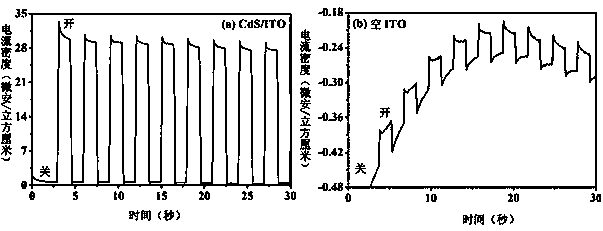

A thermal evaporation method for preparing near-stoichiometric cds thin films with quantum dots as precursors

A thermal evaporation method and stoichiometric technology, applied in the field of material chemistry, can solve the problems of increasing complexity and achieve the effect of simple method, simplified preparation process and reduced preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

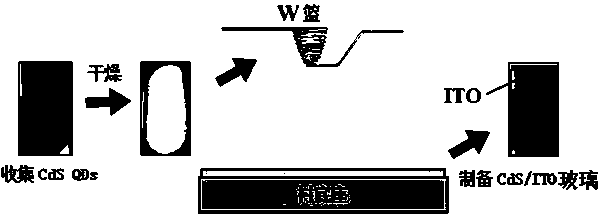

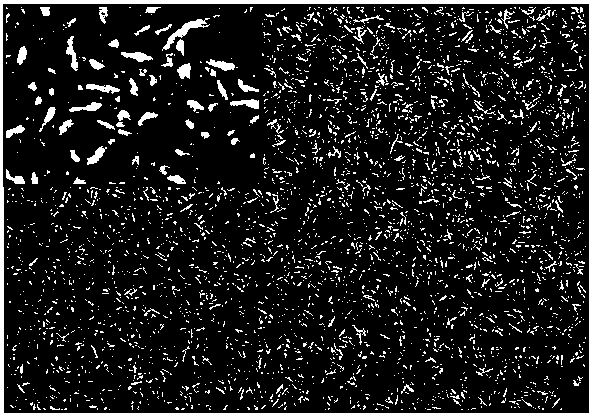

Method used

Image

Examples

Embodiment

[0033] 1. Preparation:

[0034] (1) Configuration solution: 75mL, 0.125M nitric acid, Cd(NO3)2·4H2O aqueous solution and sodium sulfide Na2S aqueous solution.

[0035] (2) Clean the substrate: select indium tin oxide (ITO) conductive glass as the substrate. First, the conductive ITO / glass substrate was cleaned with deionized water containing detergent to preliminarily remove oil stains and dust on the substrate surface. After this process was carried out with the assistance of ultrasound for 30 minutes, it was cleaned with deionized water and ultrasonically cleaned for 10 minutes, and then replaced with new deionized water for 10 minutes, and the cycle was repeated 3 times. Then, the substrate is boiled in a mixed solution of ammonia (NH3·H2O), hydrogen peroxide (H2O2) and deionized water at a volume ratio of 1:2:5 at 80°C until no bubbles are generated to remove all residual organic contamination. Sewage. Afterwards, wash with deionized water and ultrasonically clean for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com