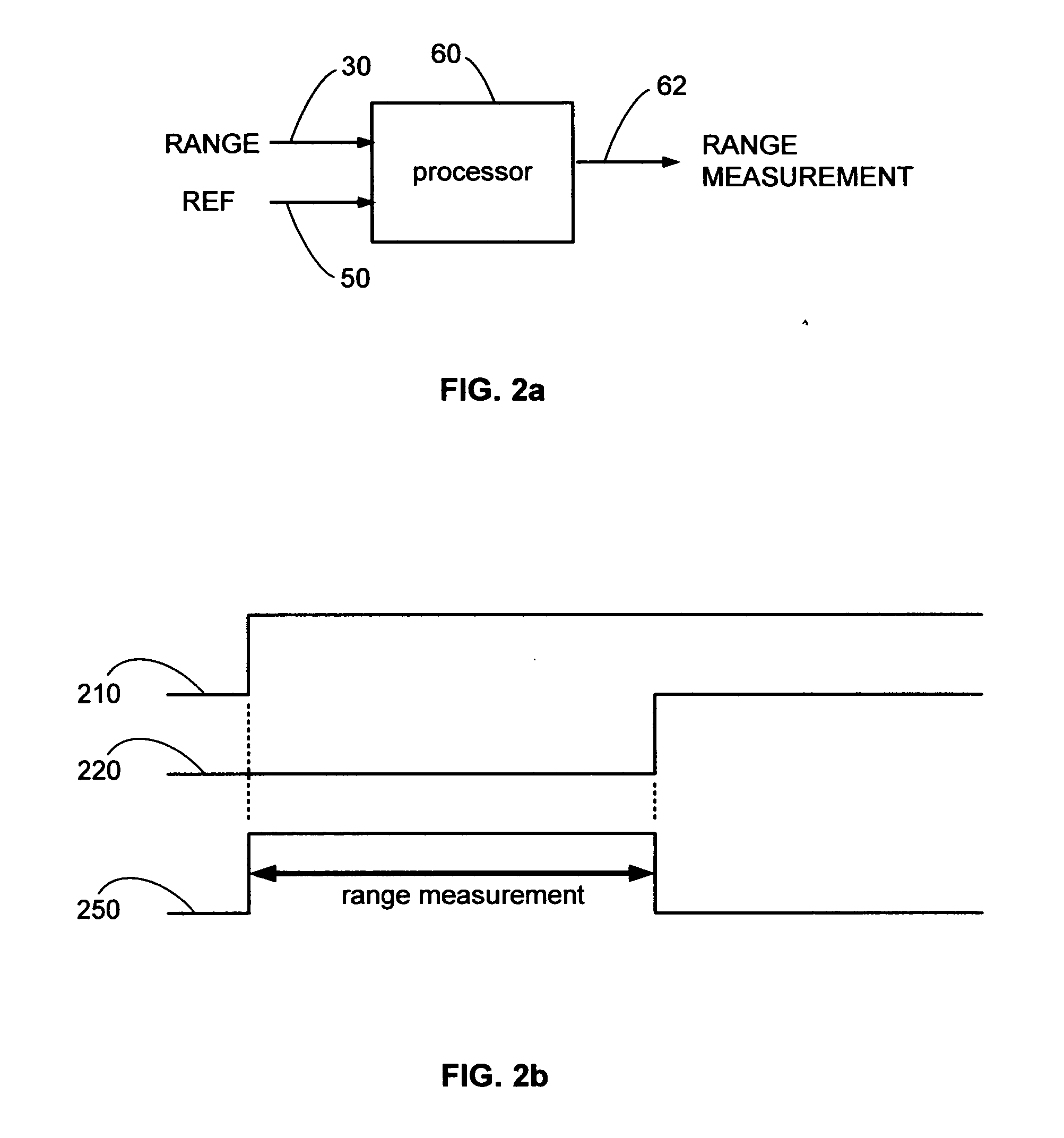

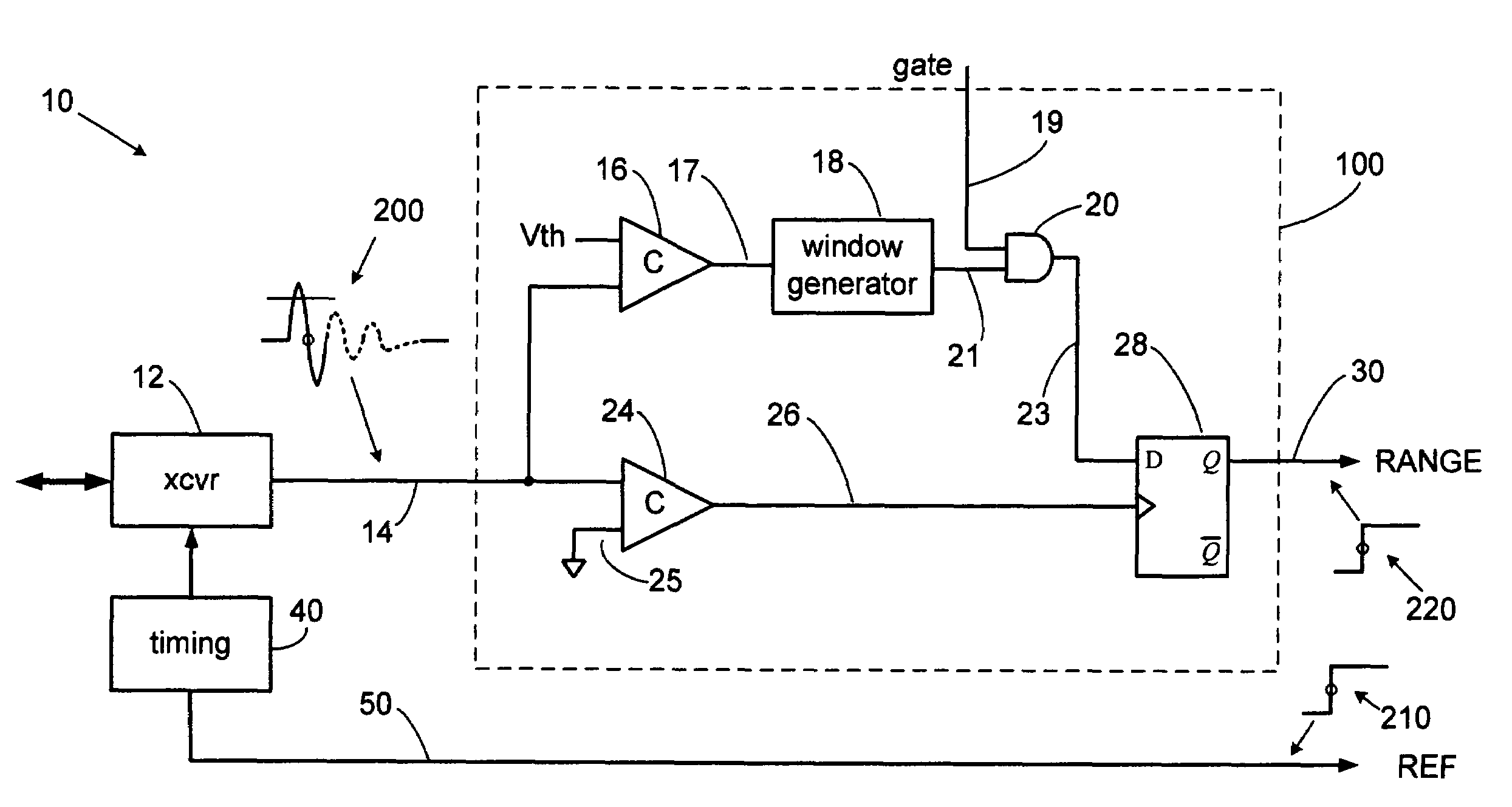

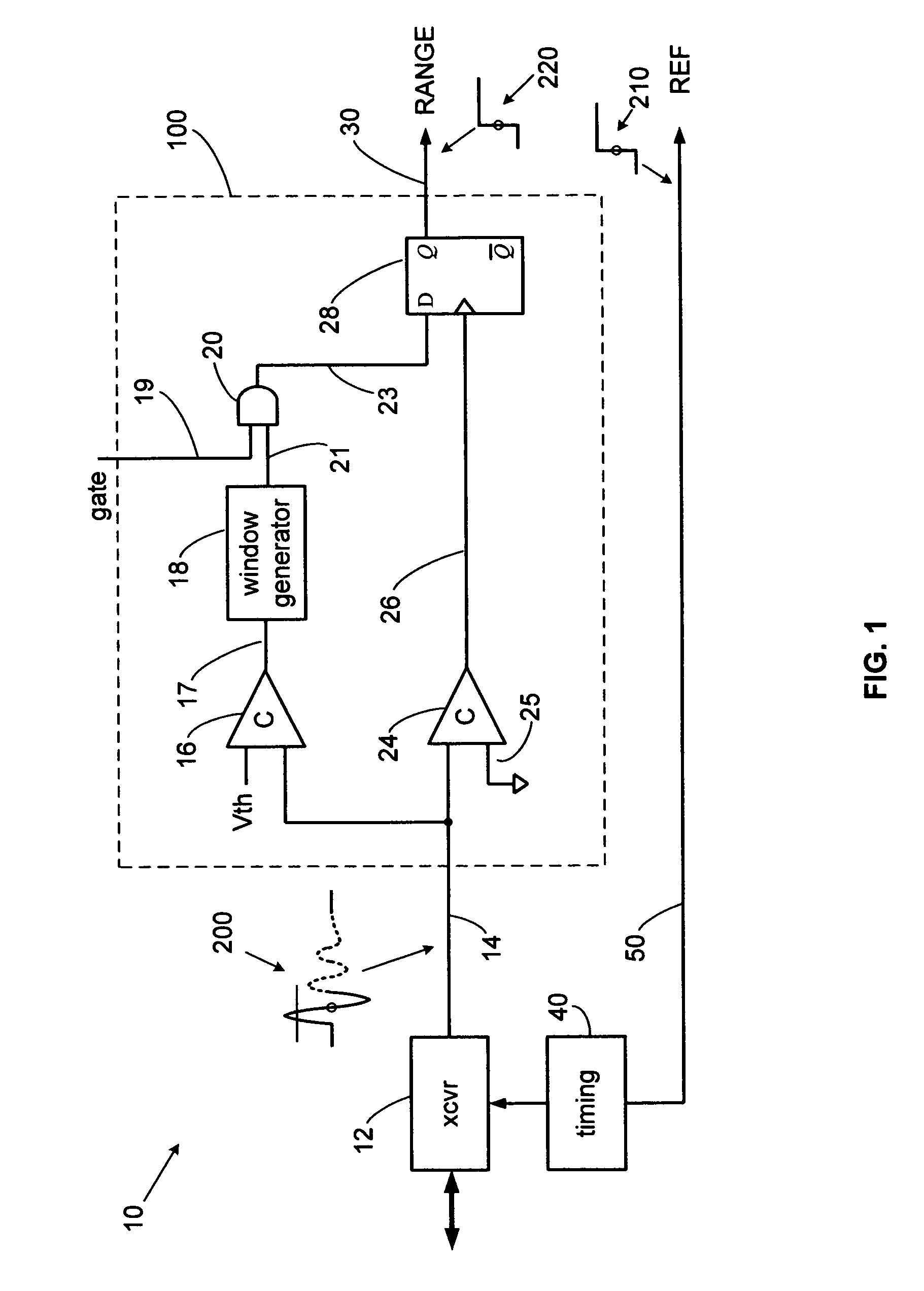

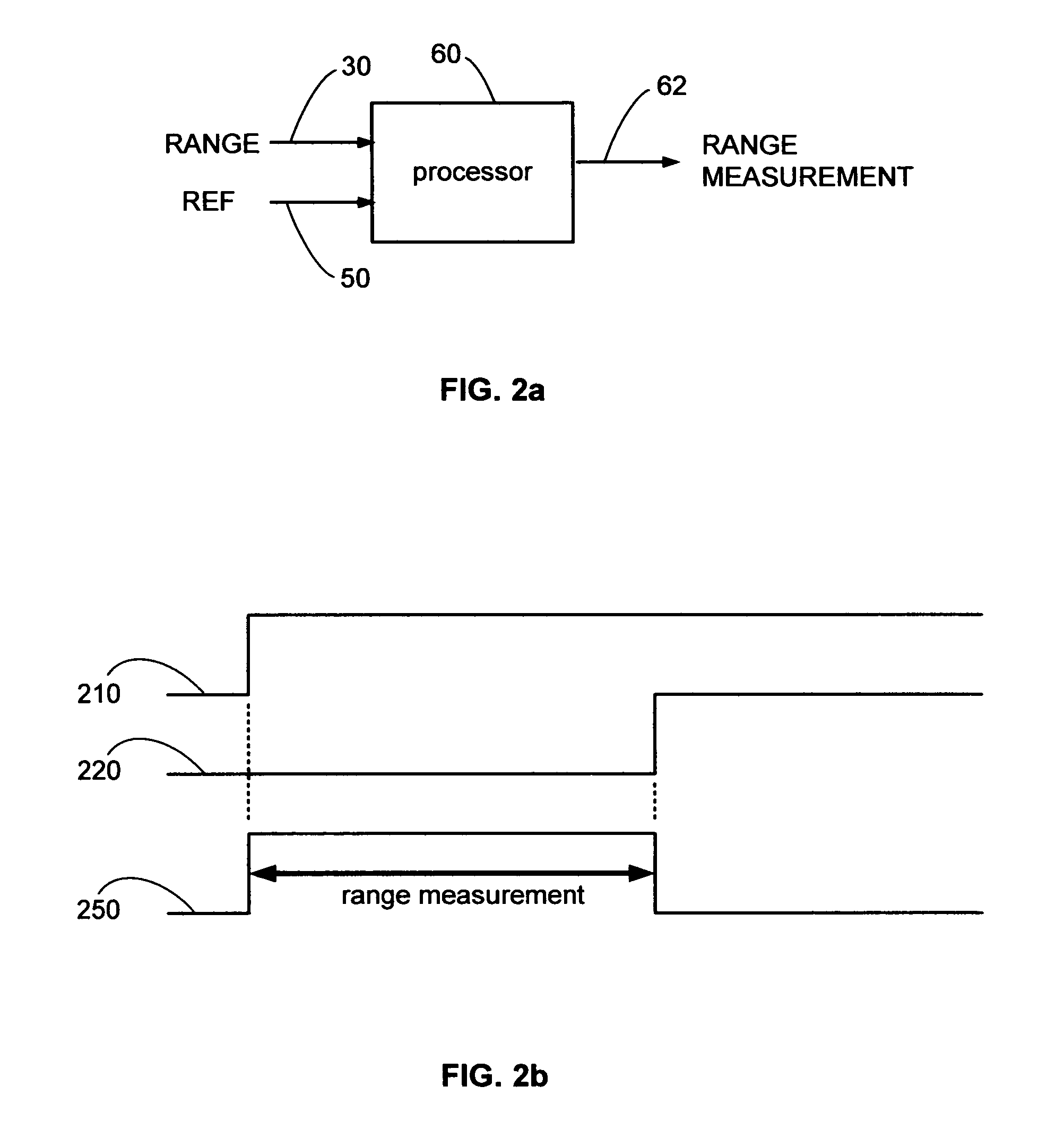

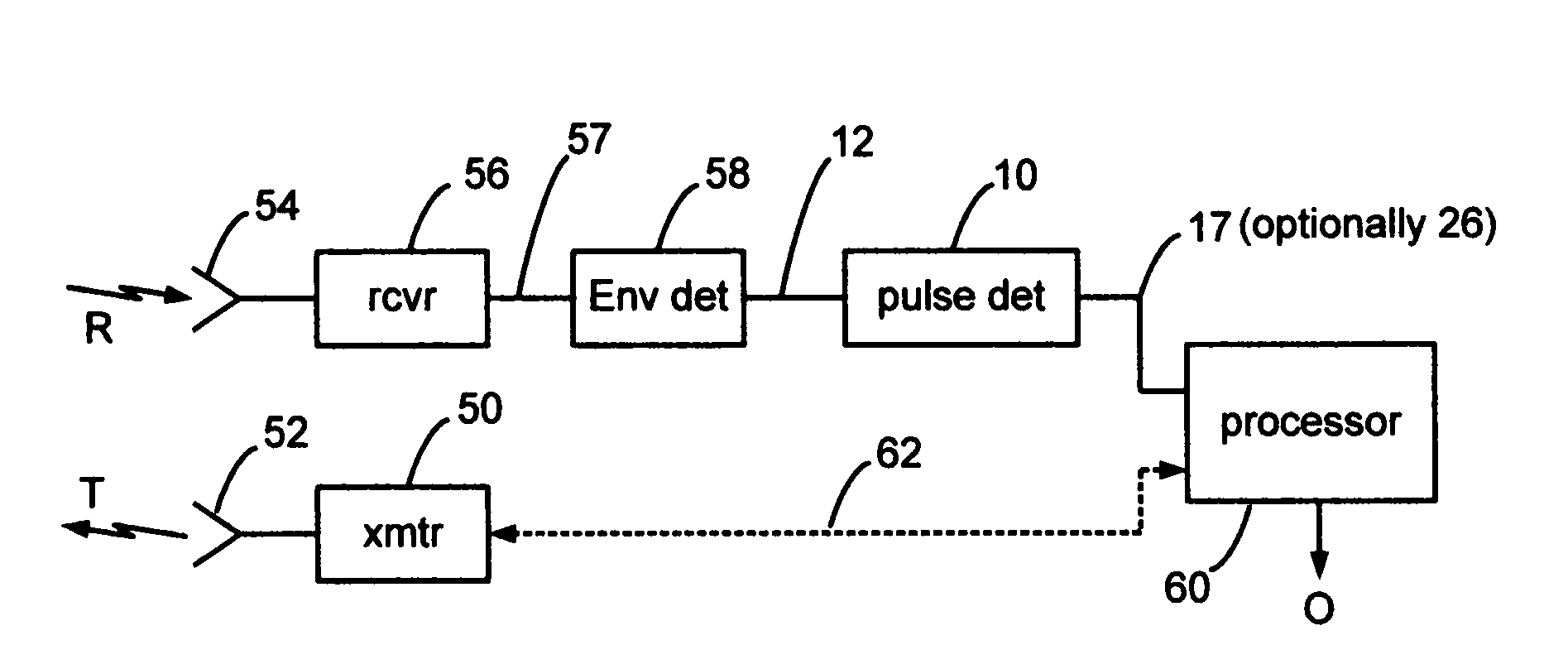

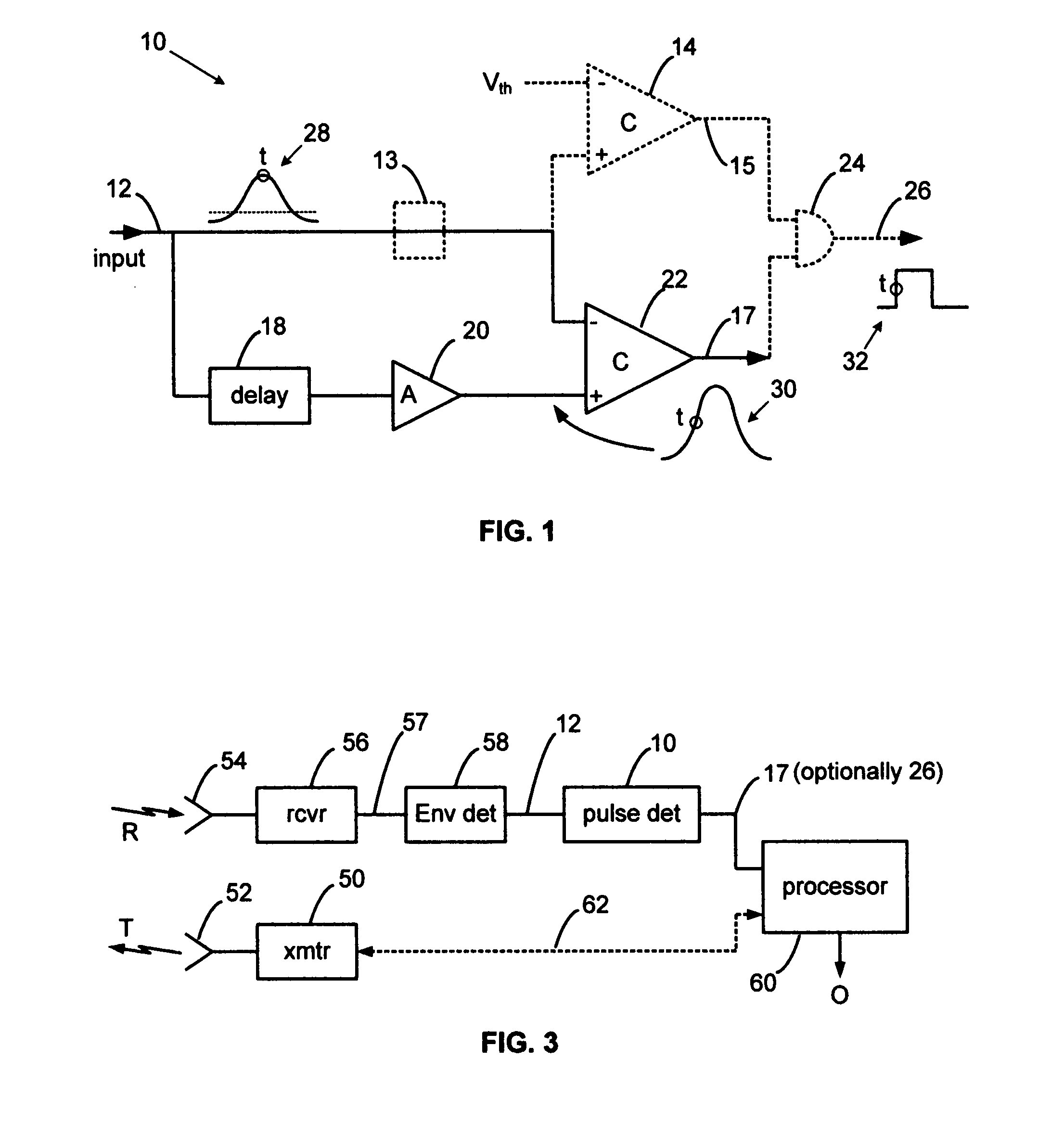

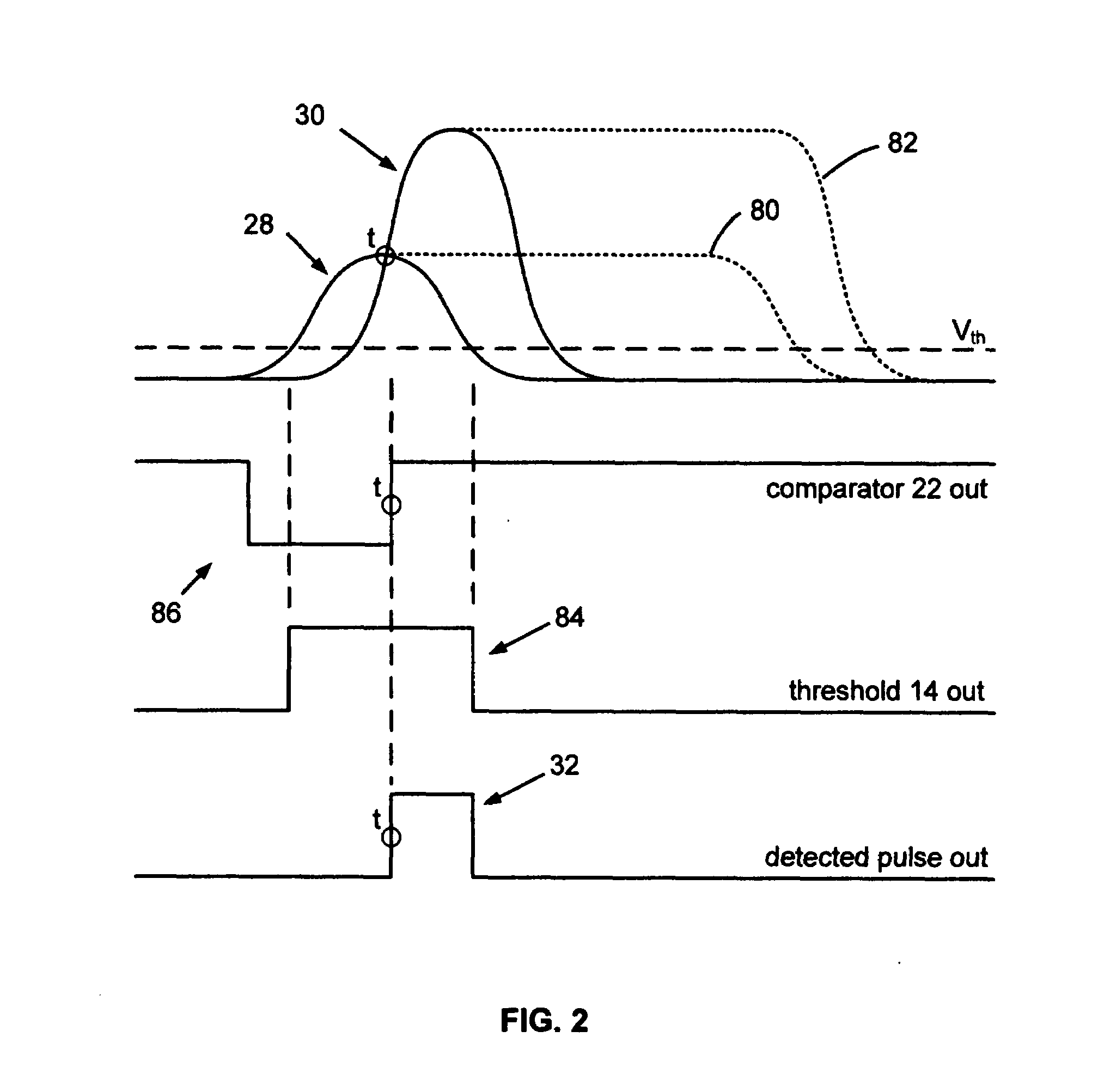

Precision pulse detection system for radar sensors

ActiveUS20080048905A1Improve accuracyGood anti-noise performanceAmplitude demodulation by homodyne/synchrodyne circuitsResistance/reactance/impedenceHandwritingPhase detector

A precision pulse detection system for time-of-flight sensors detects a zero axis crossing of a pulse after it crosses above and then falls below a threshold. Transmit and receive pulses flow through a common expanded-time receiver path to precision transmit and receive pulse detectors in a differential configuration. The detectors trigger on zero axis crossings that occur immediately after pulse lobes exceed and then drop below a threshold. Range errors caused by receiver variations cancel since transmit and receive pulses are affected equally. The system exhibits range measurement accuracies on the order of 1-picosecond without calibration even when used with transmitted pulse widths on the order of 500 picoseconds. The system can provide sub-millimeter accurate TDR, laser and radar sensors for measuring tank fill levels or for precision radiolocation systems including digital handwriting capture.

