Patents

Literature

70results about How to "Absence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

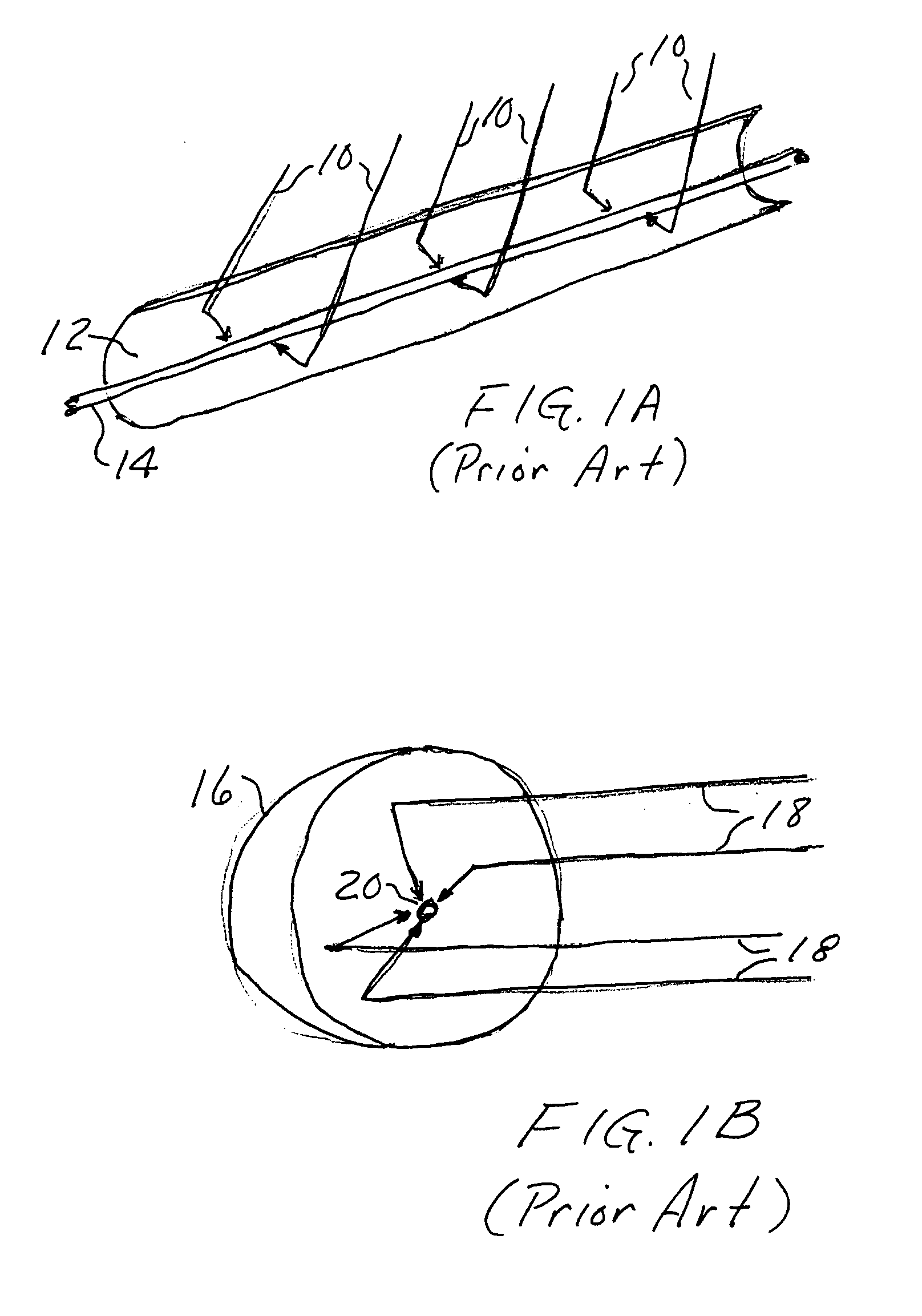

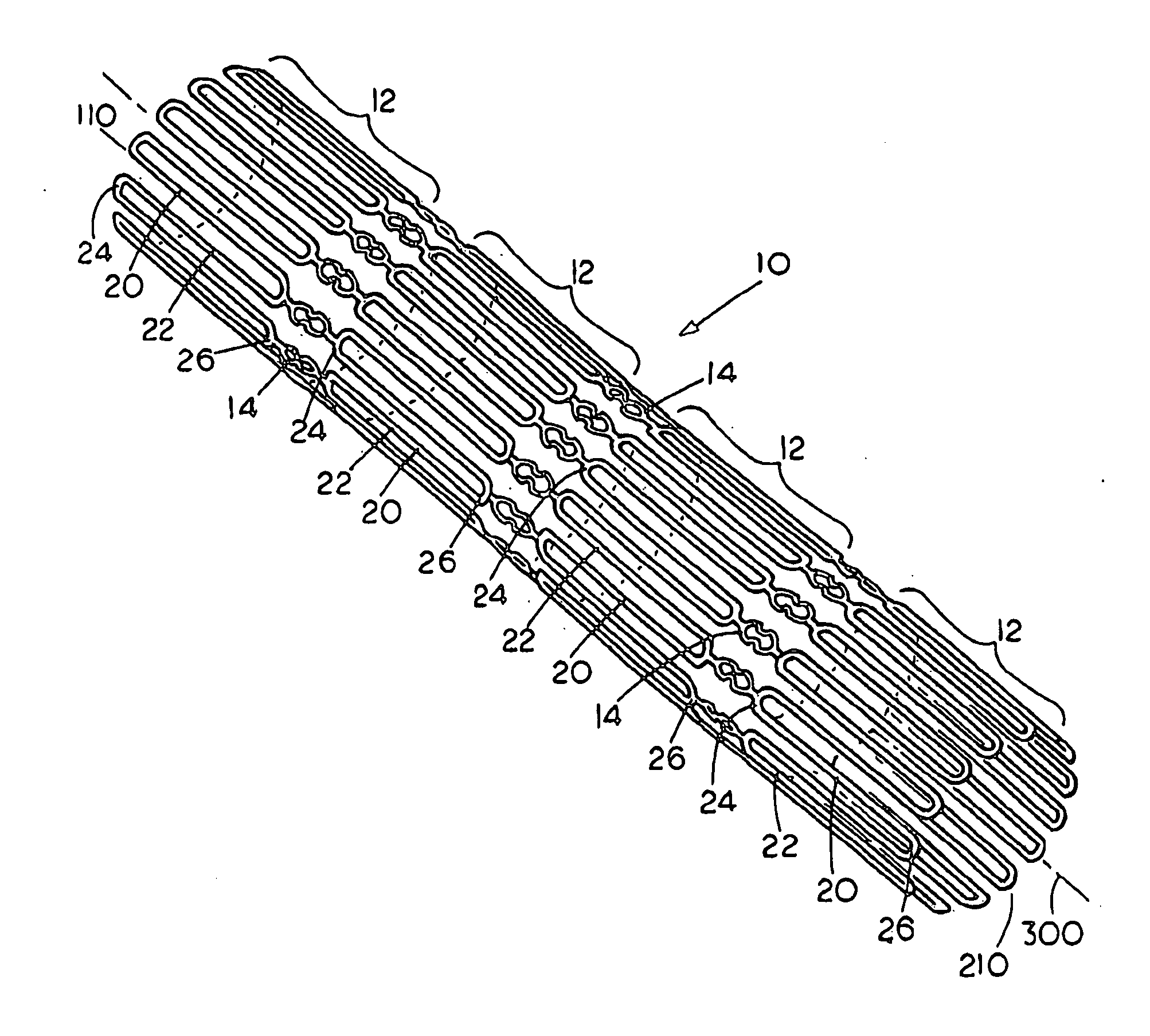

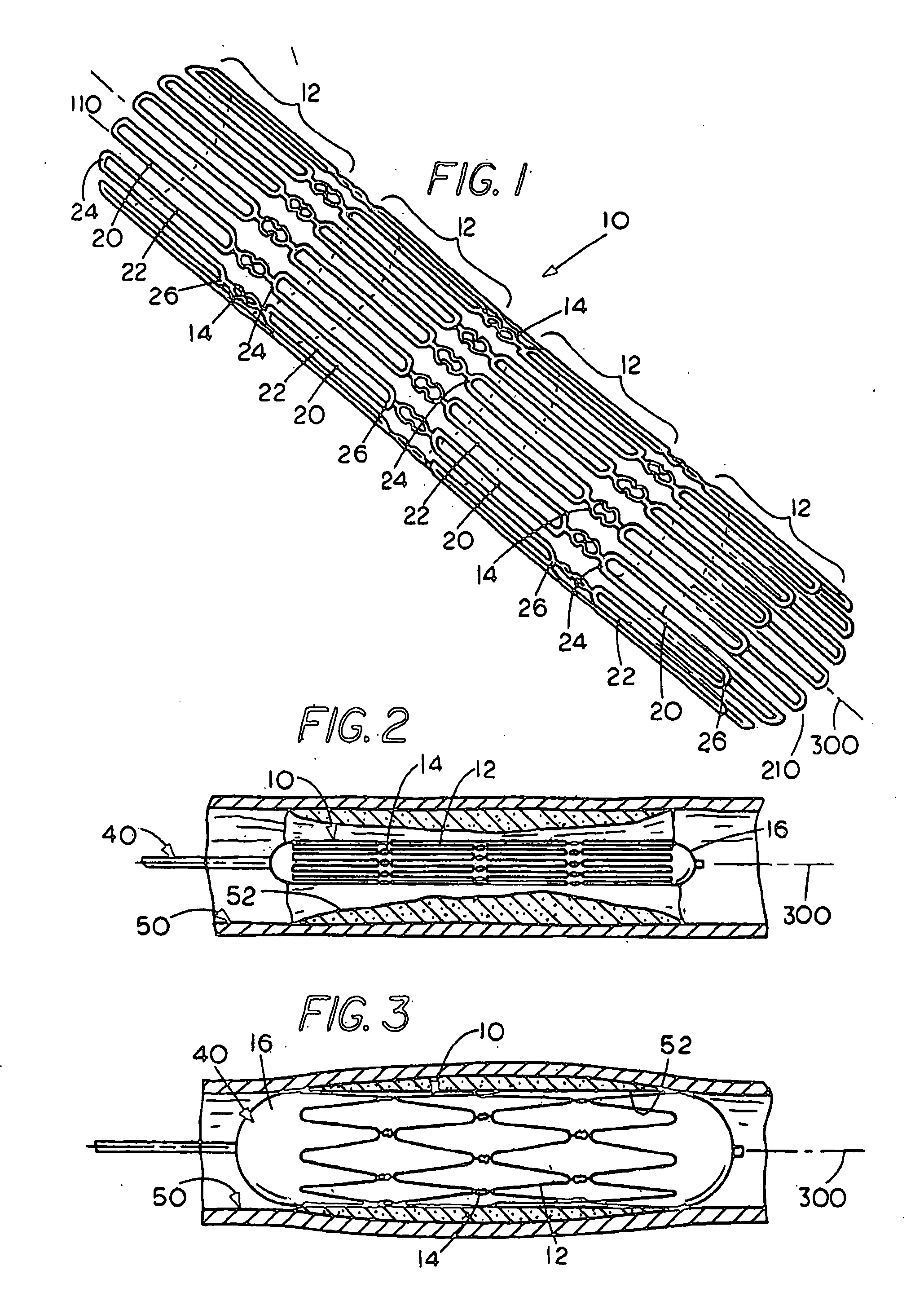

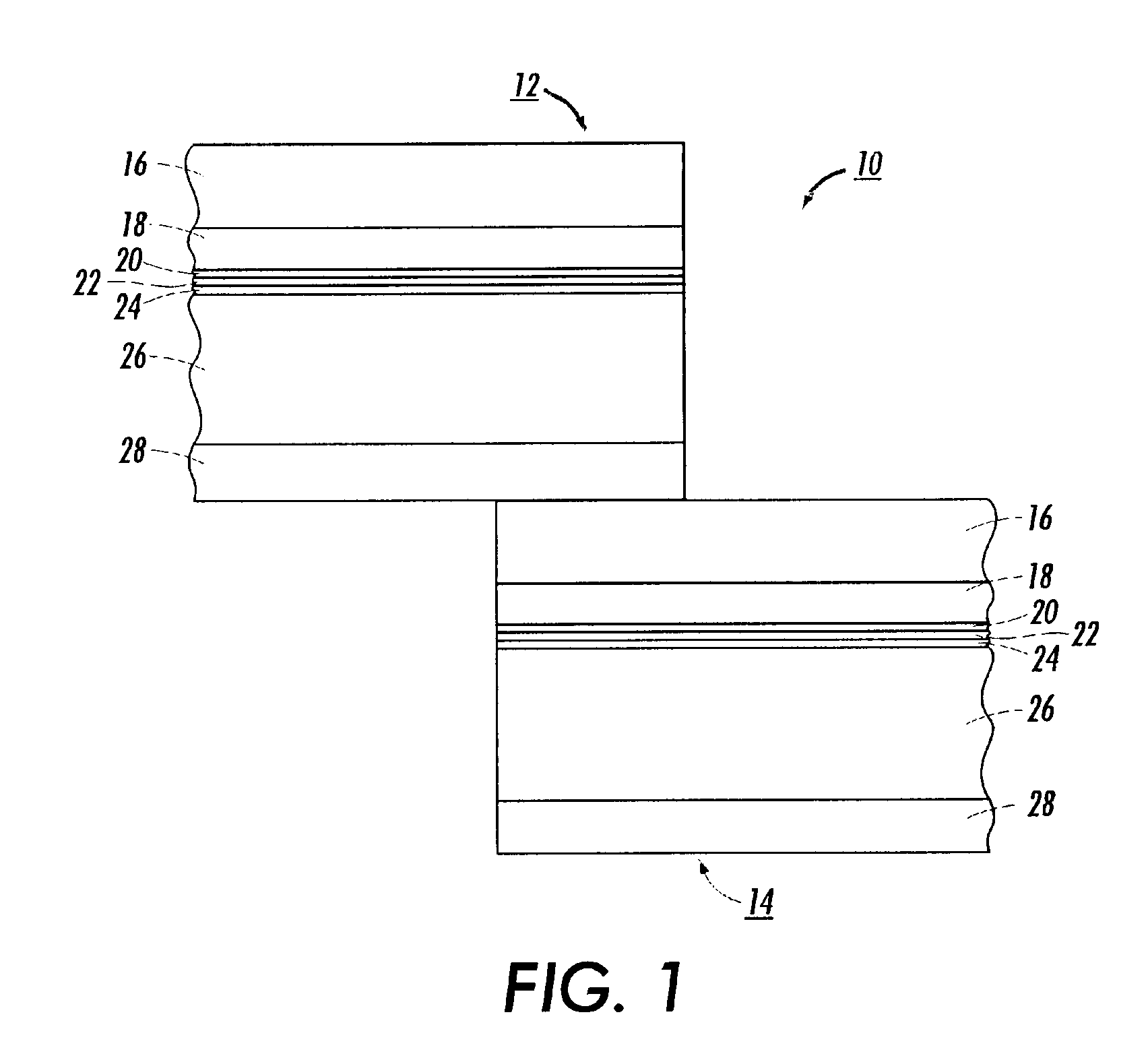

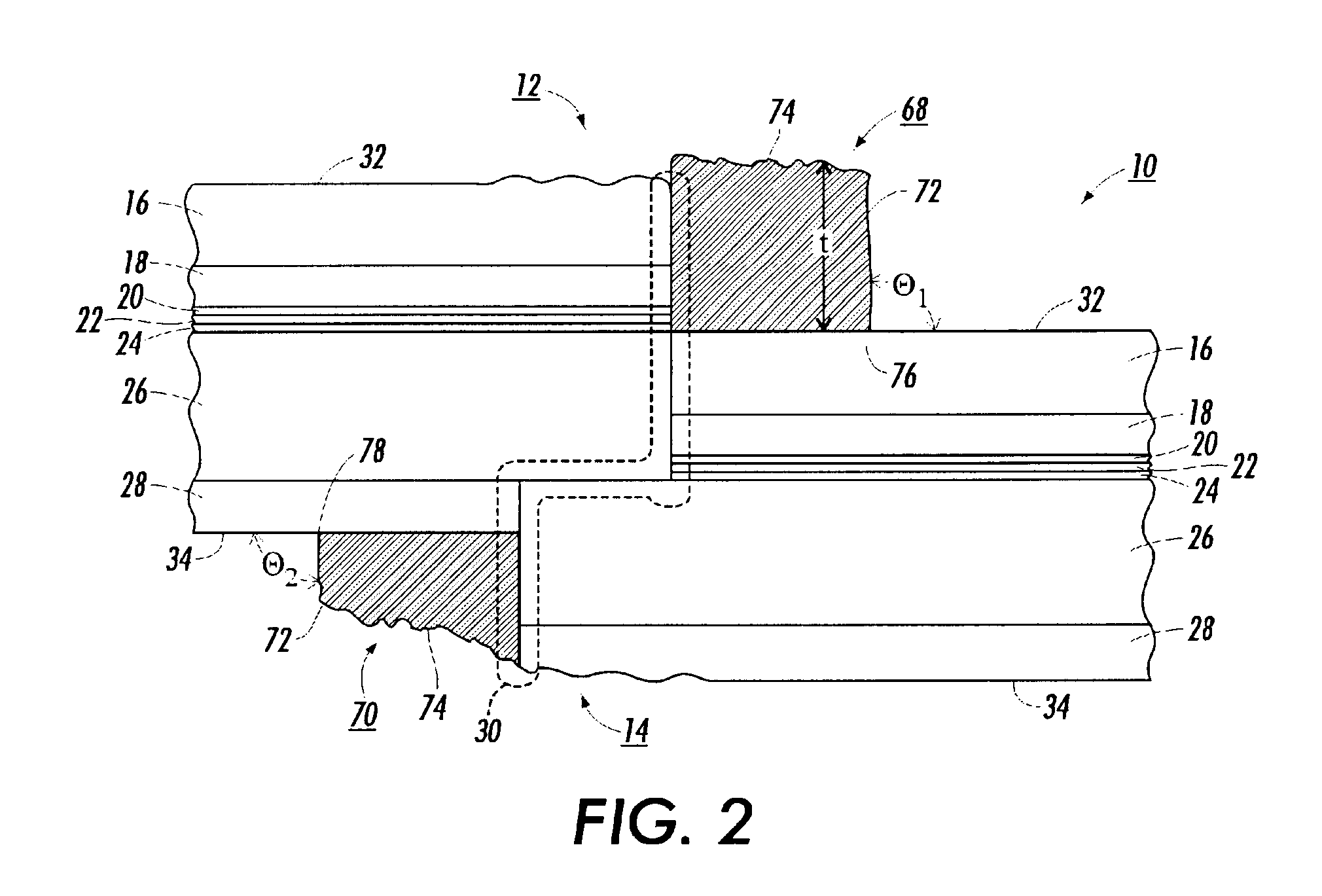

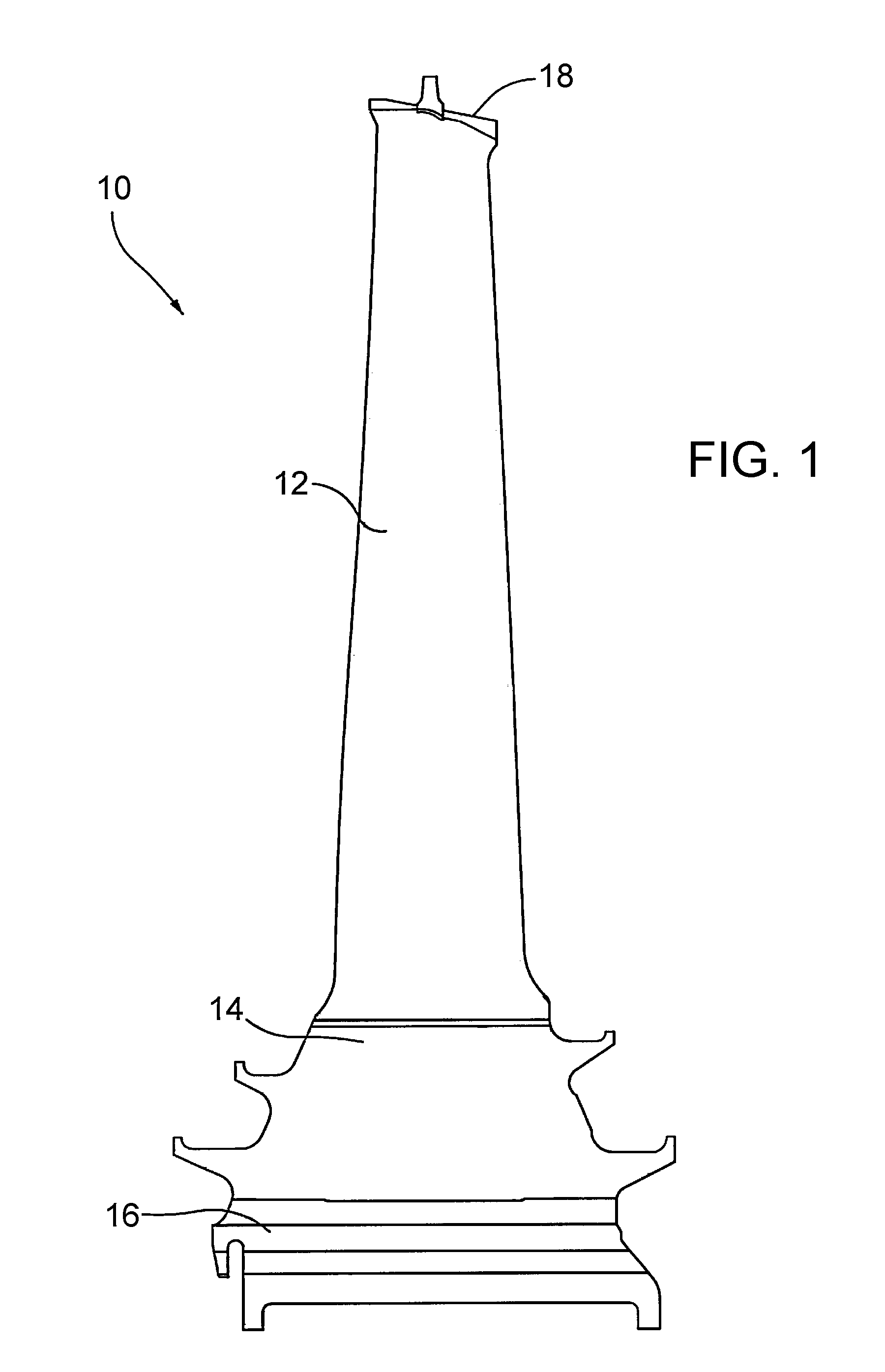

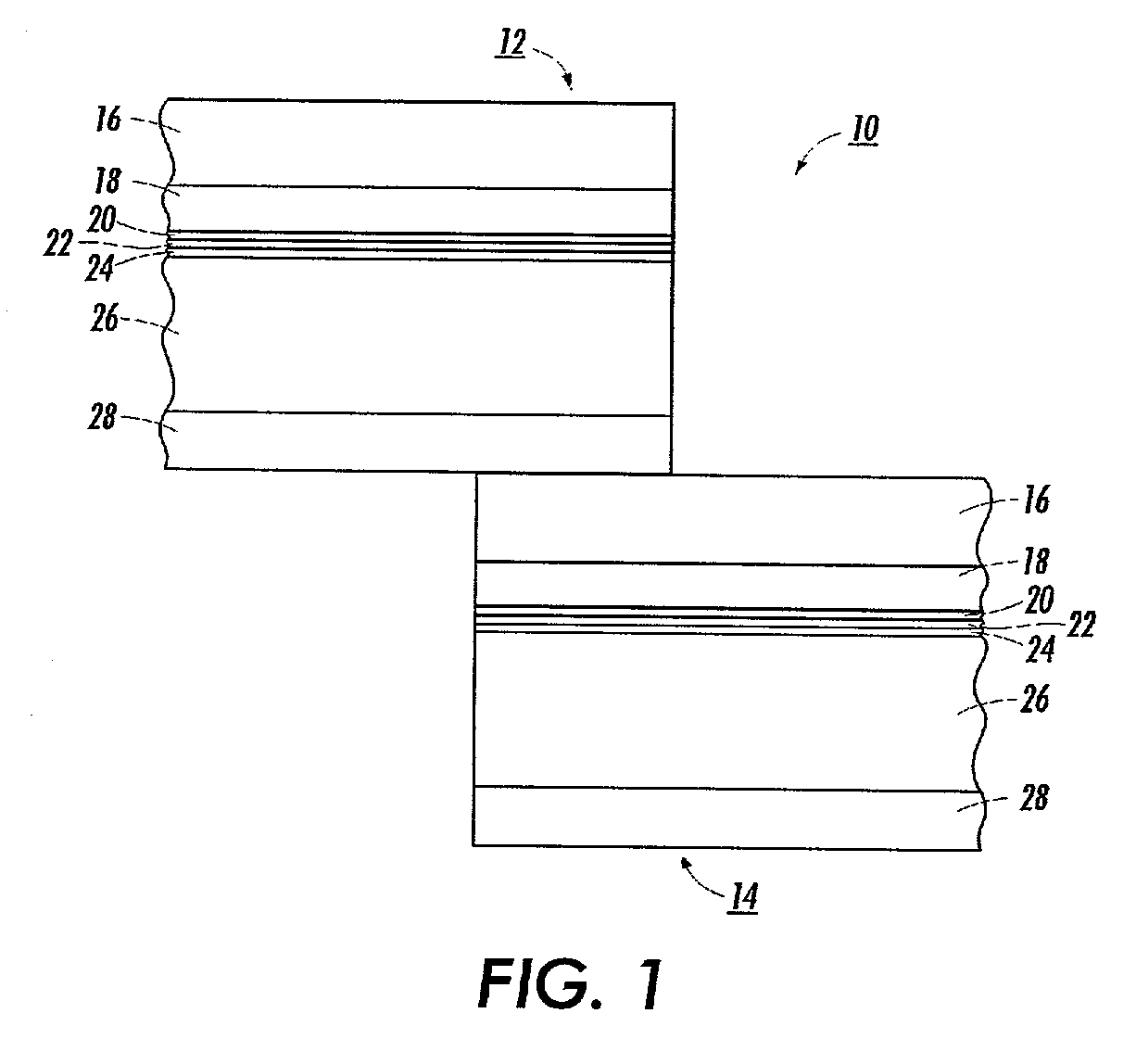

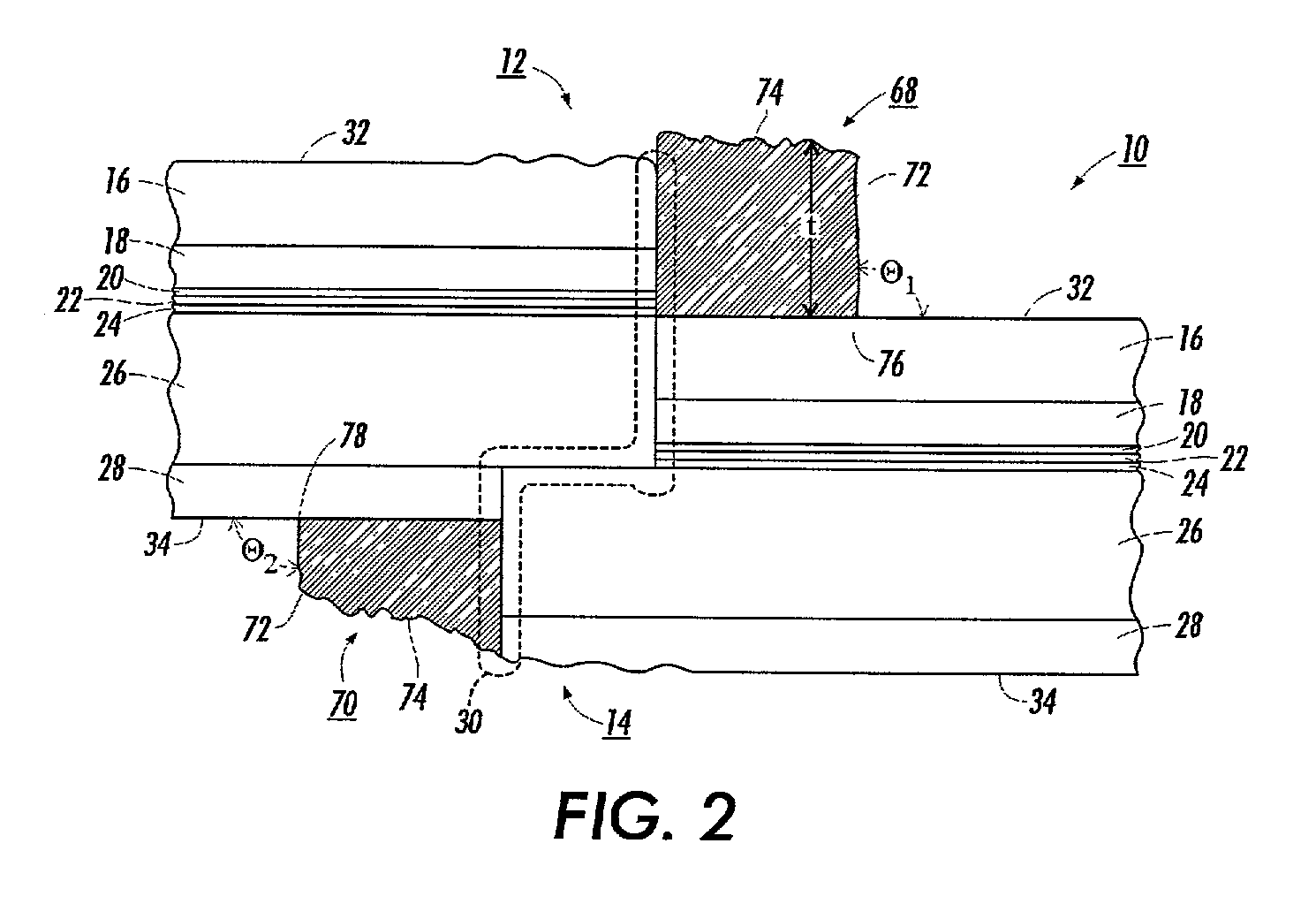

Expandable stent having plurality of interconnected expansion modules

InactiveUS20050004656A1Significantly improvedSmall surface areaStentsBlood vesselsInsertion stentInterconnection

