AC spot-welding dynamic electric resistance real-time measuring device and method

A dynamic resistance, real-time measurement technology, applied in measuring devices, welding monitoring devices, welding power sources, etc., can solve problems such as inability to measure, dynamic resistance measurement errors, etc., and achieve the effects of convenient measurement, high real-time performance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

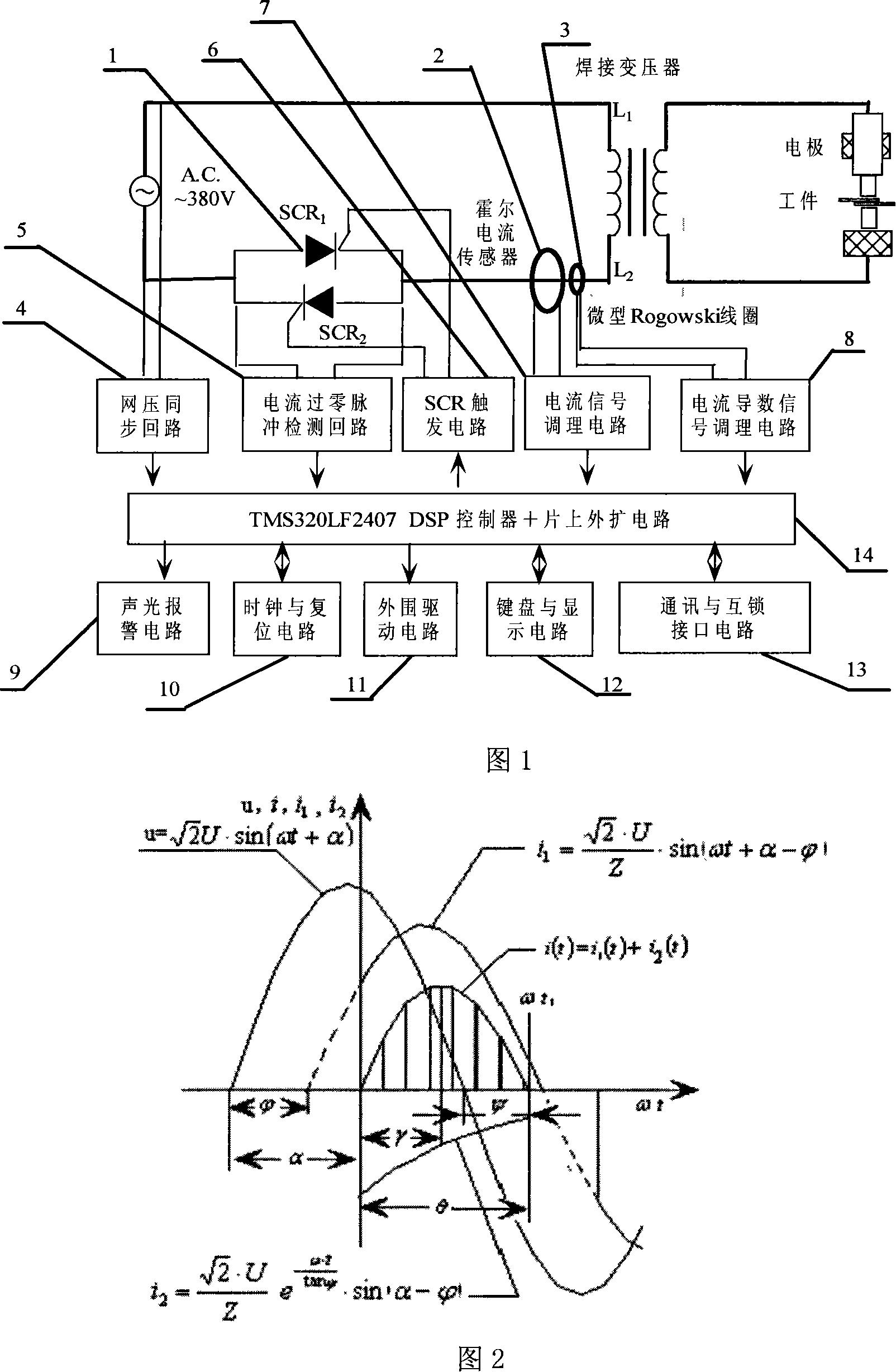

[0049] As shown in Figure 1, this embodiment includes: a pair of anti-parallel thyristors 1, a Hall current sensor 2, a miniature Rogwski coil (Rockwell coil) 3, a network voltage synchronization circuit 4, a current zero-crossing pulse detection circuit 5, SCR (SCR) trigger circuit 6, welding current signal conditioning circuit 7, current derivative signal conditioning circuit 8, sound and light alarm circuit 9, clock and reset circuit 10, peripheral drive circuit 11, keyboard and display circuit 12, communication and interaction Lock interface circuit 13, DSP (Digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com