Owner:MCEWAN TECH

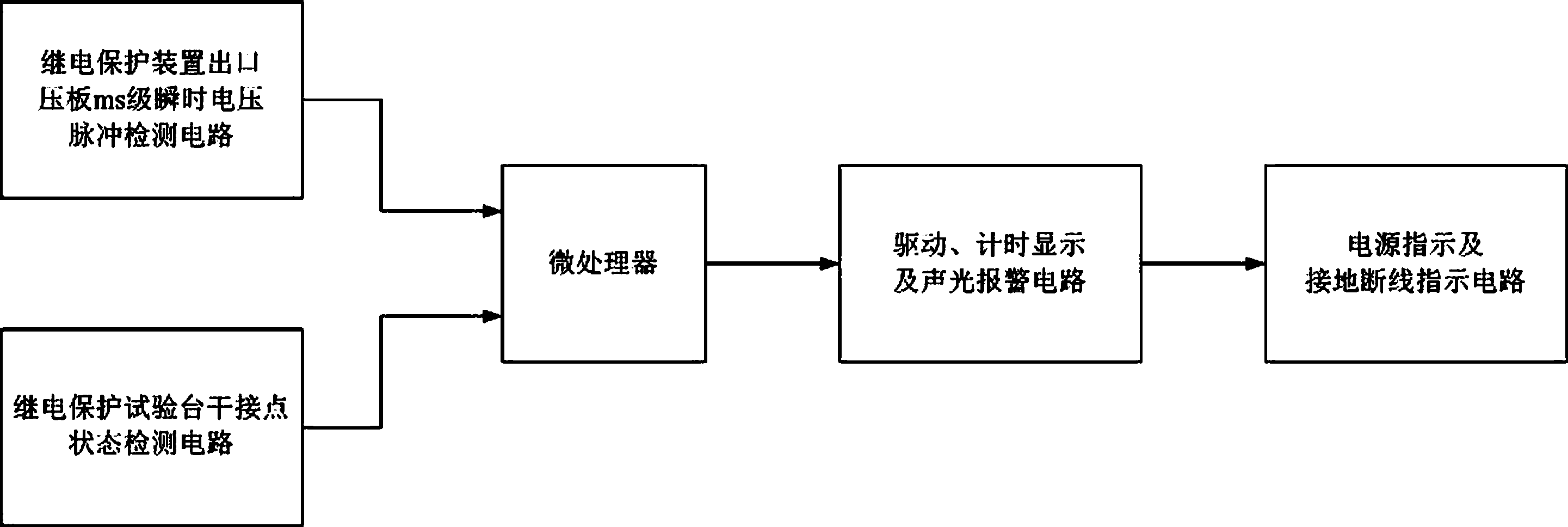

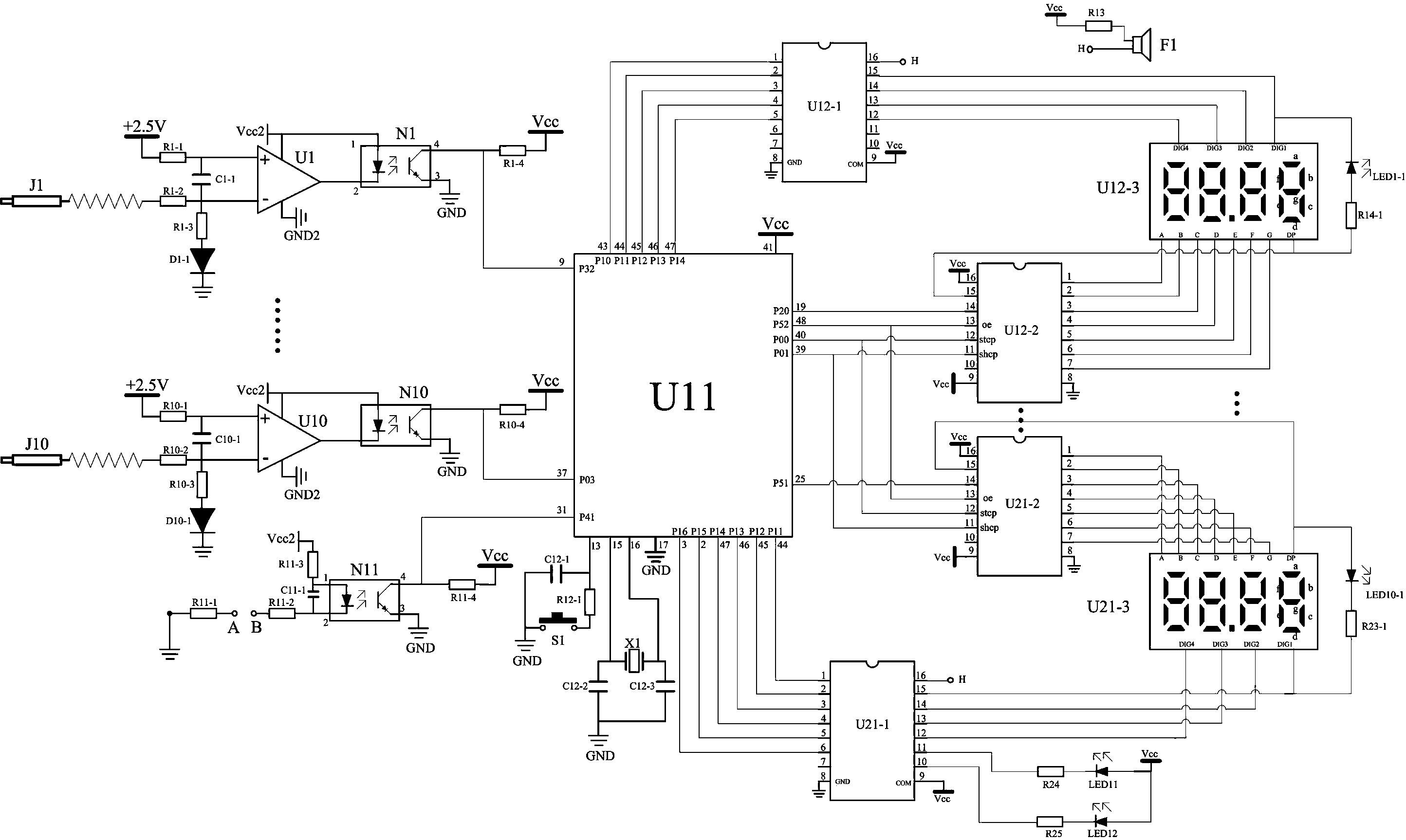

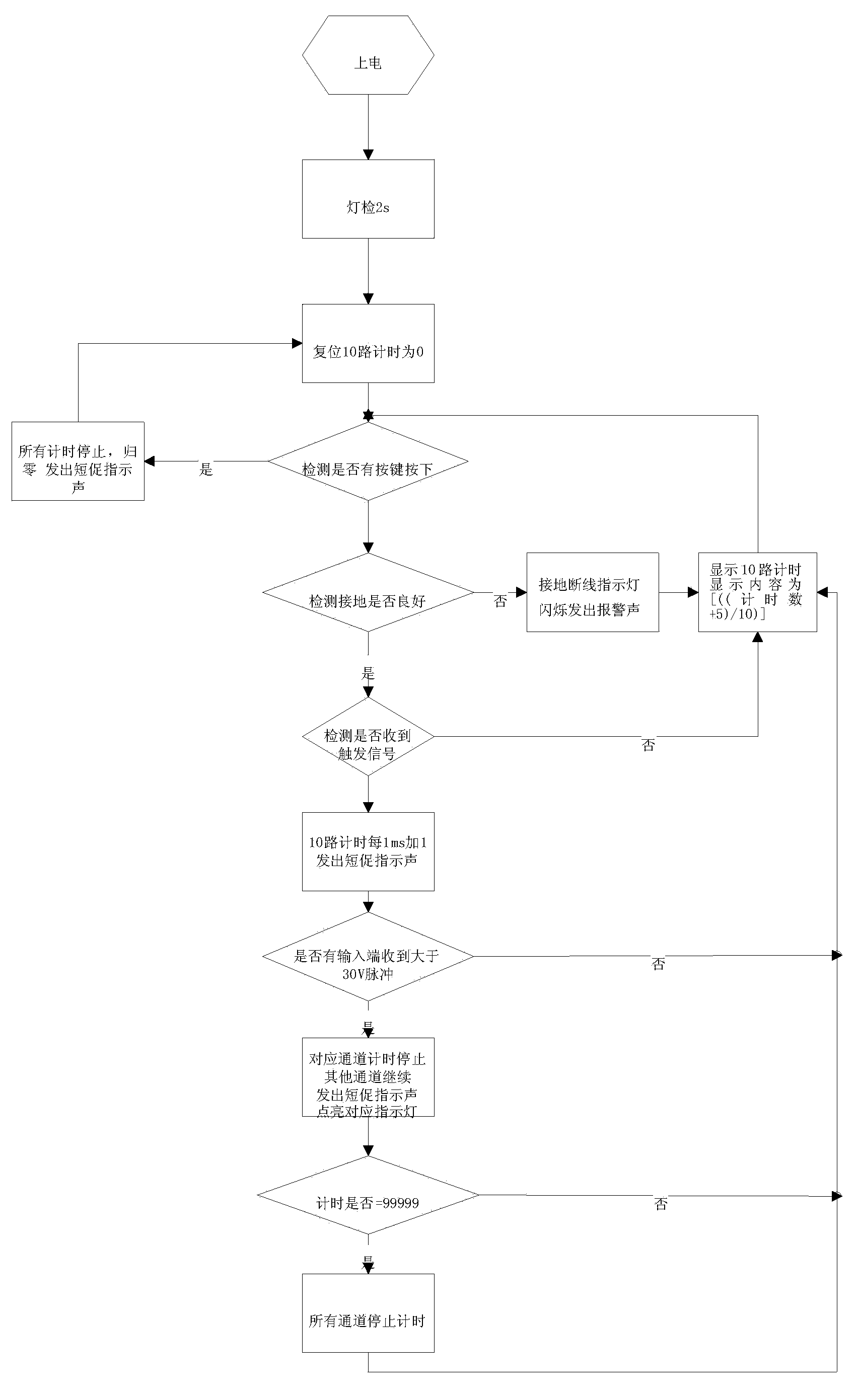

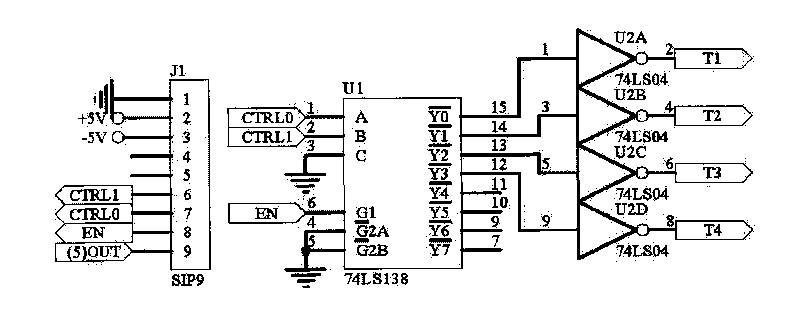

Relay protection device pressboard outlet logic detection apparatus

The invention relates to a relay protection device pressboard outlet logic detection apparatus. The logic detection apparatus comprises a relay protection device outlet pressboard ms-level instantaneous voltage impulse detection circuit, a relay protection test-stand dry contact state detection circuit, a microprocessor, a drive, timing display and sound-light alarm circuit and a power indication and grounding disconnection indication circuit, wherein the output terminals of the relay protection device outlet pressboard ms-level instantaneous voltage impulse detection circuit and the relay protection test-stand dry contact state detection circuit are connected with corresponding input terminals of the microprocessor respectively; the output terminal of the microprocessor is connected with the input terminal of the drive, timing display and sound-light alarm circuit; the input terminal of the power indication and grounding disconnection indication circuit is connected with the output terminal of the drive, timing display and sound-light alarm circuit. The advantages of the logic detection apparatus are that: detection accuracy and sensitivity are high, and wiring and operation are simple.

Owner:STATE GRID CORP OF CHINA +1

Precision pulse detection system for radar sensors

ActiveUS7446695B2Improve accuracyGood anti-noise performanceAmplitude demodulation by homodyne/synchrodyne circuitsResistance/reactance/impedenceHandwritingPhase detector

A precision pulse detection system for time-of-flight sensors detects a zero axis crossing of a pulse after it crosses above and then falls below a threshold. Transmit and receive pulses flow through a common expanded-time receiver path to precision transmit and receive pulse detectors in a differential configuration. The detectors trigger on zero axis crossings that occur immediately after pulse lobes exceed and then drop below a threshold. Range errors caused by receiver variations cancel since transmit and receive pulses are affected equally. The system exhibits range measurement accuracies on the order of 1-picosecond without calibration even when used with transmitted pulse widths on the order of 500 picoseconds. The system can provide sub-millimeter accurate TDR, laser and radar sensors for measuring tank fill levels or for precision radiolocation systems including digital handwriting capture.

Owner:MCEWAN TECH

Self-referencing radar pulse detector

InactiveUS20100073221A1Accurate and simple and inexpensiveZero delayAmplitude-modulated carrier systemsCommunication jammingLeading edgeRadar

An automatic pulse detector compares a radar video pulse to a delayed and amplified version of itself. The radar video pulse serves as an amplitude reference for a comparator. A delayed and amplified version of the same pulse serves as the pulse to be detected. Time of detection is amplitude independent and is not degraded by flat-topped pulses. Pulse detection occurs at a fixed, fractional point on the leading edge of a pulse where noise has less temporal influence than at the top of a pulse. Unlike a time-of-peak detector, the self-referencing pulse detector is well-suited to detecting wide, flat-topped pulses produced by expanded-time, pulse-echo radars operating in relatively narrow ISM bands.

Owner:MCEWAN TECH

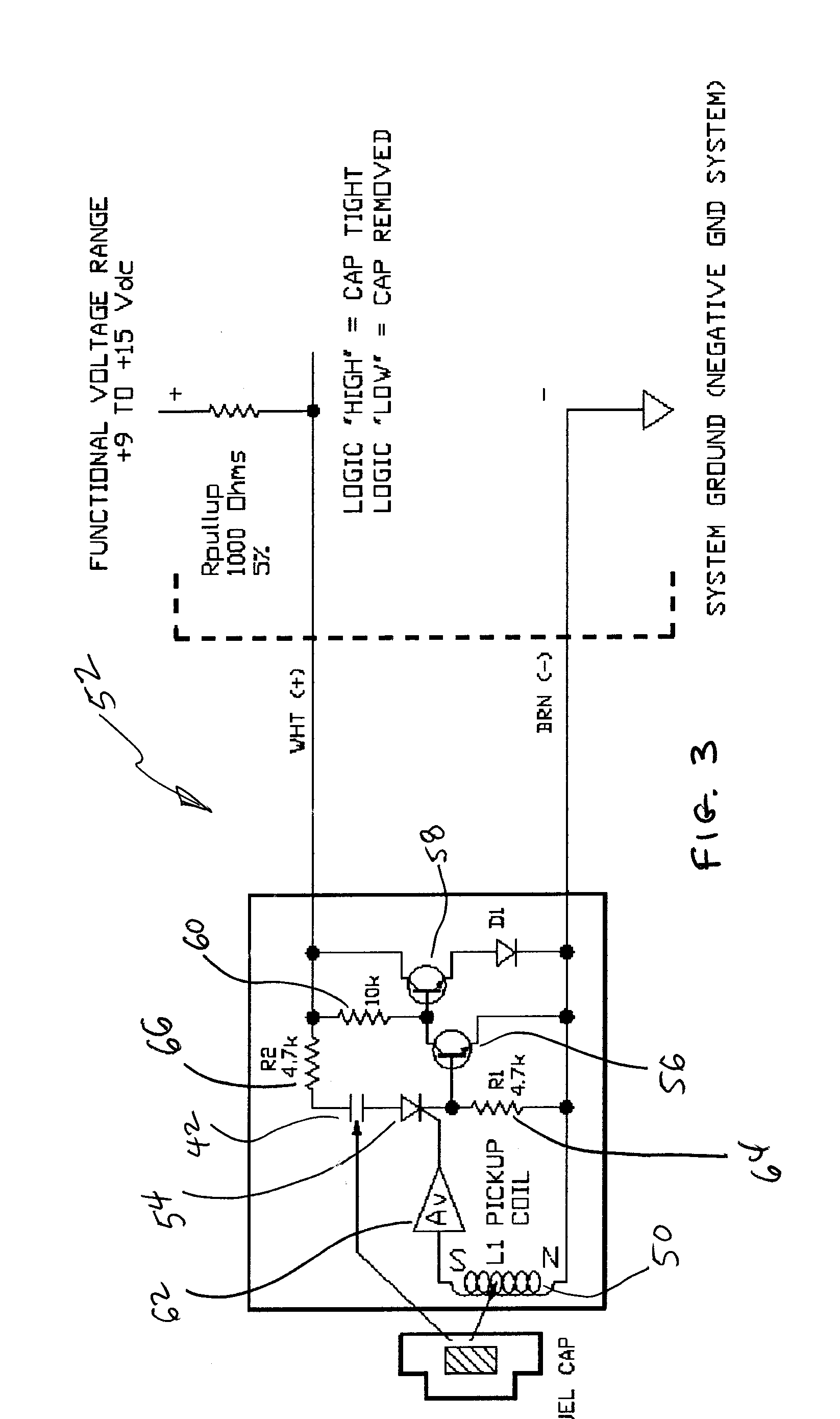

Active fuel cap sensor using magnetic impulse detection

InactiveUS20030102976A1Effective monitoringEfficient and cost-effective and reliable monitoringBurglar alarm by openingOptical signallingDashboardFuel tank

Abstract of Disclosure An apparatus and circuit for monitoring the closed position of a fuel cap relative to a tank connection pipe . The fuel cap has a ratchet torque limiter for controlling the tightening of the fuel cap to the tank connection pipe. A magnet is connected to the fuel cap and a magnetic switch, such as a reed switch, is connected to the tank connection pipe or proximal thereto. The movement of the magnet relative to the magnetic switch, indicating a locked fuel cap condition, is sensed by an abrupt change in magnetic field strength of the magnet. When releasing members snap over the cams therein, a current pulse is induced in a pickup coil . This current pulse is sensed and a logic level high voltage is produced corresponding to a tightened fuel cap condition. A dashboard lamp is then extinguished indicated that the fuel cap is safely and securely tightened.

Owner:LAVALLEE ROGER

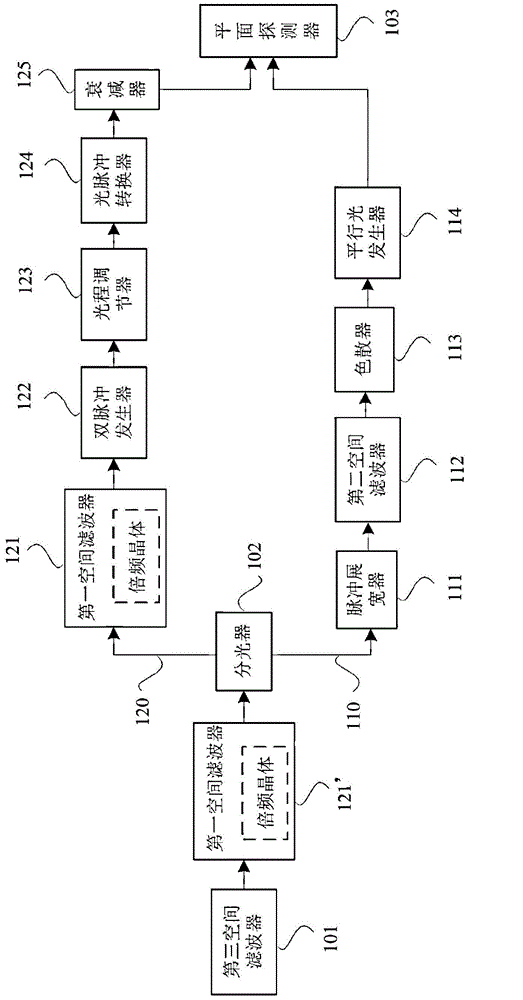

Single-shot laser pulse detection device

ActiveCN104697649AAvoid the problem of high beam quality requirements and large aperture laserAvoid the problem of high quality requirements and large aperture laserInstrumentsTime delaysOptoelectronics

The invention provides a single-shot laser pulse detection device. The single-shot laser pulse detection device comprises a detection light path for transmitting baseband detection light pulses, a reference light path for transmitting frequency-doubled reference light pulses, a dual-pulse generator for obtaining dual-pulses having a first time delay and transmitted collinearly along the reference light path, a light pulse converter for converting the dual-pulses into a series of dual-pulse form sub-pulses mutually delayed in time, separated from each other in space and propagated in parallel basically, a pulse stretcher for translating each frequency component of the baseband detection light pulses so as to stretch in the time domain, a dispersor for separating the frequency components in the baseband detection light pulses in space, and a plane detector for generating third-order mutual-correlation pulse signals from the baseband detection light pulses and the sub-pulses from the dispersor. The single-shot laser pulse detection device is capable of accurately measuring the waveform of the femtosecond petawatt lase pulses and solving the problem of difficult diagnosis of ultrafast and ultrastrong pulses large in dynamic range.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