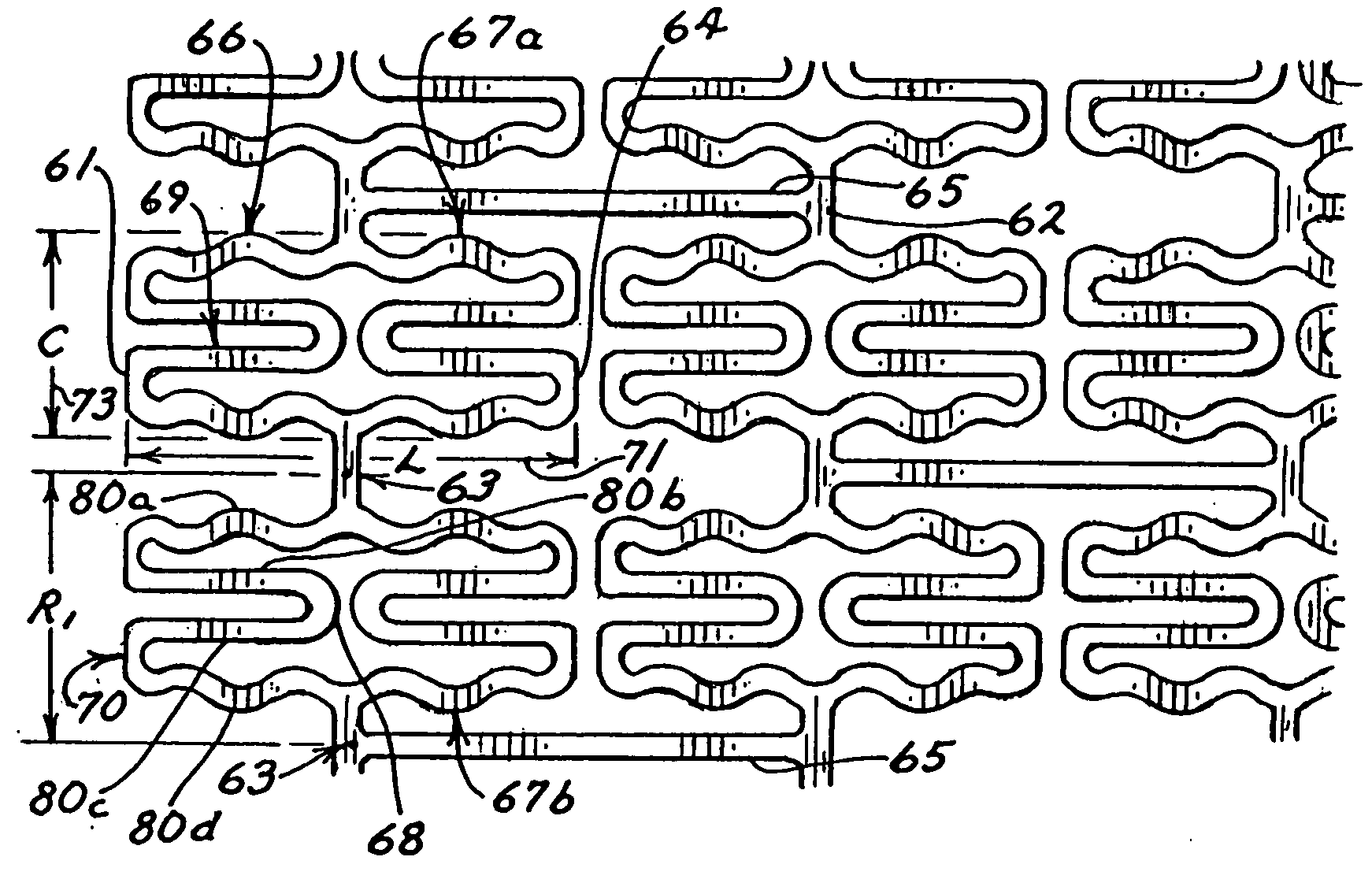

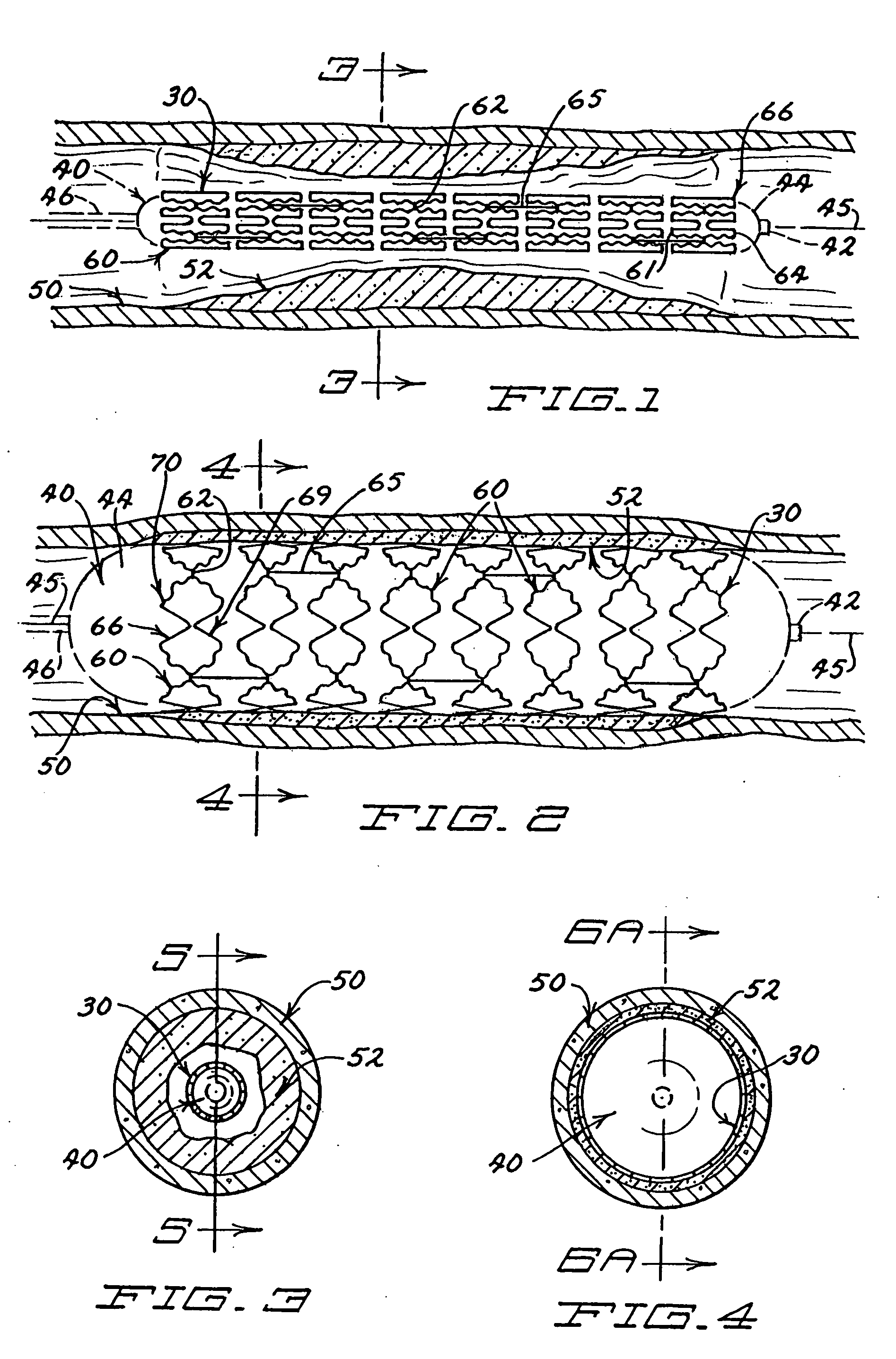

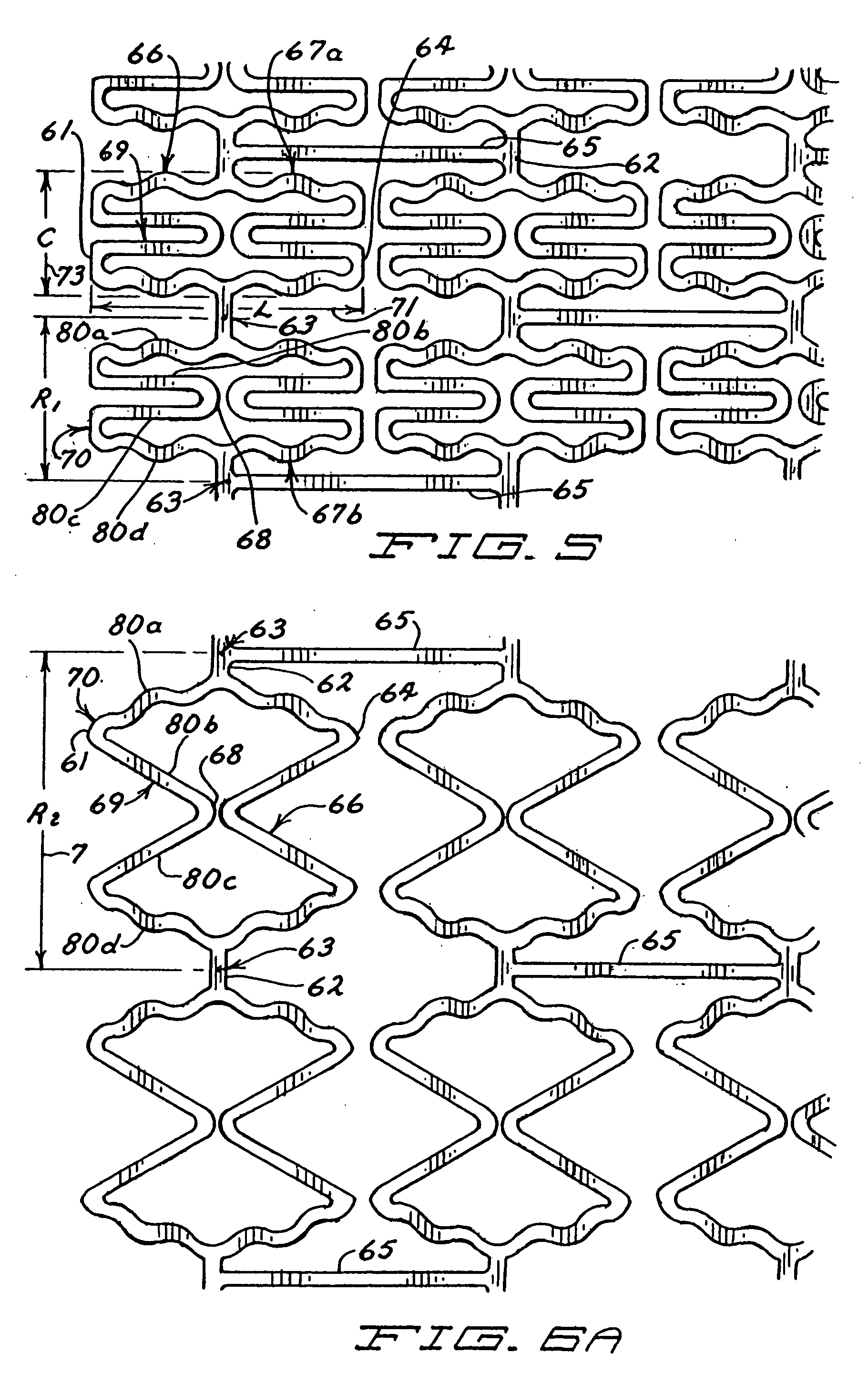

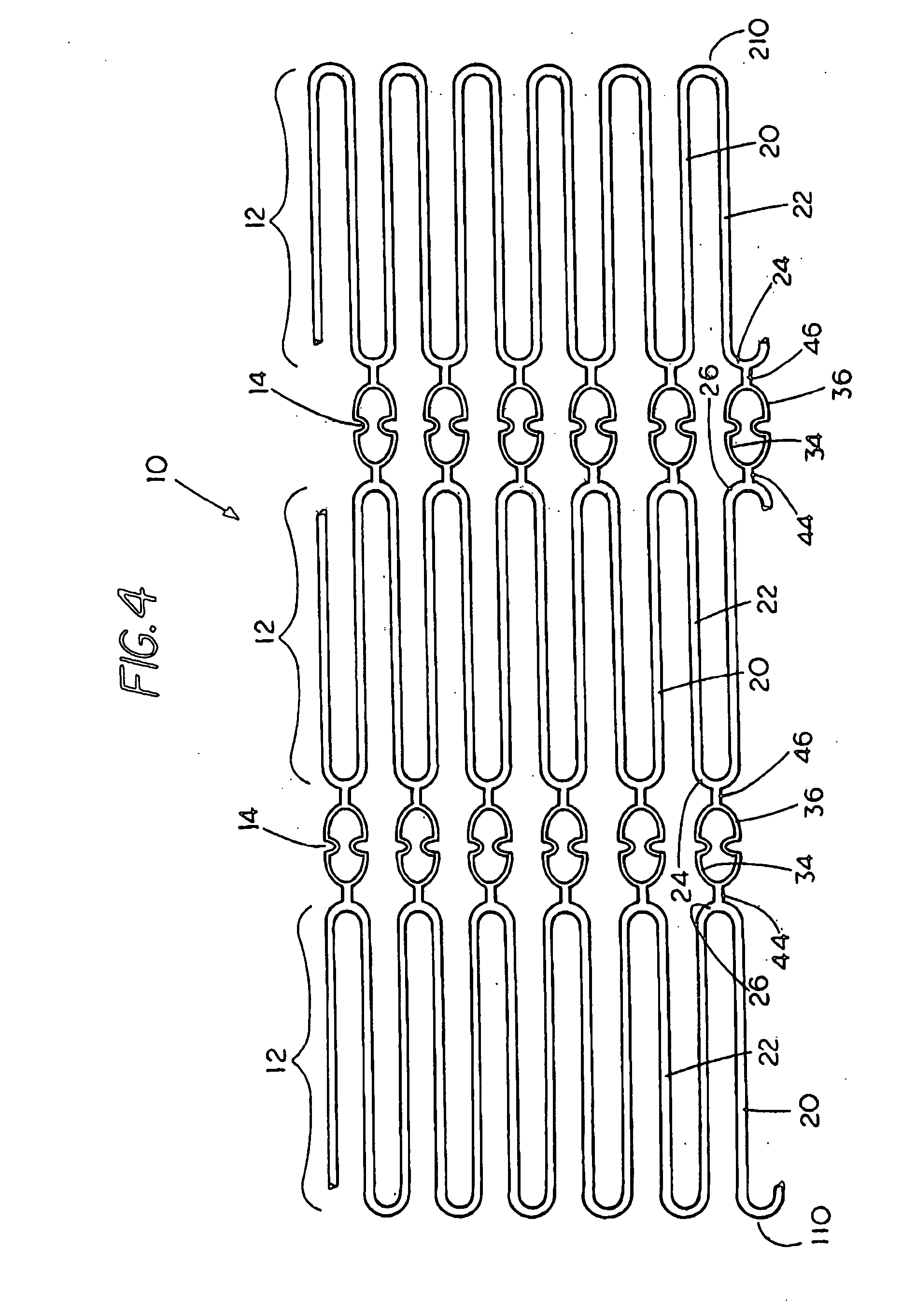

Expandable stents are disclosed. The stents have a plurality of rings or modules interconnected in series, with selectable links between the rings to provide for articulation. The preferred stent includes a plurality of modules, each of the modules being radially interconnected to form a ring configured to be expandably interconnected and being interconnected to each other in series by respective interconnection bridges. Each ring including a continuous strand of a material, the continuous strand of material being interconnected end to end so as to generally encompass a radial space within the ring. The strand of material being configured to include a repeating series of interconnected repeating W-shaped strand configurations having a repeating dip, rise, dip, rise, loop, dip, rise, dip, rise, loop patterned configuration. Preferably, the continuous strand of a material has an outer surface including cavities being at least partially filled with compositions containing medicinal agents selected to provide medically desirable effects upon positioning within a patient. Preferably, the continuous strand of a material has a series of narrowings that facilitate the bending of the strand. Alternate rings have at least one and preferably a number of expansion cells. The expansion cells preferably have at least one accordion structure on each side of the cell, which allows for significant expansion. The material of the respective stents being deformable such that each ring can be deformed from a first configuration wherein each ring has a first circumference and, in certain embodiments, each expansion cell has a first radial length, to a second configuration wherein each ring has a second circumference greater than the first circumference. Methods of producing the devices are also disclosed, including various etching methods.

Owner:STENT TECH

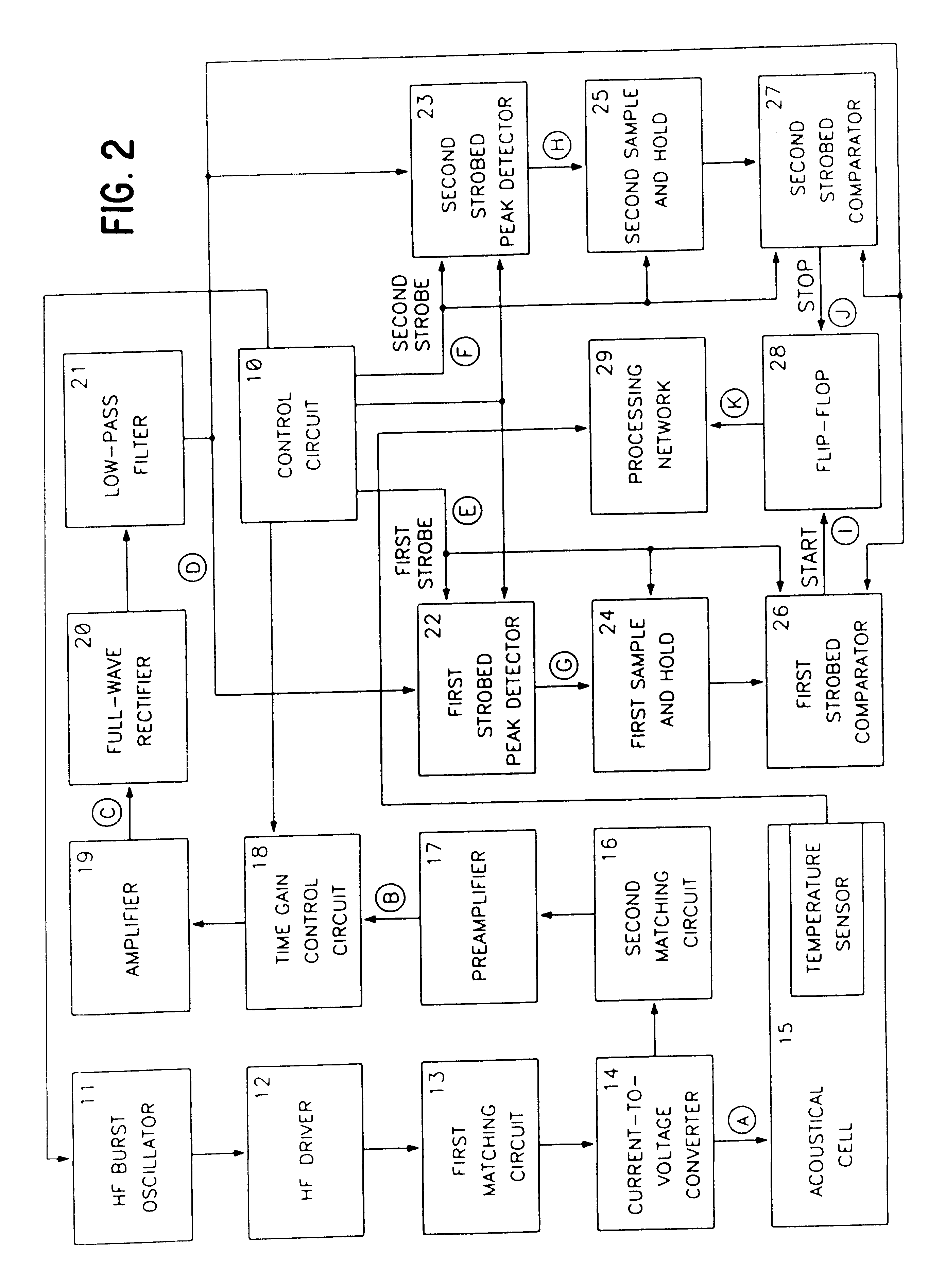

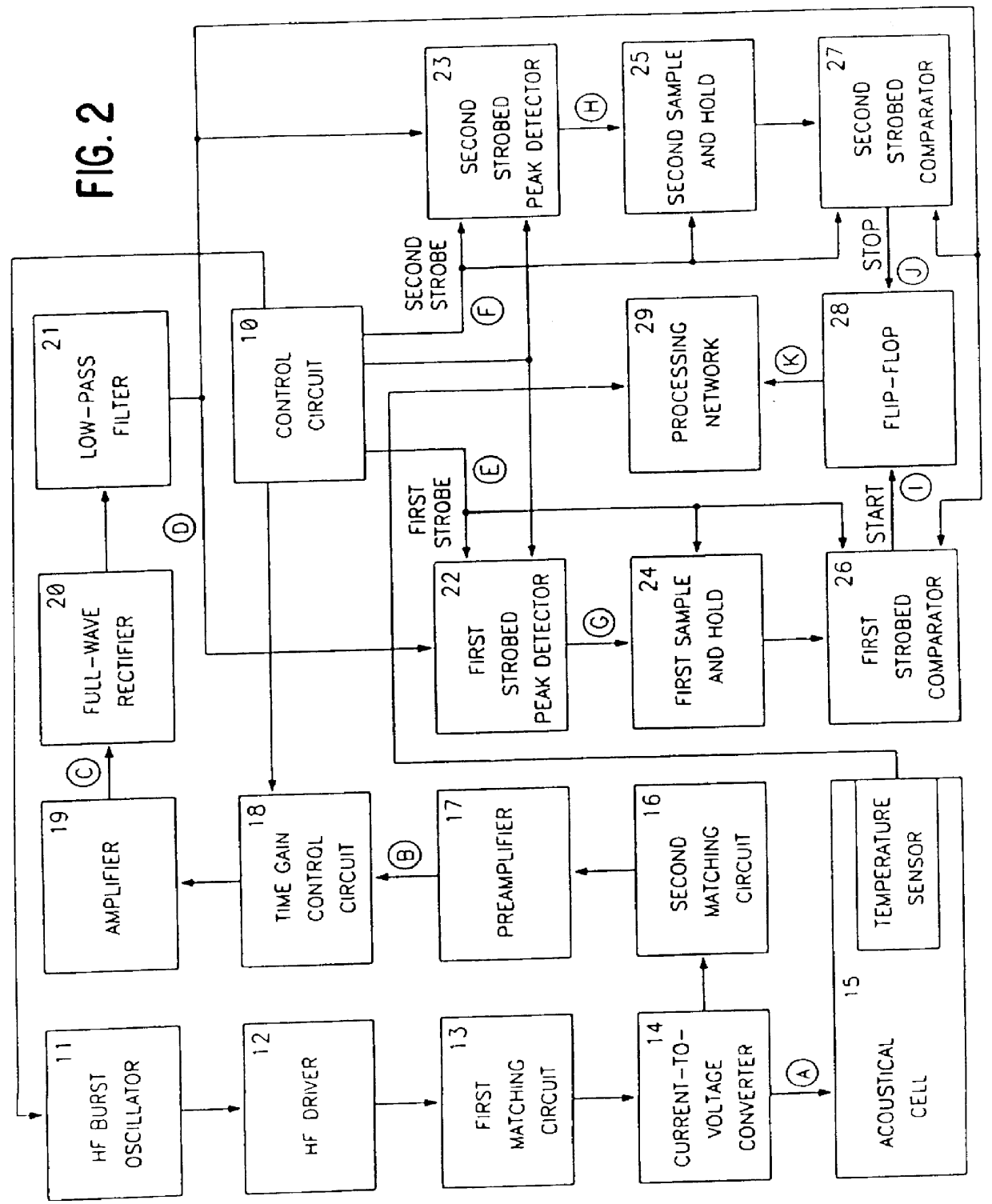

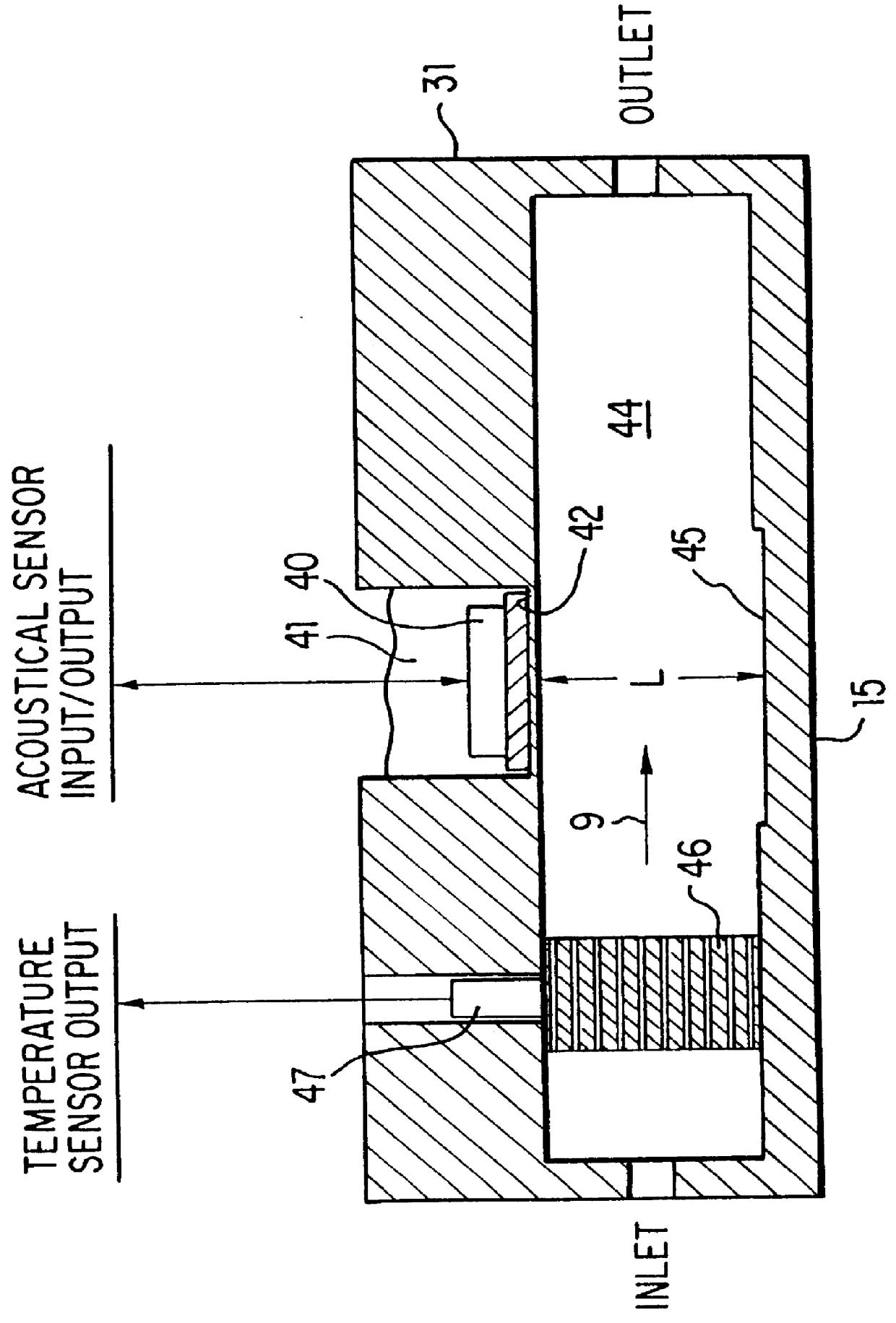

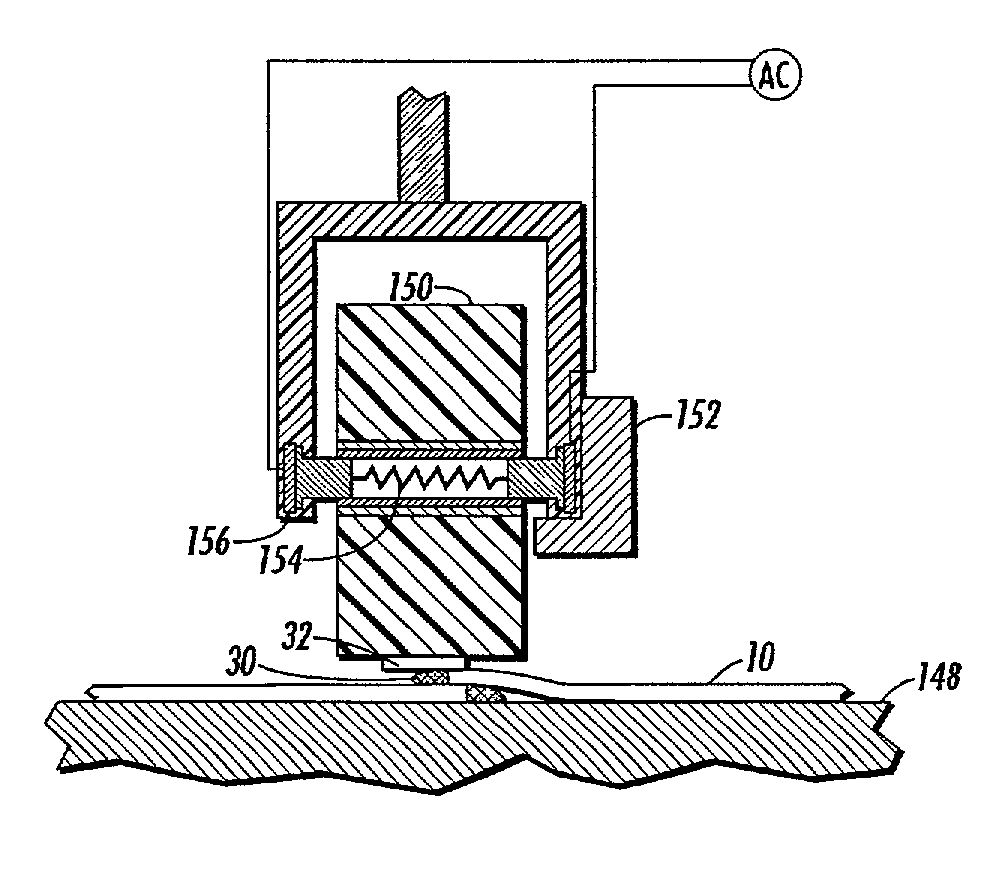

Apparatus and methods for performing acoustical measurements

InactiveUS6279379B1Good repeatabilityAbsenceVibration measurement in solidsSpectral/fourier analysisFast Fourier transformCorrelation function

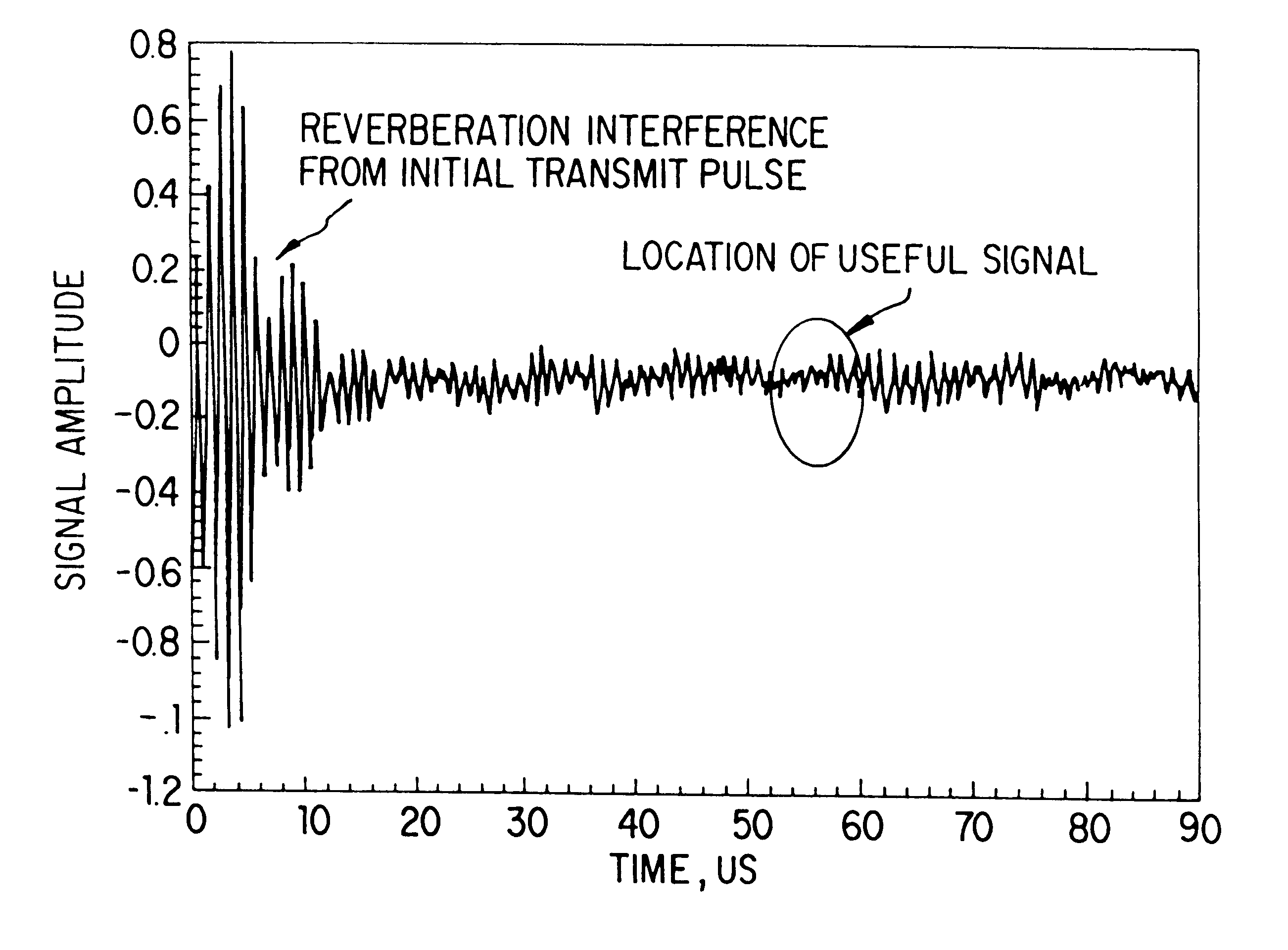

Apparatus (15, 30) and methods for performing acoustical measurements are provided having some and preferably all of the following features: (A) the system (15, 30) is operated under near-field conditions; (B) the piezoelement (40) or piezoelements (40, 48) used in the system are (i) mechanically (41, 49) and electrically (13, 16) damped and (ii) efficiently electrically coupled to the signal processing components of the system; (C) each piezoelement (40, 48) used in the system includes an acoustical transformer (42, 50) for coupling the element to a gaseous test medium (9); (D) speed of sound is determined from the time difference between two detections of an acoustical pulse (81, 82) at a receiver (40, FIG. 3; 48, FIG. 7); (E) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (F) forward and inverse Fourier transforms employing fast Fourier transform techniques are used to implement the cross-correlation techniques; in such a mathematical manner that the peak of the cross-correlation function corresponds to the detection of a pulse at the receiver and (G) stray path signals through the body (31) of the acoustic sensor (15, 30) are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measured and on mixtures of compressible gases. Methods and apparatus (29) for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

