Multi-section lithium battery equalization repairing method based on LED lamp characteristic

A technology of LED lamp and repair method, which is applied in charge equalization circuit, arrangement of multiple synchronous batteries, repair/maintenance of secondary batteries, etc., can solve the complex repair process of multi-cell lithium battery, the operation process is not intuitive, and the control is complicated. and other problems, to achieve the effect of balancing the simplicity of the processing process, avoiding complex control and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

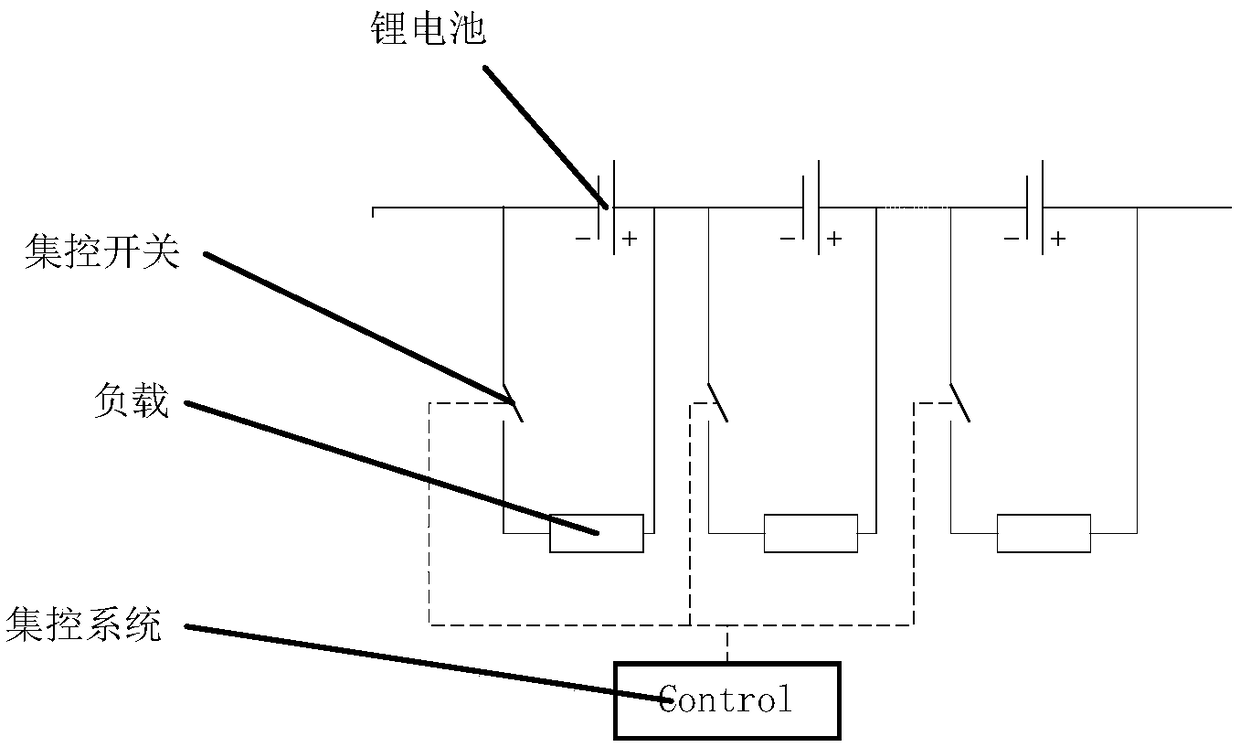

[0033] The multi-cell lithium battery balanced repair method based on the characteristics of LED lights in the present invention includes a lithium battery 2, and the lithium battery 2 is used for a power unit of an electric vehicle, and also includes the following repair method:

[0034] S1. Take out the lithium battery 2; control the discharge of the power source of the lithium battery 2 of the power unit through the BMS system carried by the electric vehicle, and take out the lithium battery 2 after the lithium battery 2 is discharged to the cut-off voltage;

[0035] S2, the sorting signal line 3; the signal line 3 connected to the lithium battery 2 is sorted out from the lithium battery 2 for backup;