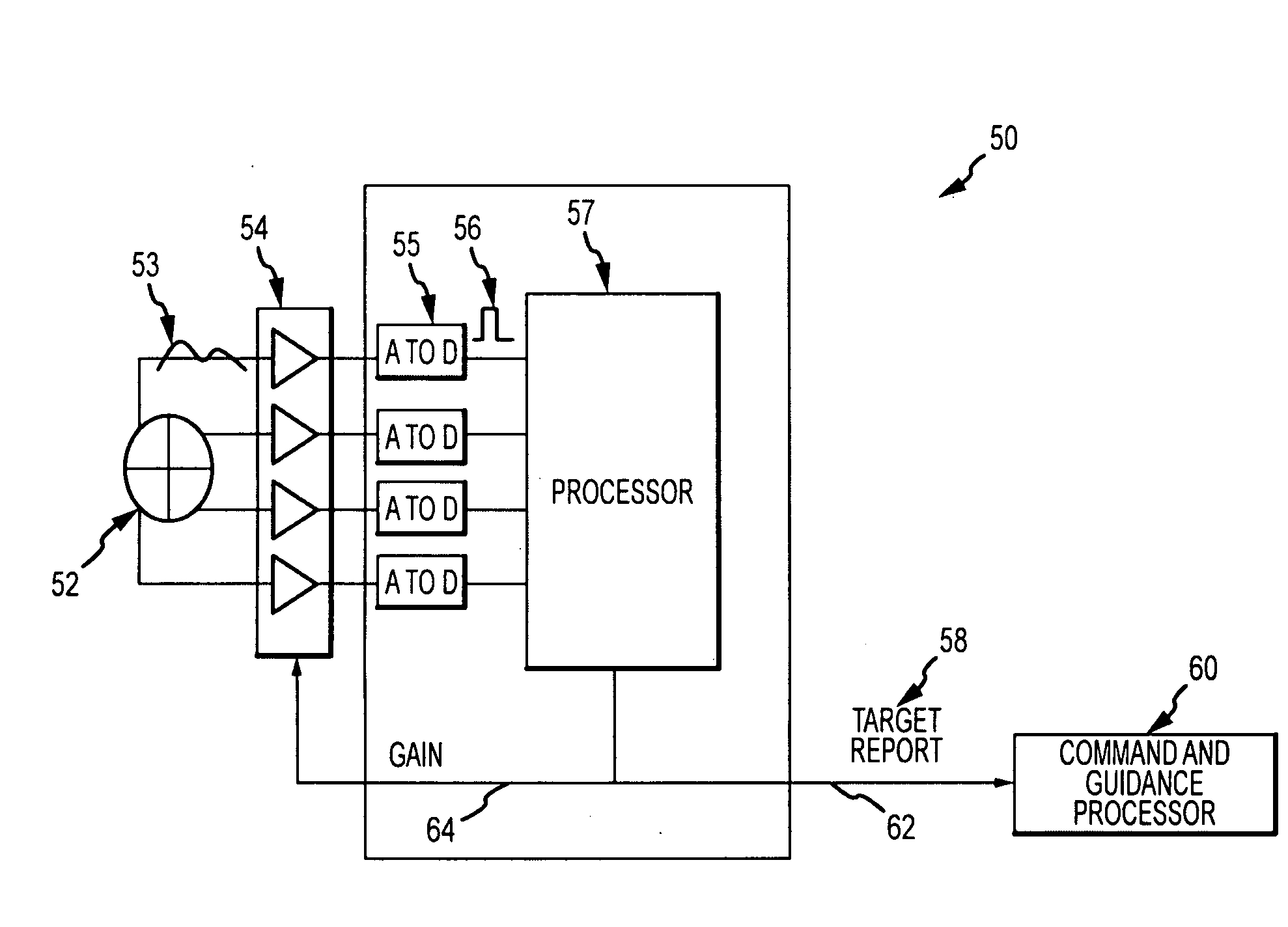

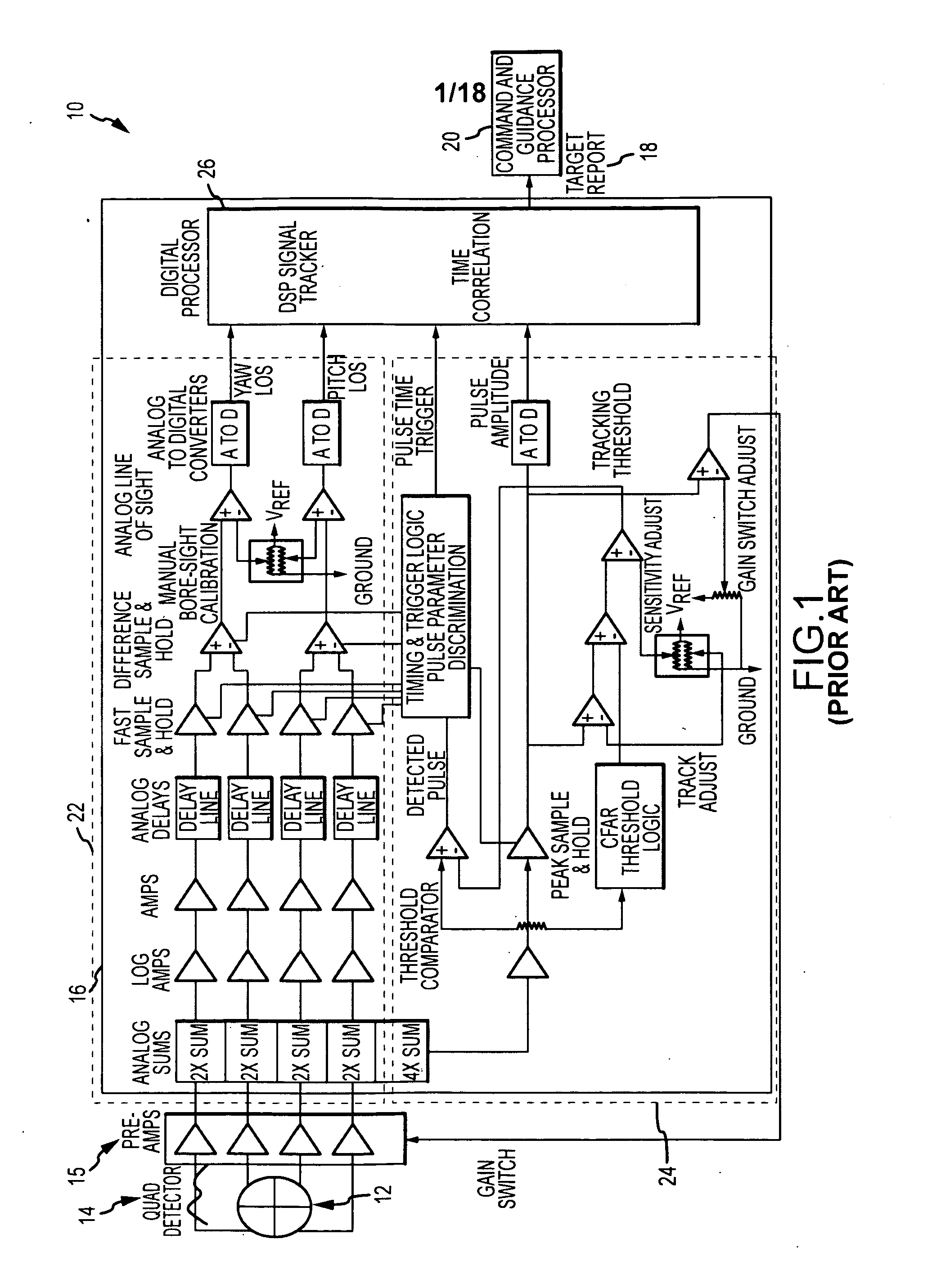

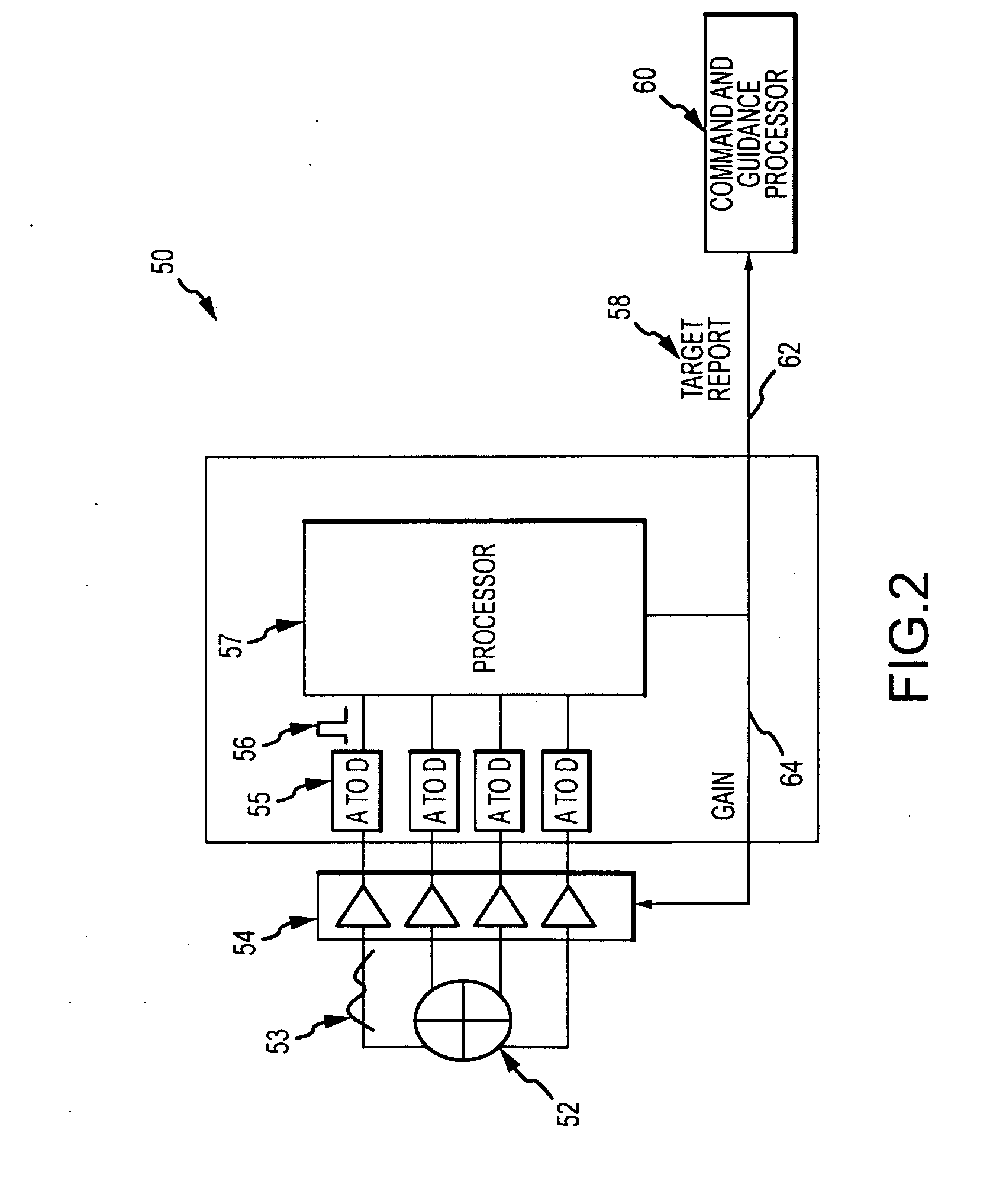

Enhanced countermeasures for all-digital line-of-sight (LOS) processor

ActiveUS20100067608A1Improved pulse detectionSmall sizeDirection controllersModulated-carrier systemsSemi activeWide field

An all-digital line-of-sight (LOS) process architecture addresses the size, weight, power and performance constraints of a receiver for use in semi-active or active pulsed electromagnetic (EM) targeting systems. The all-digital architecture provides a platform for enhanced techniques for sensitive pulse detection over a wide field-of-view, adaptive pulse detection, LOS processing and counter measures.

Owner:RAYTHEON CO

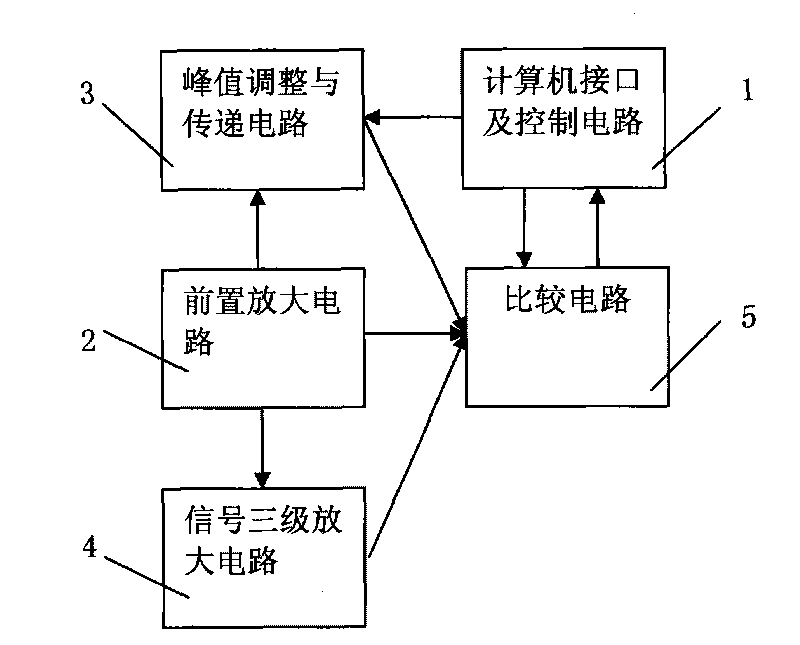

Pulse-detecting circuit used for ultrasonic gas flowmeter based on time difference method

InactiveCN101718567AAvoid complex controlsSimple structureVolume/mass flow measurementElectricityThree level

The invention discloses a pulse-detecting circuit used for an ultrasonic gas flowmeter based on a time difference method. The pulse-detecting circuit is characterized by comprising a computer interface, a control circuit, a pre-amplification circuit, a peak value adjusting and transmitting circuit, a signal three-level amplification circuit, and a comparison circuit; wherein the pre-amplification circuit is respectively connected with the peak value adjusting and transmitting circuit and the signal three-level amplification circuit; and the pre-amplification circuit, the peak value adjusting and transmitting circuit and the signal three-level amplification circuit are electrically connected through the comparison circuit and the computer interface as well as the control circuit respectively. By adopting a peak value transmission method, the invention automatically changes a comparative level used for generating a zero-crossing comparison control signal according to changes of the peak value of a signal, avoids complex controls needed by a gain control, and simplifies a circuit structure to be very simple; and moreover, the invention avoids precision loss generated during conversion and a balanced contradiction between cost and precision without adopting AD / DA conversion.

Owner:NANJING UNIV

Combined integration and pulse detection

ActiveUS8426828B2Material analysis by optical meansPhotometry electrical circuitsHigh energyElectromagnetic radiation

A pixel for the detection of electromagnetic radiation or high energy particles or charge packets, in particular for detecting X-ray photons, comprises a radiation receptor for converting the radiation into a sensing signal, the pixel being adapted for performing both pulse detection and integration of the same sensing signal.

Owner:CAELESTE CVBA +1

Pulse wave velocity measurement device, pulse wave velocity measurement method and pulse wave velocity measurement program