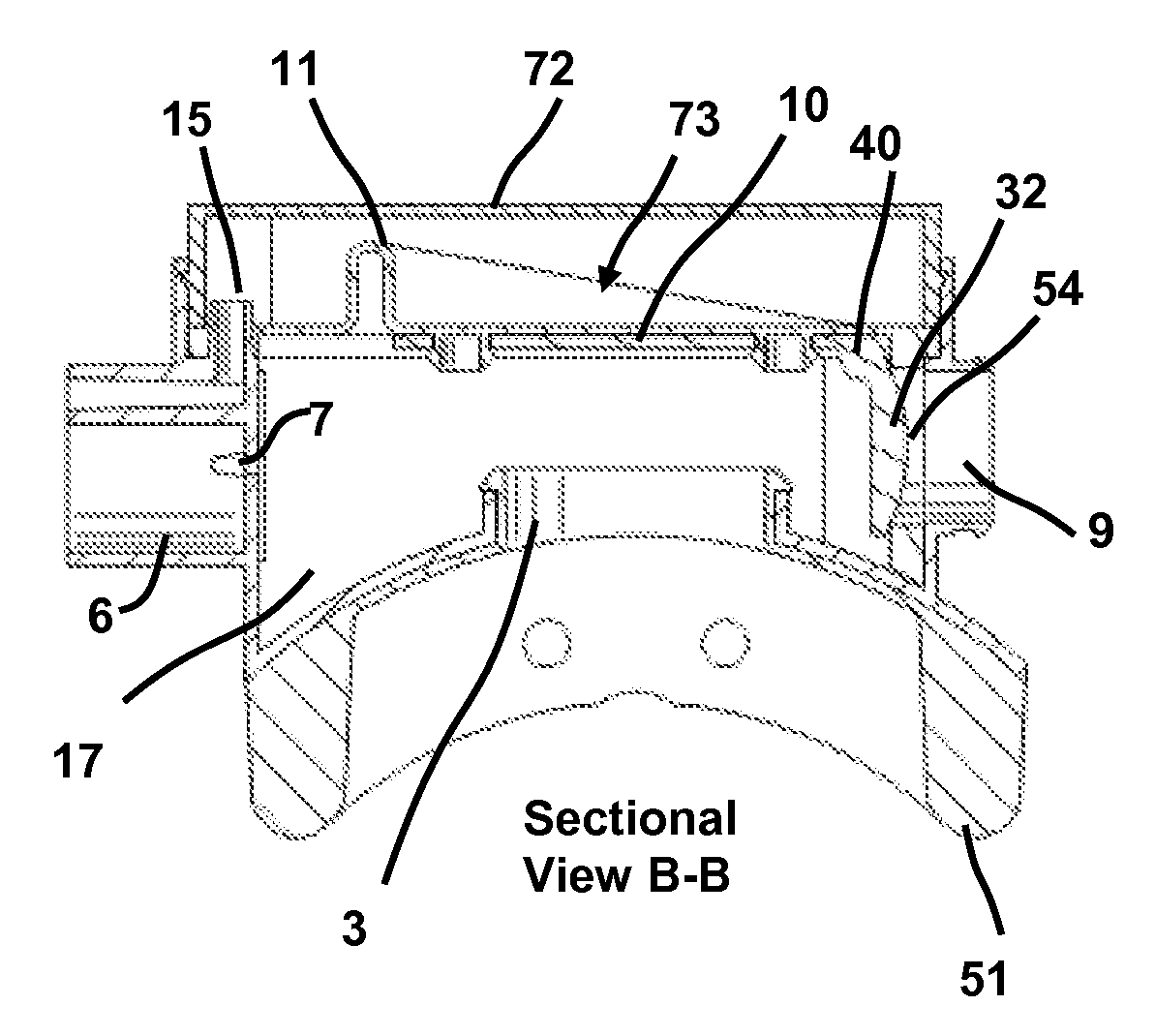

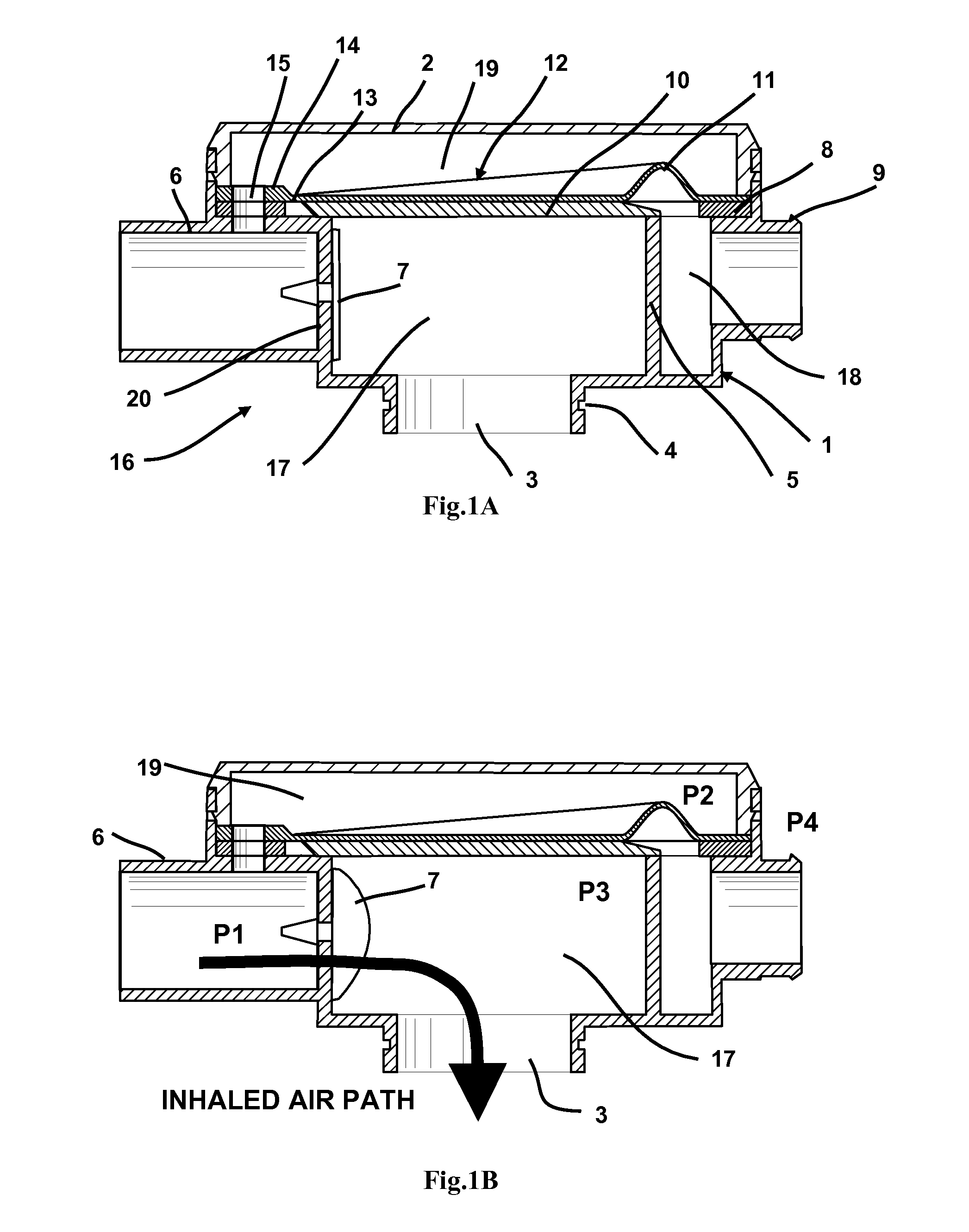

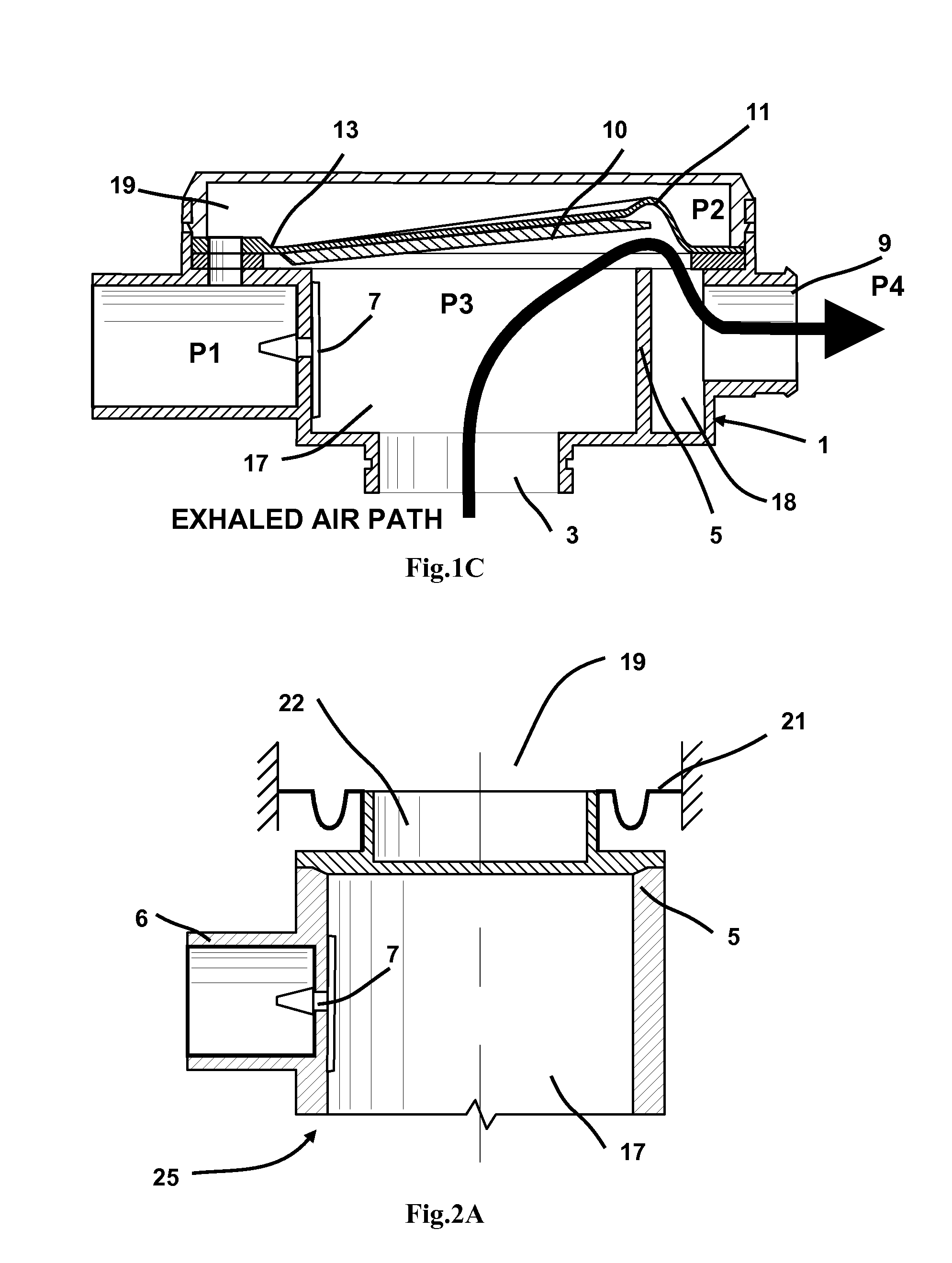

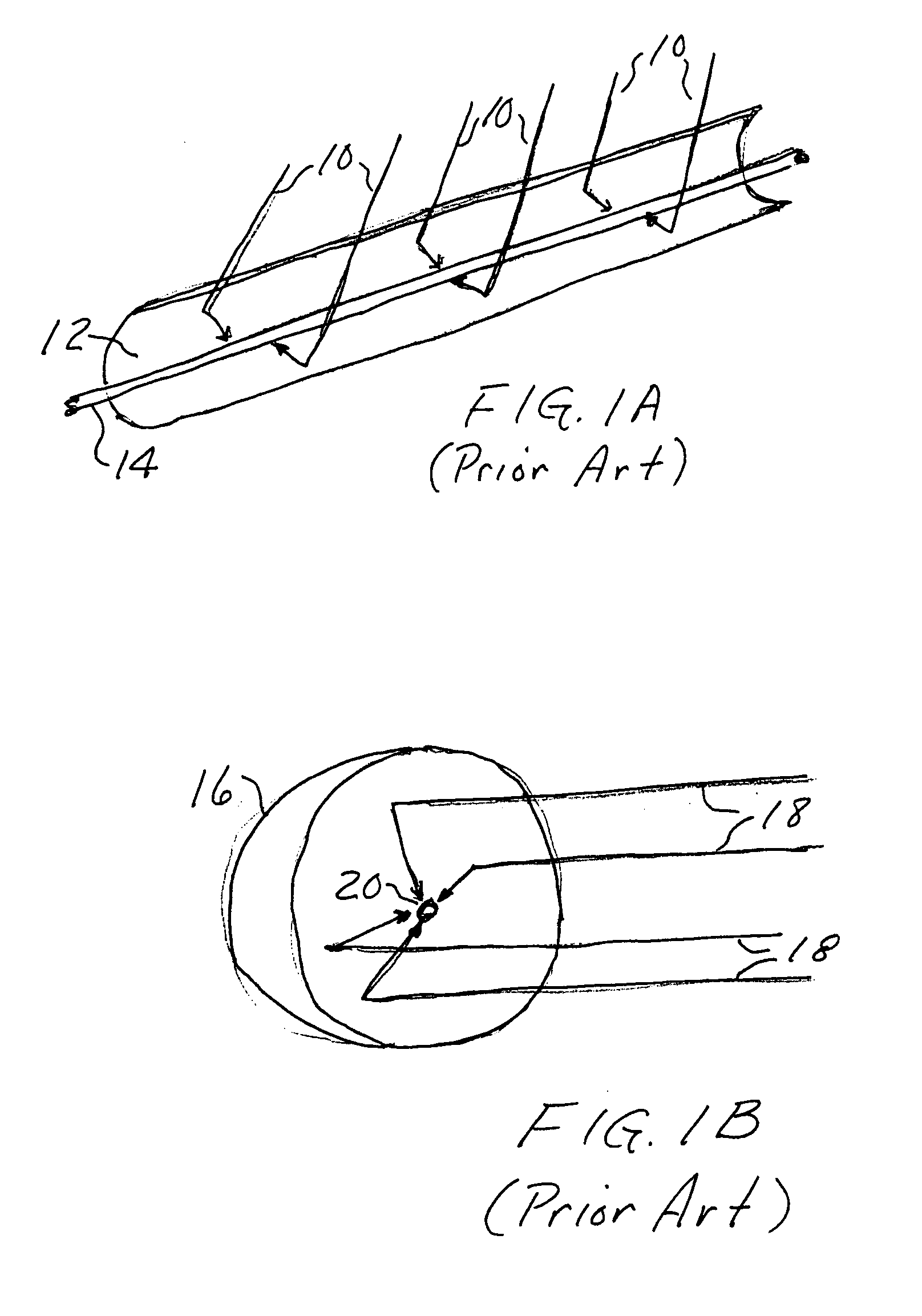

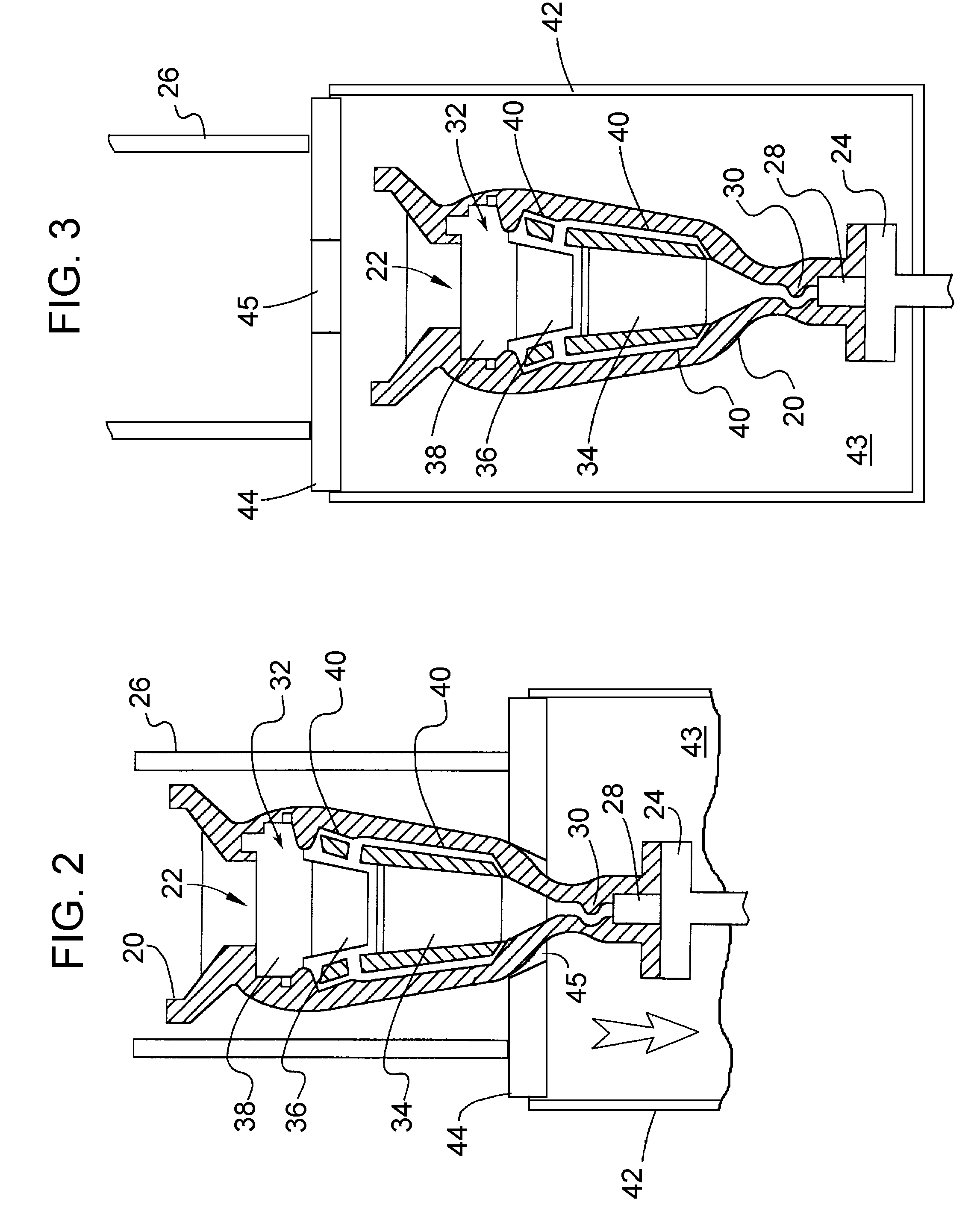

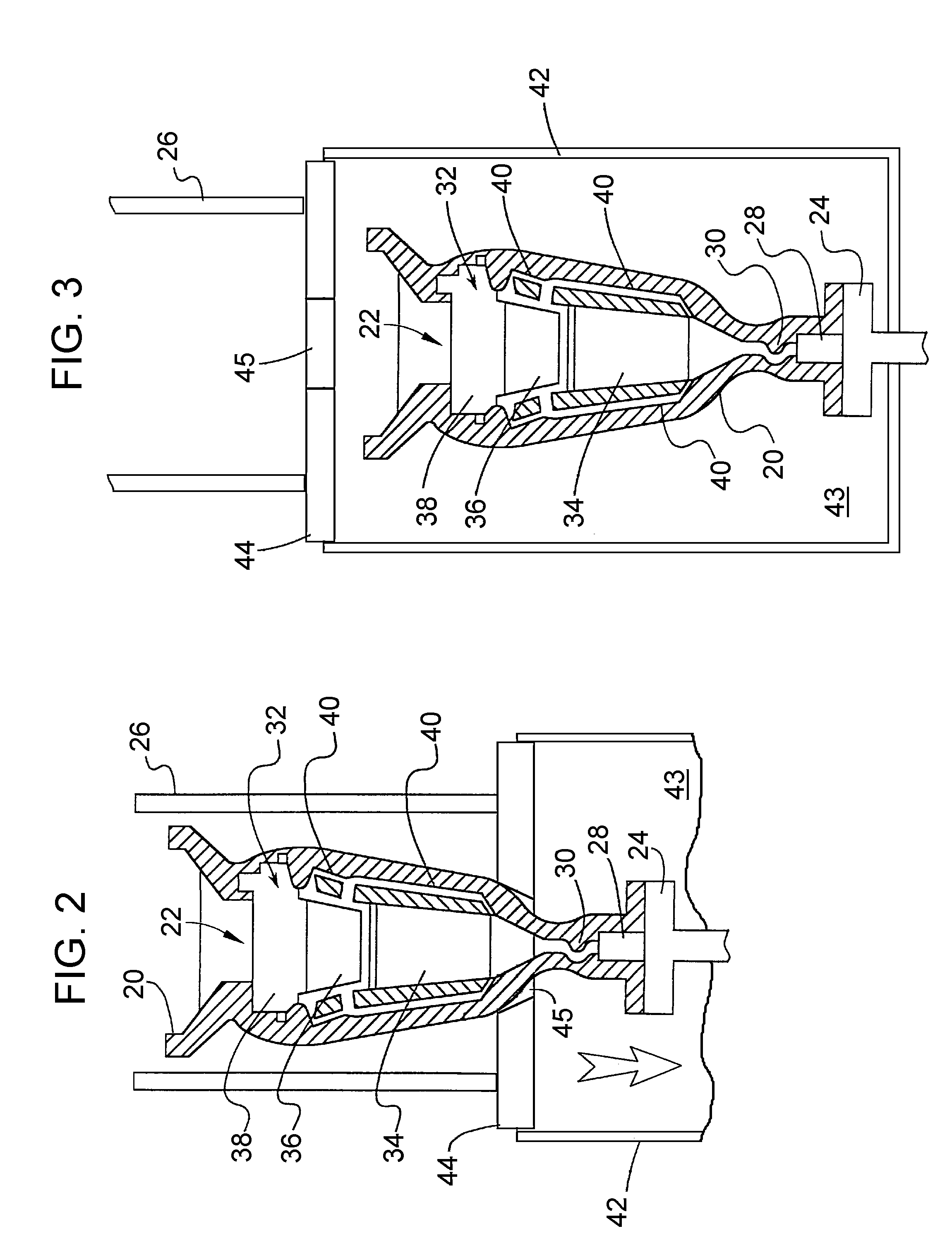

Exhaust Apparatus For Use in Administering Positive Pressure Therapy Through the Nose or Mouth

InactiveUS20080142013A1Superior CO removalReduce traffic requirementsRespiratory masksMedical devicesNasal cavityPositive pressure

We describe the use of a flow directing apparatus for incorporation into a patient mask or adjacent to it and for use with a source of pressurized breathable gas such as electronically or electronically controlled fan blower or positive displacement ventilator to provide nasal or oro-nasally administered continuous positive airway pressure or bi level therapies. Such therapies are commonly used to treat sleep disordered breathing including sleep apnea and other syndromes, as well as ventilatory insufficiency. The valve apparatus includes means to direct expired air to atmosphere and inspired air from a pressure source to a user's airway. In this way advantage is provided compared to alternative means as described in the prior art which vent a user's expired gas to atmosphere through a fixed open vent.

Owner:HALLETT MICHAEL DAVID +1

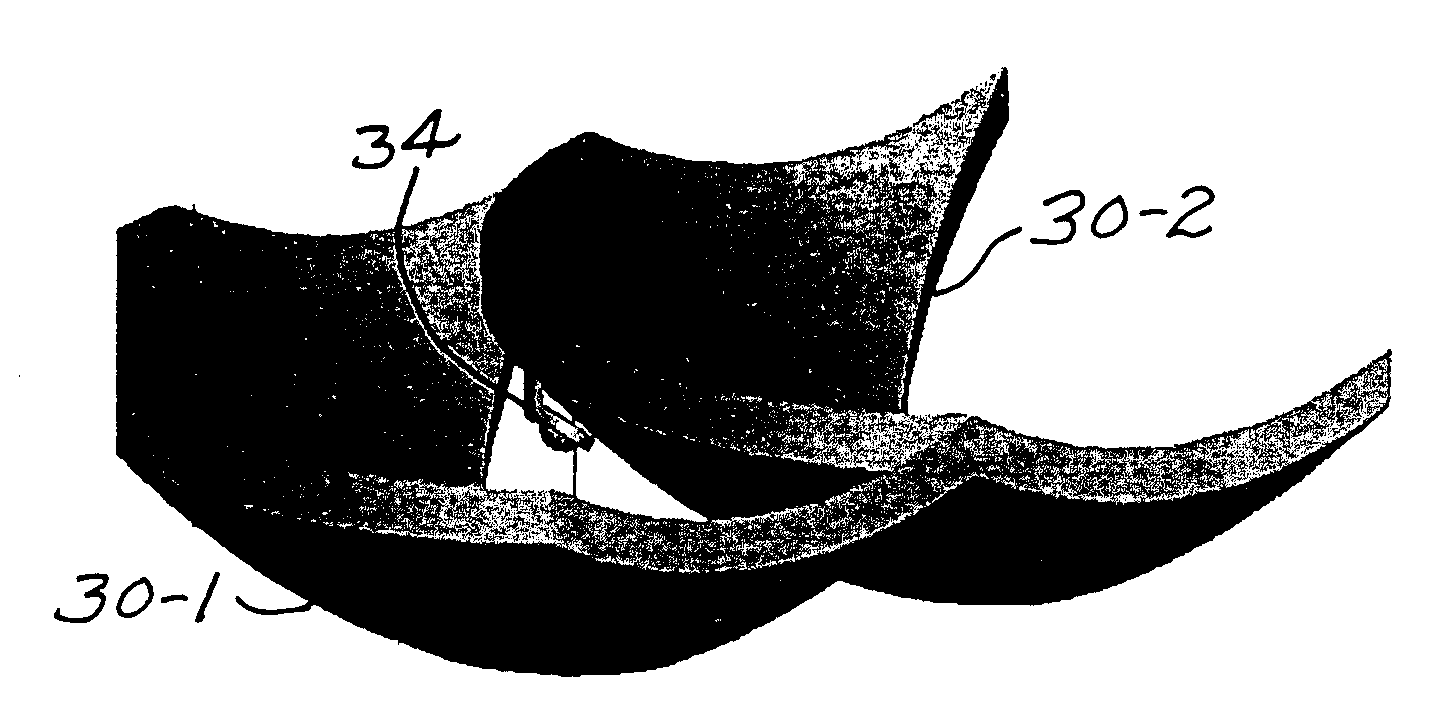

Compact micro-concentrator for photovoltaic cells

ActiveUS7297865B2Improve efficiencyEasy to manufacturePhotovoltaic supportsRoof covering using slabs/sheetsOptoelectronicsDirect radiation

Owner:CREDIT SUISSE CAYMAN ISLANDS BRANCH

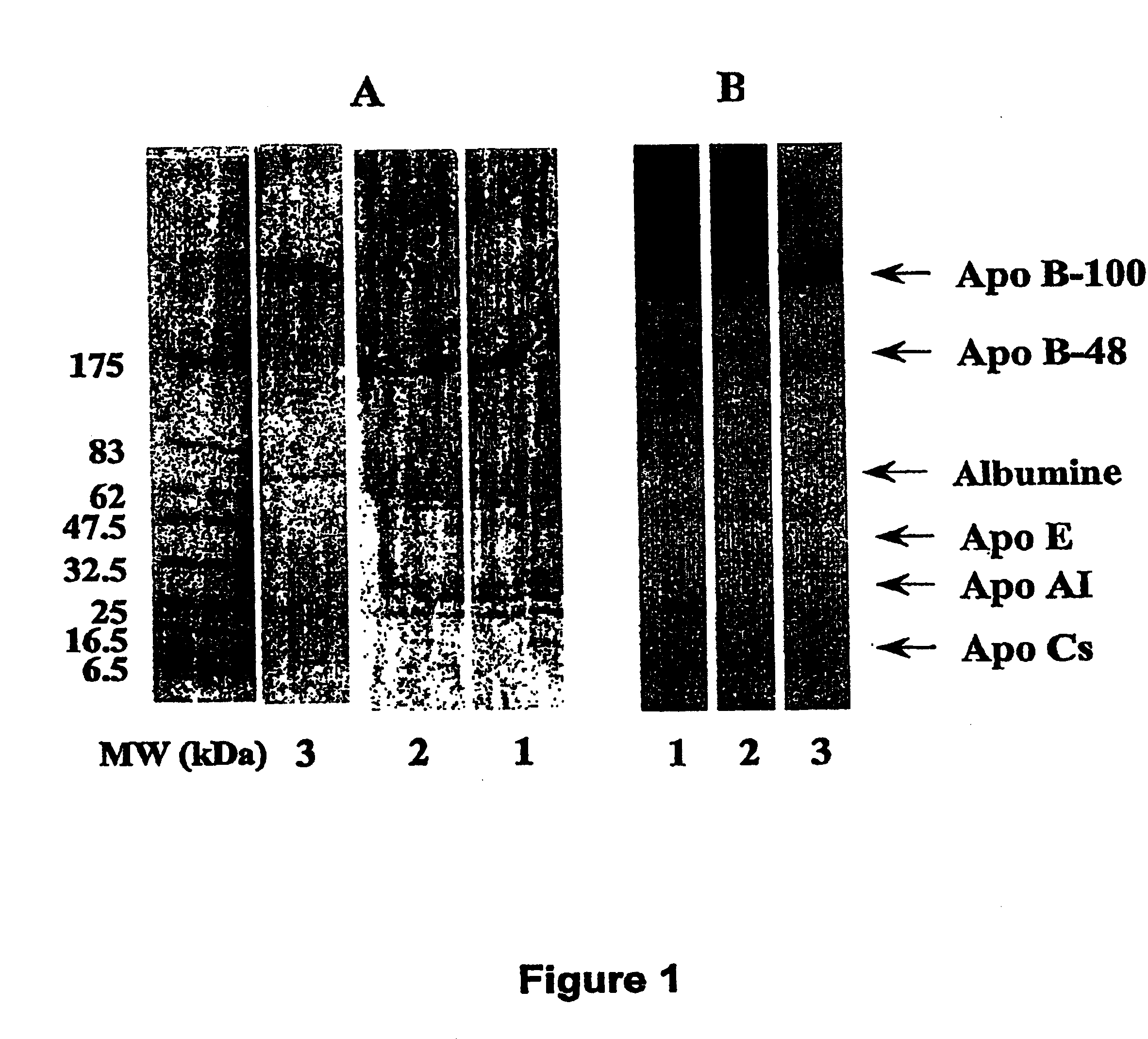

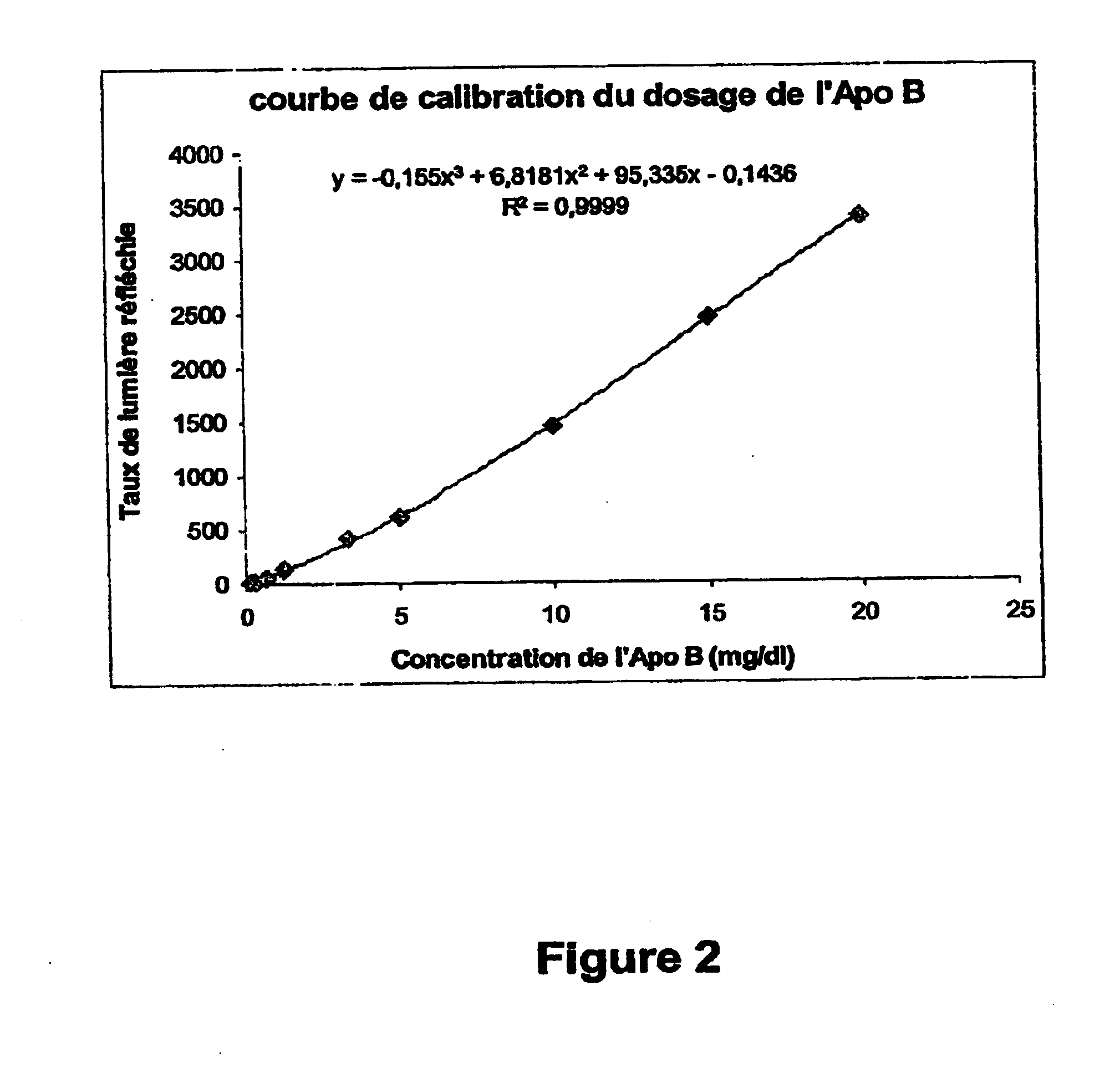

Compositions and methods for apo-b48 and apo-b100 assay

InactiveUS20050152900A1High affinityAbsenceApolipeptidesMetabolism disorderDifferential measurementApolipoprotein B48

The invention concerns compositions and methods for assay or detection of apolipoprotein-B48 in samples. In particular, it concerns a method for differential measurement of apolipoprotein-B48 (“Apo-B48”) and apolipoprotein-B100 (“Apo-B100”) in biological samples. The invention also concerns synthetic products of Apo-B100, the corresponding antibodies, kits containing same, and their uses for detecting, differentially quantifying and / or recording an amount of Apo-B48 and / or Apo-B100 in a sample, or for quantifying and / or recording atherogenic lipoparticles in a sample. The products, materials and kits hereinabove can also be used for differentially modulating the levels of Apo-B48 and / or Apo-B100 or their activity, in vitro or in vivo, and for regulating lipid metabolism in a subject.

