Verifying device of grating groove defect

A defect inspection and grating technology, which is applied in the direction of using optical devices, optical testing flaws/defects, measuring devices, etc., can solve the problems of grating line defects, inconsistencies, main scale stains, front and rear phases, etc., and achieve the effect of simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

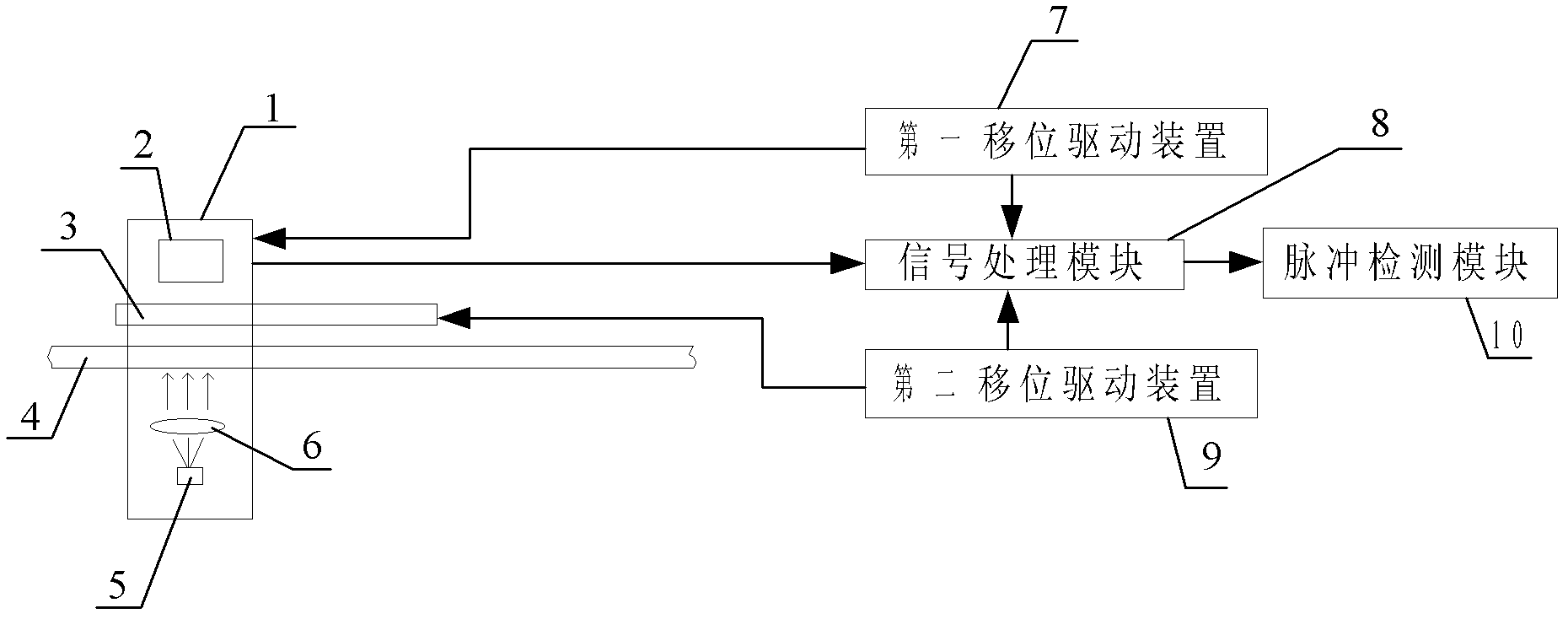

[0012] combine figure 1 Describe this embodiment, the grating line defect inspection device, the detection device includes a standard grating 3, a signal detection head 1, a first displacement drive device 7, a second displacement drive device 9, a signal processing module 8, and a pulse detection module 10 , The signal detection head 1 further includes a light source 5 , an optical system 6 , and a signal detection chip 2 . The first displacement drive device 7 drives the signal detection head 1 to move the position; the second displacement drive device 9 drives the standard grating 3 to move the position; the signal processing module 8 pairs the signal detection head 1, the first displacement drive device 7, the second displacement drive device The information obtained by the two-shift driving device 9 is converted and processed; the pulse detection module 10 is used to analyze and calculate the phase distribution of the grating to be measured 4; the standard grating 3 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com