Pulse-detecting circuit used for ultrasonic gas flowmeter based on time difference method

A gas flow meter and ultrasonic technology, applied in the direction of liquid/fluid solid measurement, flow measurement/mass flow measurement, measurement devices, etc., can solve problems such as complex circuits, violations, and high software overhead, and achieve simple and reasonable structure of the circuit , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

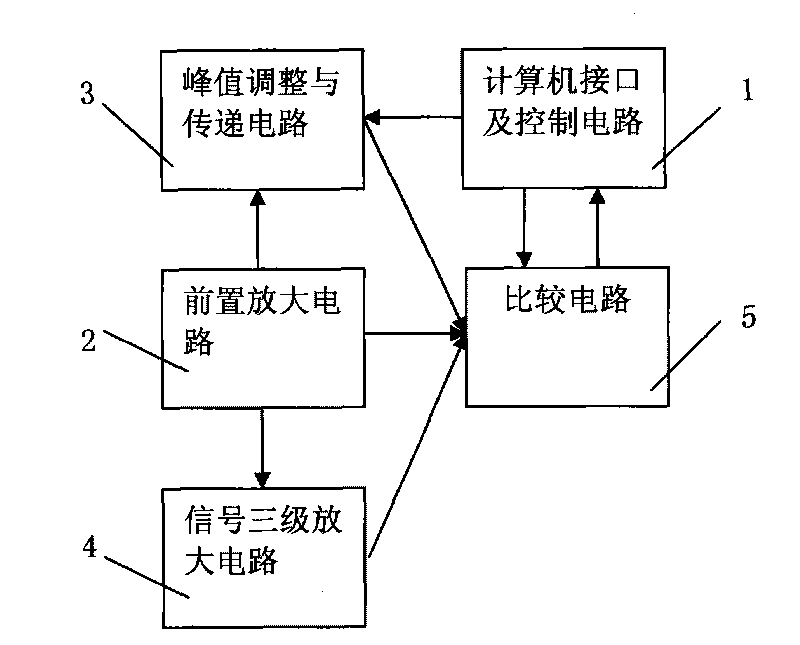

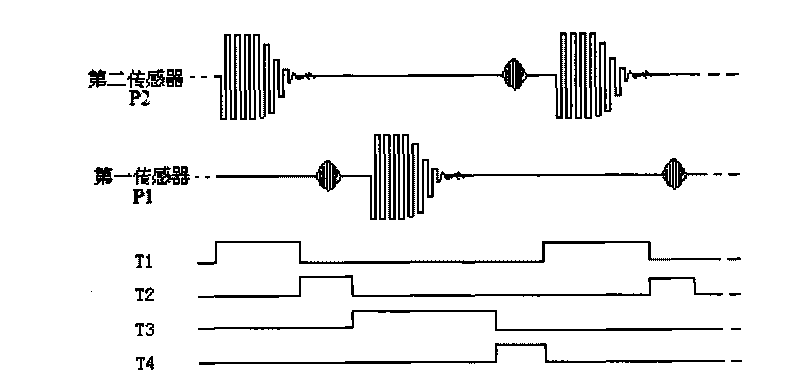

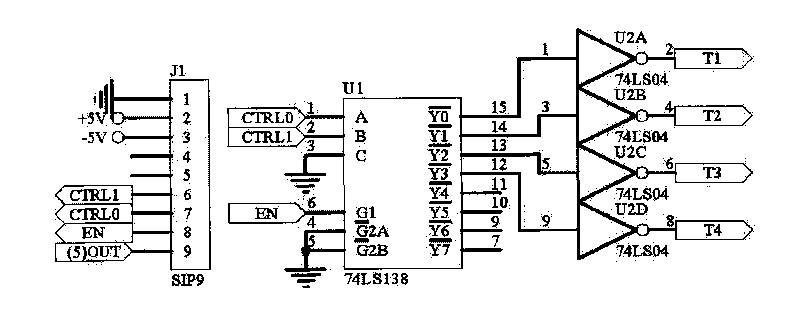

[0026] Such as figure 1 As shown, a signal detection circuit for a time-difference method ultrasonic gas flowmeter of the present invention includes a computer interface and a control circuit 1, a preamplifier circuit 2, a peak value adjustment and transfer circuit 3, a signal three-stage amplifier circuit 4 and a comparison Circuit 5. The preamplifier circuit 2 is electrically connected to the peak adjustment and transfer circuit 3 and the signal three-stage amplifying circuit 4 respectively, and the preamplifier circuit 2, the peak adjustment and transfer circuit 3 and the signal three-stage amplifying circuit 4 are respectively passed through The comparison circuit 5 is electrically connected to the computer interface and the control circuit 1; the synchronous signal input by the computer interface and the control circuit 1 controls the working sequence of the circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Input resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com