Owner:GENFIT SA

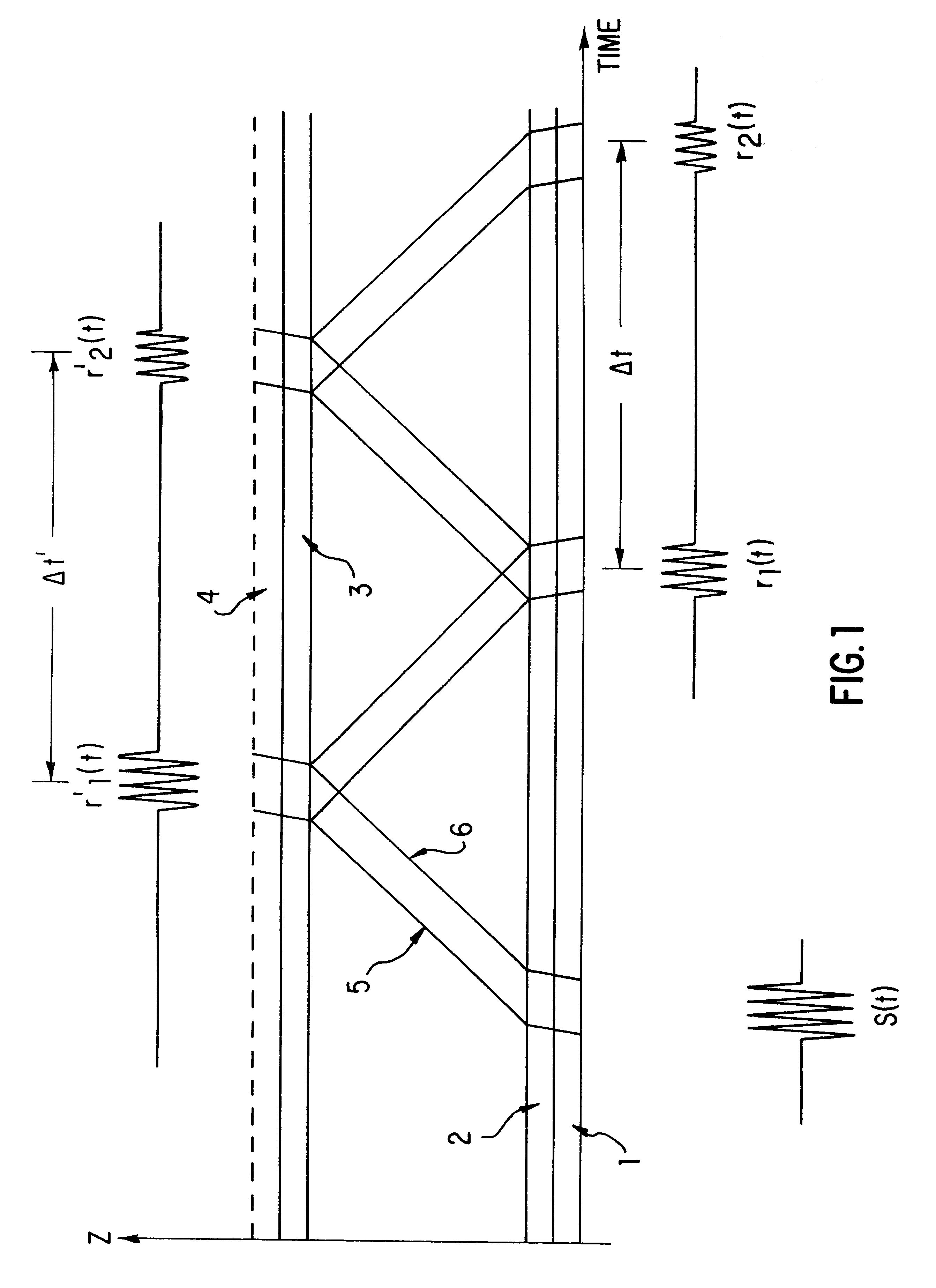

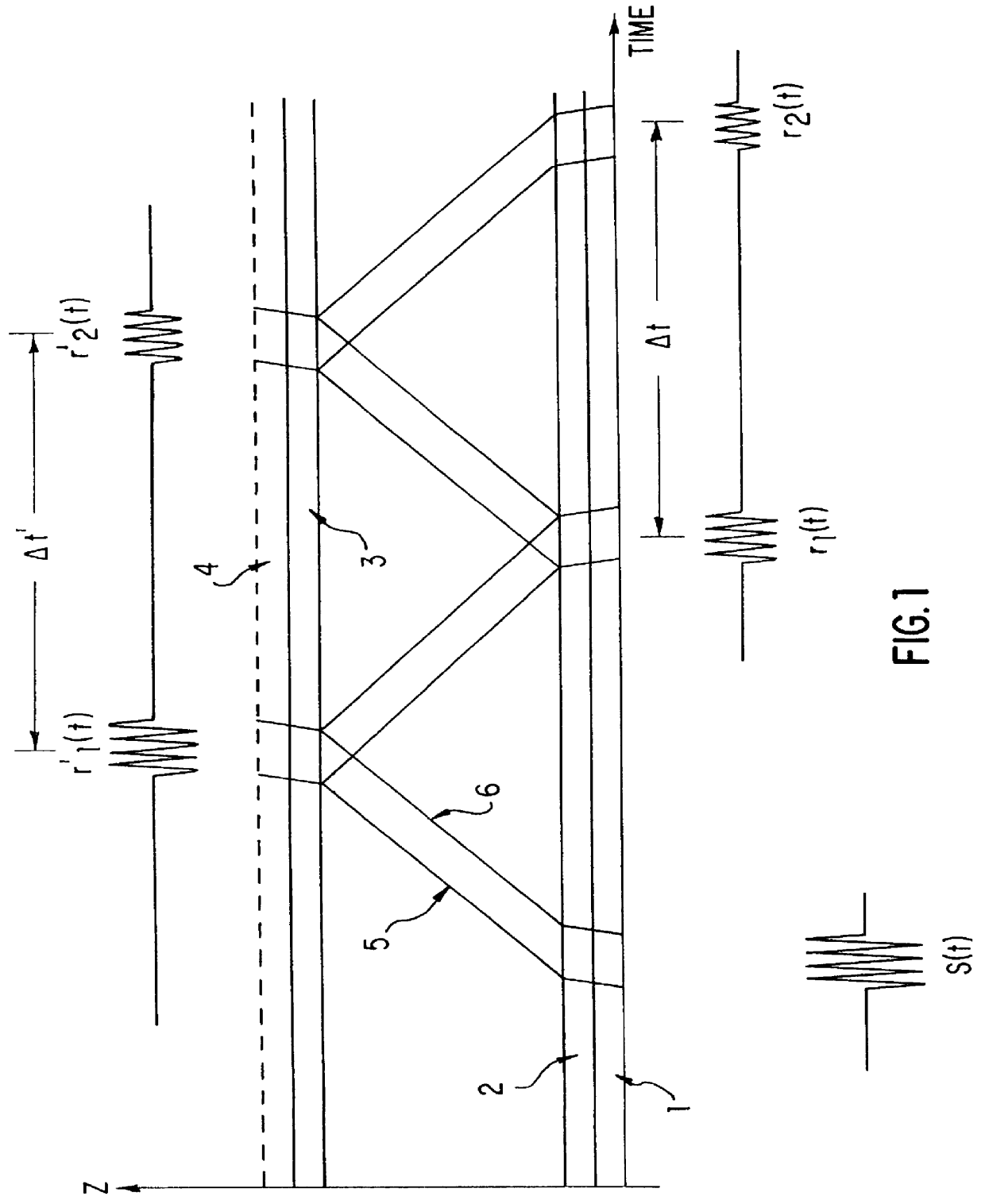

Apparatus and methods for performing acoustical measurements

InactiveUS6116080AGood repeatabilityAbsenceAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesFast Fourier transformTransformer

Apparatus and methods for performing acoustical measurements are provided having some and preferably all of the following features: (1) the system is operated under near-field conditions; (2) the piezoelement or piezoelements used in the system are (a) mechanically and electrically damped and (b) efficiently electrically coupled to the signal processing components of the system; (3) each piezoelement used in the system includes an acoustical transformer for coupling the element to a gaseous test medium; (4) speed of sound is determined from the time difference between two detections of an acoustical pulse at a receiver; (5) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (6) fast Fourier transform techniques are used to implement the cross-correlation techniques; and (7) stray path signals through the body of the acoustic sensor are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measures and on mixtures of compressible gases. Methods and apparatus for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

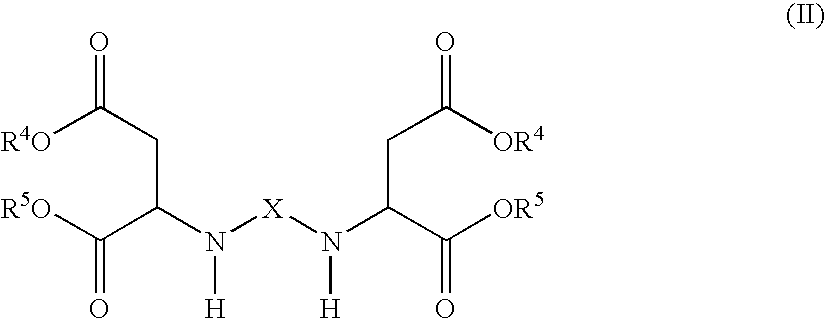

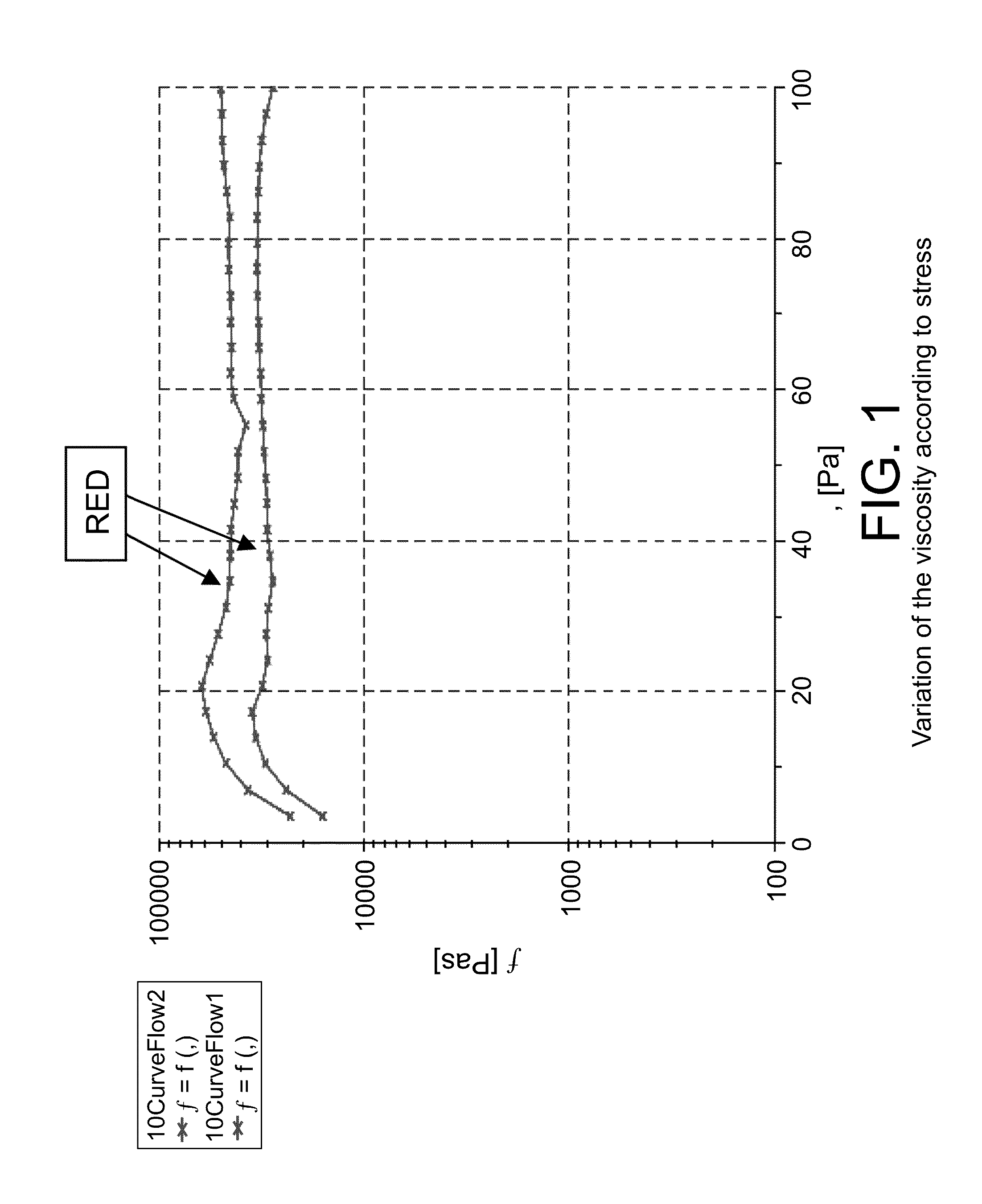

Polyurethane-urea elastomers

The present invention is directed to polyurethane-urea materials and to a process for their production. These polyurethane-ureas are preferably optically clear and comprise the reaction product of a (cyclo)aliphatic polyisocyanate or prepolymer thereof, with an isocyanate-reactive component that comprises one or more aromatic diamines which contains two primary amine groups, and one or more compounds containing two secondary amine groups which may be linked to aliphatic and / or aromatic moieties. This isocyanate-reactive component may additionally comprise one or more hydroxyl-functional compounds. The present invention offers a relatively fast “Green-Cure Time” of solid polyurethane-ureas which enables these to be demolded in a relatively short time period, followed by subsequent post-curing outside the mold.

Owner:COVESTRO LLC

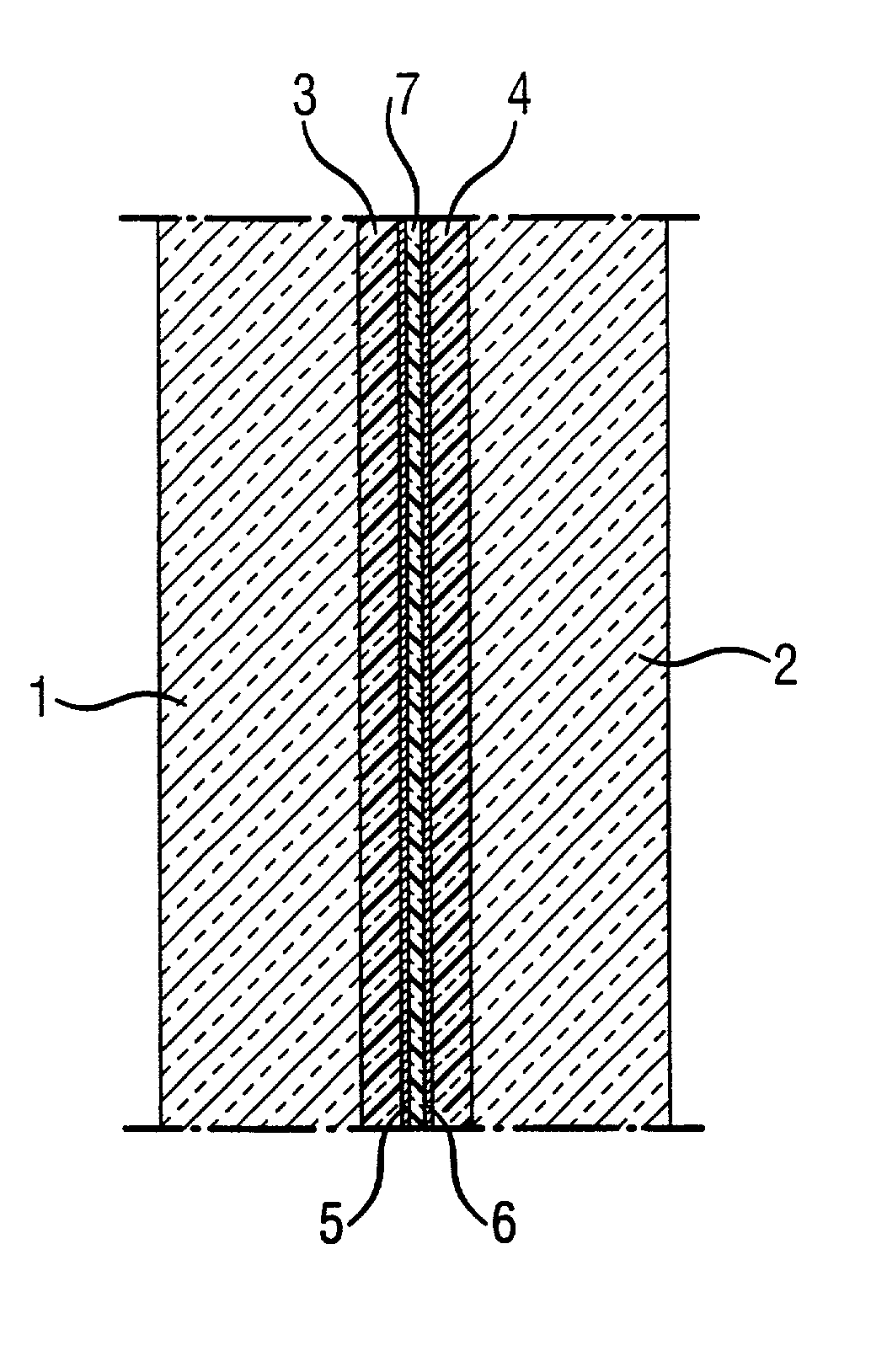

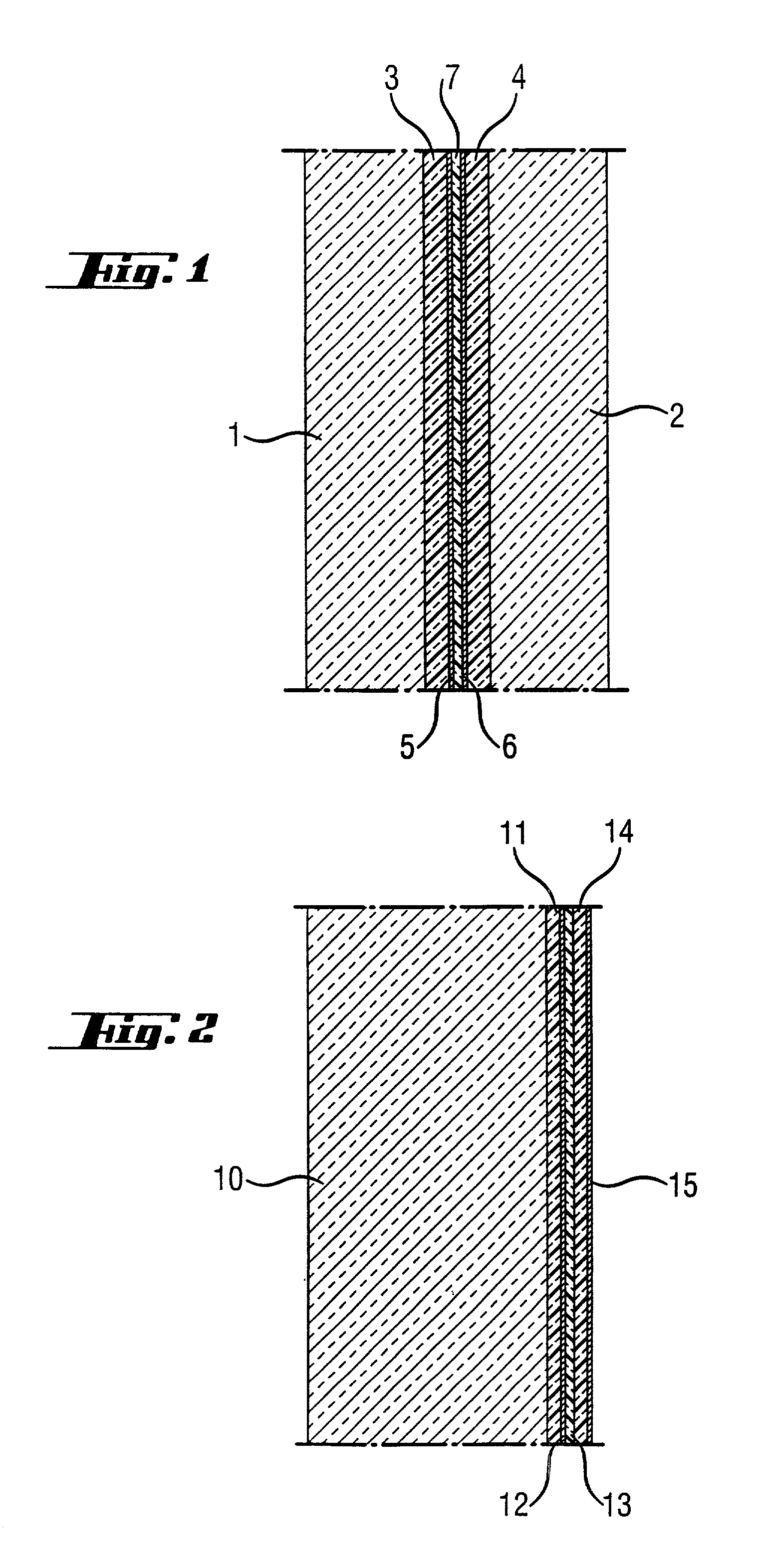

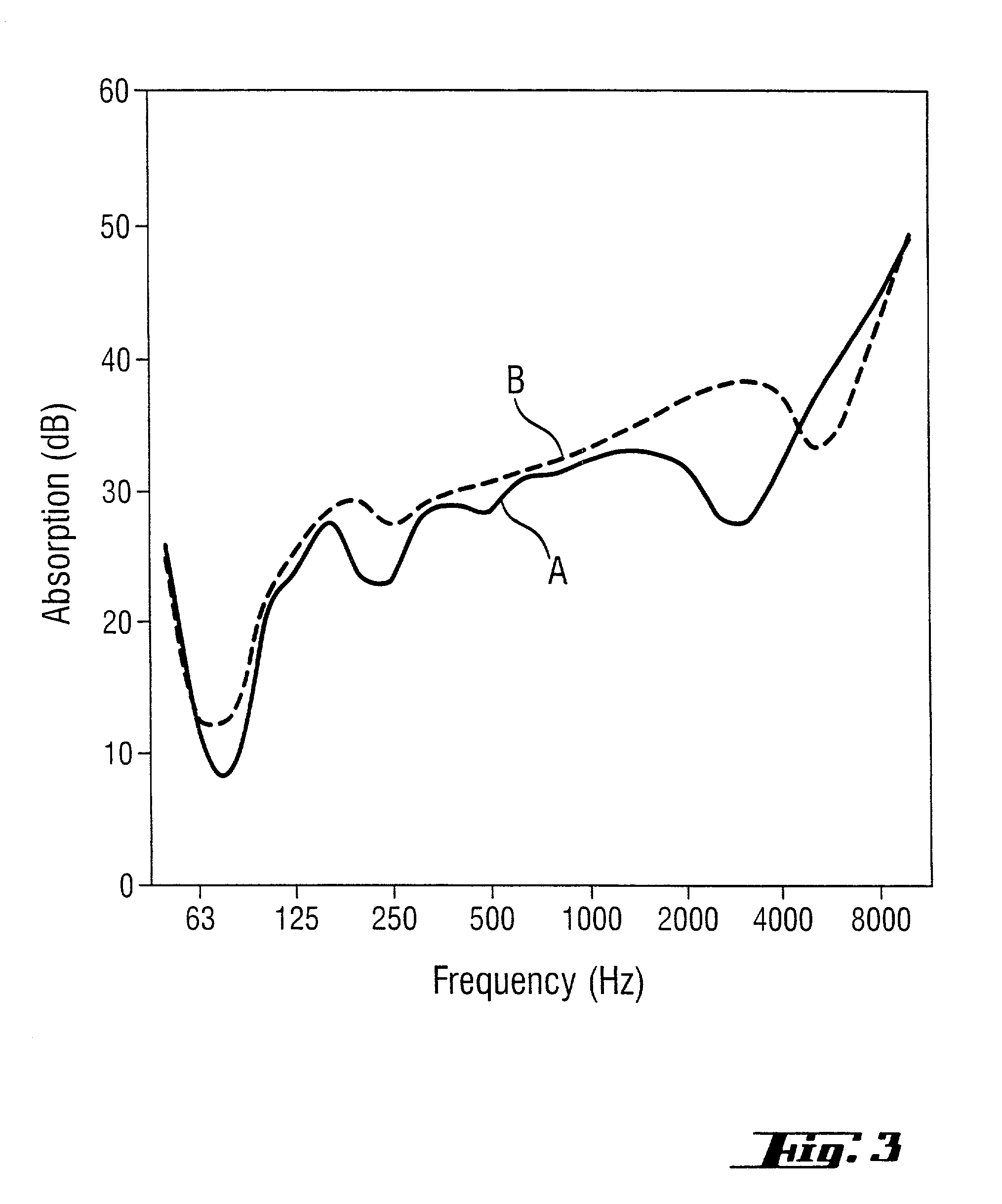

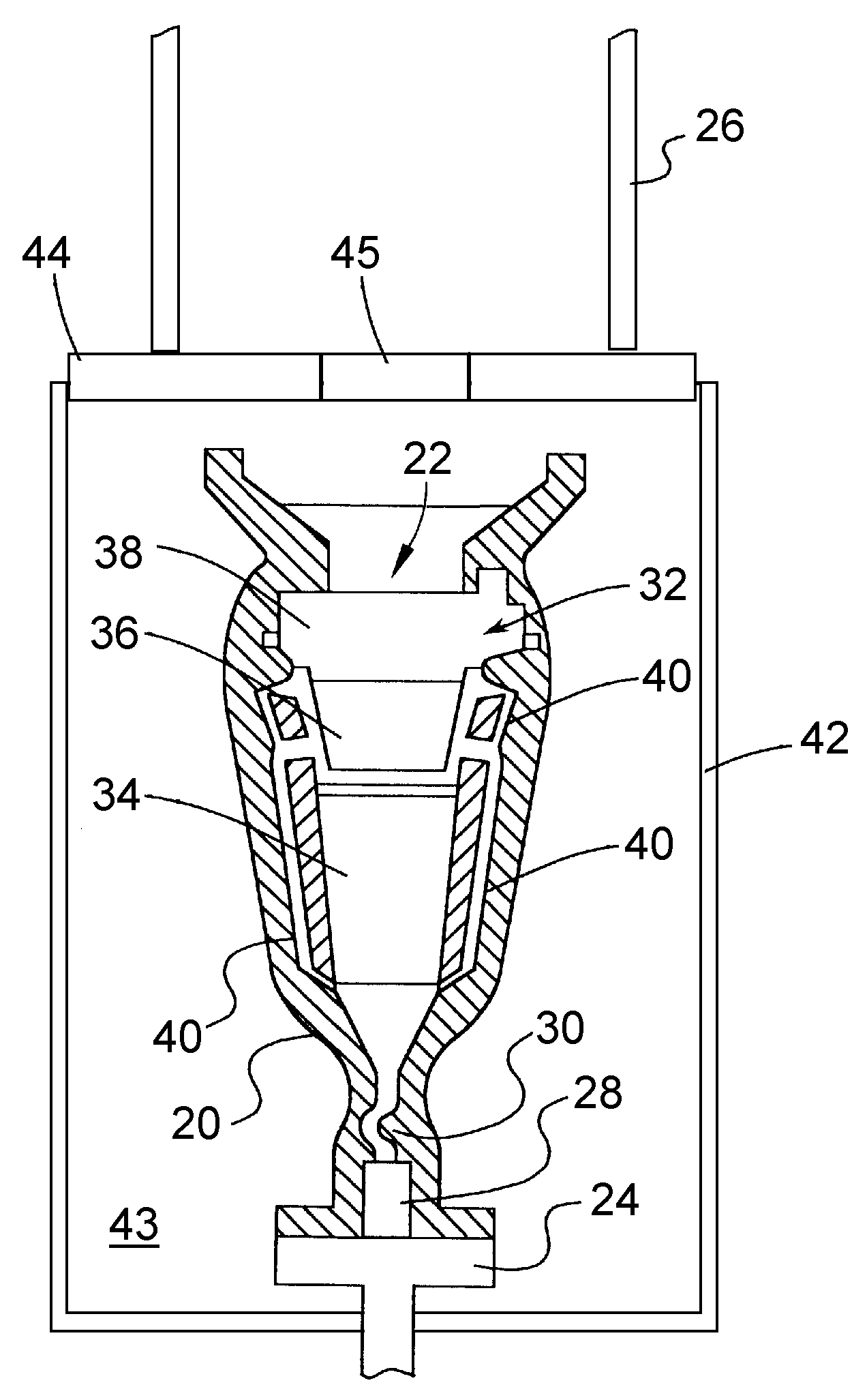

Soundproofing laminated window for vehicles

InactiveUS20020068177A1Reduce noise radiationExcellent ease of useWindowsWindscreensEngineeringElectrical and Electronics engineering

The invention relates to a soundproofing window in which an intermediate film provides for damping of vibrations transmitted in particular by structure-borne conduction.

Owner:SAINT GOBAIN VITRAGE SA

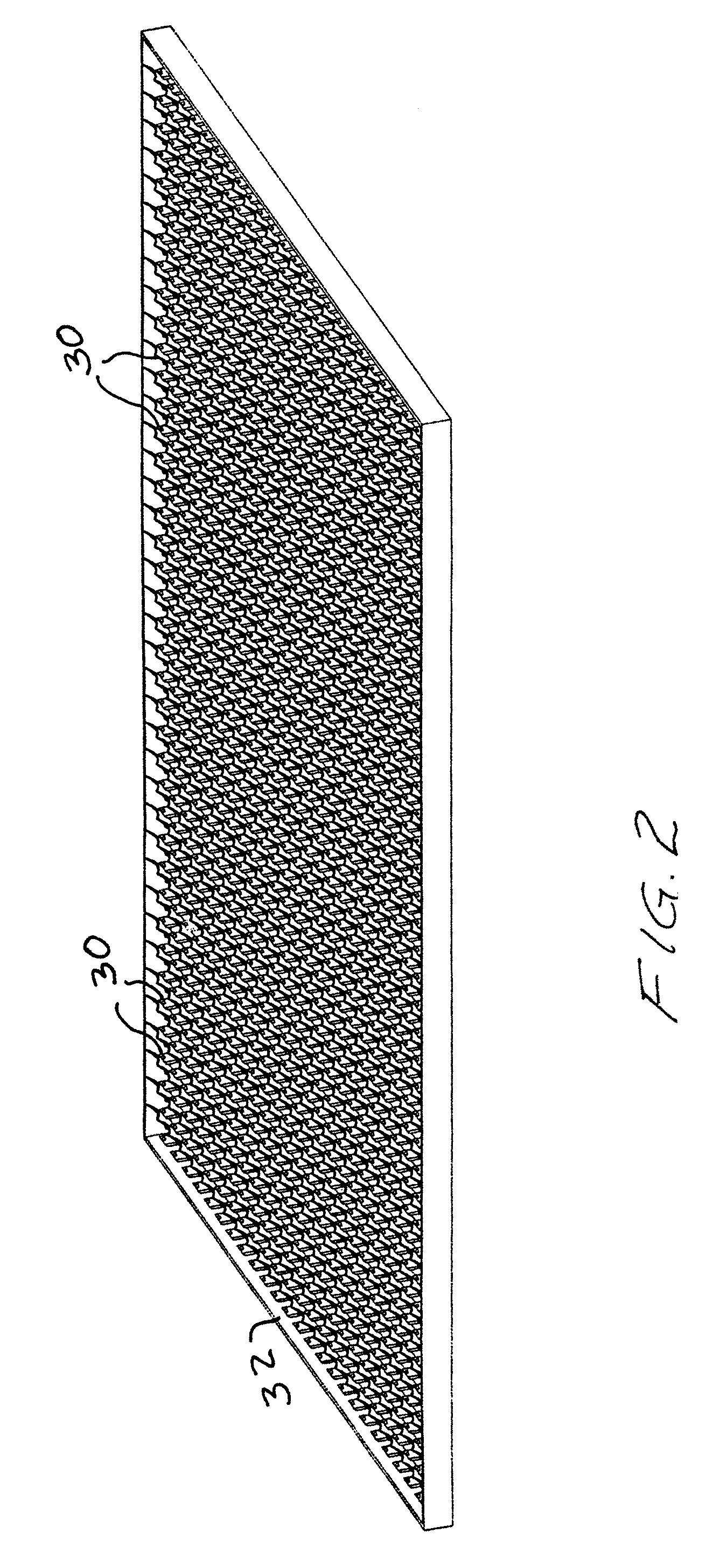

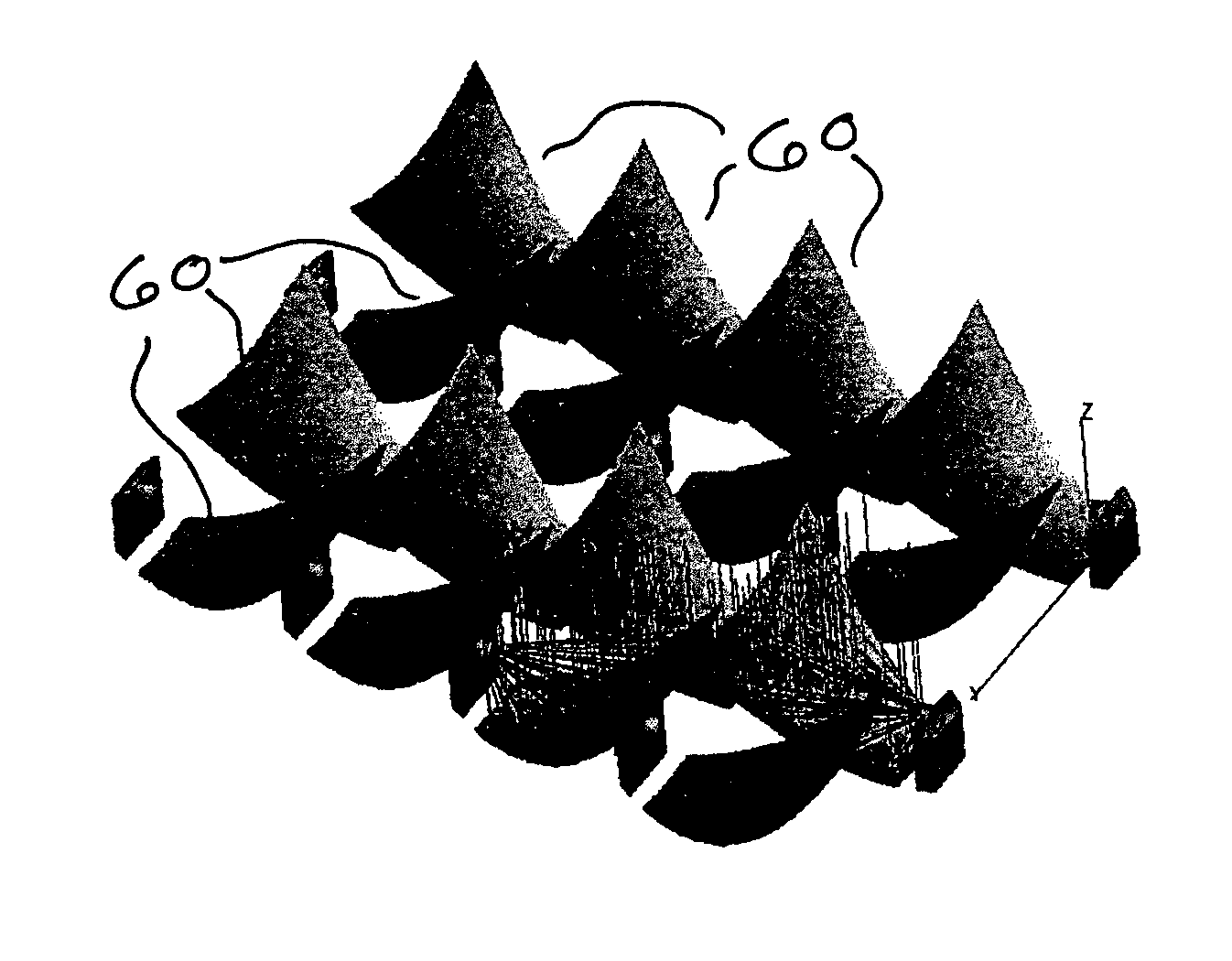

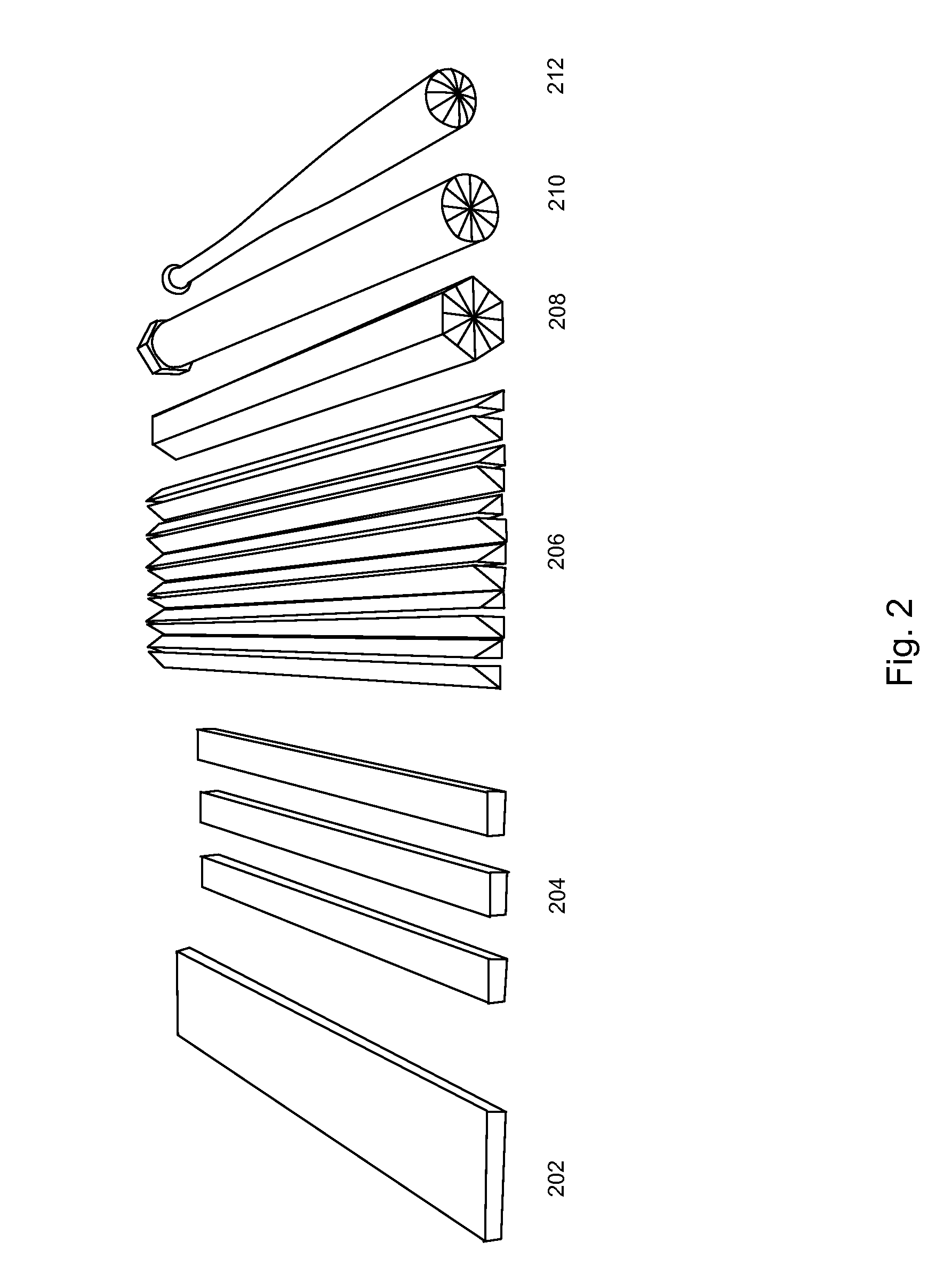

Compact micro-concentrator for photovoltaic cells

ActiveUS20050022858A1Reduce heatSatisfactory propertyPhotovoltaic supportsRoof covering using slabs/sheetsOptoelectronicsDirect radiation

A reflector array comprises a plurality of partial parabolic reflectors arranged in rows and columns with each reflector directing radiation to a receiver or from a transmitter located at the focus of the reflector. In a compact photovoltaic cell arrangement, each cell is shielded from direct radiation by the adjacent reflector. The reflectors can be formed as one unit with reflective material or with the reflecting surfaces coated with aluminum, silver, or other suitable reflecting material. A secondary reflector can be positioned at the focus of a reflector for directing radiation to a receiver or from a transmitter located at a more accessible location in the array.