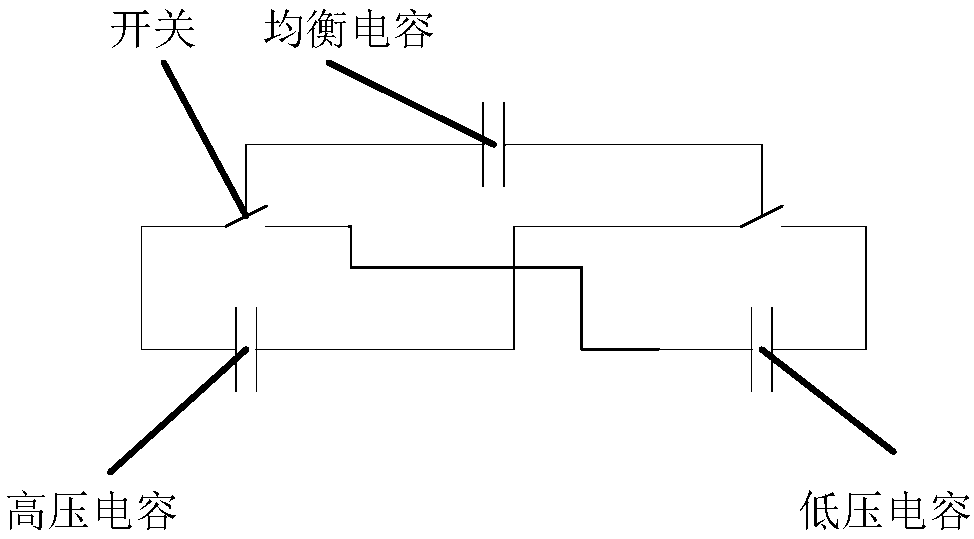

[0036] S3. Connect the balance repair tool 1; the balance repair tool 1 includes a socket 4, and the socket 4 includes a socket, and each group of signal lines 3 in the S2 is sequentially connected to the socket from low voltage to high voltage, and the socket Connect the eq...

Embodiment 2

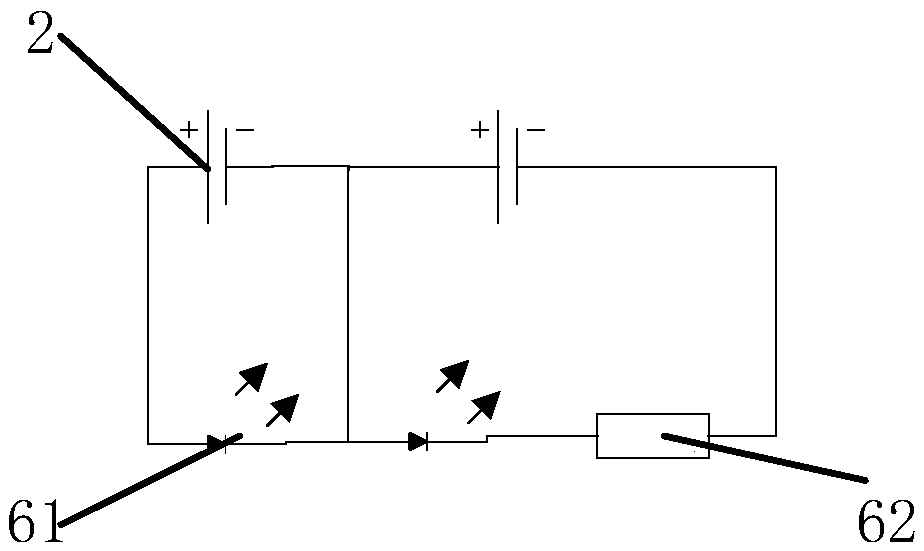

[0041]In this embodiment, the following further limitations are made on the basis of Embodiment 1: in the S3, the number of sockets of the socket 4 is at least 20. In the power unit of a conventional electric vehicle, there are 7-20 signal lines 3 of the lithium battery 2, that is, usually 7-20 lithium batteries 2 are connected in series to form a lithium battery 2 group to provide power, so at least 20 power strips 4 need to be provided. The socket can meet the purpose of connecting the conventional lithium battery 2 into the equalization repair tool 1. The equalization circuit includes an equalizer 6 formed by connecting at least one LED lamp 61 in parallel, or at least one LED lamp 61 connected in series with a resistor 62 and then connected in parallel. The equalizer 6 and a single lithium battery 2 are connected in parallel to form an equalizer circuit. If a single LED lamp 61 is not enough to balance the single-cell lithium battery 2 , then parallel connection can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com