Liquid level detection type self-calibration high-precision water gauge

A technology of liquid level detection and water level gauge, which is applied in the direction of liquid level indicator, liquid/fluid solid measurement, measuring device, etc. It can solve the problems of weight change of heavy hammer, inability to follow up, manual correction, etc., and achieve high precision and large range Measuring, avoiding cumulative errors, and realizing the effect of automatic error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

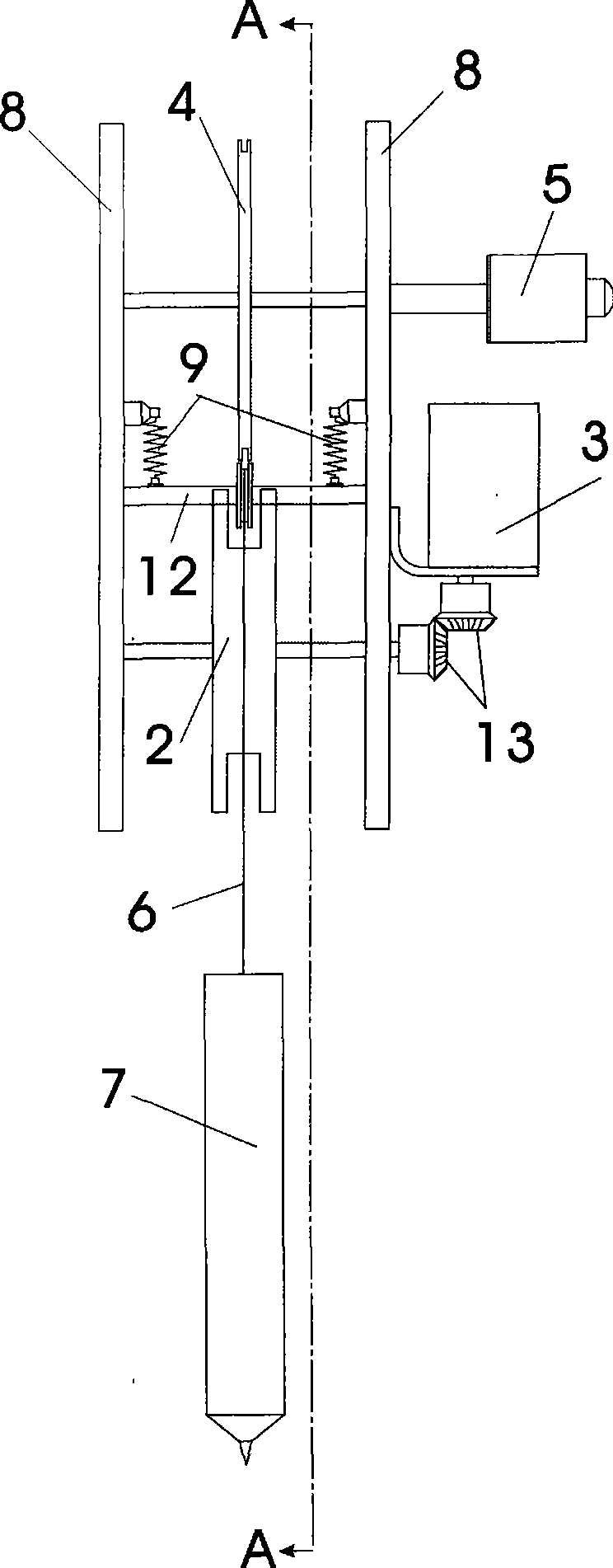

[0025] The structural details of the embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