Owner:CREDIT SUISSE CAYMAN ISLANDS BRANCH

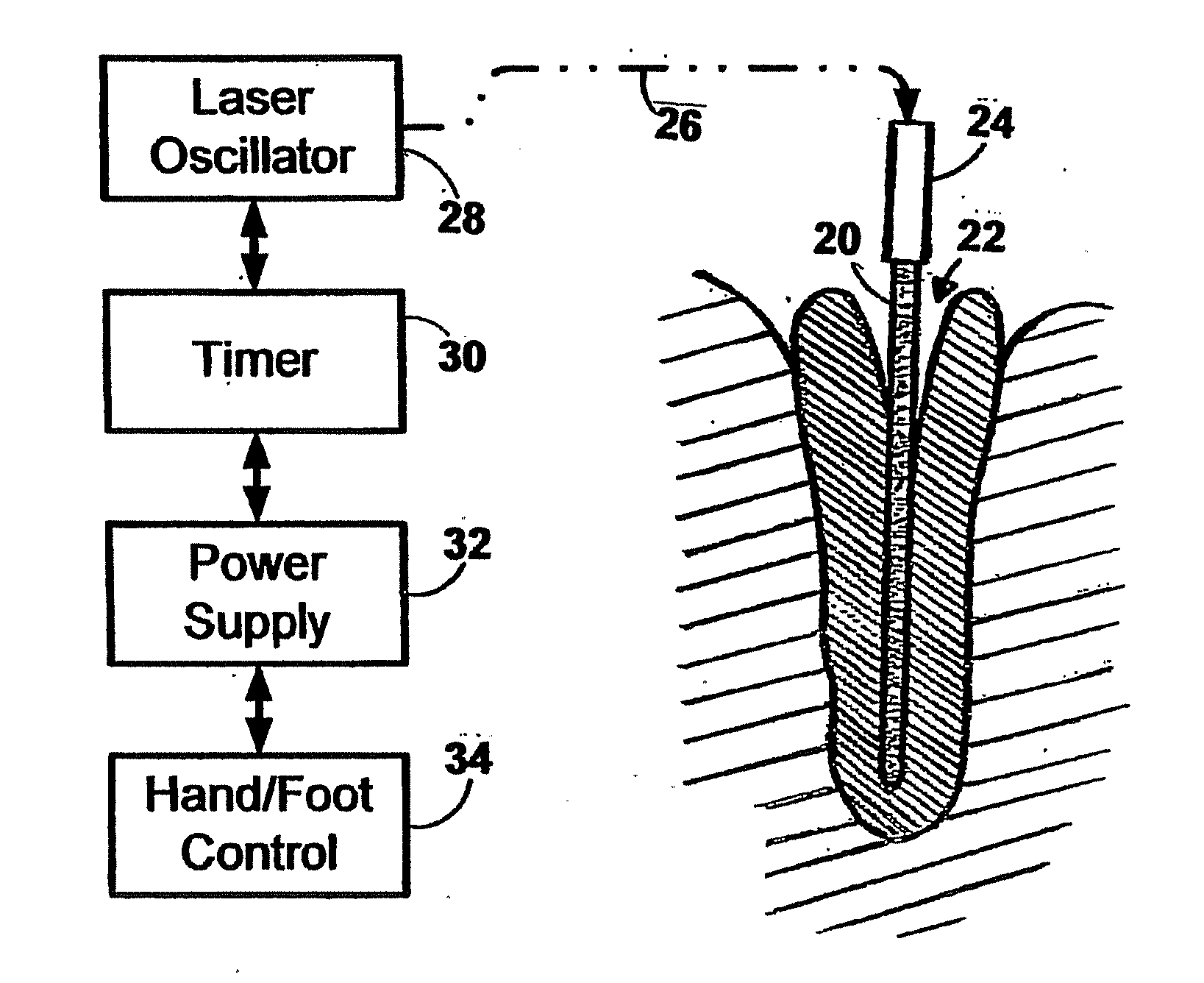

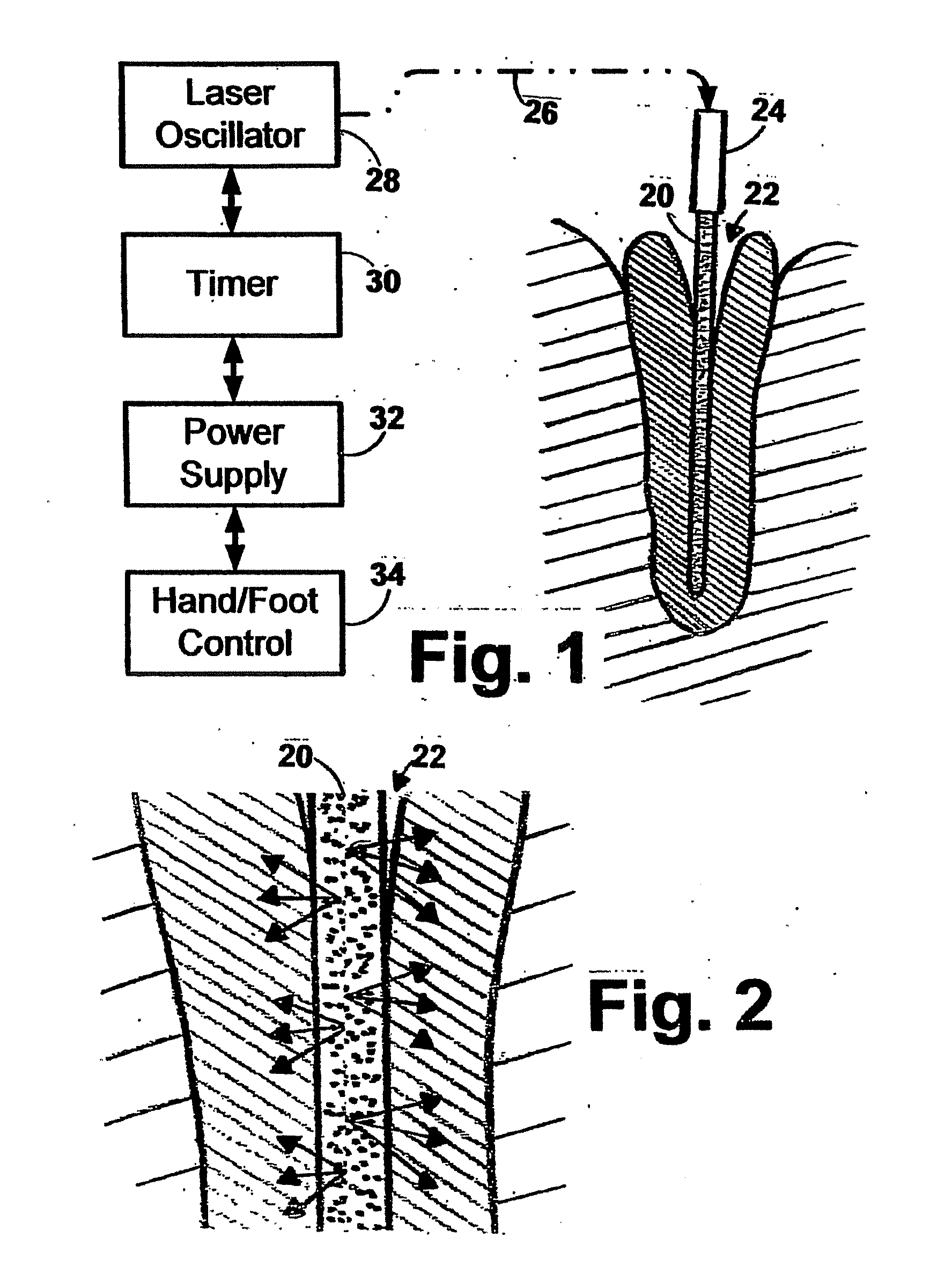

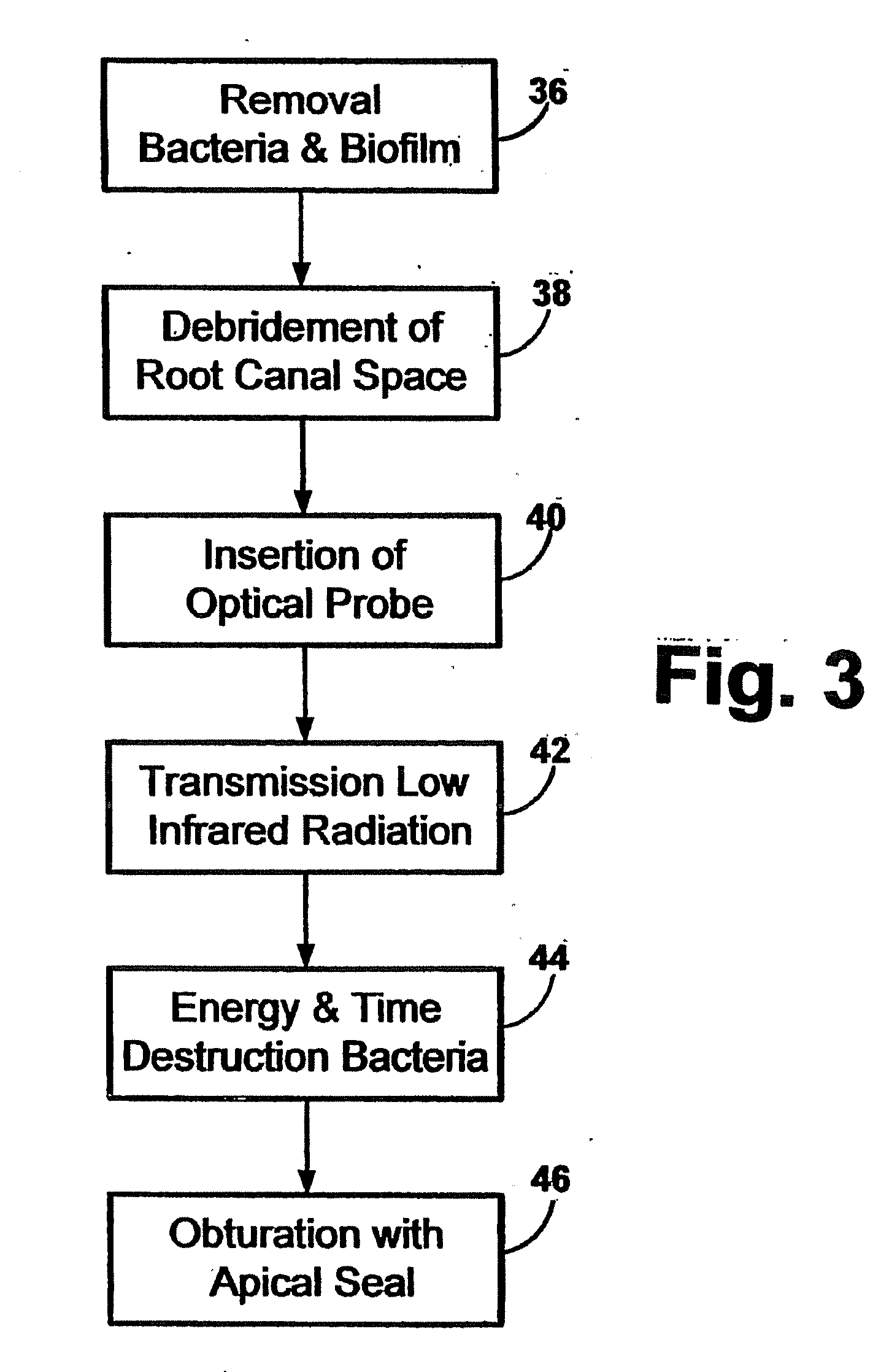

Instrument for Delivery of Optical Energy to the Dental Root Canal System for Hidden Bacterial and Live Biofilm Thermolysis

InactiveUS20080138772A1Lower average energyAbsenceDental toolsLight therapyOrganismTooth Supporting Structures

Systems, processes, techniques, and apparatus are described for thermolytic eradication of bacteria and biofilm in the root canal of a human tooth involve an elongated and flexible optical probe and a laser oscillator that provides the probe with near infrared energy. The optical probe can be sufficiently long for insertion into substantially the entire length of the root canal of the tooth. The optical probe causes lateral dispersion of the radiation from the probe throughout the root canal. The radiation is provided at an energy density and for a period of time that are necessary to selectively target bacteria and live biofilm in the dentinal tubules of an entire root canal system, at once, thereby (1) inhibiting creation of a blackbody “hot tip”, and (2) inducing laser interstitial thermotherapy (LITT) within the root-canal space. Near infrared wavelengths from about 700 nm through about 1100 nm can be used.

Owner:NOMIR MEDICAL TECH

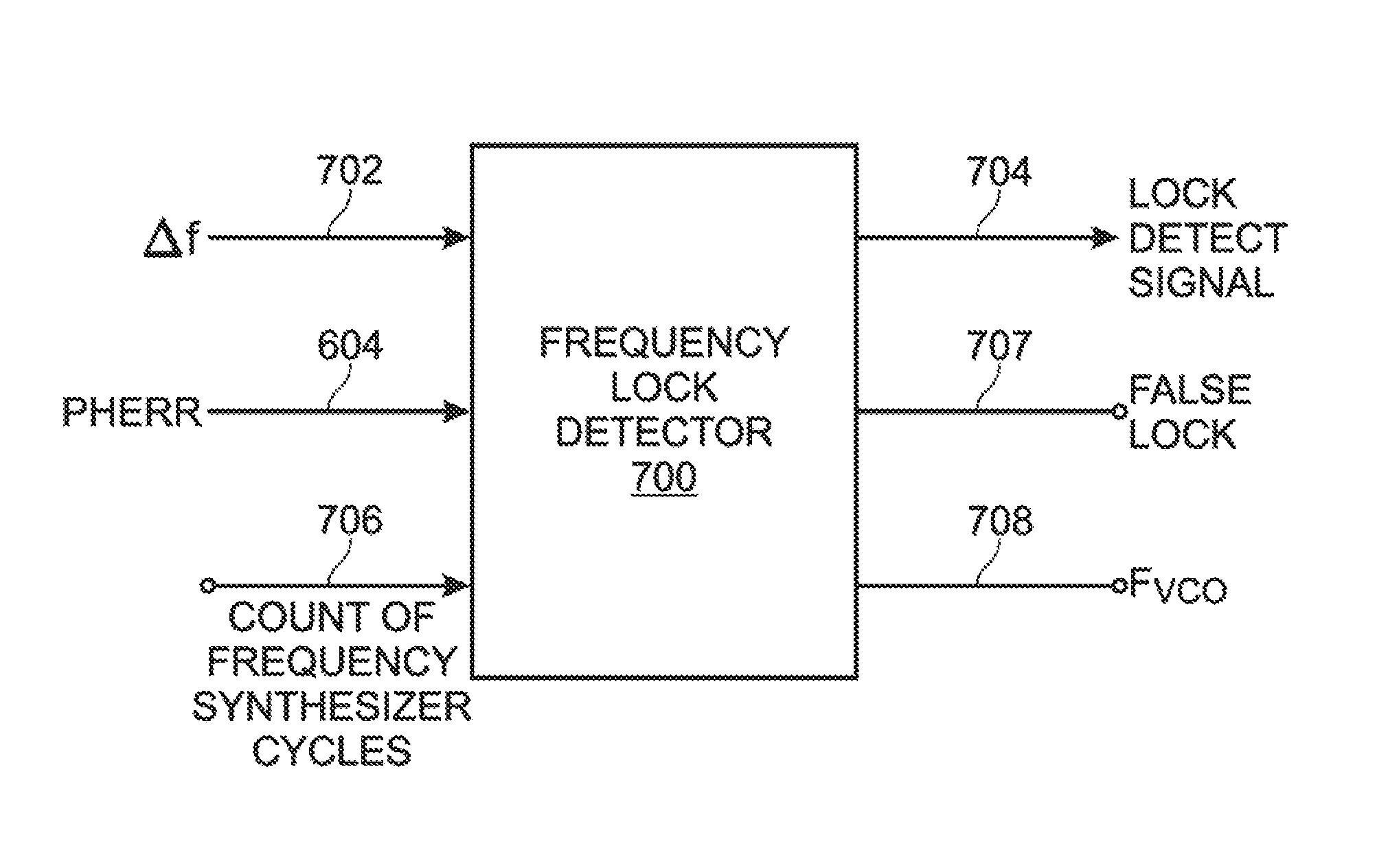

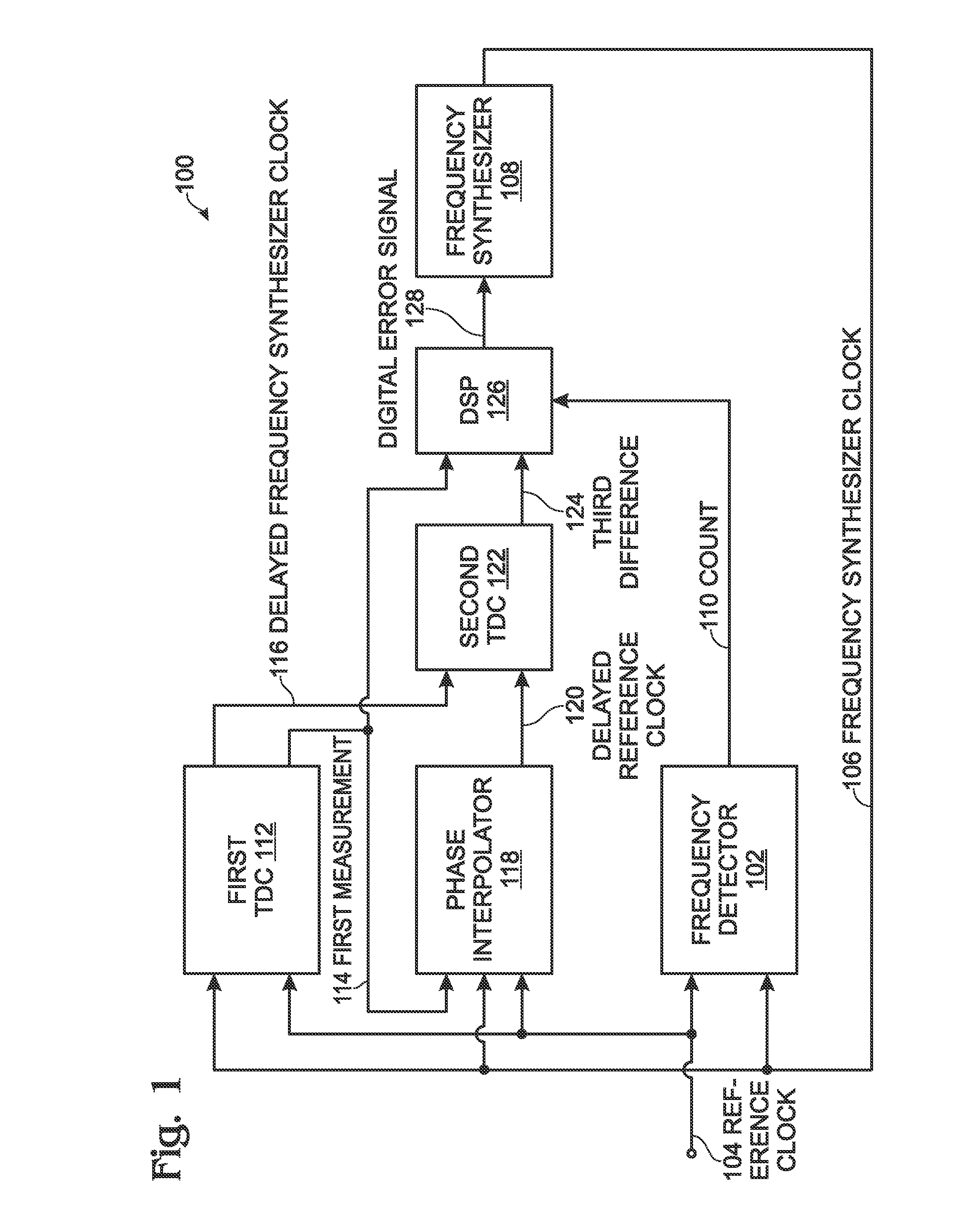

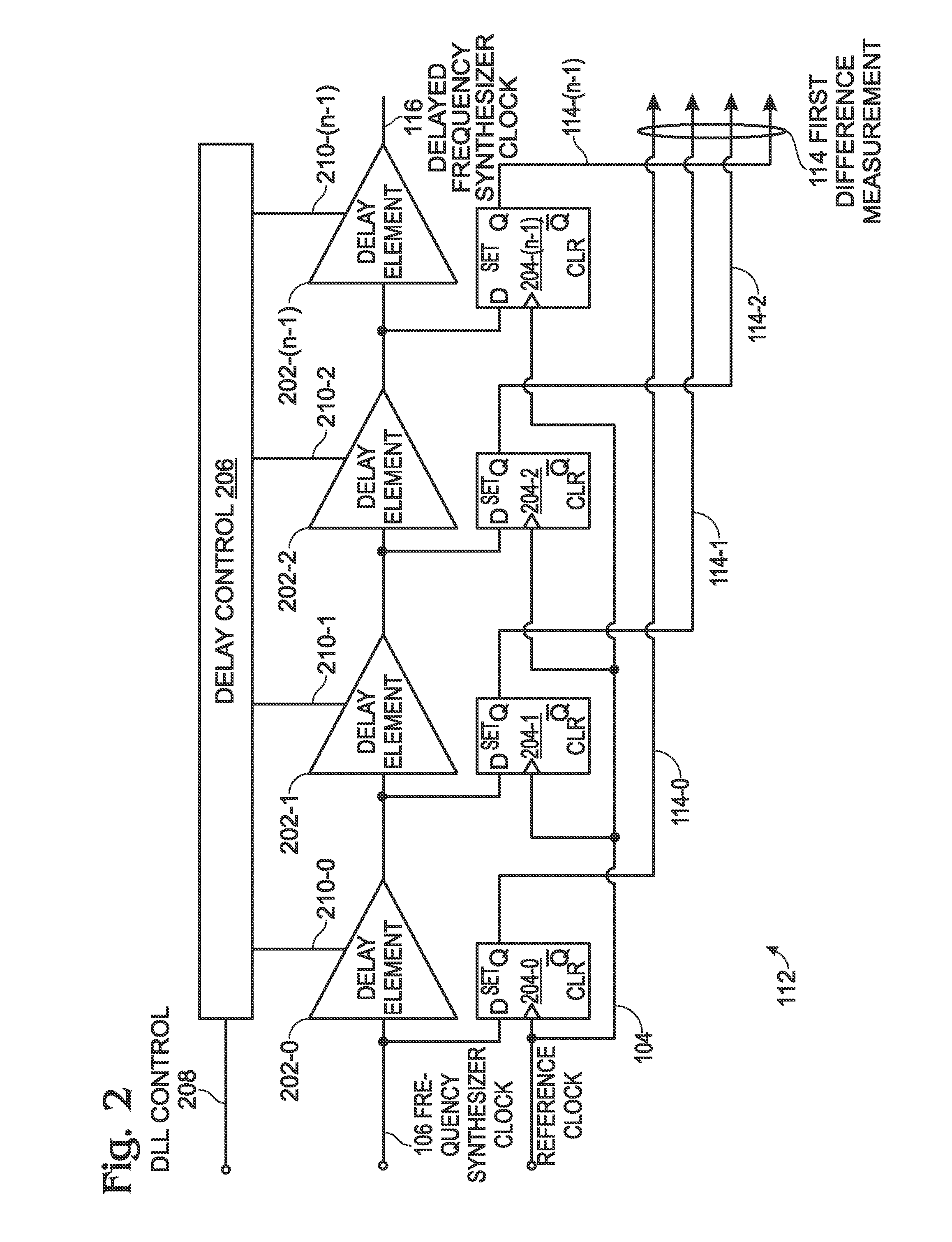

Lock detection using a digital phase error message

ActiveUS8248106B1Improve performanceReduce power consumptionPulse automatic controlFrequency/rate-modulated pulse demodulationClock rateEngineering

A system and method are provided for frequency lock detection using a digital phase error. A lock detection module accepts a digital phase error (pherr) message proportional to an error in phase between a reference clock and a (synthesizer clock*Nf). Also accepted is a unitless frequency error tolerance value (Δf). The lock detection module periodically supplies a lock detect signal, indicating whether the synthesizer clock frequency is within the frequency error tolerance value of the reference clock frequency.

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

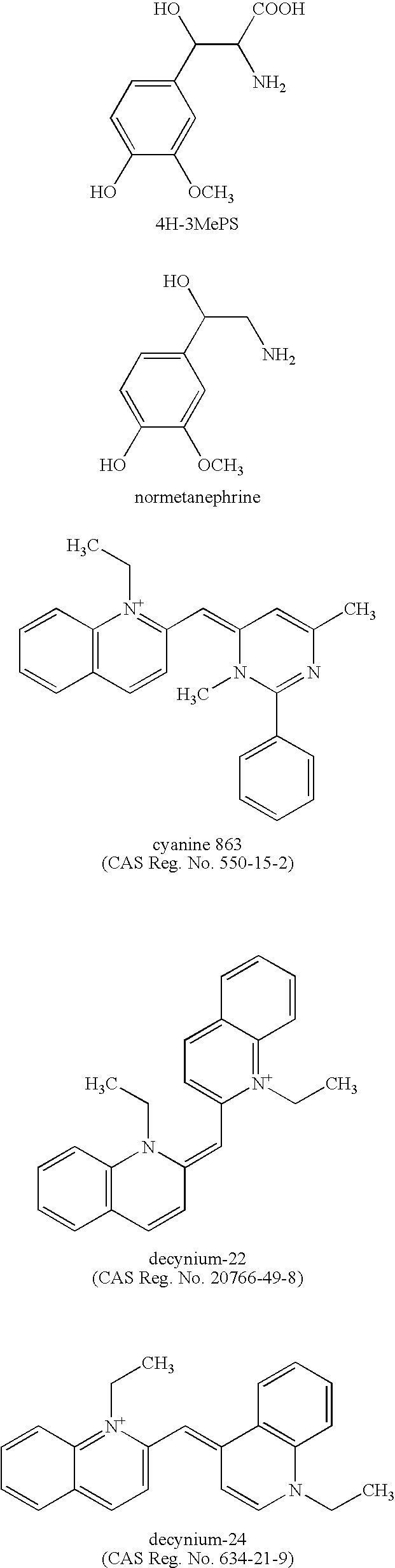

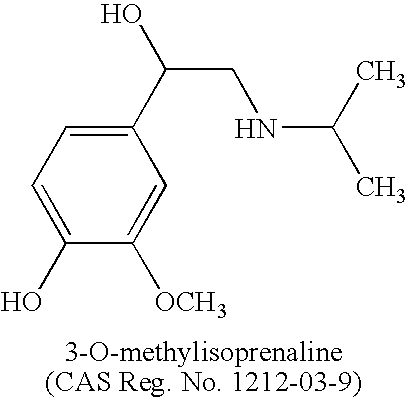

Methods for the Treatment of ADHD and Related Disorders

The invention features methods, compositions, and kits for the treatment of attention deficit hyperactivity disorder and related behavioral disorders by administering an organic cation 3 (hOCT3) inhibitor.