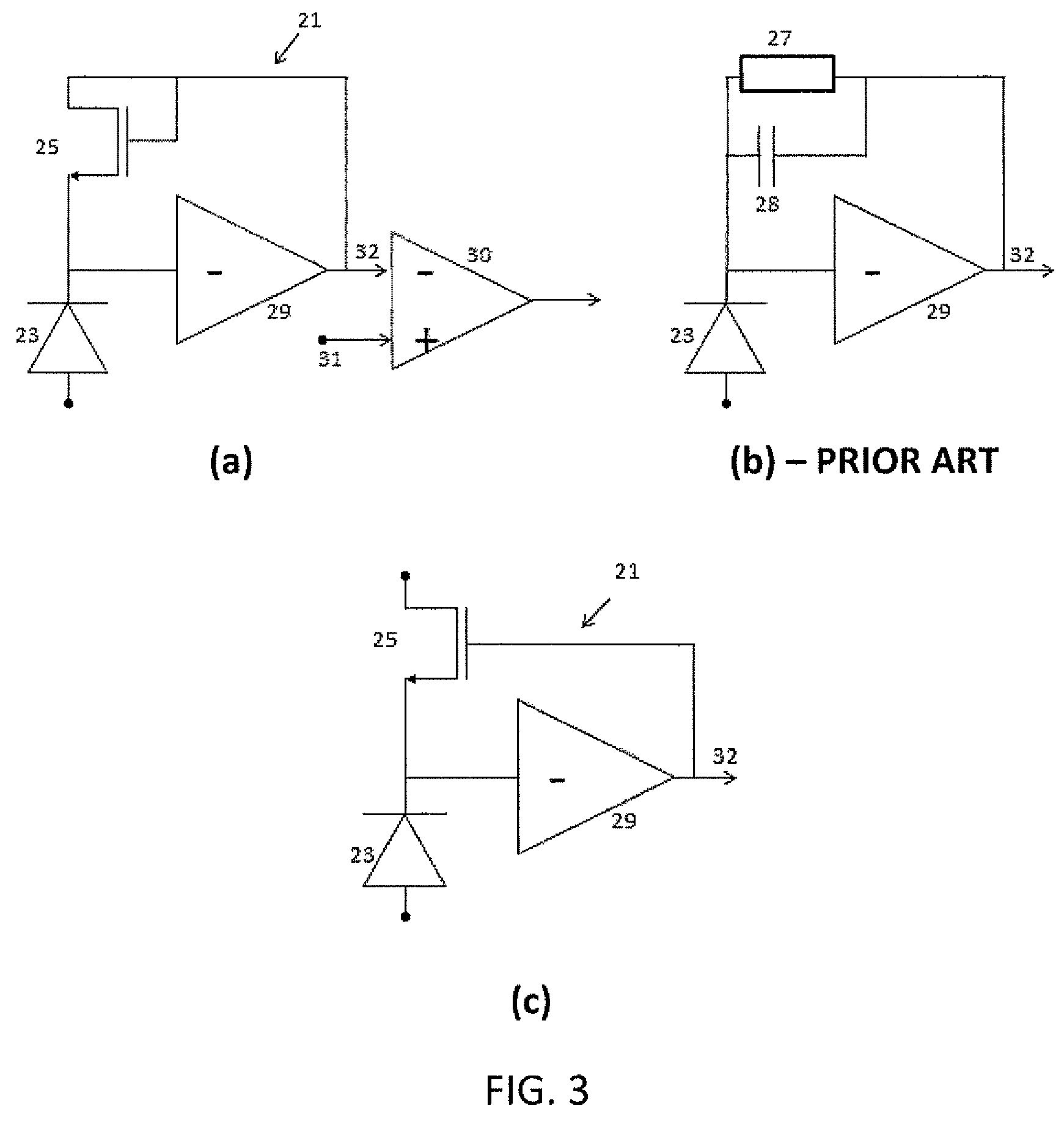

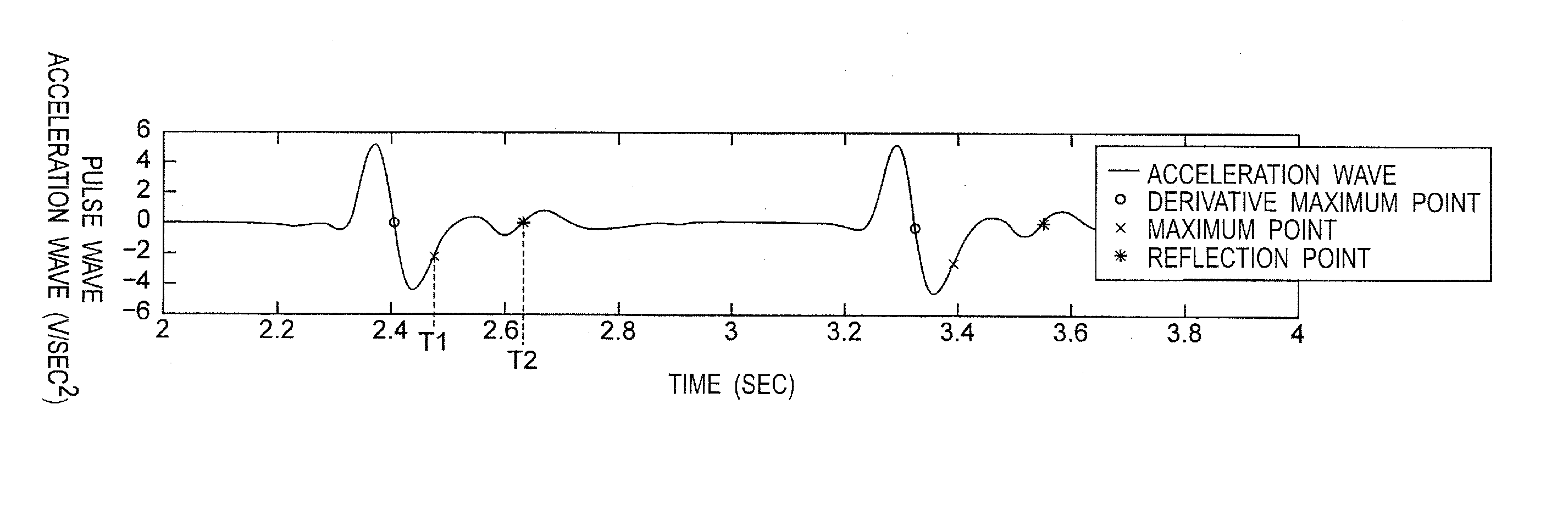

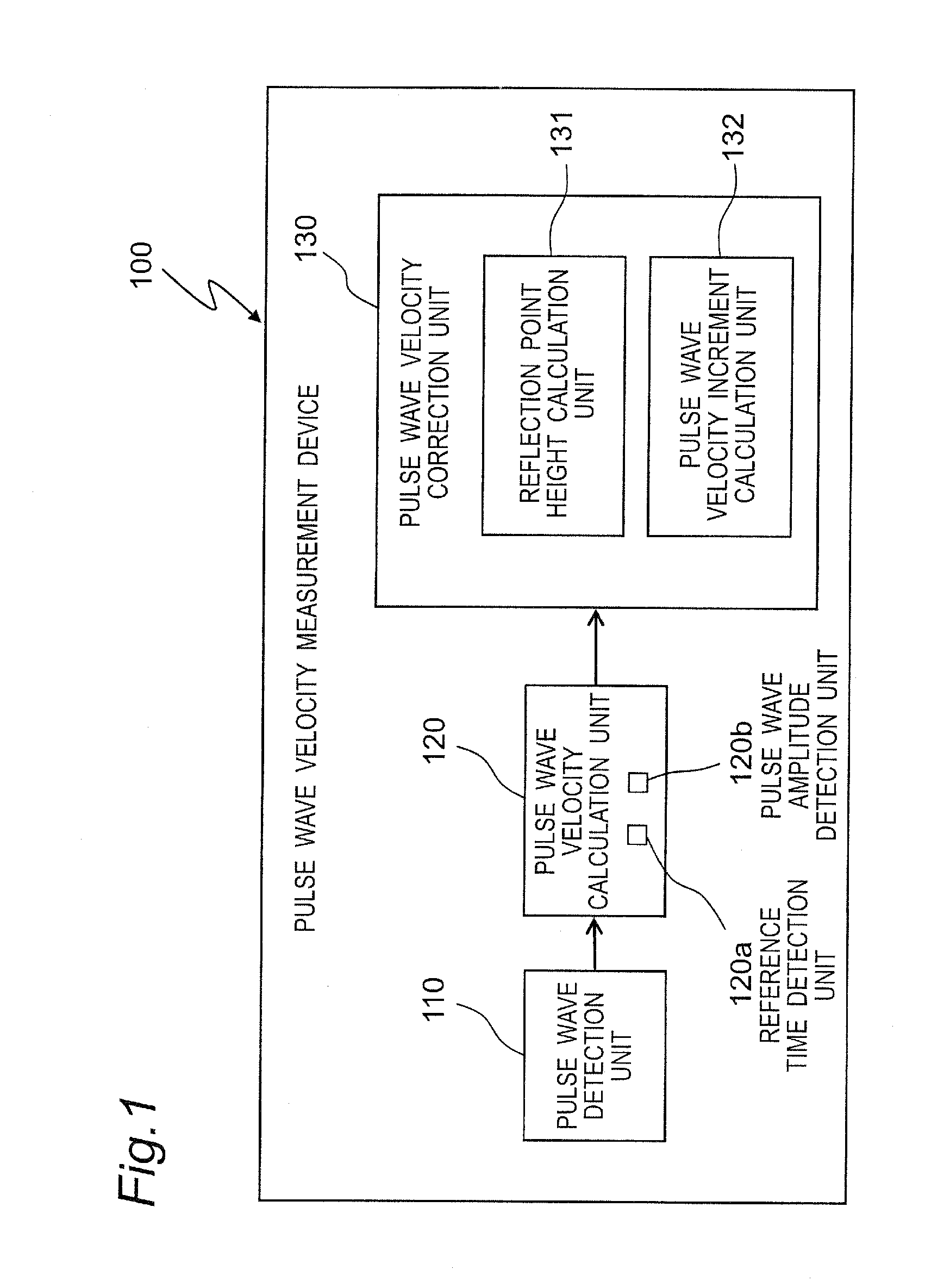

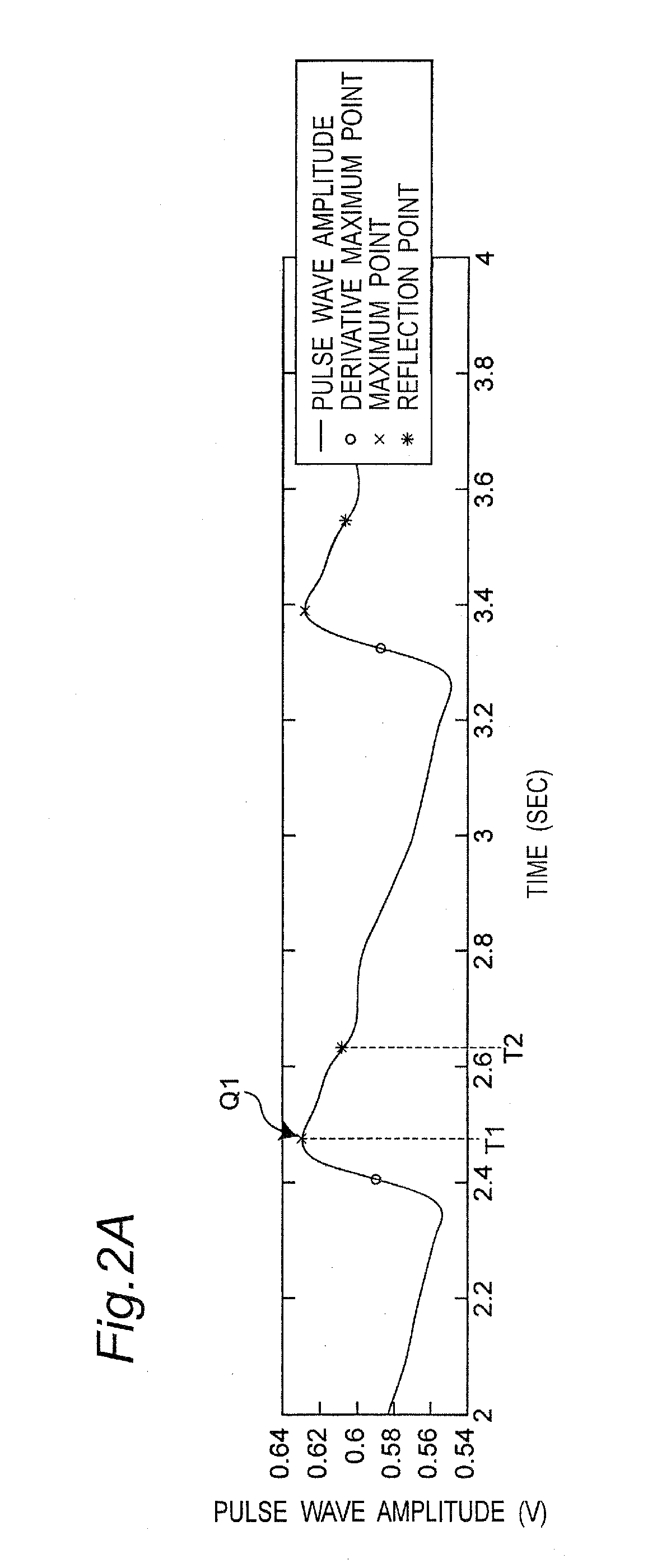

InactiveUS20130018272A1Accurate measurementImprove convenienceEvaluation of blood vesselsCatheterBiological bodyArterial velocity

A pulse wave velocity measurement device comprises a pulse wave detection unit (110) for detecting a pulse wave in a living body, a pulse wave velocity calculation unit (120) for calculating a pulse wave velocity on basis of the pulse wave detected by the pulse wave detection unit (110), and a pulse wave velocity correction unit (130) for correcting the pulse wave velocity calculated by the pulse wave velocity calculation unit (120) so as to eliminate an increment in the pulse wave velocity that results from influence of hydrostatic pressures caused according to a position of the living body. Thus, the pulse wave velocity measurement device can be provided that are capable of accurate measurement of the pulse wave velocity without being influenced by the hydrostatic pressures caused according to the position of the living body.