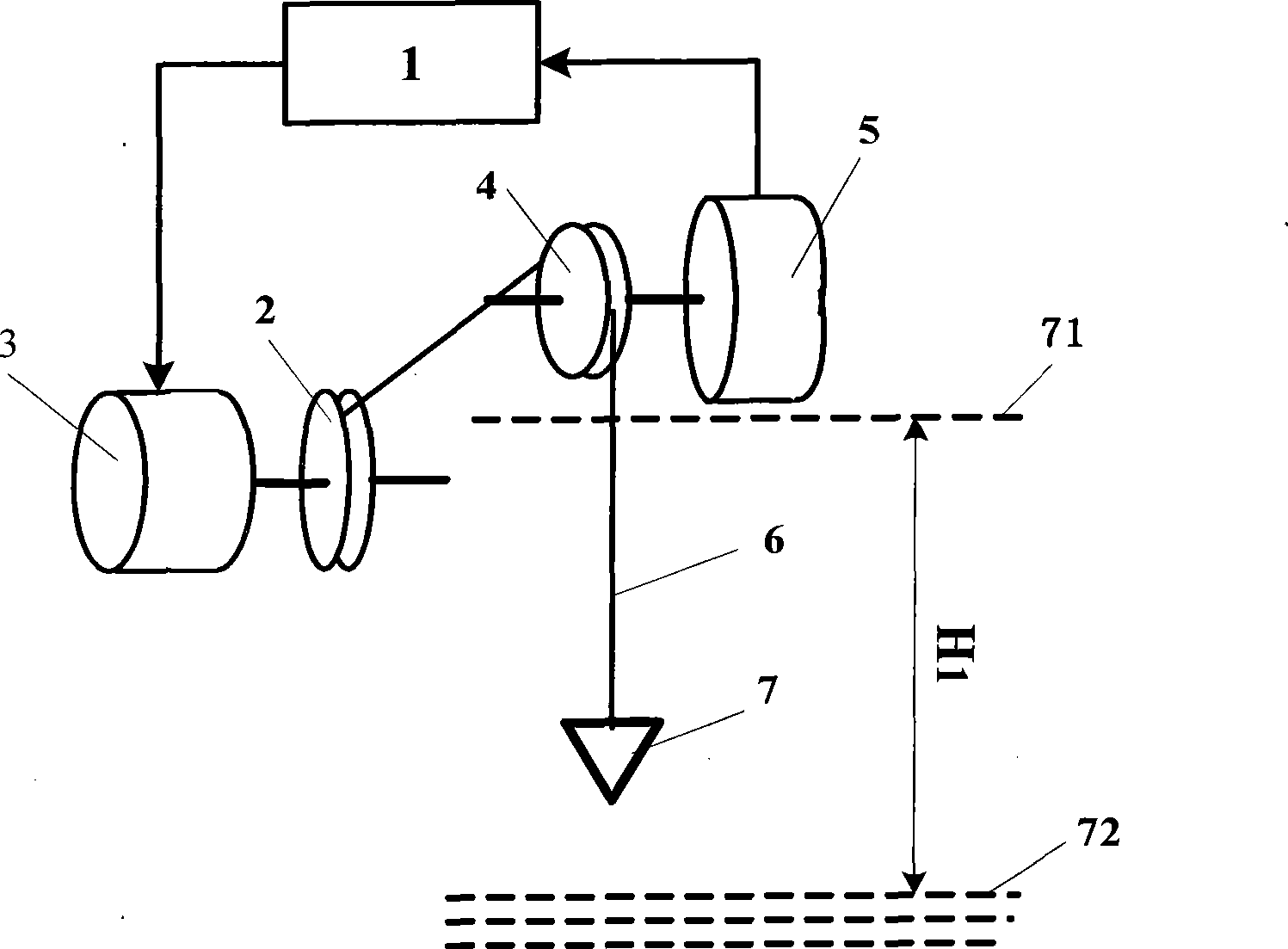

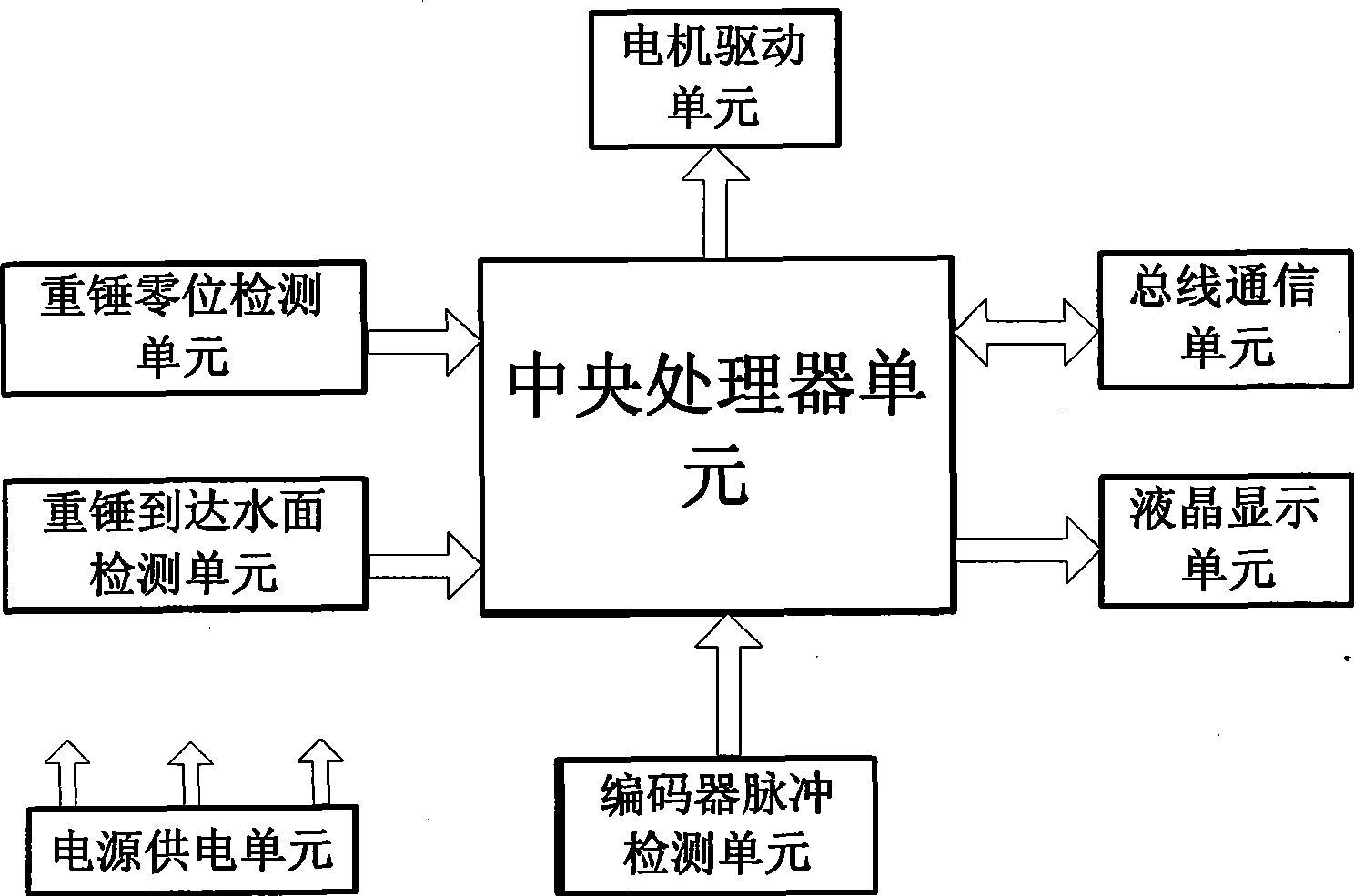

[0026] like figure 1 As shown, the present invention includes a controller 1, a wire take-up reel 2, a motor 3 that drives the wire reel 2 to rotate, a measurement transmission wheel 4, a rotary encoder 5, a steel wire rope 6 and a weight 7, and the rotating shaft of the motor 3 is connected to the steel wire The rotating shaft of take-up reel 2, steel wire rope 6 one ends are coiled on the steel wire take-up reel 2, and the other end connects weight 7 through measuring driving wheel 4, and the rotating shaft of rotary encoder 5 is connected with the rotating shaft of measuring driving wheel 4. The controller 1 issues a motor drive command to drive the motor 3 to rotate, and the motor 3 drives the steel wire take-up wheel 2 to rotate, thereby retracting the steel wire rope 6. Under the action of the weight 7, the steel wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com