Owner:THE MCLEAN HOSPITAL CORP

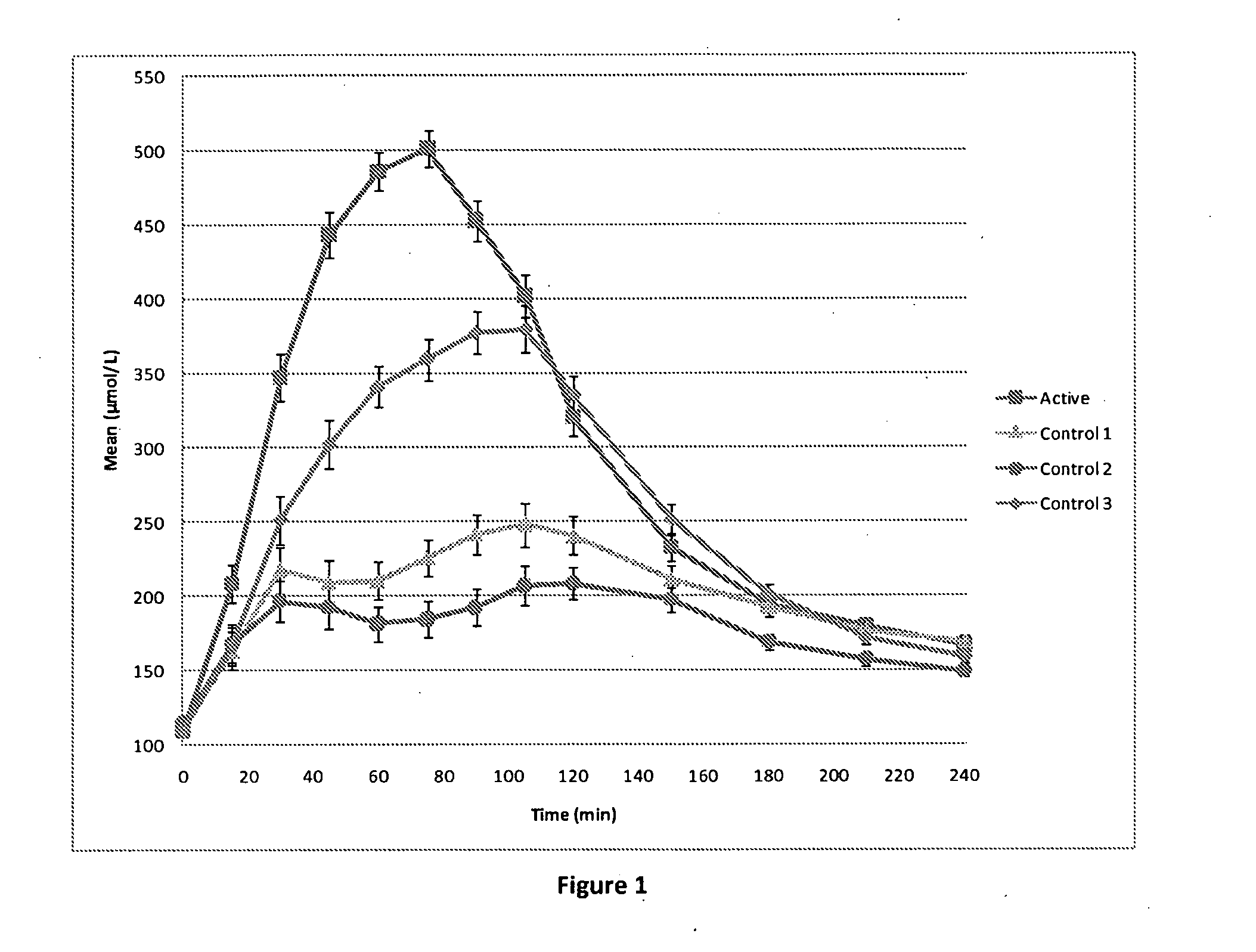

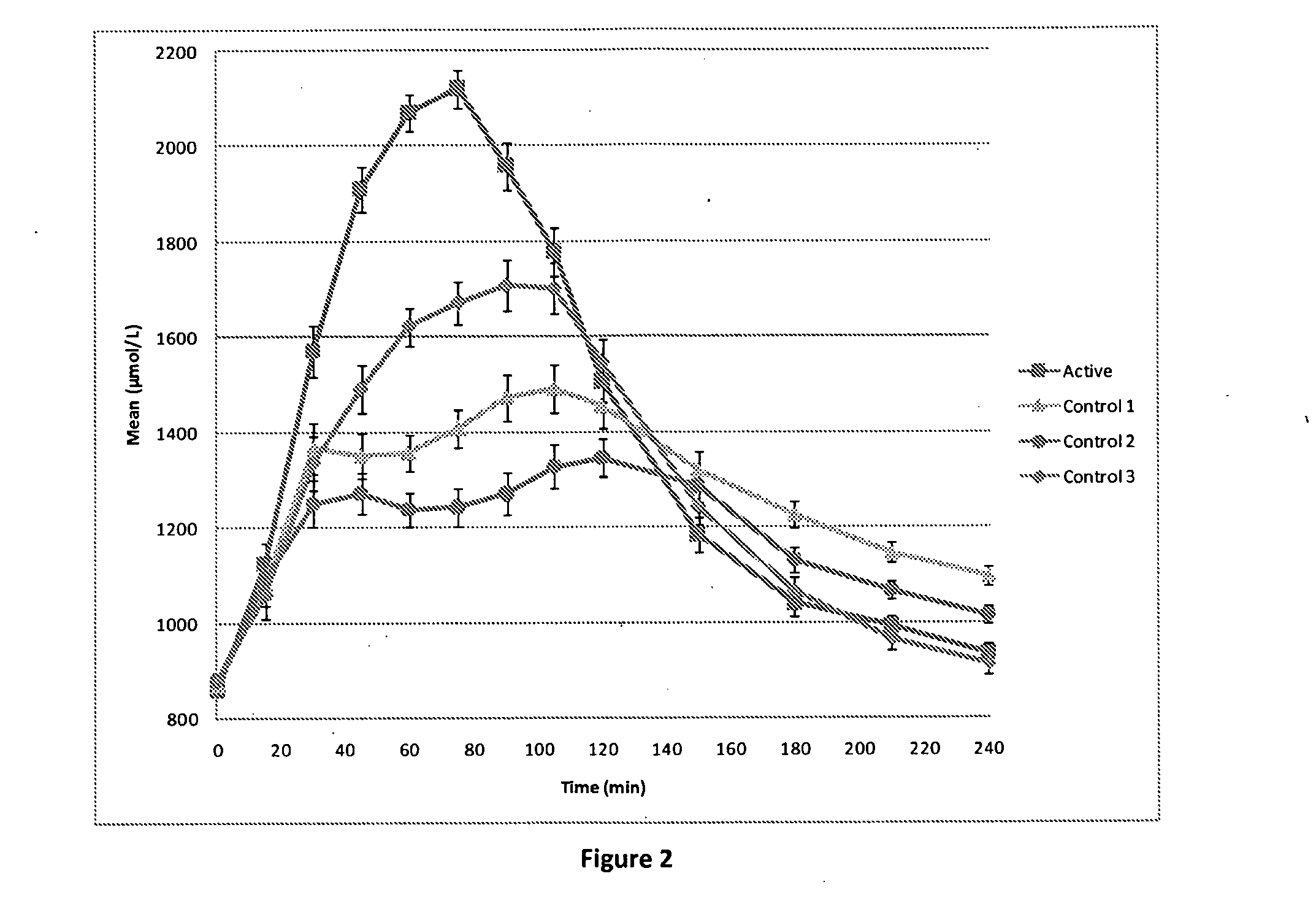

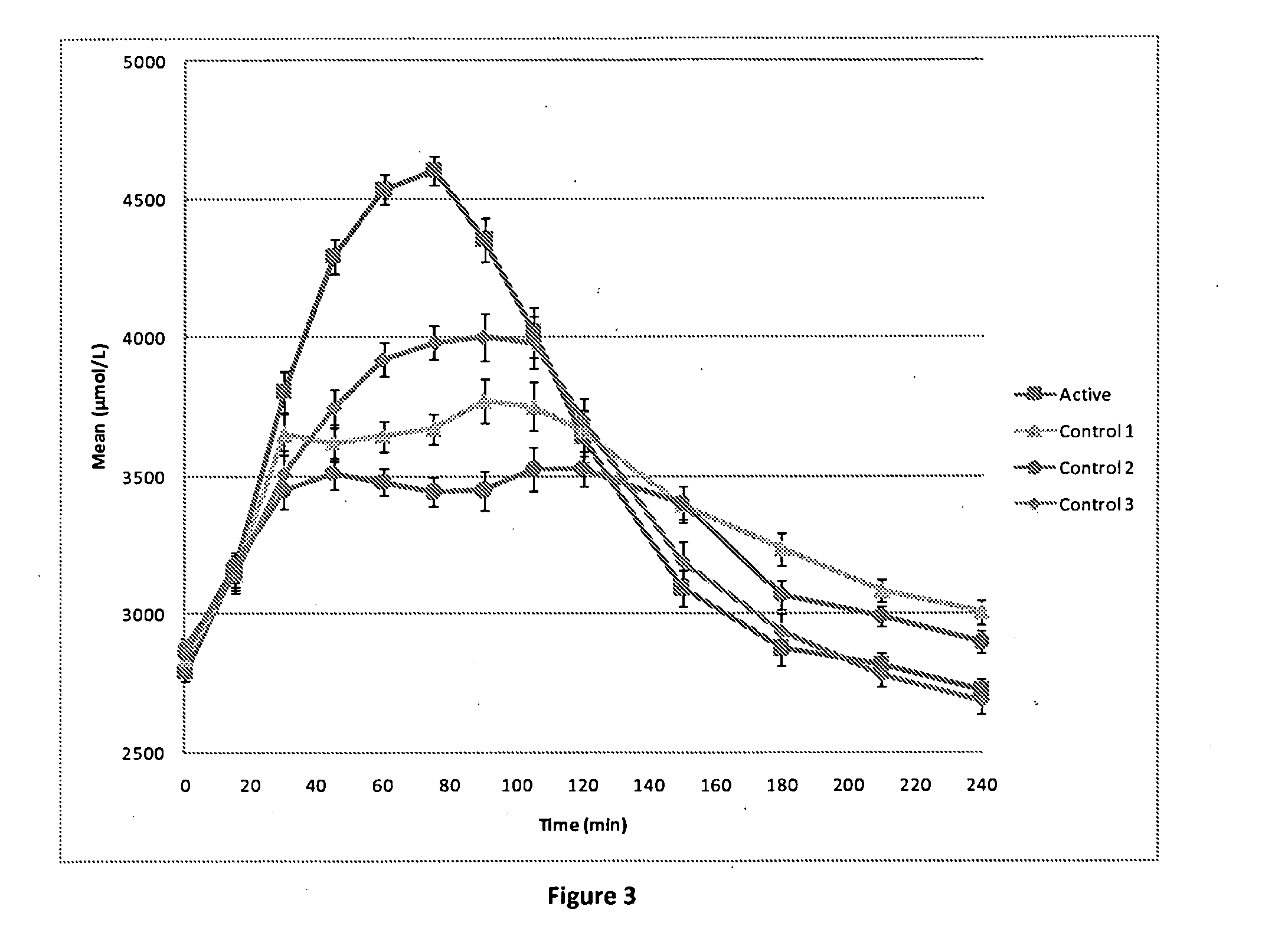

Low-caloric high-protein nutritional composition for the stimulation of muscle protein synthesis

ActiveUS8846759B2Improve bioavailabilityReduce heatBiocidePeptide/protein ingredientsDiseaseFree form

The present invention relates to the use of a low-caloric high-protein nutritional composition for use in the prevention or treatment of a disease or condition in a mammal, which involves muscle decline, as well as to specific low-caloric high-protein nutritional compositions for stimulating muscle protein synthesis in a mammal. In particular, the invention relates to the use of a nutritional composition comprising per 100 kcal: (i) at least about 12 g of proteinaceous matter which comprises at least about 80 weight % of whey protein, relative to the total proteinaceous matter, and which comprises at least about 11 weight % of leucine, relative to the total proteinaceous matter, of which at least about 20 weight % is in a free form, relative to the total leucine, (ii) a source of fat and a source of digestible carbohydrates, for the prevention or treatment of a disease or condition which involves muscle decline in a mammal, especially an elderly mammal, wherein the nutritional composition is administered as 1 to 2 servings daily, each serving comprising between 80 and 200 kcal.

Owner:NV NUTRICIA

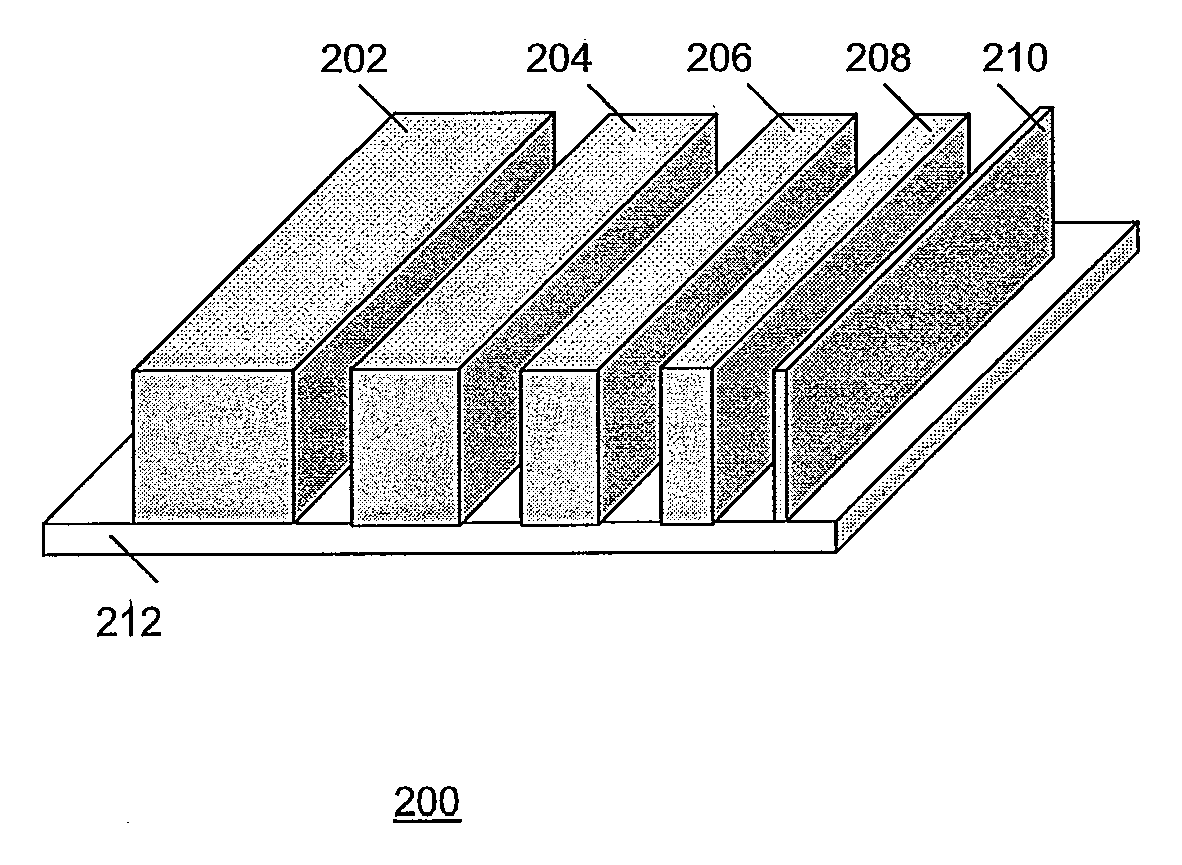

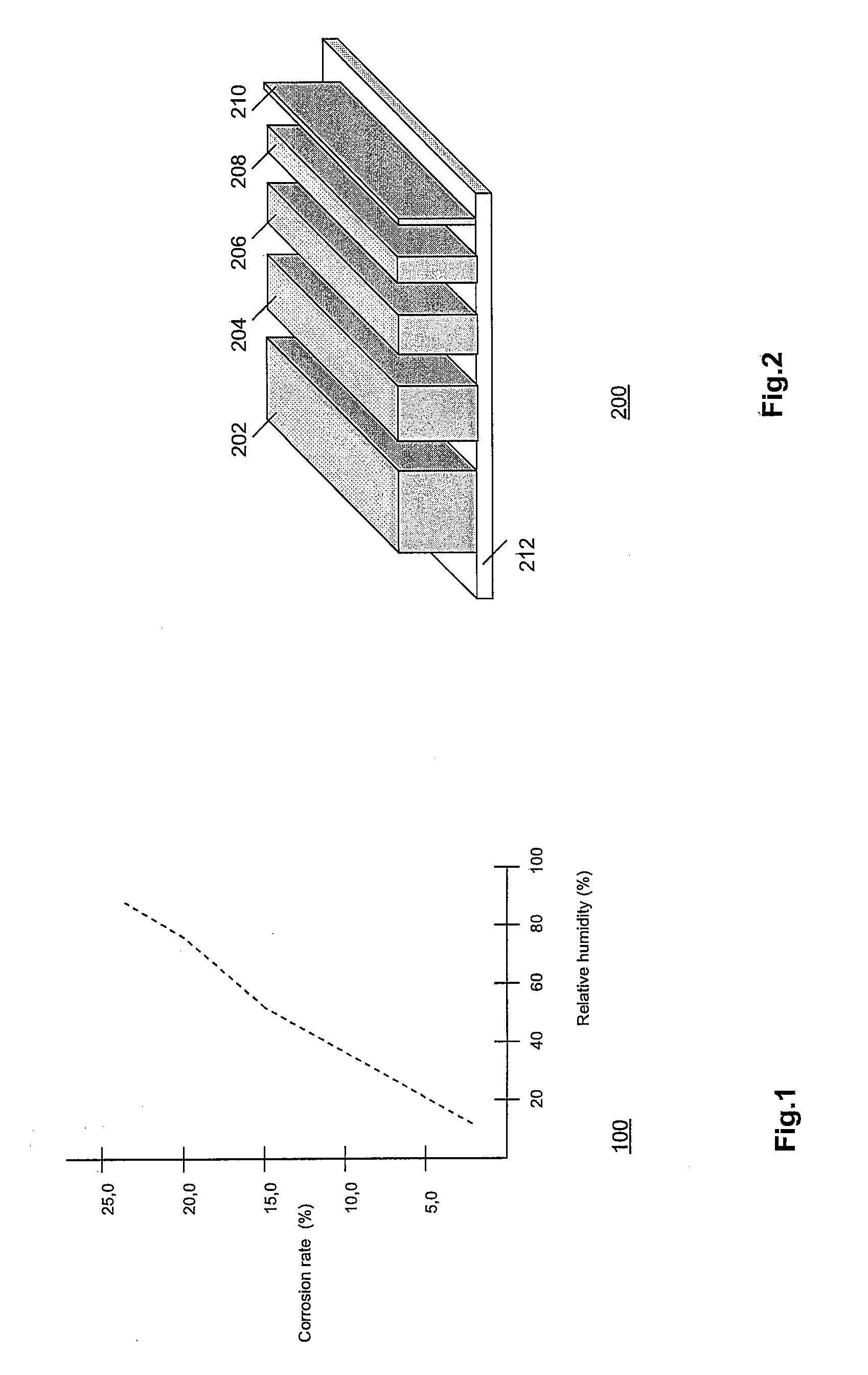

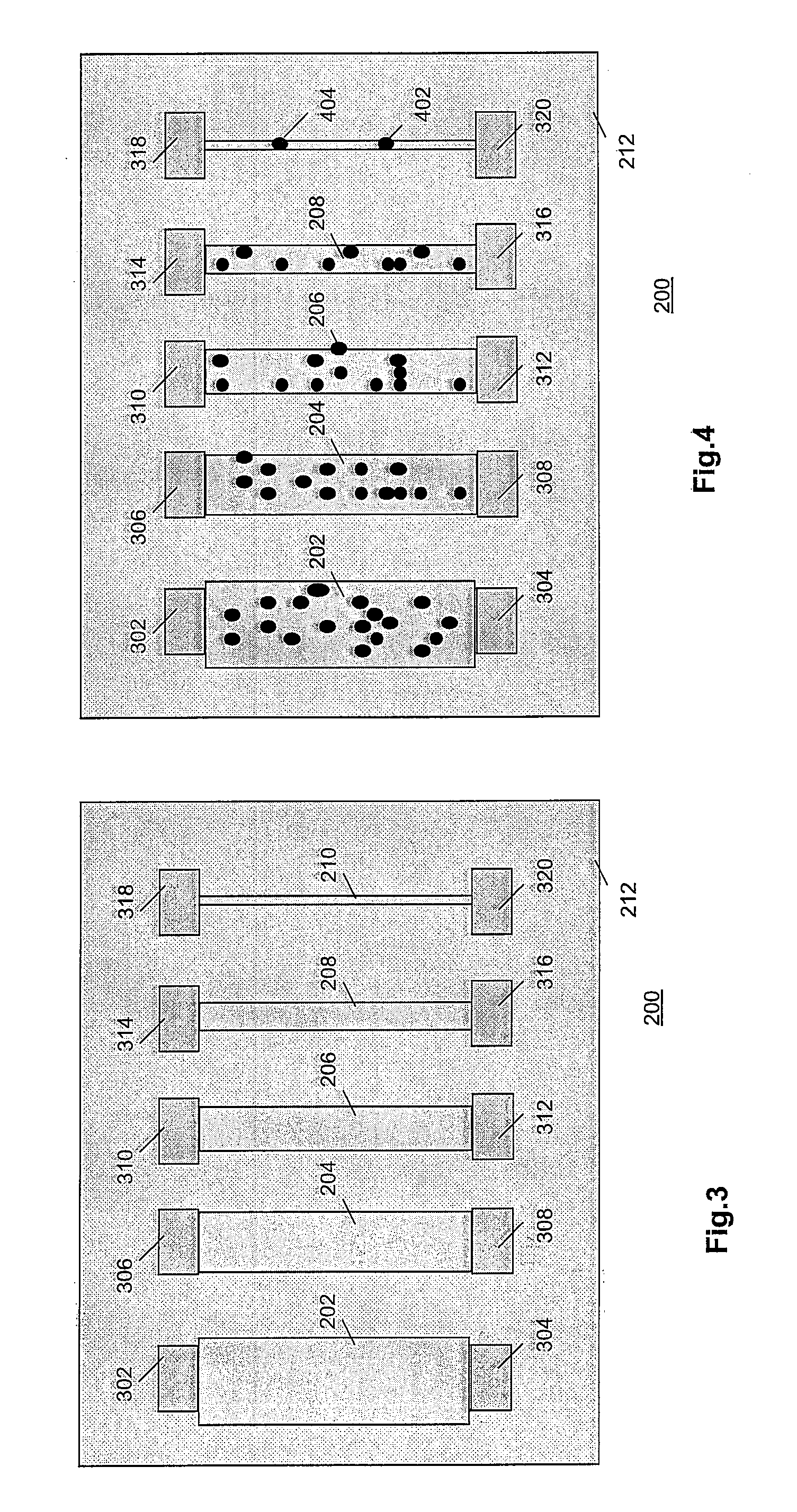

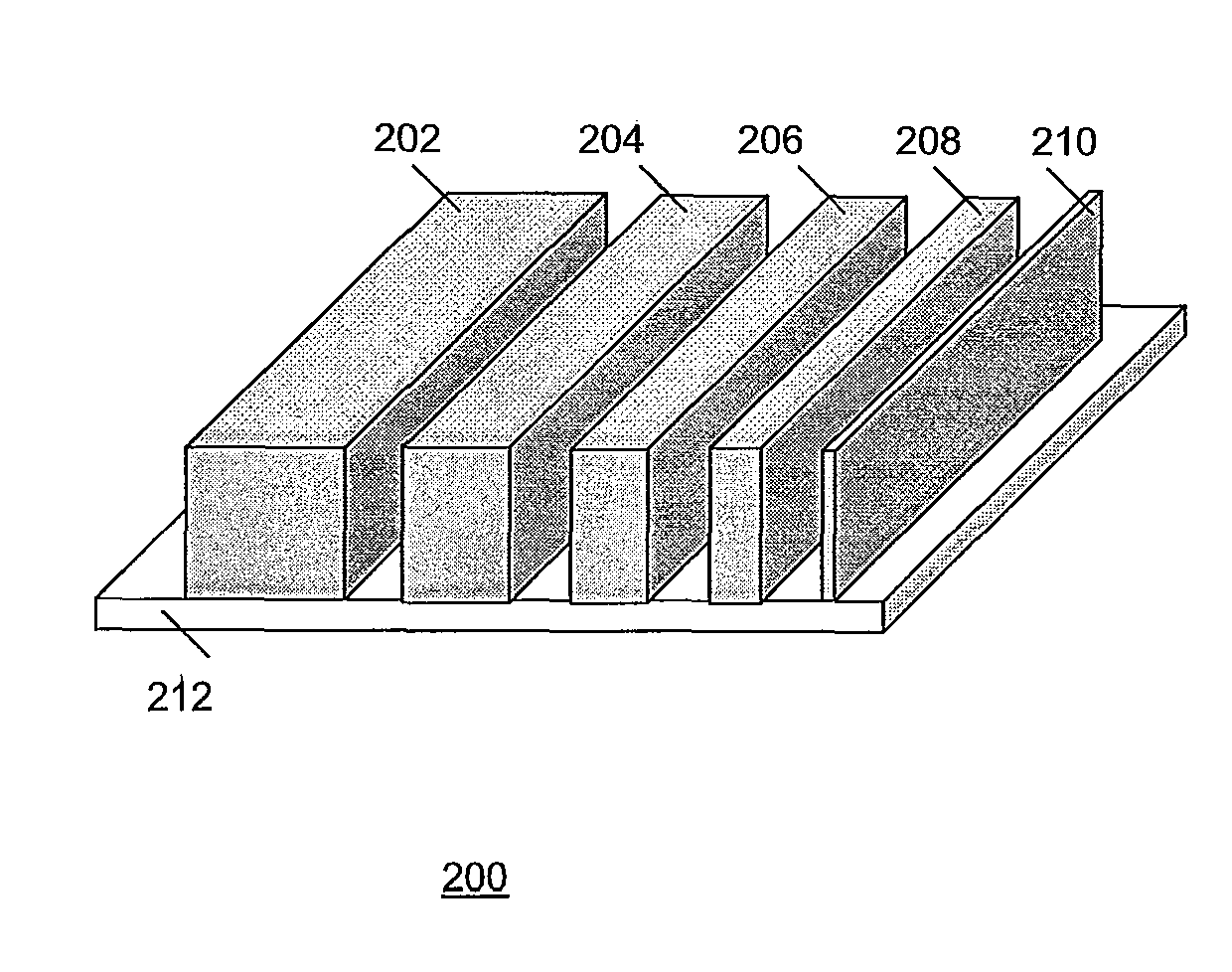

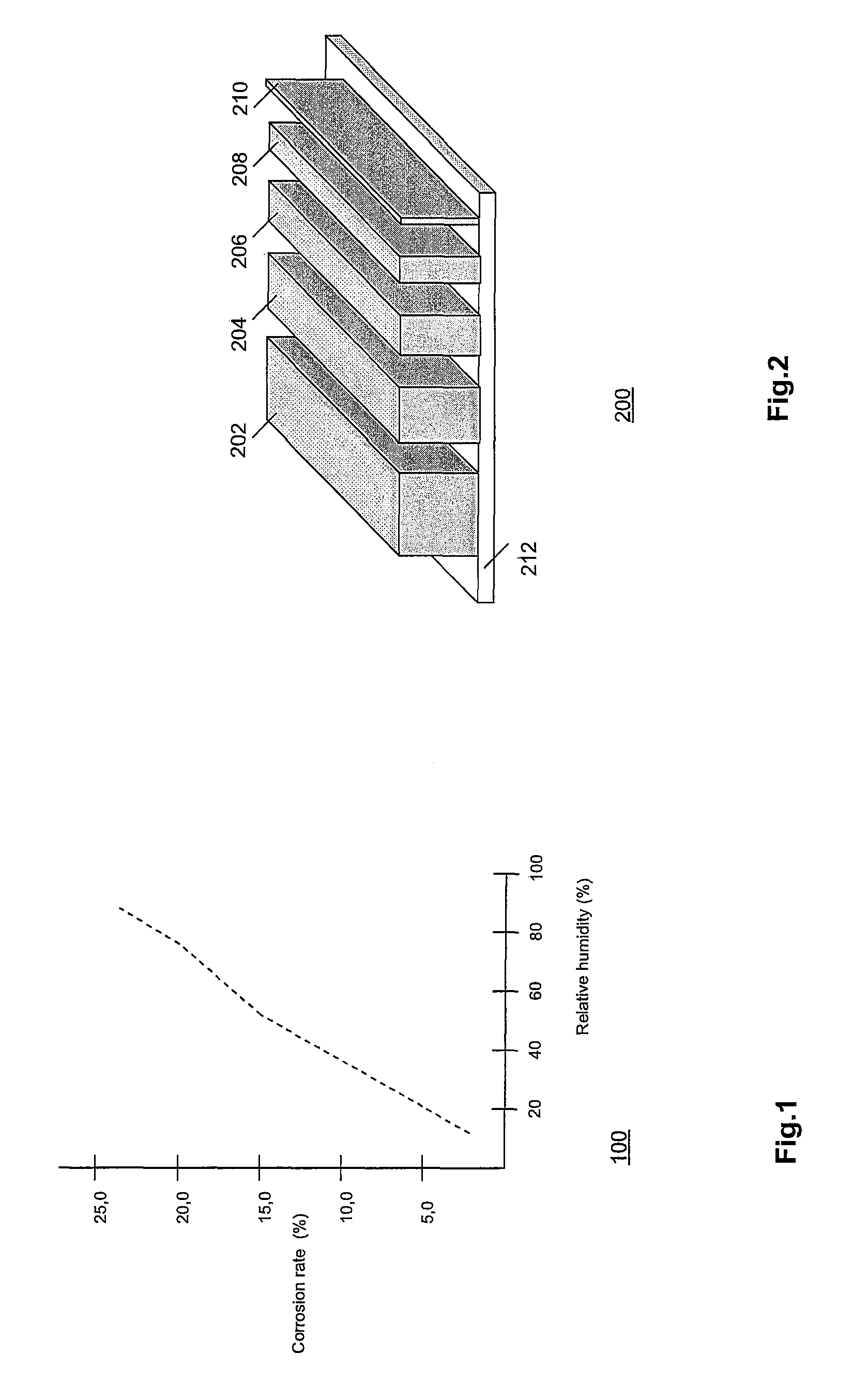

Humidity sensor based on progressive corrosion of exposed material

InactiveUS20100192688A1Easy to controlCorrosion controlWeather/light/corrosion resistanceUsing mechanical meansCorrosionEngineering

A sensor senses a characteristic of an environment, e.g., humidity. The sensor has a substrate with strips of material that is sensitive to corrosion as a result of the characteristic. The strips are configured to respond differently to the characteristic. By means of repeatedly measuring the resistances of the strips, the environment can be monitored in terms of accumulated exposure to the characteristic. The strips are manufactured in a semiconductor technology so as to generate accurate sensors that behave predictably.

Owner:AMS INT

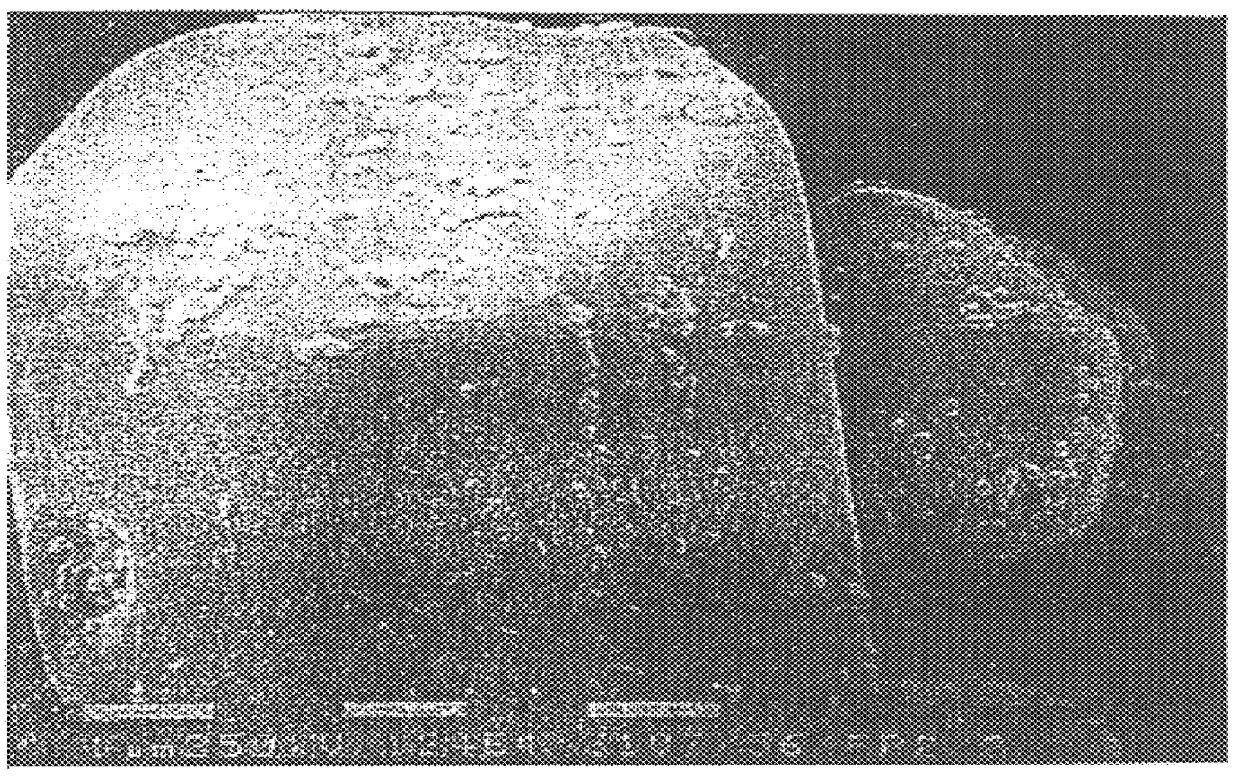

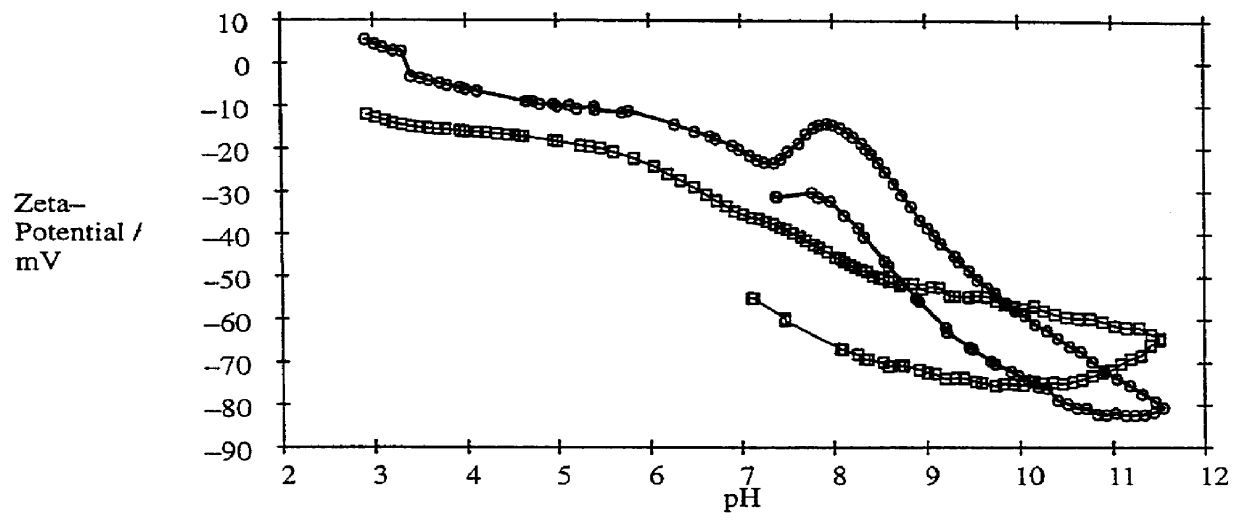

Phosphor composition with a coating of colloidal SiO2 particles and an oxygen compound of magnesium, calcium, barium, zinc, or aluminum

InactiveUS6013979AOptimal brightness and definition and adhesionMinimum level of color impurityCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersFluorescenceOxygen compound

The invention relates to a display screen having a phosphor layer of a phosphor composition of a phosphor coated with an oxygen compound of one of the elements magnesium, calcium, barium, zinc and aluminium, and with colloidal SiO2 having an average particle size of 70 nm< / =d< / =130 nm. The invention further relates to a phosphor composition of a phosphor coated with an oxygen compound of one of the elements magnesium, calcium, barium, zinc and aluminium, and with colloidal SiO2 having an average particle size of 70< / =d< / =130 nm, and to a method of manufacturing the phosphor composition.

Owner:U S PHILIPS CORP

Humidity sensor based on progressive corrosion of exposed material

InactiveUS8683861B2Easy to controlFlawless operation of the integrated circuitWeather/light/corrosion resistanceUsing mechanical meansElectrical resistance and conductanceEngineering

A sensor senses a characteristic of an environment, e.g., humidity. The sensor has a substrate with strips of material that is sensitive to corrosion as a result of the characteristic. The strips are configured to respond differently to the characteristic. By means of repeatedly measuring the resistances of the strips, the environment can be monitored in terms of accumulated exposure to the characteristic. The strips are manufactured in a semiconductor technology so as to generate accurate sensors that behave predictably.