Owner:SHARP KK

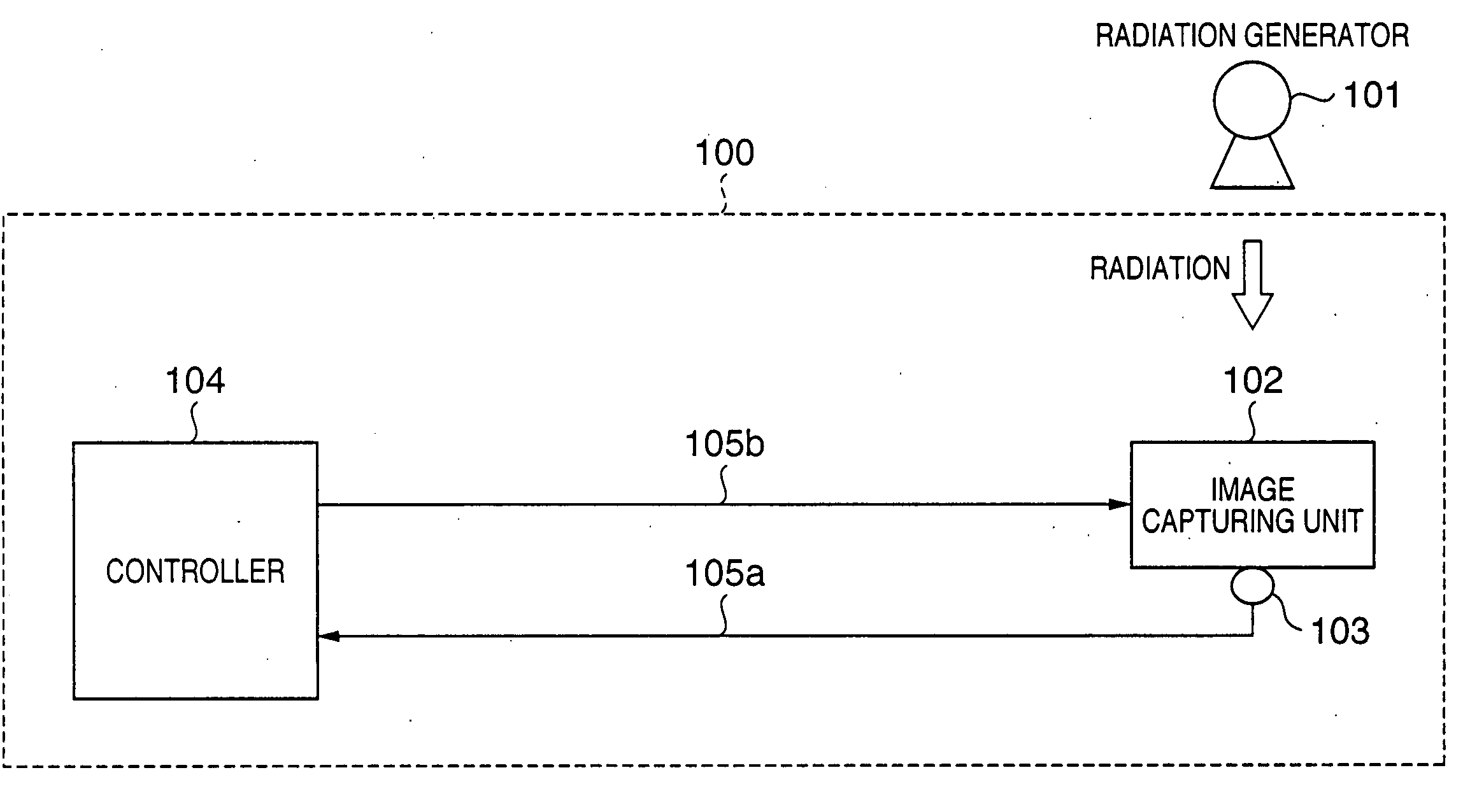

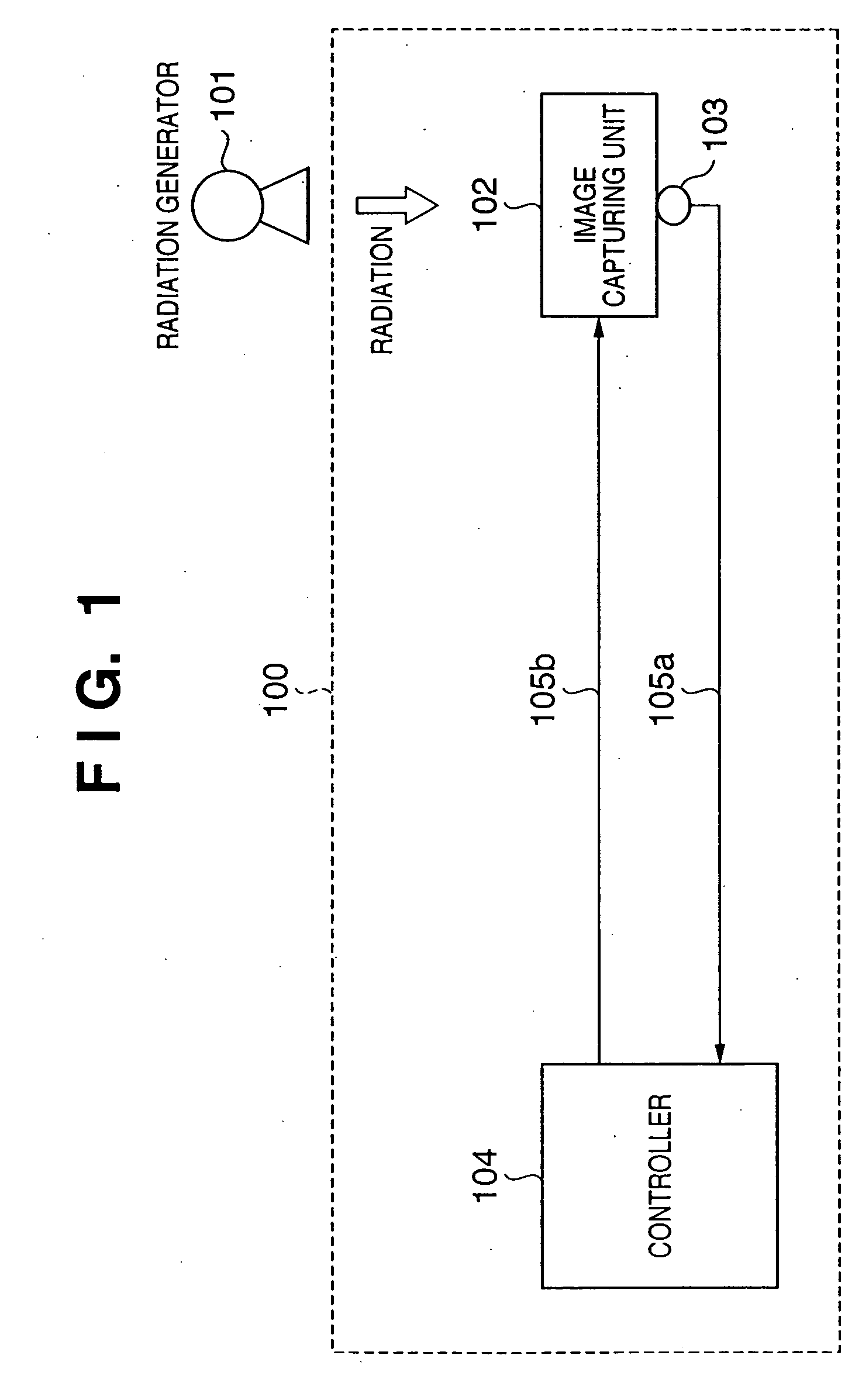

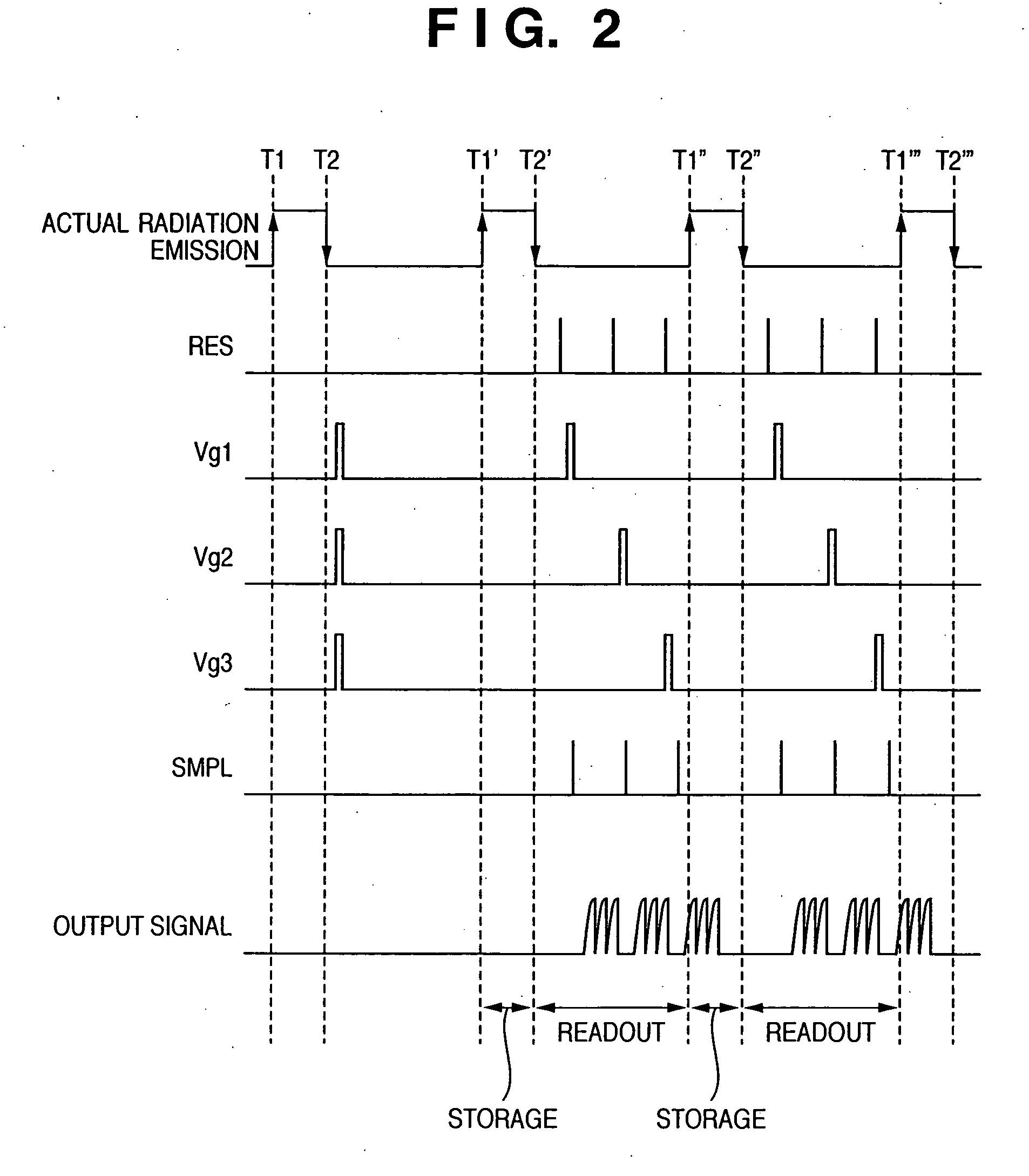

Radiographic imaging apparatus and system, method therefor, and program

ActiveUS20060071171A1Reduce image qualityReliably madeTelevision system detailsSolid-state devicesRadiation pulseImaging equipment

A radiographic imaging apparatus includes an imaging means which captures a radiation image based on a radiation pulse emitted from a radiation generator, a radiation pulse detection means which detects the radiation pulse, and a control means which controls the imaging means based on a detection result obtained by the radiation pulse detection means. The control means includes a computing unit which computes the pulse width and period of the radiation pulse based on the detection result obtained by the radiation pulse detection means, and controls the imaging means based on the pulse width and period of the radiation pulse which are computed by the computing unit.

Owner:CANON KK

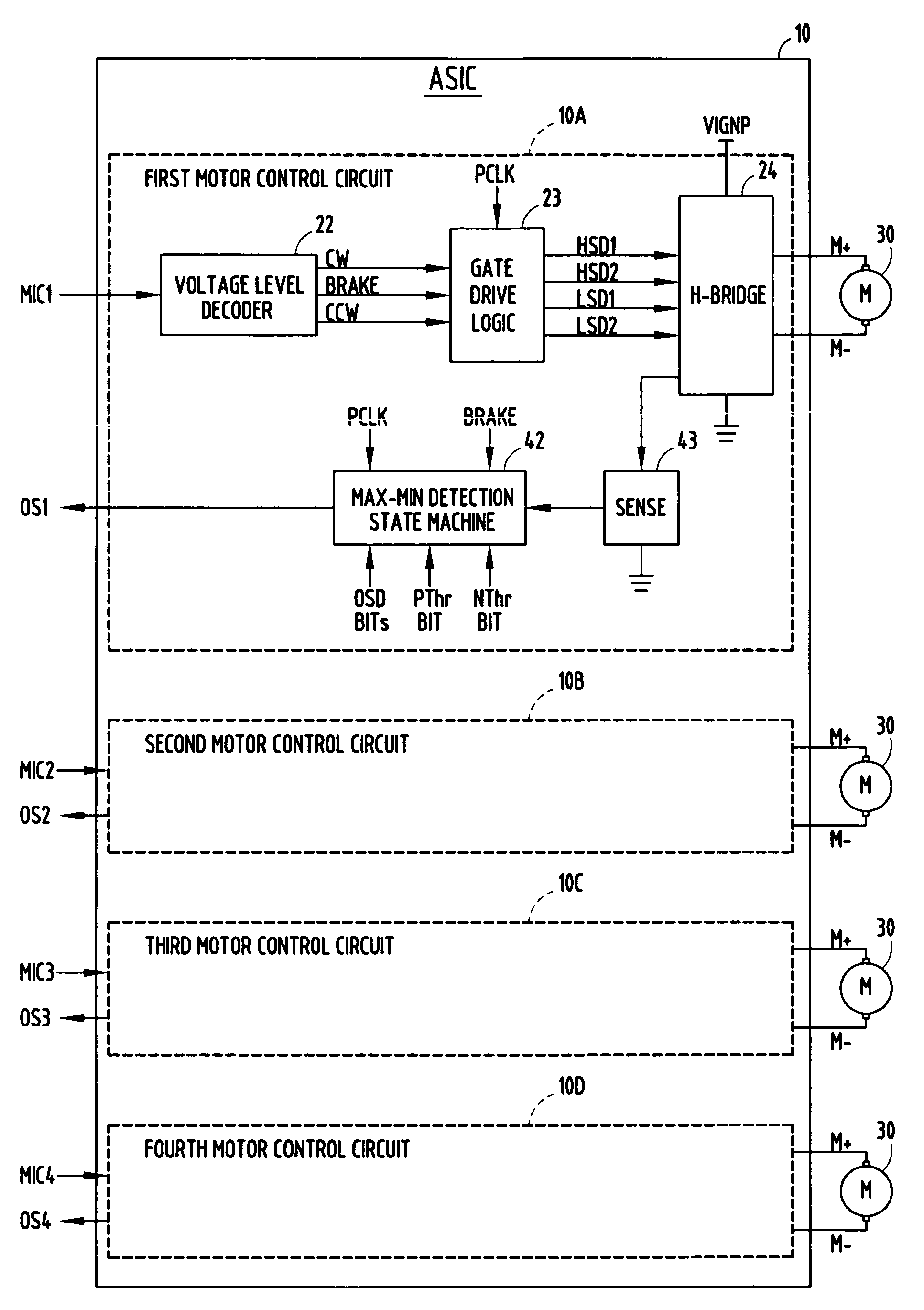

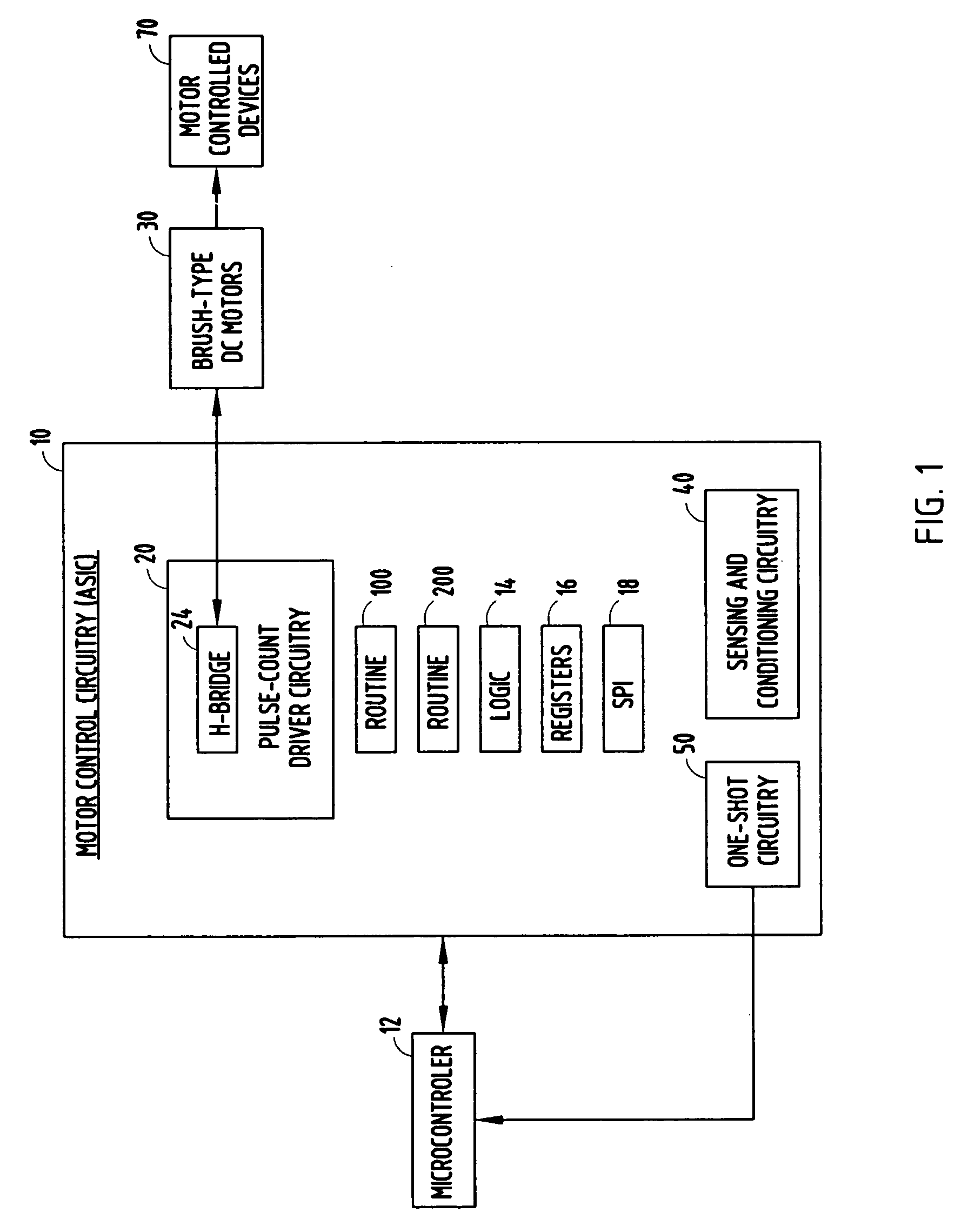

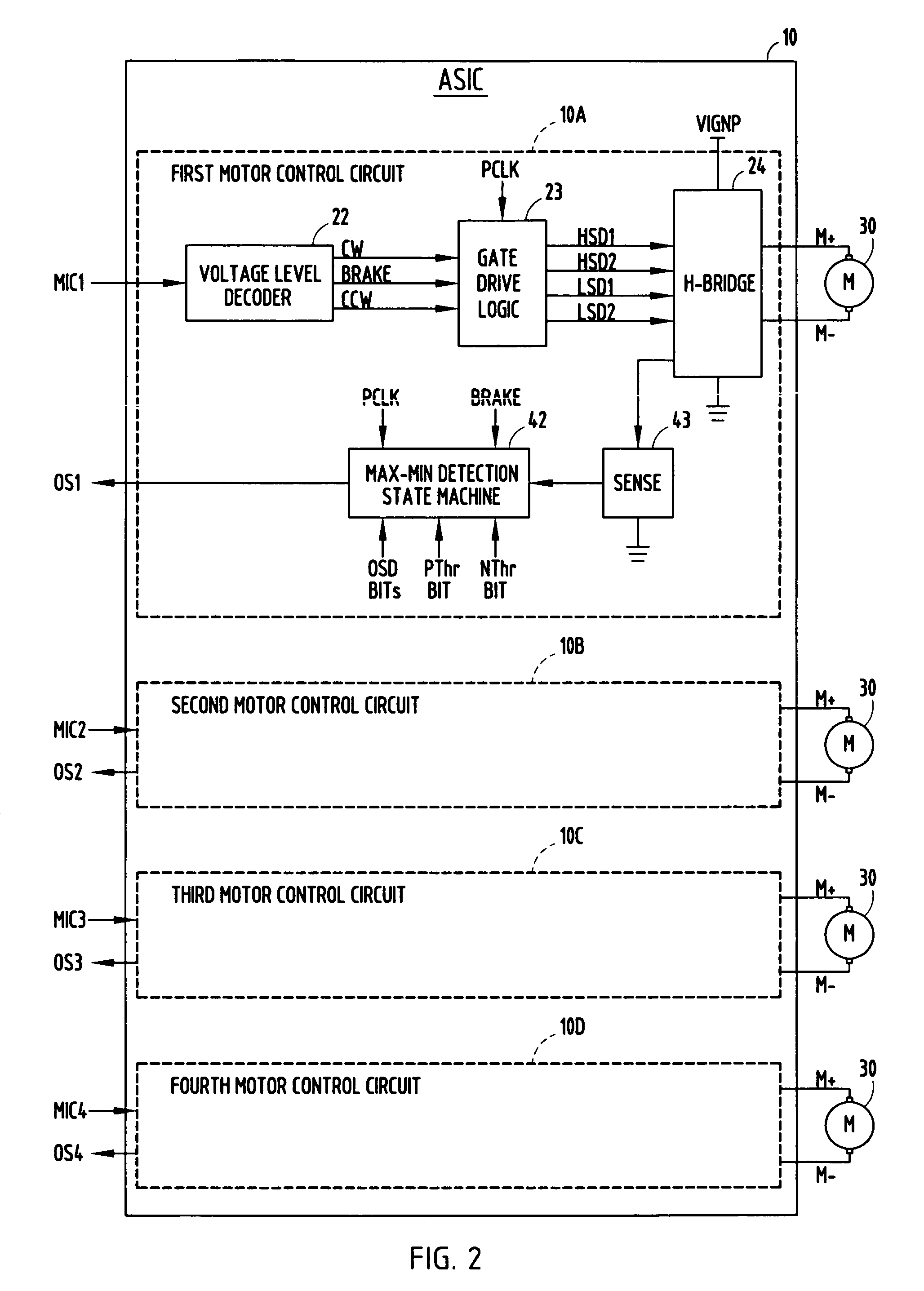

Method of brake pulse rejection in commutation pulse detection circuits

ActiveUS7180257B1Eliminating and significantly reducing sensitivity noiseEliminating and significantly reducing and variationProgramme controlElectronic commutation motor controlError processingManufacturing variation

A system and method is provided for improved monitoring and controlling of mechanically commutated DC motors. The system and method include DC motors, pulse-count driver circuitry for driving the motors, motor position sensing circuitry, and motor control circuitry. The system and method provide for improved motor current waveform sensing that is able to effectively reject false brake pulses, avoid erroneous processing due to fluctuating battery voltage levels, and reduce the sensitivity to variations in motor current signals due to dynamic motor load, manufacturing variation, system aging, temperature, brush bounce, EMI, and other factors. The system and method also include an improved ability to multiplex additional external motor drivers to the motor control circuitry, select between sequential and simultaneous drive modes using an SPI bit, and monitor the system controller for an error condition and simultaneously driver motors in response to the error condition.