Owner:AMS INT

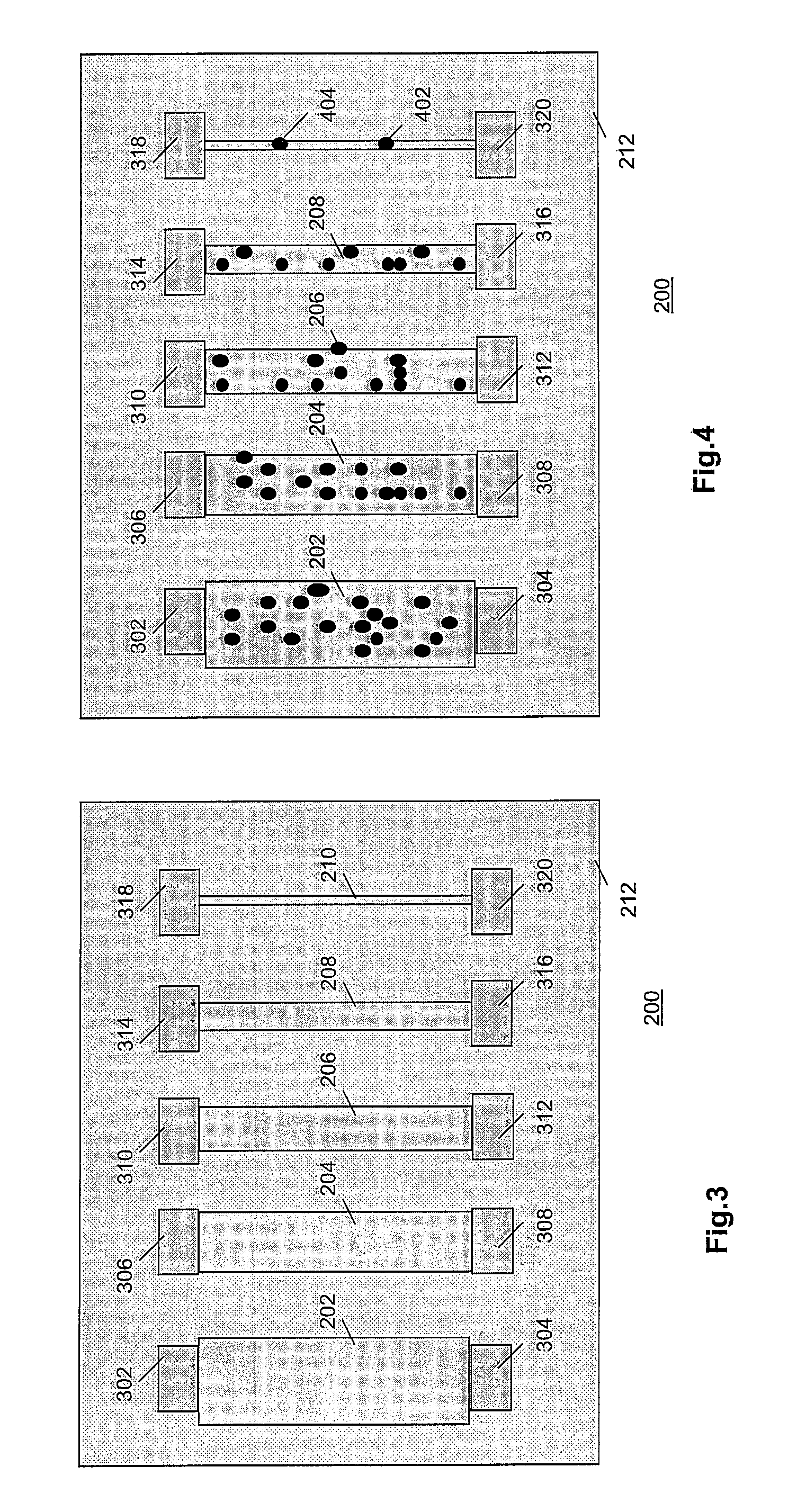

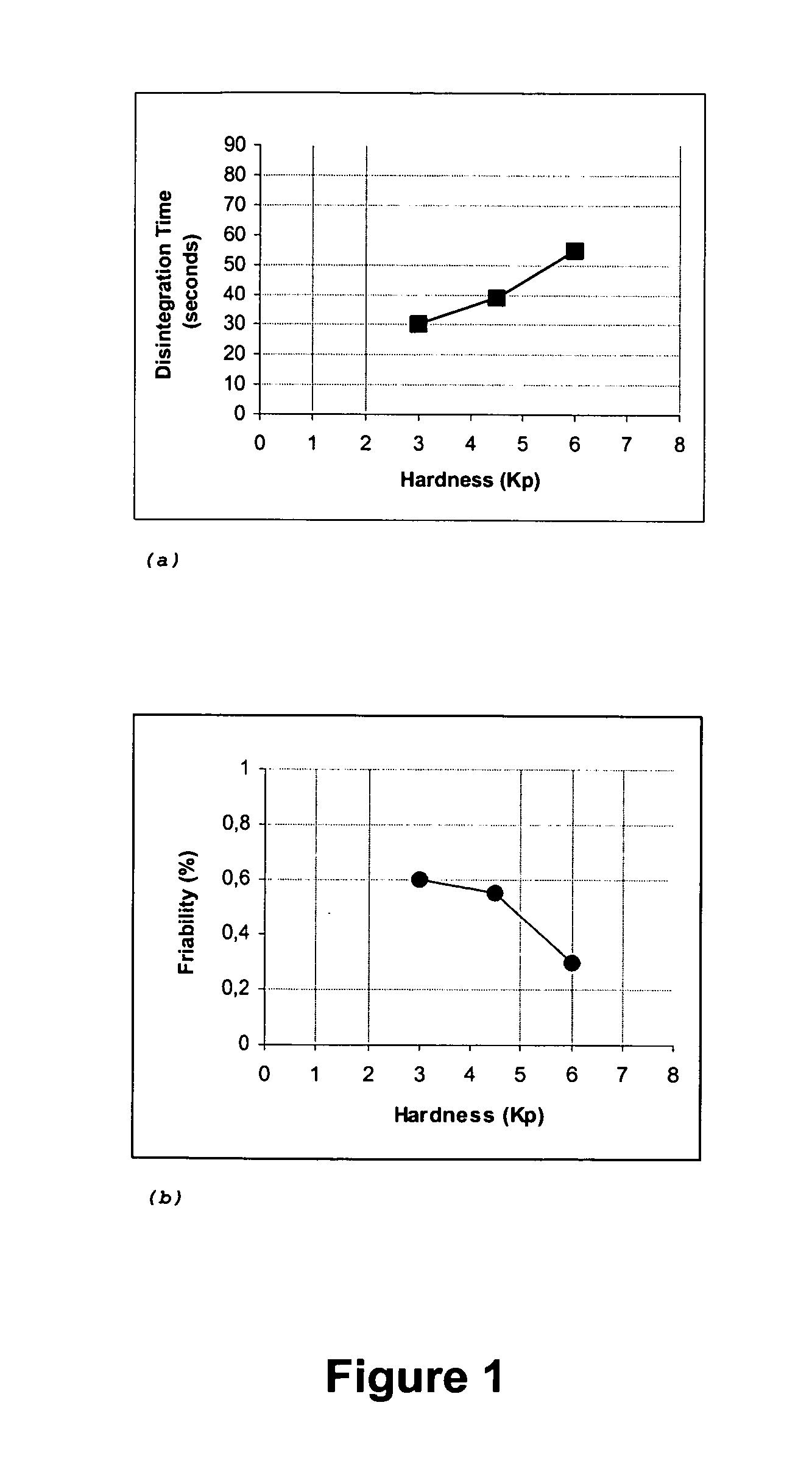

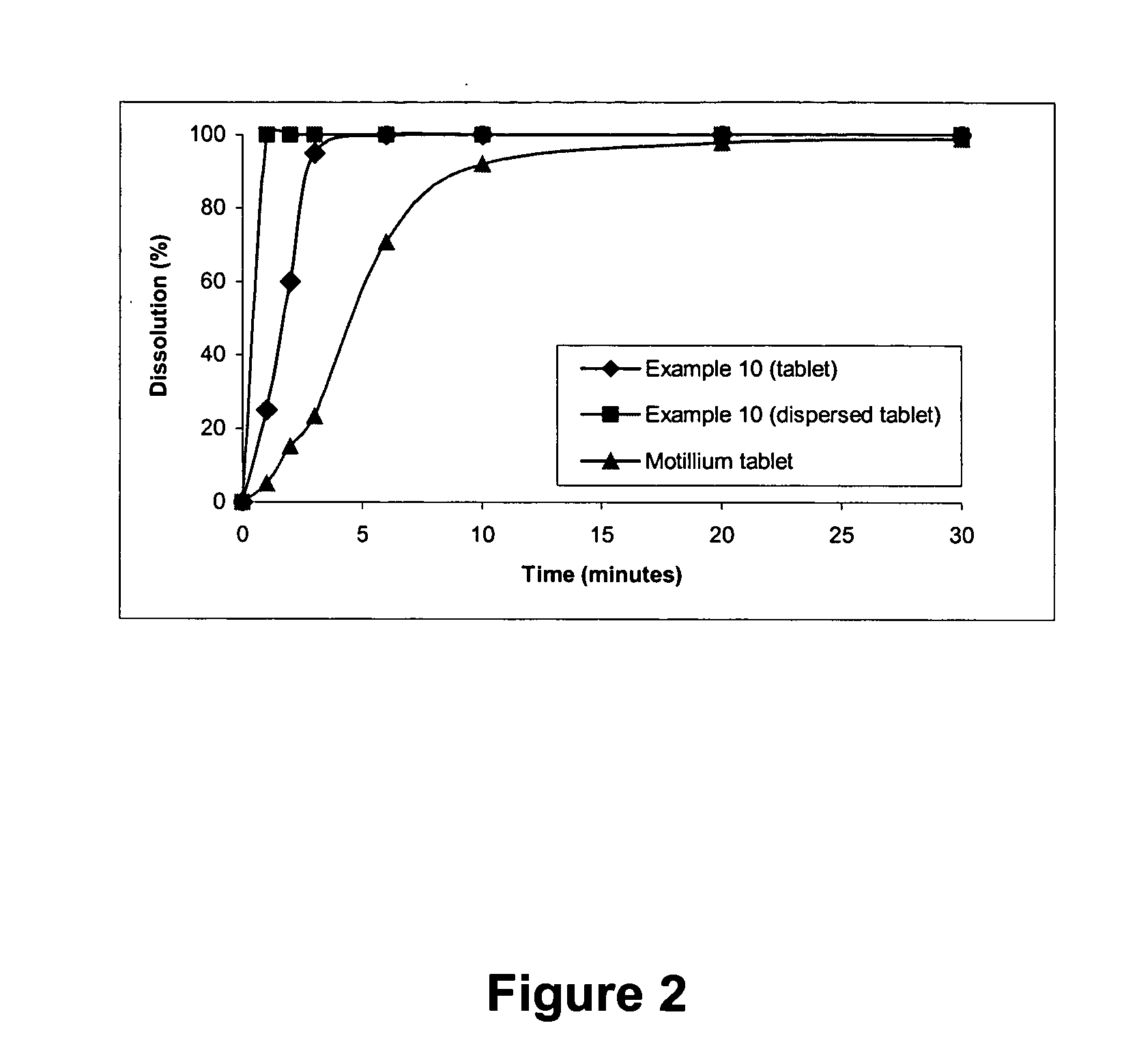

Fast water-dispersible domperidone tablets

InactiveUS20060051414A1Improves Structural IntegrityPleasant tasteBiocideDispersion deliverySolubilityWater dispersible

The present invention relates to fast water-dispersible tablets containing domperidone for oral administration. The formulations comprise domperidone or pharmaceutically acceptable salts thereof, about 60-80% of a “auxiliary” granulate (w / w), and about 10-30% of microcrystalline cellulose (w / w), expressed in relation to the total weight of the tablets, a sweetener, a flavouring agent and a lubricant. The “auxiliary” granulate is obtained by wet granulation of D-mannitol and maize starch gum in a high shear granulator, it facilitates the flowability and the compressibility of the mixture and, because of its high solubility in water, contributes to the fast dispersion of the tablet. The formulations have an enhanced structural integrity, for instance having a friability lower than 1.0% and hardness values between 3 and 6 Kp, and are able to disperse in water within 3 minutes, preferably within 2 minutes and most preferably within 1 minute, to provide a dispersion that passes through a 710 μm diameter mesh size sieve and presents a pleasant taste and the absence of perceptible granules in the mouth. This invention also refers to the process for the preparation of said pharmaceutical preparations.

Owner:LAB MEDINFAR PROD FARMS

Low-Caloric High-Protein Nutritional Composition for the Stimulation of Muscle Protein Synthesis

ActiveUS20130203658A1Improve bioavailabilityHigh blood levelPeptide/protein ingredientsMetabolism disorderDiseaseWhey protein

The present invention relates to the use of a low-caloric high-protein nutritional composition for use in the prevention or treatment of a disease or condition in a mammal, which involves muscle decline, as well as to specific low-caloric high-protein nutritional compositions for stimulating muscle protein synthesis in a mammal. In particular, the invention relates to the use of a nutritional composition comprising per 100 kcal: (i) at least about 12 g of proteinaceous matter which comprises at least about 80 weight % of whey protein, relative to the total proteinaceous matter, and which comprises at least about 11 weight % of leucine, relative to the total proteinaceous matter, of which at least about 20 weight % is in a free form, relative to the total leucine, (ii) a source of fat and a source of digestible carbohydrates, for the prevention or treatment of a disease or condition which involves muscle decline in a mammal, especially an elderly mammal, wherein the nutritional composition is administered as 1 to 2 servings daily, each serving comprising between 80 and 200 kcal.

Owner:NV NUTRICIA

Method for producing a food product, food product and barm for producing said product (variants)

InactiveUS20040175460A1Increase rangeImprove propertiesMilk preparationFrozen sweetsChemistryDairy industry

The invention relates to the food industry, particularly to the dairy industry, and can be used for putting into use some new food technologies and producing a large number of new food products noted for improved properties. The invention is directed to raising the physiological activity of food products, particularly of fermented milk products and to improving other properties thereof. In accordance with the invention, the proposed process for producing a product (variants) comprises: (1) combining a food base or at least one of its components with at least one physiologically acceptable carrier and / or with at least one its starting component, precursor; (2) combining the food base or at least one of its components with at least one microorganism or other biological system; (3) forming at least one "carrier-biocatalyst" system; (4) participation of at least part of the microorganisms and / or other biological systems of an immobilized biocatalyst in obtaining the final product due to metabolic processes, for example, due to microbial synthesis and / or transformation of the food base (substrate); (5) providing the presence of at least one formed immobilized biocatalyst in the composition of the product. The invention discloses also products obtained in accordance with the claimed process, that are called "biocatalyzed products", as well as starters for obtaining such products.

Owner:ZENOVICH SERGEI MIKHAILOVICH

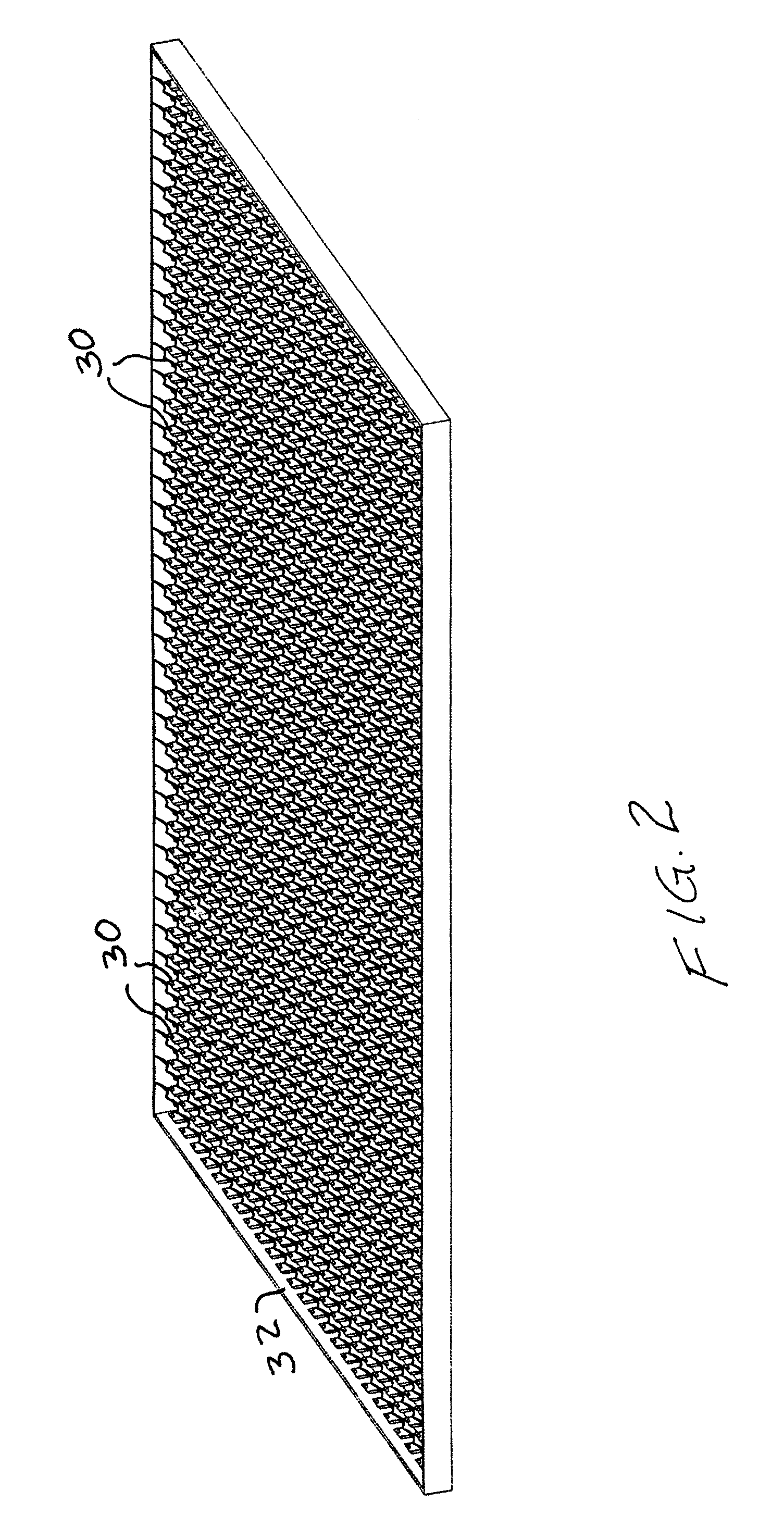

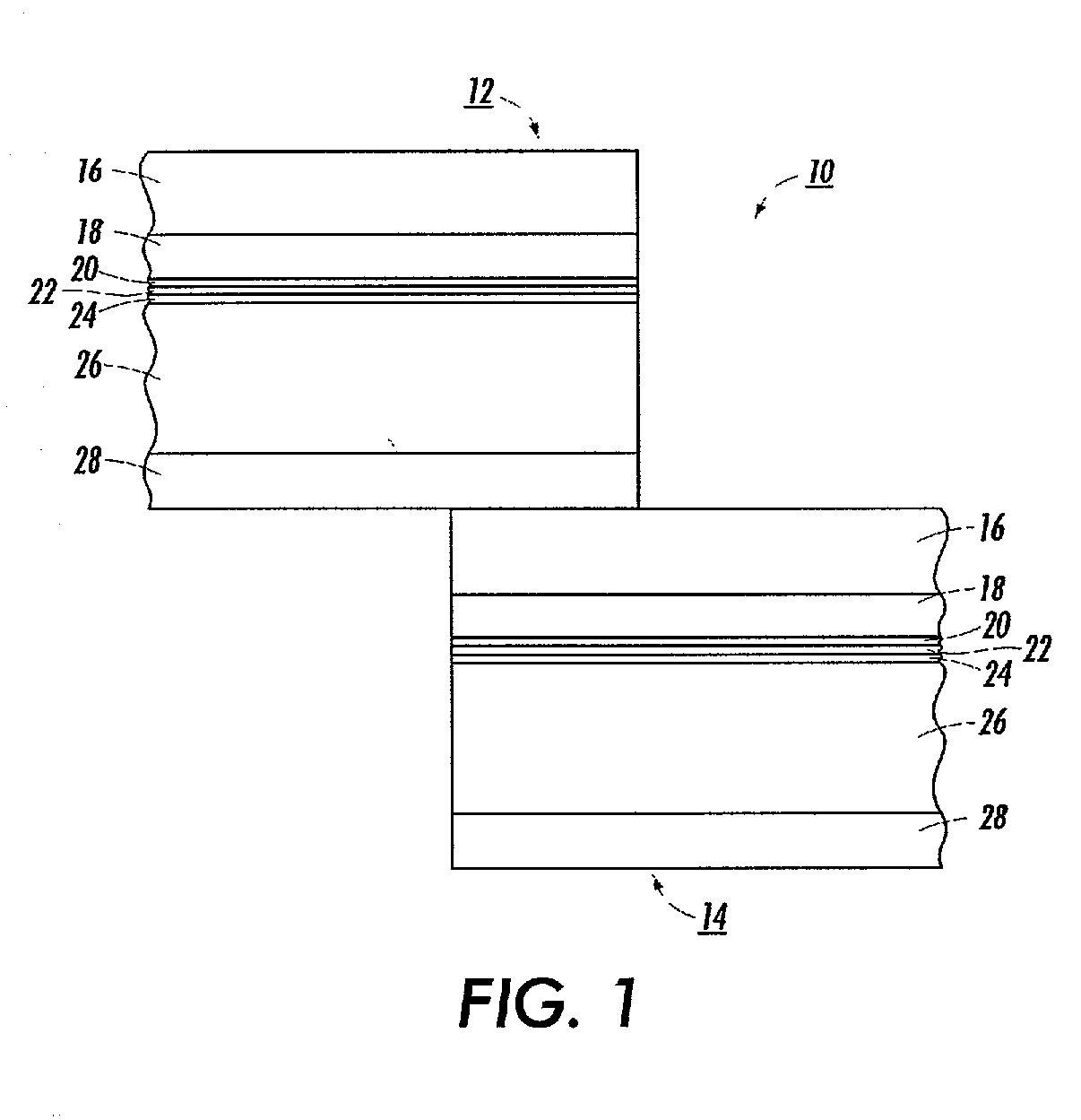

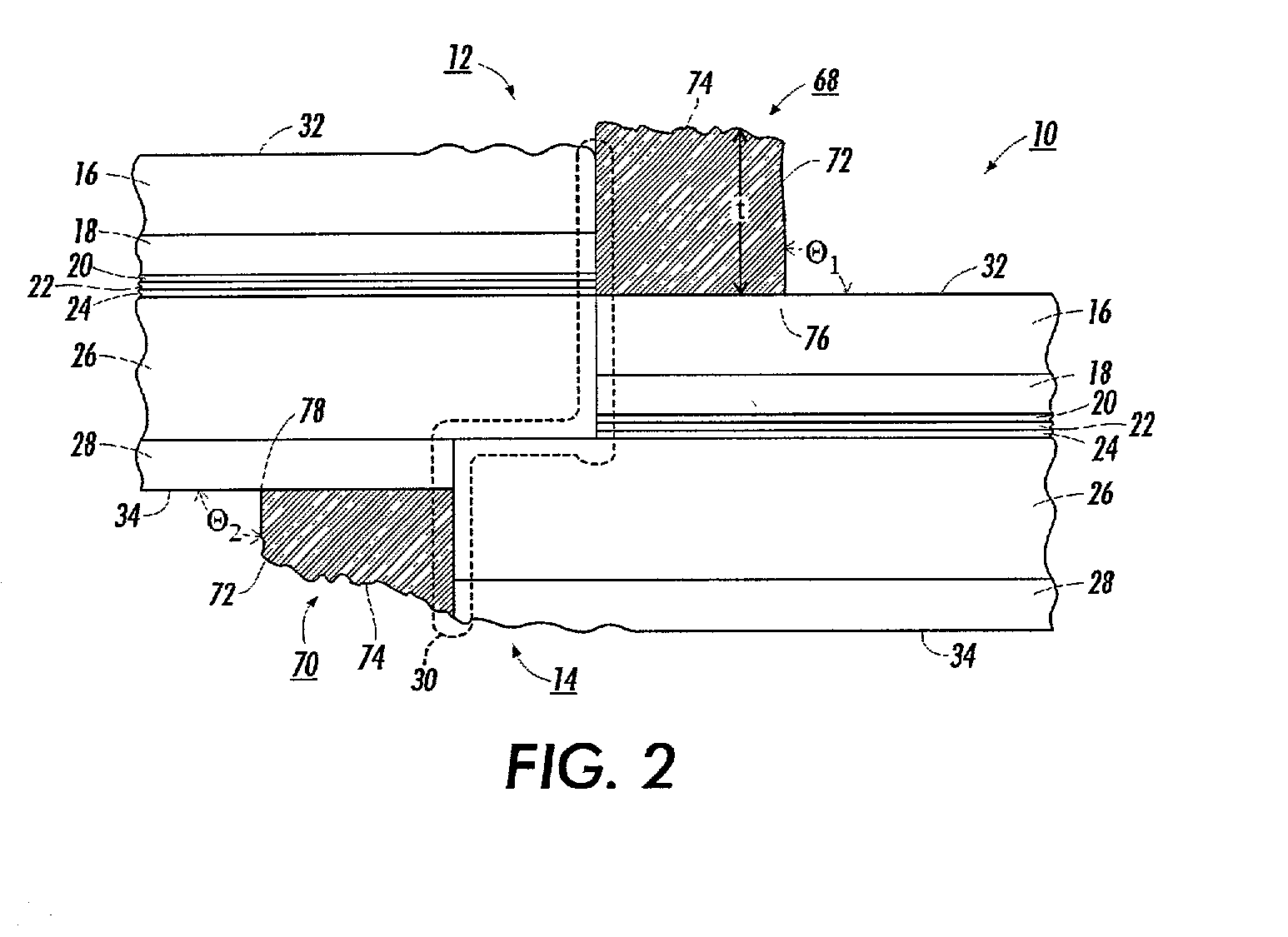

Flexible cells for axially interconnecting stent components

InactiveUS20060190072A1AbsenceEasily and efficiently producedStentsBlood vesselsBiomedical engineeringStent

Owner:STENT TECH

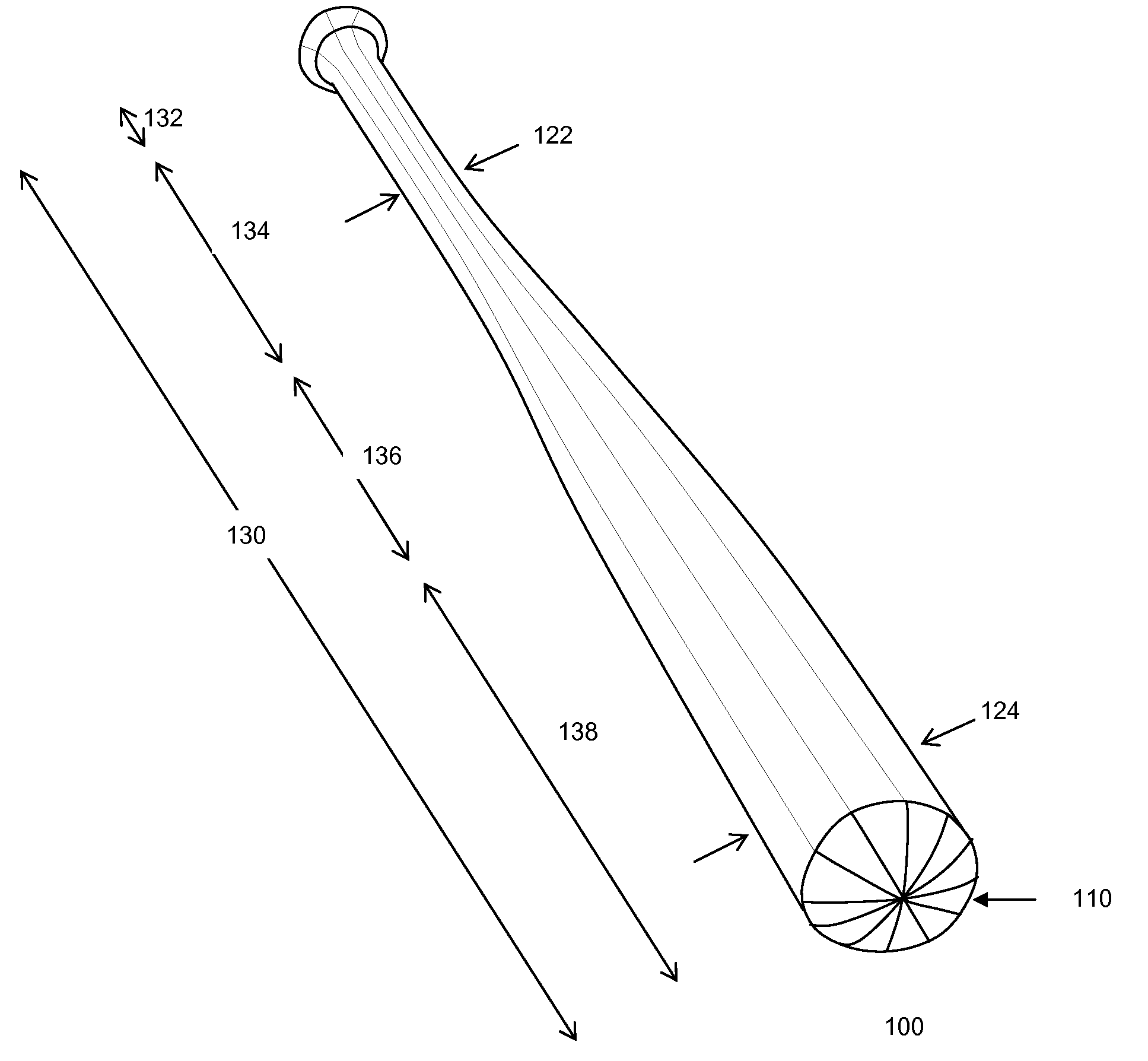

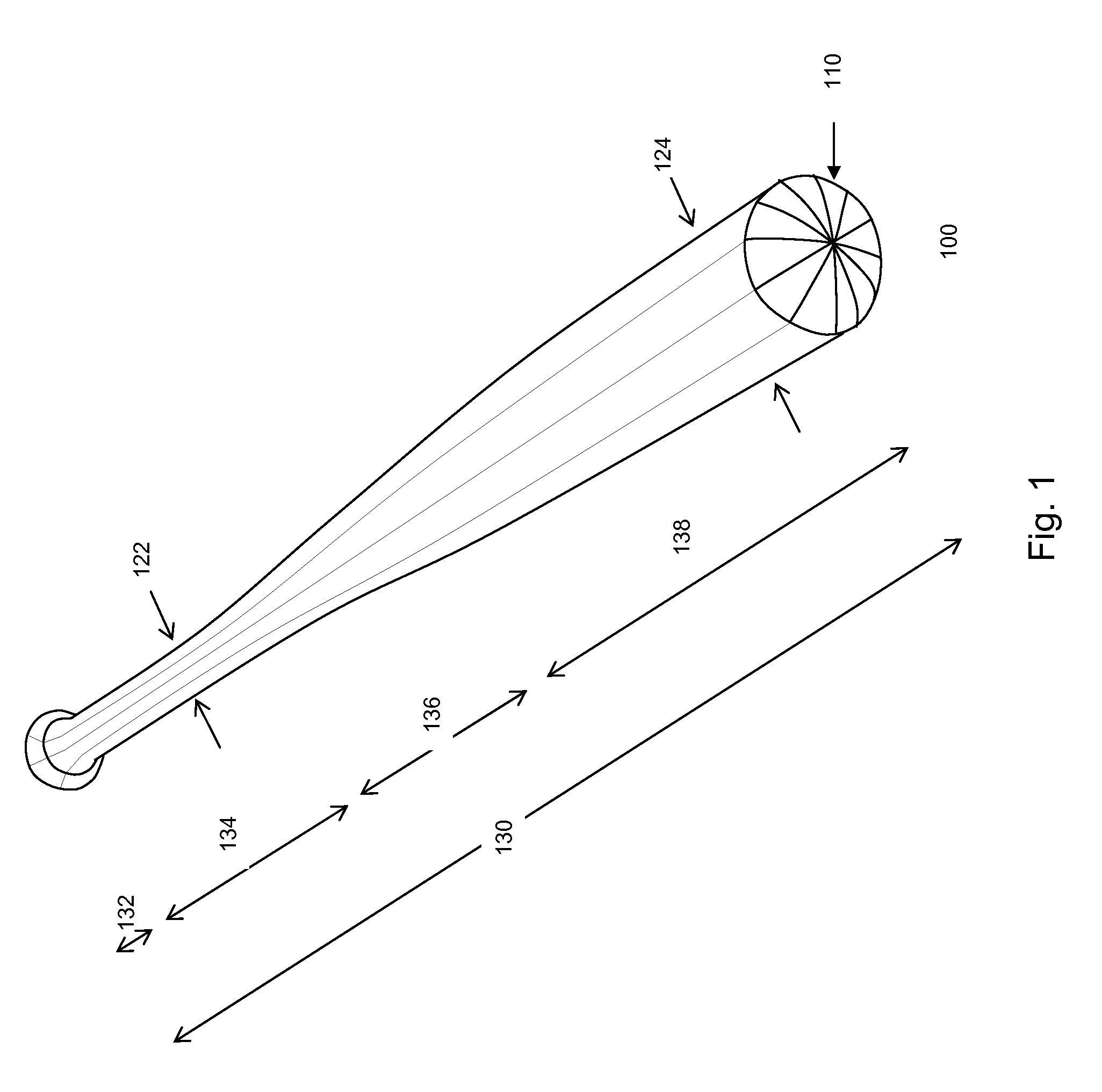

Radial Baseball Bat

InactiveUS20080308187A1Large effective hitting areaAbsence of stingFibreboardDovetailed workBaseball batPolyurethane adhesive

A laminated wood bat having may comprise wedges of wood adhered together in such a manner that the entire surface or sections of the surface of the bat barrel, throat, and handle have the tight grain of the normal hitting surface. Adjacent wedges of wood may be cut from the same strip of wood. The bat may be glued together with a low viscosity polyurethane adhesive.