Owner:APTIV TECH LTD

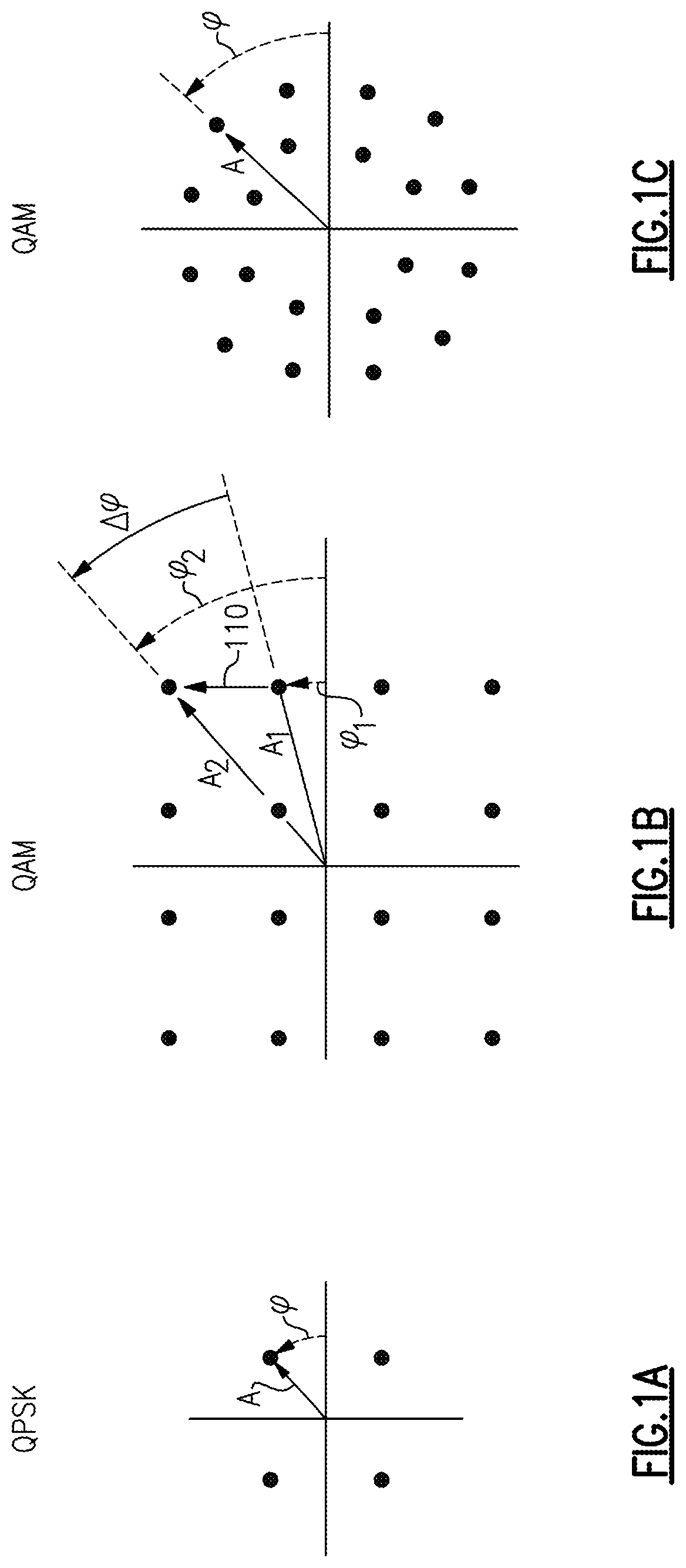

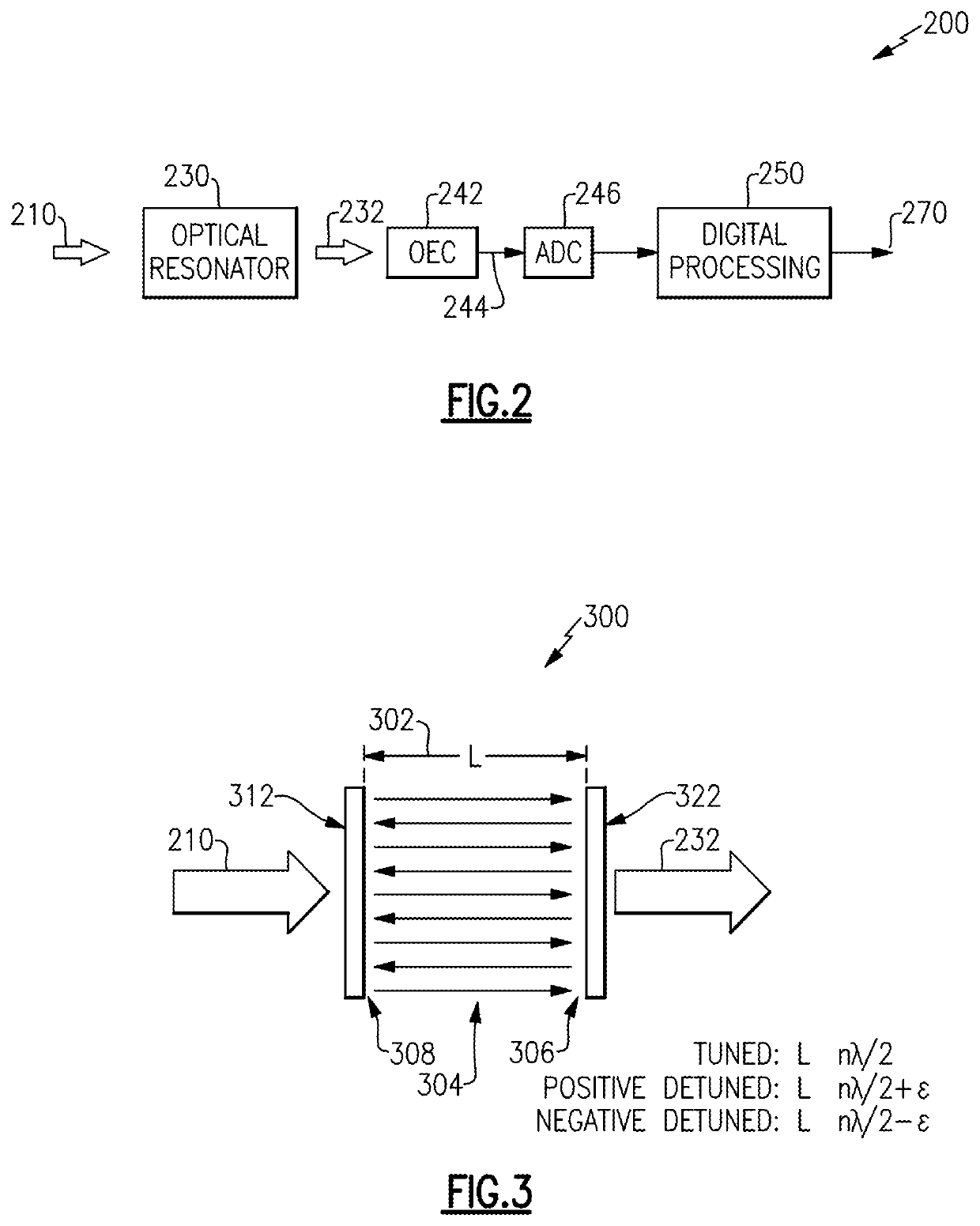

Demodulation of phase modulated signals using threshold detection

Optical receivers configured to demodulate phase modulated optical signals. In one example, an optical signal receiver includes an optical resonator configured to receive an arriving optical signal and to emit an output optical signal in response to receiving the arriving optical signal, the optical resonator being further configured to transform phase transitions corresponding to phase modulation of the arriving optical into intensity modulation of the output optical signal, an opto-electrical converter configured to convert the output optical signal into an electrical signal, a pulse detector configured to detect pulses in the electrical energy indicative of the phase transitions in the arriving optical signal, and a memory configured to record timing information associated with the pulses detected by the pulse detector.

Owner:RAYTHEON CO

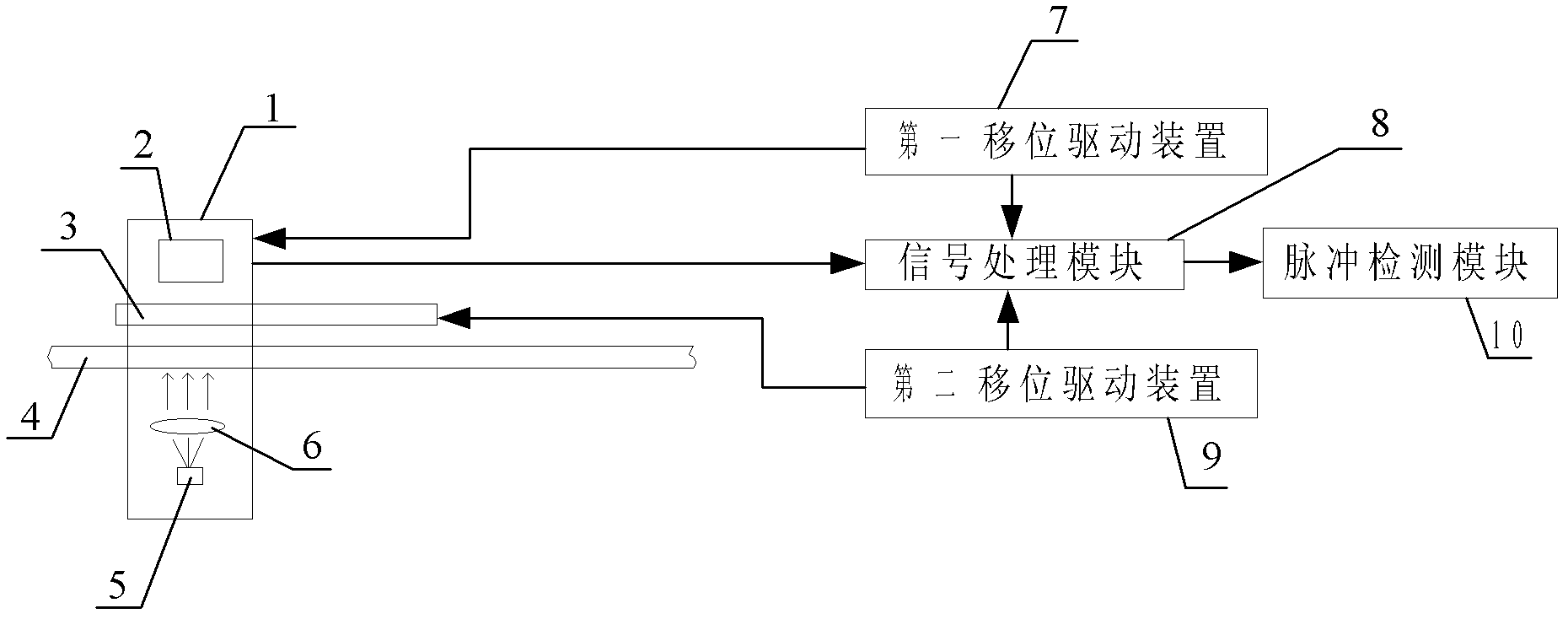

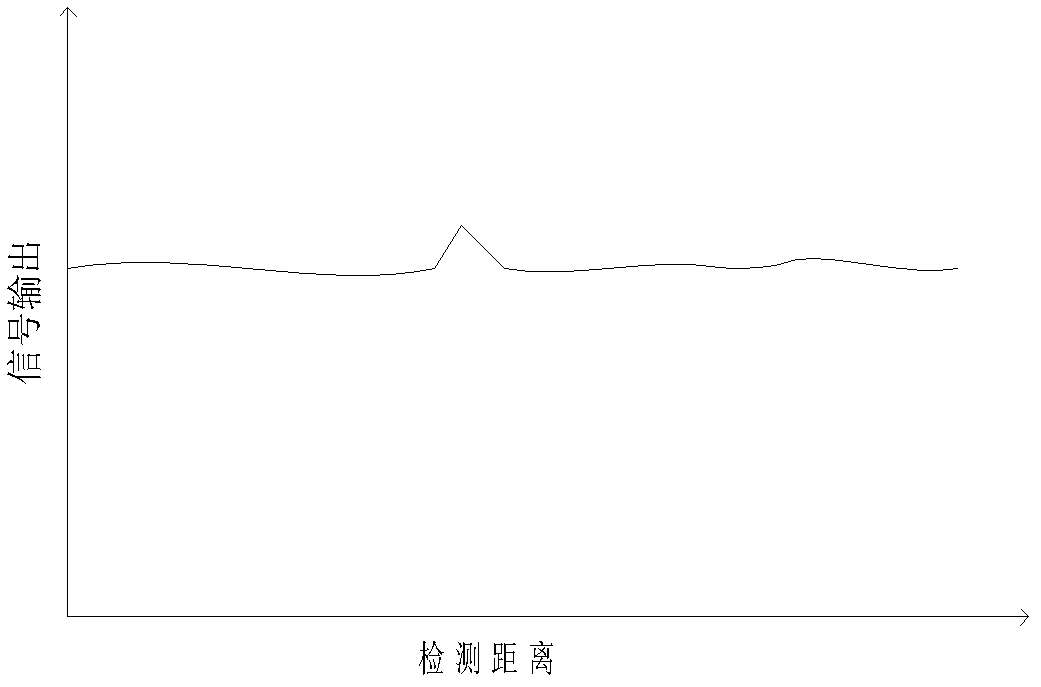

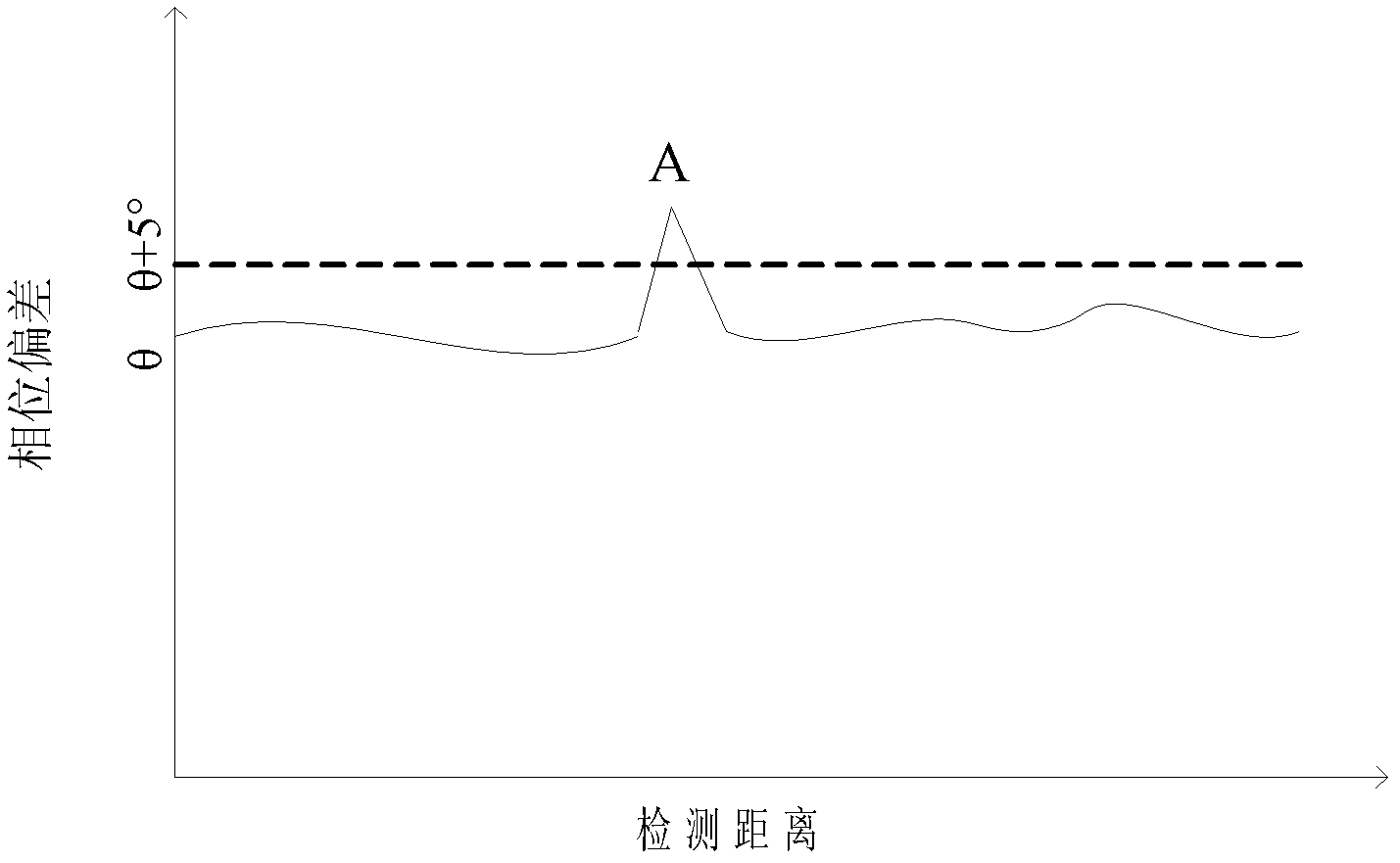

Verifying device of grating groove defect

InactiveCN102628811AEfficient detectionAccurate judgmentOptically investigating flaws/contaminationUsing optical meansPhotovoltaic detectorsGrating

A verifying device of a grating groove defect aims at resolving the problem that a main ruler has the conditions of stain and inconsistency of front and back phases in the manufacture process of a grating ruler, and a manual method cannot finish verifying of the grating ruler. A first shifting driving device of the verifying device drives a signal detection head to move along the detection direction, the signal detection head detects light transmitted by a light source and modulated by a grating to be measured and a standard grating, the light is converted into electric signals through a photoelectric detector, amplification processing and analog-digital conversion are conducted through a signal processing module on the electric signals, finally a pulse detection module is used for detecting and scoring the defect and copying existence and position of the defect through pulse signals, a second shifting driving device moves the position of the standard grating, and the processing is repeated till the detection finished. The verifying device is used for measuring the defect of long grating, groove evenness detection and phase consistency detection of a length grating ruler.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

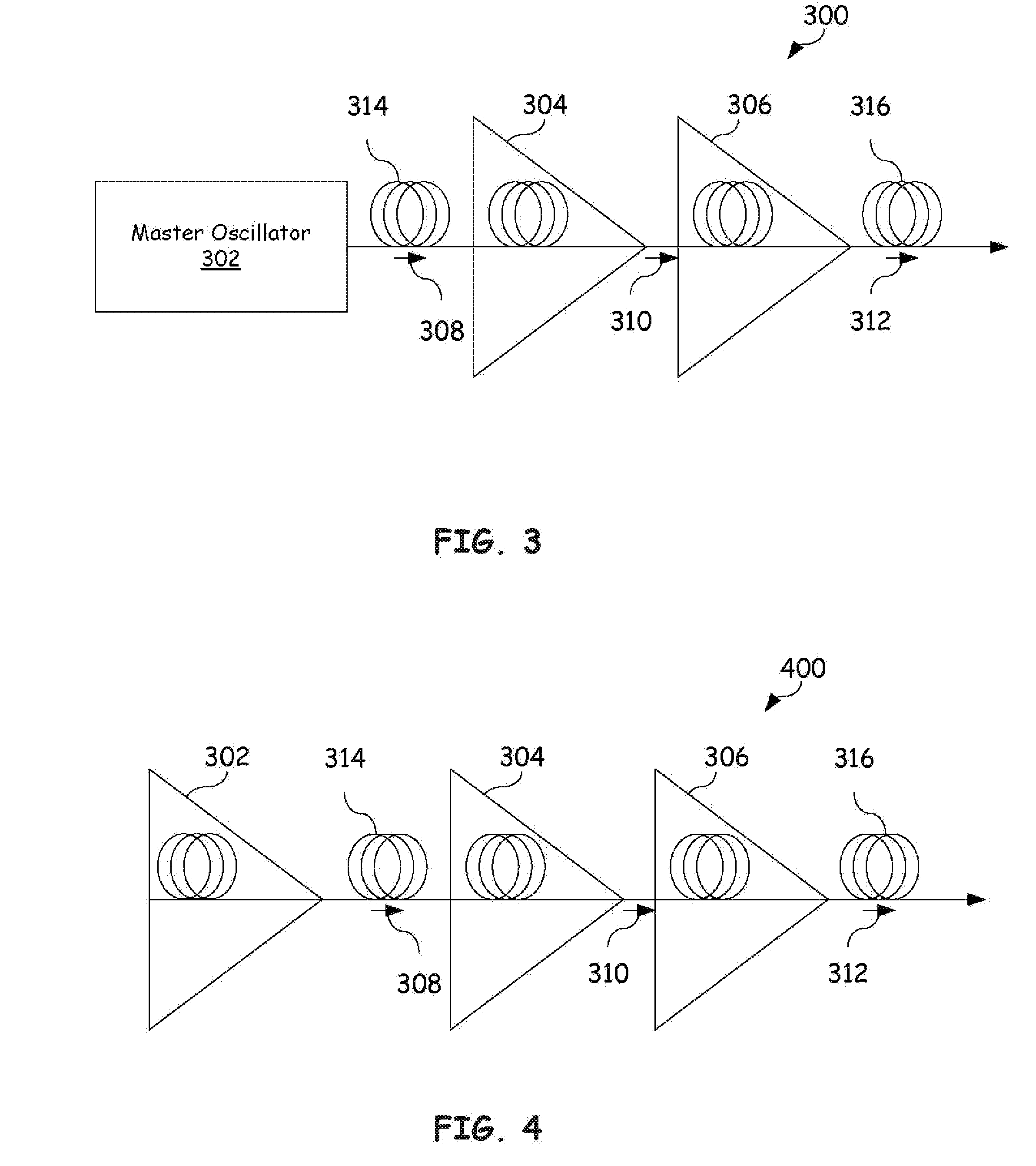

Pre-amplifier for detection lasers within laser ultrasonic inspection systems

A pulse detection laser is provided. The pulse detection laser includes a single frequency oscillator, a continuous pre-amplifier, and a pulsed amplifier. The single frequency oscillator generates a seed laser beam and is optically coupled to the continuous preamplifier. The continuous pre-amplifier amplifies the seed laser to produce an intermediate power laser beam. A pulsed amplifier optically coupled to the continuous pre-amplifier receives the intermediate power laser beam and amplifies the intermediate power laser beam to produce a pulse detection laser beam. One task of this pulse detection laser is to illuminate ultrasonic displacements. Light from the laser is scattered, collected, and analyzed with an interferometer to demodulate the ultrasonic displacements caused by the return echoes of the ultrasound at the surface of the part.

Owner:LOCKHEED MARTIN CORP

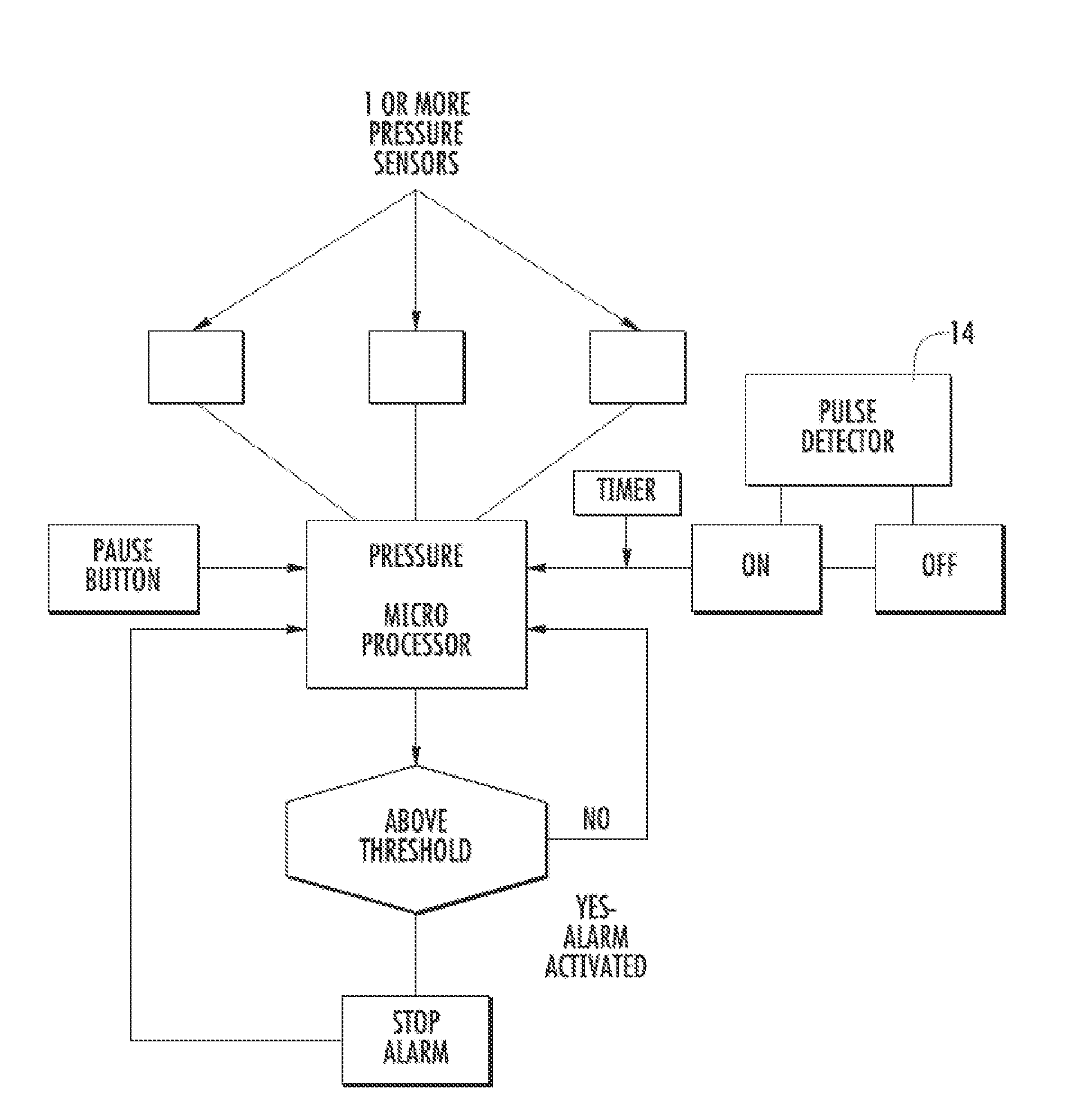

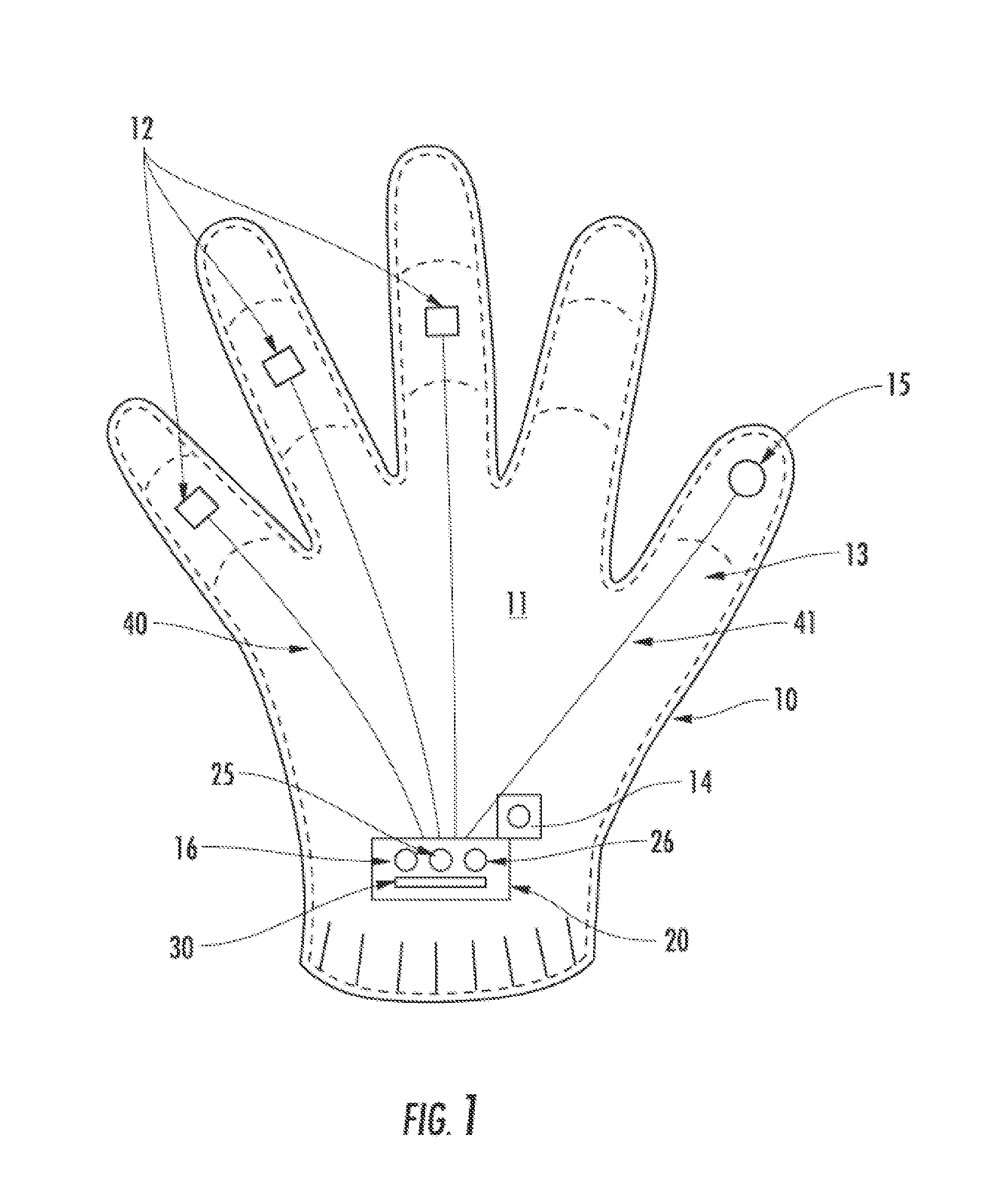

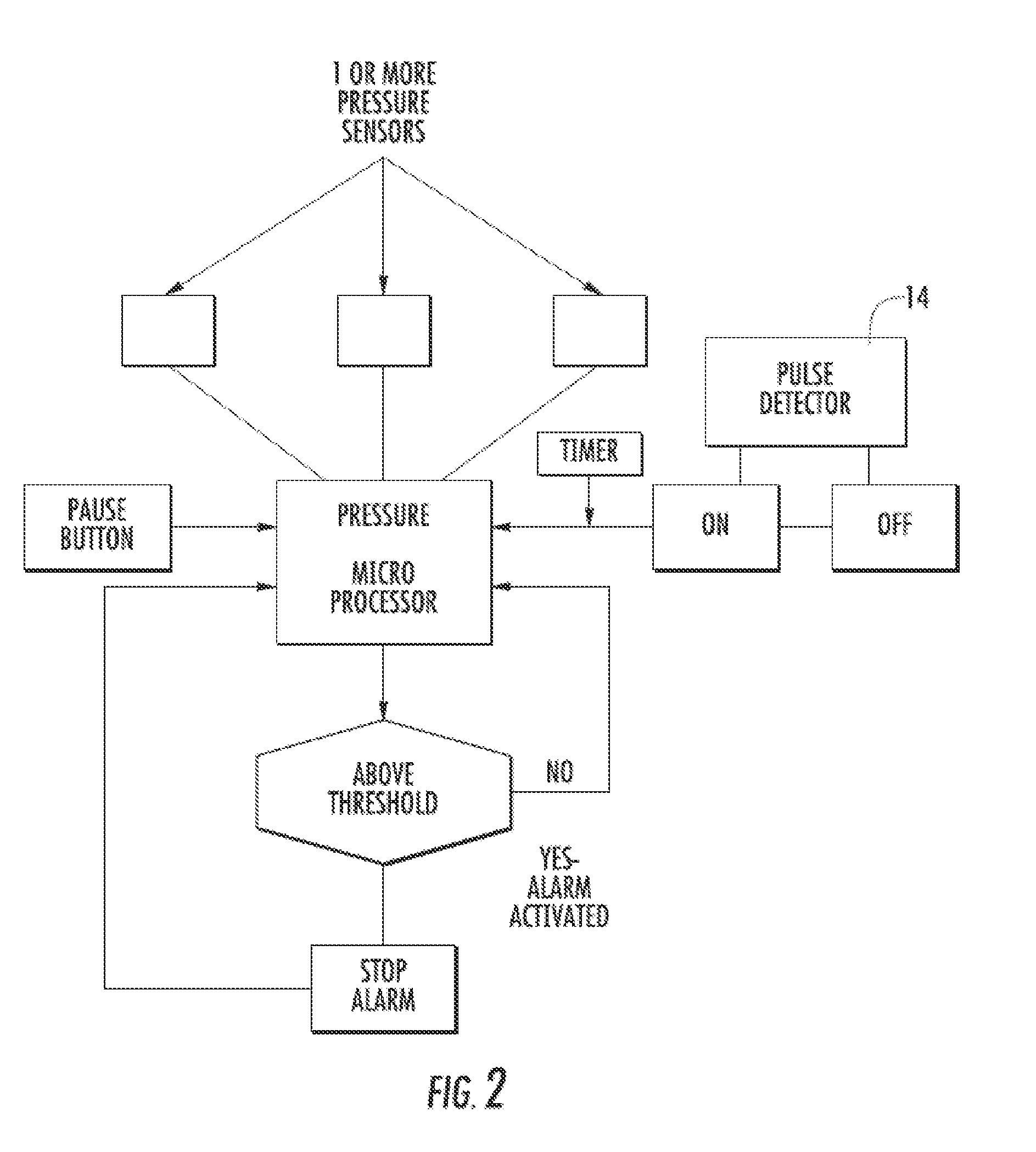

Sleep alert device

The present invention relates to a sleep alert device that acts by pressure of the fingers of the user on sensors. The invention includes a limited number of sensors as well as an instant alarm system which prevents accidental problems with previous delay alarm systems. At least one sensor is mounted on the fingers of the user or the steering wheel and with no delay of any kind connected directly or wirelessly to a control panel for control of the pressure sensors. The device has a means for detecting the wearing by the user, such as a pulse detector which can tell if the device is on or off when a pulse is detected respectively.

Owner:POWER JEROME ARNOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com