Owner:RADIAL BAT INST

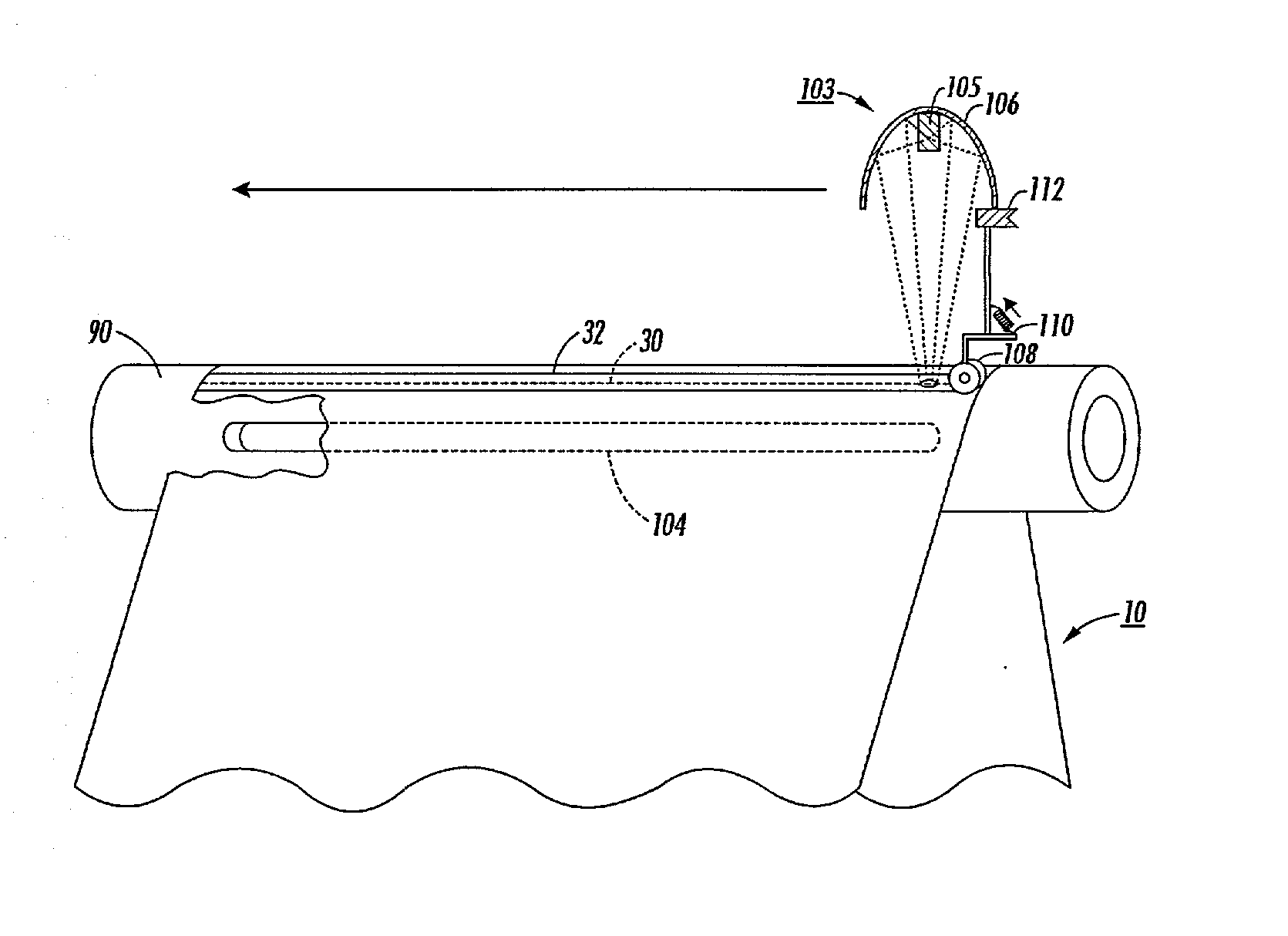

Flexible imaging member seam treatment apparatus

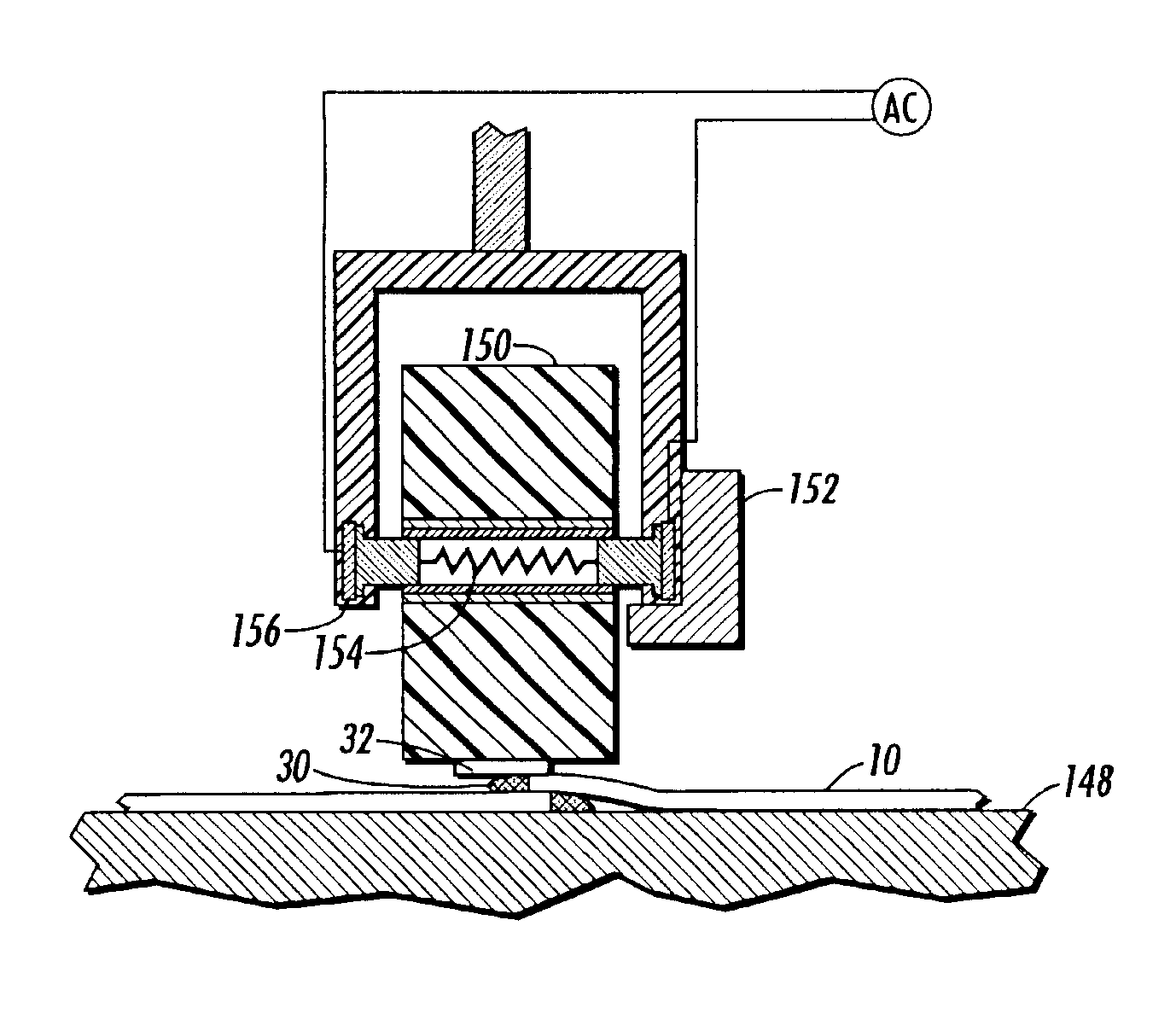

InactiveUS6803549B2Short lifePremature mechanical failureElectrography/magnetographyDomestic articlesMechanical engineeringSmooth surface

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt and a heat and pressure source that heats a treatment strip and the belt seam region and that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat and pressure source can be a heated pressure bar engaging the entire seam region or a heated pressure wheel traversing the seam region of the entire belt width.

Owner:XEROX CORP

Flexible imaging member seam treatment apparatus

InactiveUS20030221785A1Good seam region physical continuityImprove surface morphologyMechanical working/deformationFilament handlingInfrared lampEngineering

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt, a heat source that heats a treatment strip and the belt seam region, and a pressure applicator that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat source can be an infrared laser or an infrared lamp. Optics form a heat spot or a heat line on the strip and seam region, and a pressure wheel traverses the seam region after heating to compress the strip and seam and bond a thermoplastic polymer of the strip to the seam region of the belt.

Owner:XEROX CORP

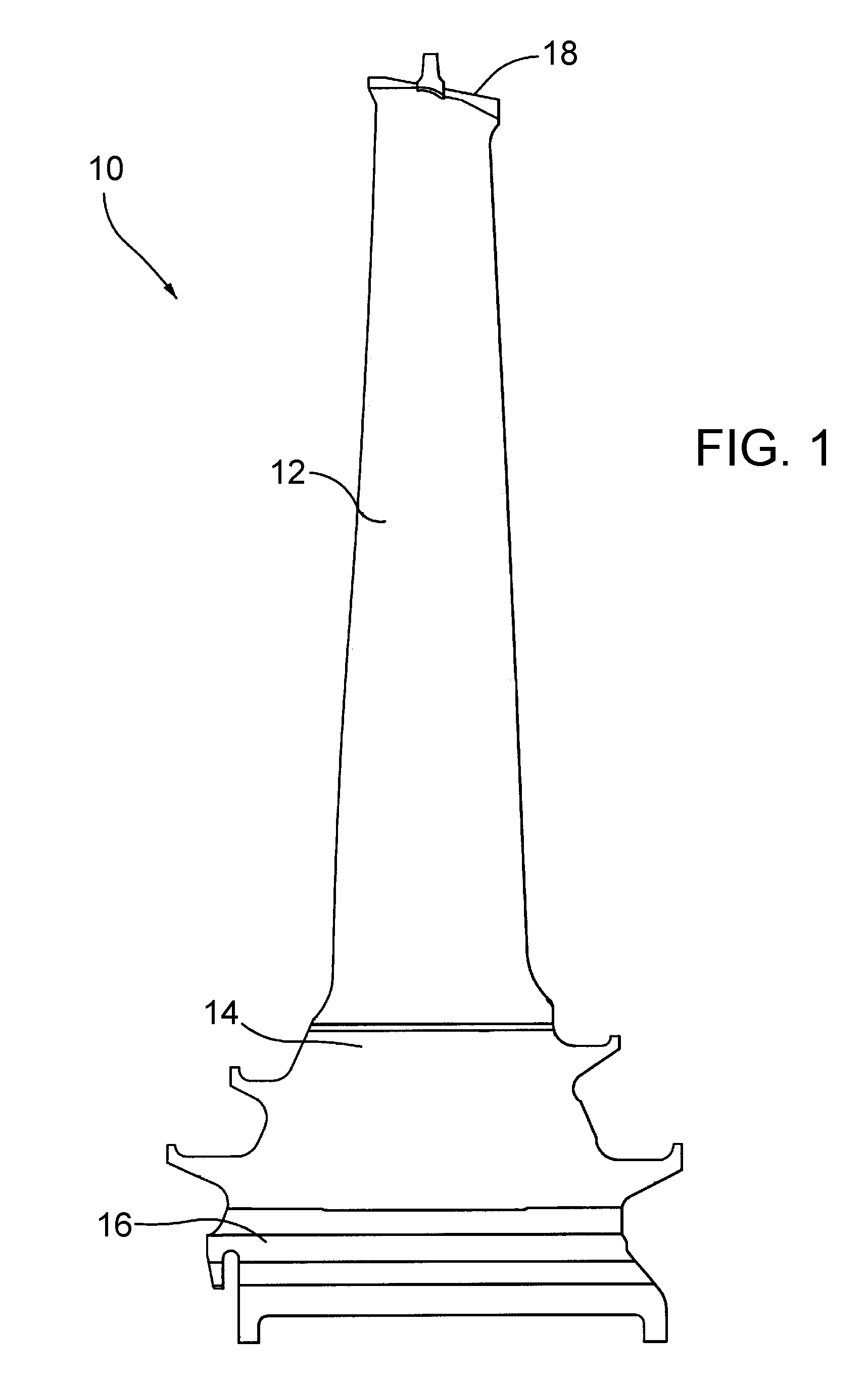

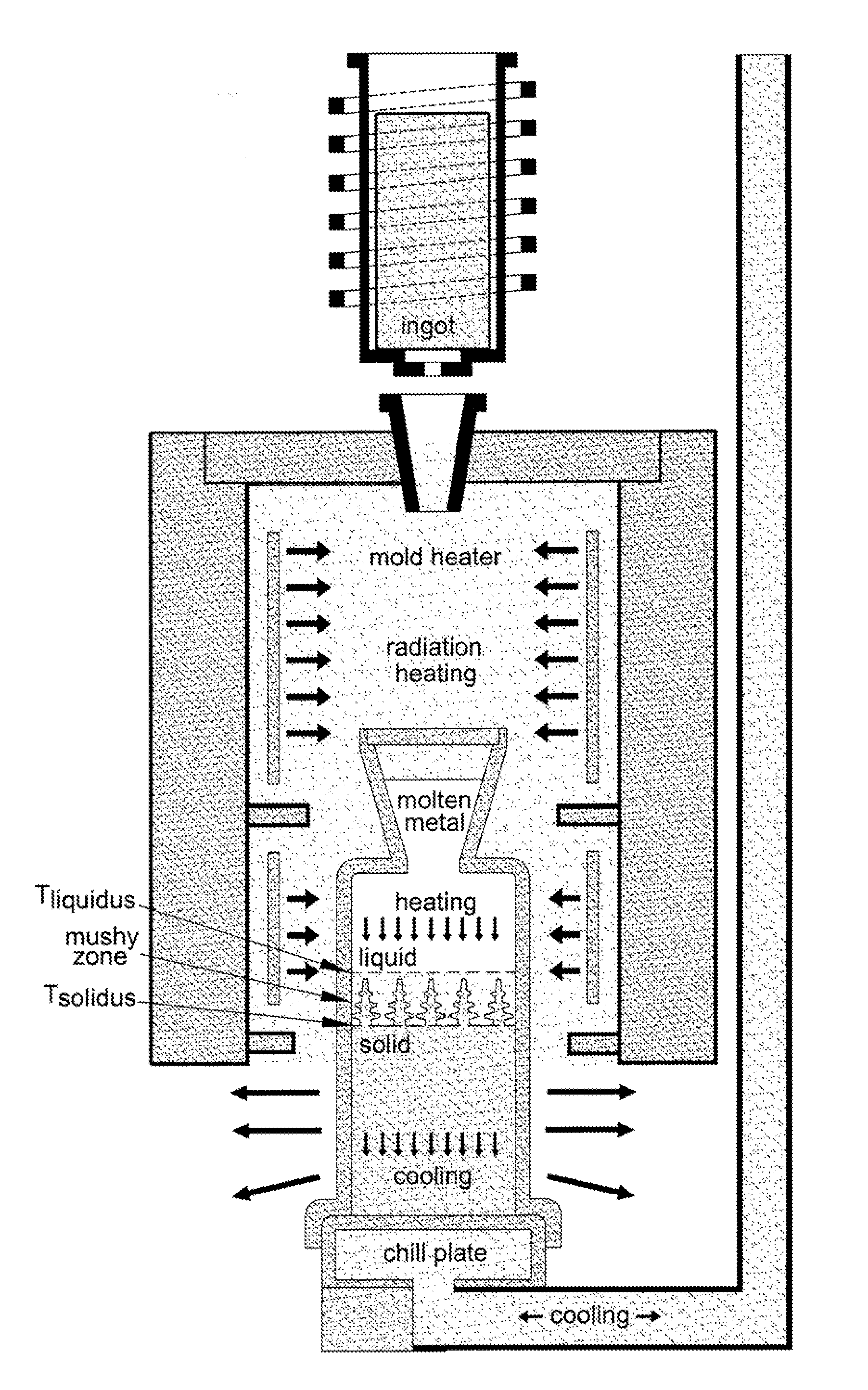

Unidirectionally-solidification process and castings formed thereby

InactiveUS20100071812A1Exceed in length and cross-section and weightReduce morbidityPolycrystalline material growthEngine manufactureMicrometerCrystal structure

A process capable of producing large metallic castings having lengths of one hundred centimeters or more and a unidirectional crystal structure substantially free of freckle defects. The process includes pouring a molten metal alloy into a preheated mold within a heating zone, withdrawing the mold from the heating zone, through a heat shield, and into a cooling zone to directionally solidify the molten metal alloy, and then cooling the mold to produce the casting and the unidirectional crystal structure thereof. The heat shield operates as a barrier to thermal radiation between the heating zone and the cooling zone, and the mold is withdrawn at a rate that, in combination with the heat shield, maintains a thermal gradient to solidify the molten metal alloy and form primary dendrite arms having an average spacing therebetween of about 150 to about 500 micrometers.

Owner:GENERAL ELECTRIC CO

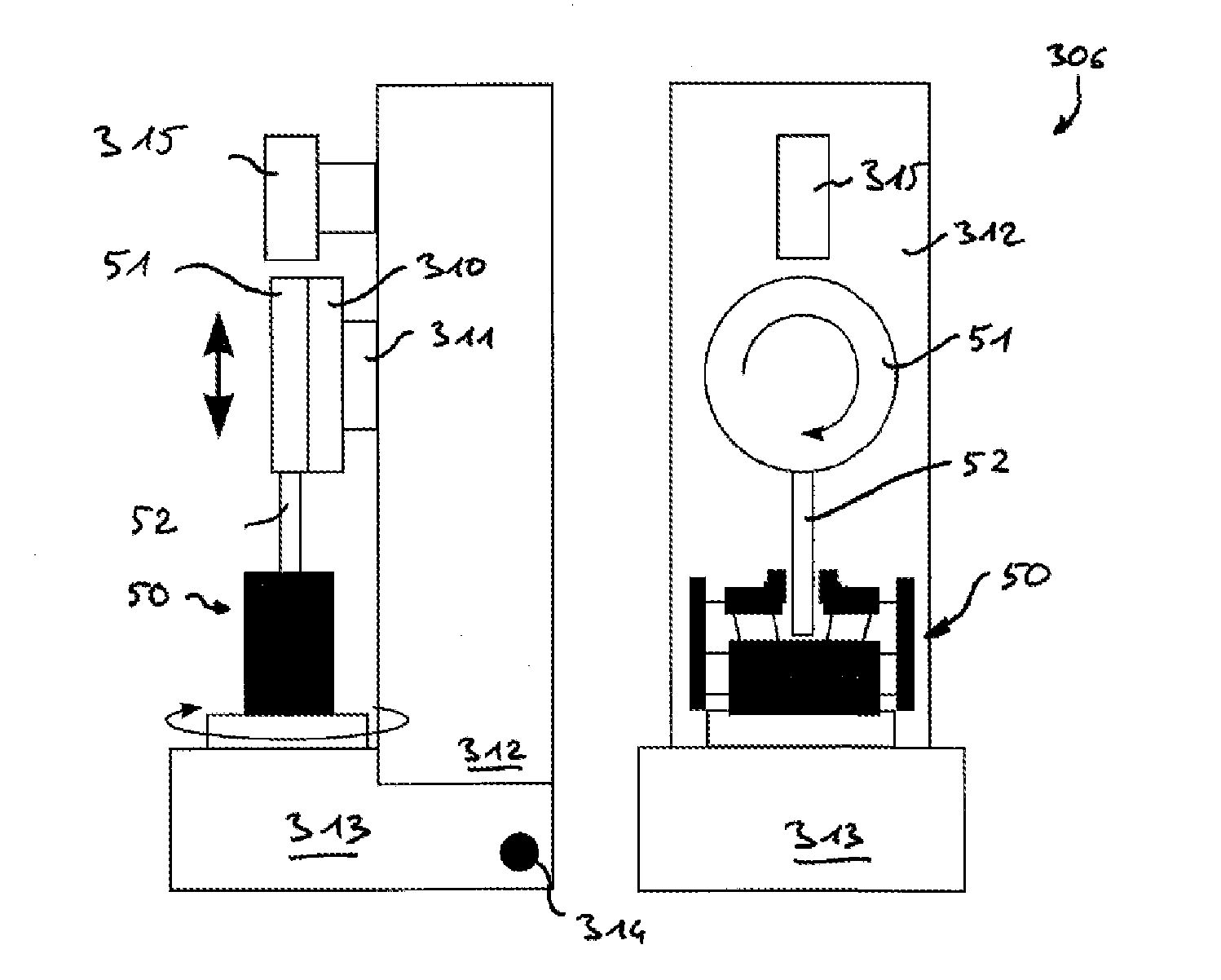

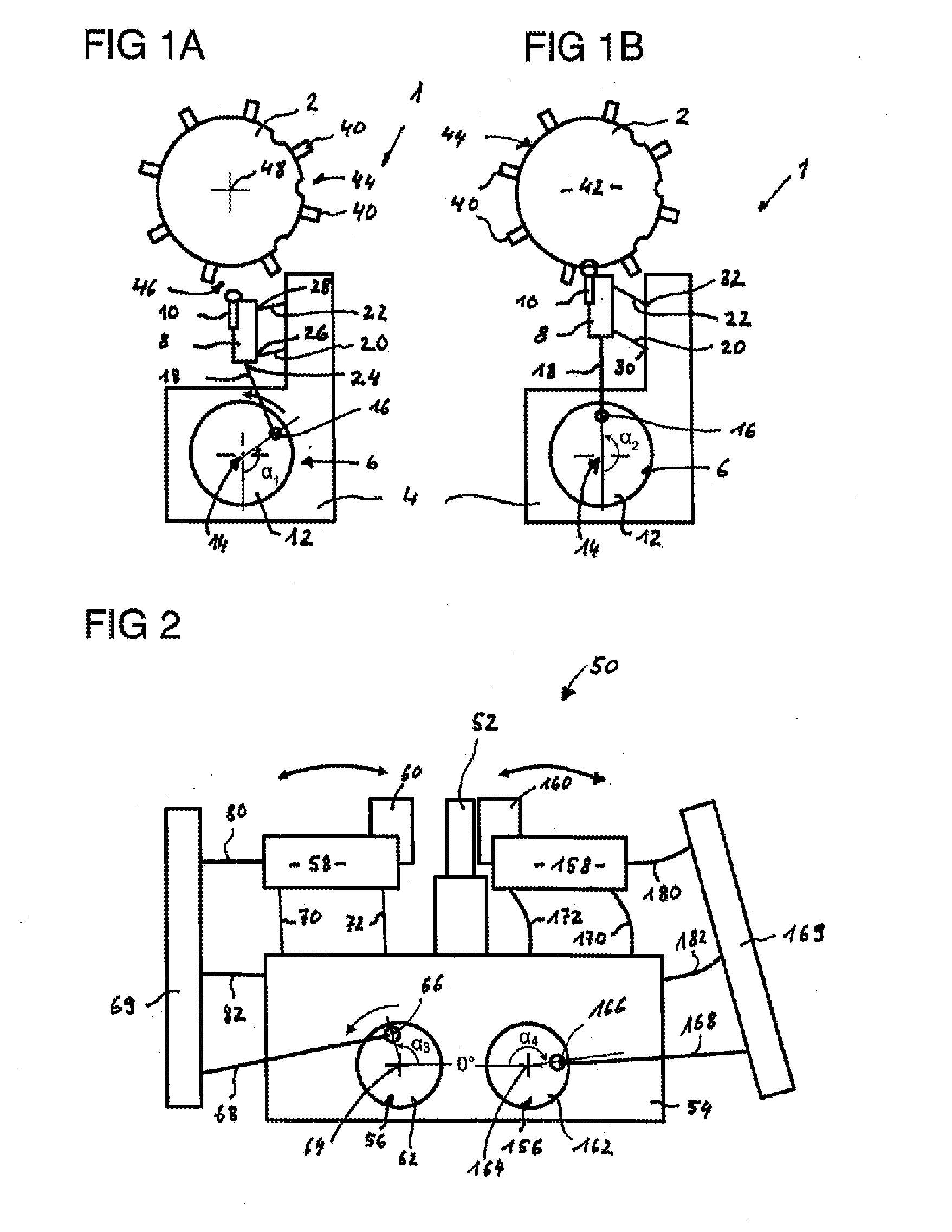

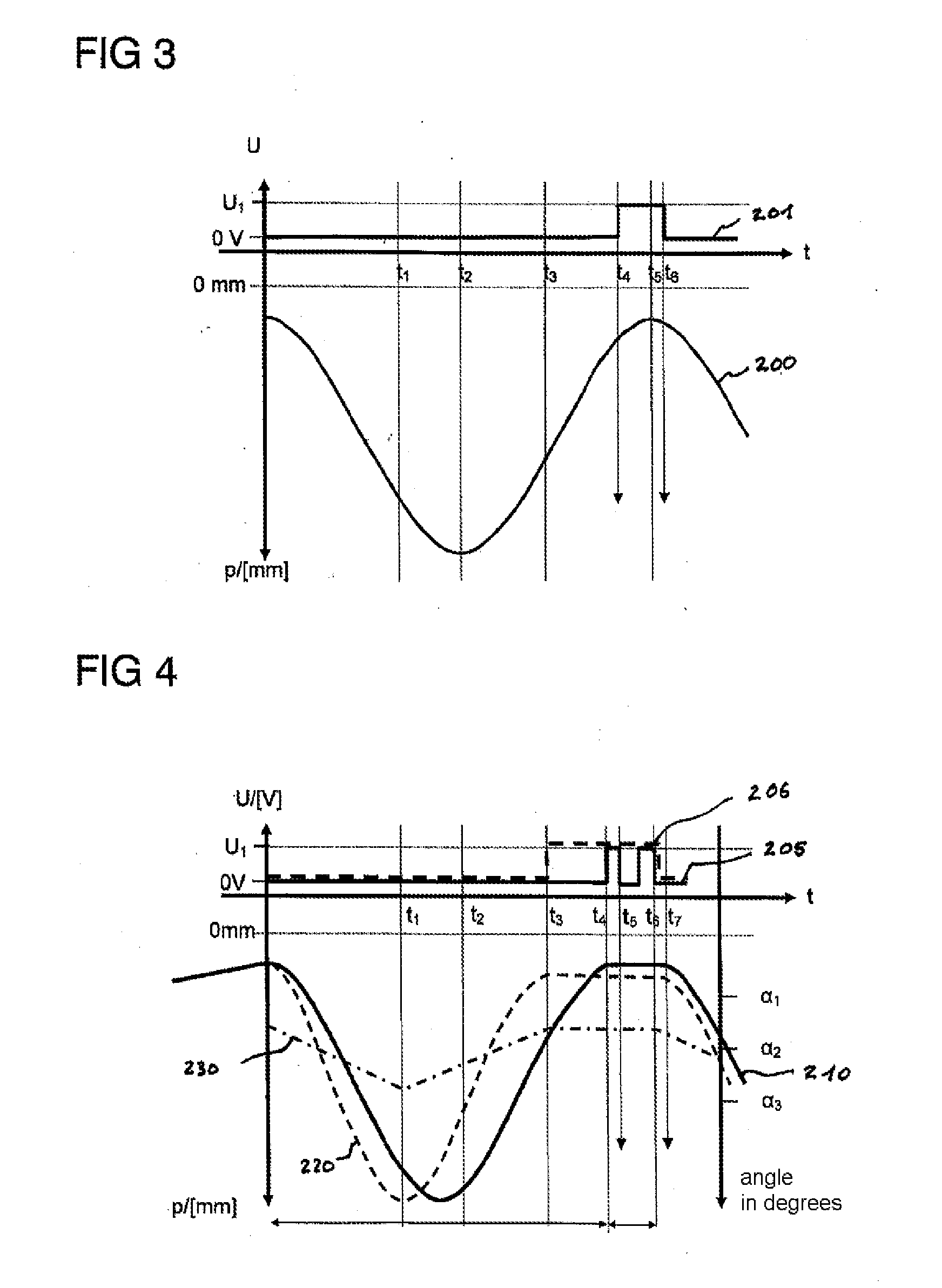

Electrochemical machining of a workpiece

ActiveUS20160074952A1Simple and precise mannerAccurate and reliable connectionElectrolysis componentsConductive material chemical/electrolytical removalElectrochemistryMechanical engineering

The invention relates to a machine having a base (300) and at least one work station (306) that has a module (50) for electrochemically machining a workpiece (51). The module comprises: a frame (54); and an electrode arrangement, having at least one electrode (60, 160), which is mechanically connected to the frame, and a drive (56, 156) for moving this electrode, which drive is attached to the frame; a workpiece holder (310, 311) for separably attaching the workpiece; and a positioning device (312, 313) for displacing the workpiece holder and the module relative to each other.

Owner:MTU AERO ENGINES GMBH

Unidirectionally-solidification process and castings formed thereby

InactiveUS20130022803A1Minimizes gradientExceed in length and cross-section and weightPropellersPump componentsCrystal structureDirectional solidification

A process capable of producing large metallic castings having lengths of one hundred centimeters or more and a unidirectional crystal structure substantially free of freckle defects. The process includes preheating a mold within a heating zone of a directional casting apparatus, pouring a molten metal alloy into a cavity of the mold, and then withdrawing the mold from the heating zone, through a heat shield, and into a cooling zone of the directional casting apparatus to directionally solidify the molten metal alloy within the cavity. The heating and cooling zones establish an axial thermal gradient that defines a solidification front in the molten metal alloy within the cavity. The mold is withdrawn at a withdrawal rate that, in combination with the axial thermal gradient, causes the solidification front to be substantially flat and perpendicular to the withdrawal direction.

Owner:GENERAL ELECTRIC CO

Butter and process for obtaining same

InactiveUS20110151081A1Improve solubilityAbsenceMilk preservationAnimal fodder preservationAdditive ingredientTubes types

The present invention relates to a new butter and a process for preparing same comprising: (a) grinding and mixing the starting ingredients, and (b) heat treatment at a temperature comprised between 70-150° C., wherein the starting ingredients comprise: (i) a fat selected from among cream, butter, anhydrous milk fat and mixtures thereof and (ii) at least one additive selected from the group of stabilizers, thickeners, texturing agents, emulsifiers and mixtures thereof. The invention also relates to a process for packaging the butter in a package, such as a spray type container, or a tube type container, or a dispensing package with a membrane stopper, as well as the packaged butter obtained.

Owner:CORPORACION ALIMENTARIA PENASANTA

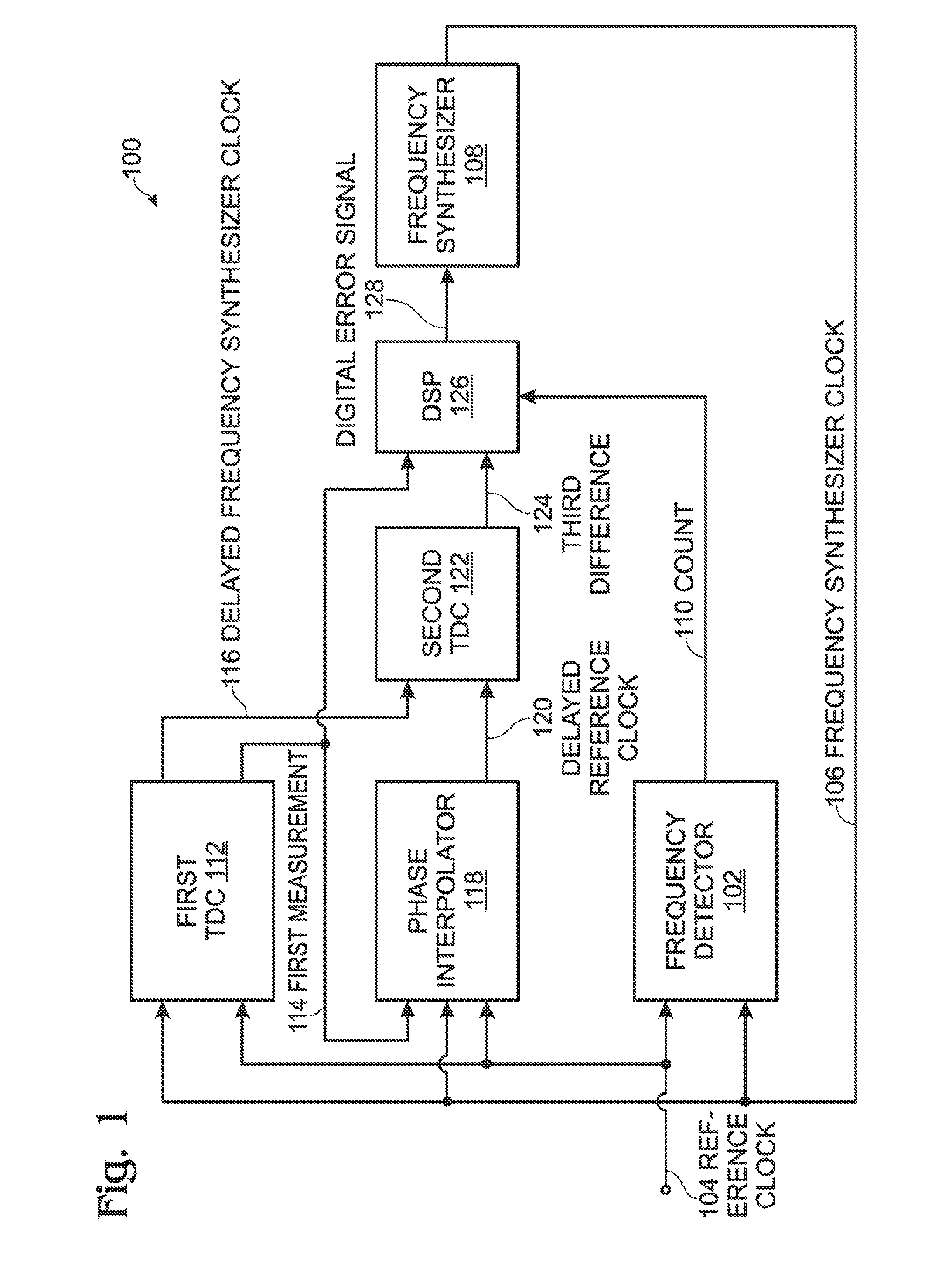

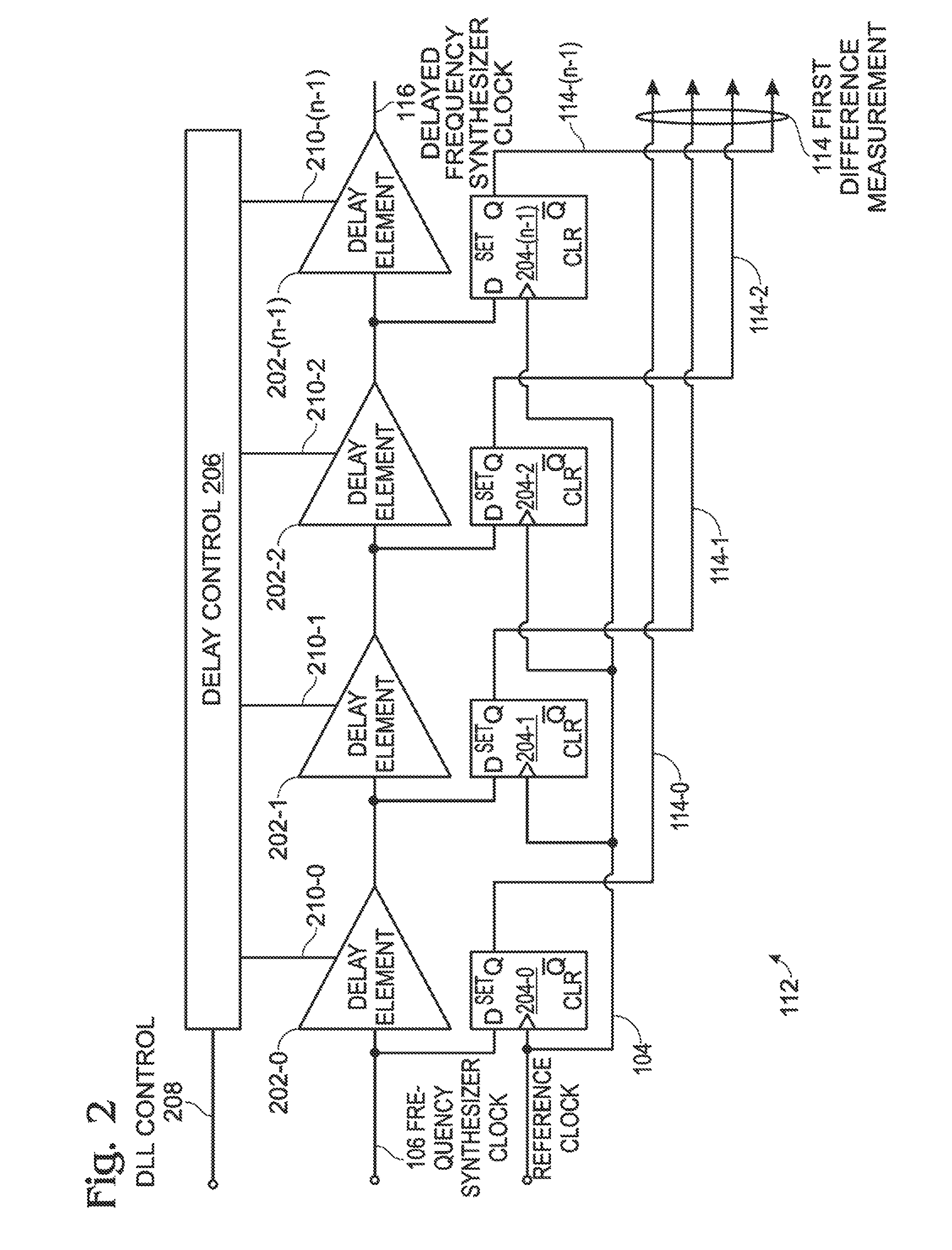

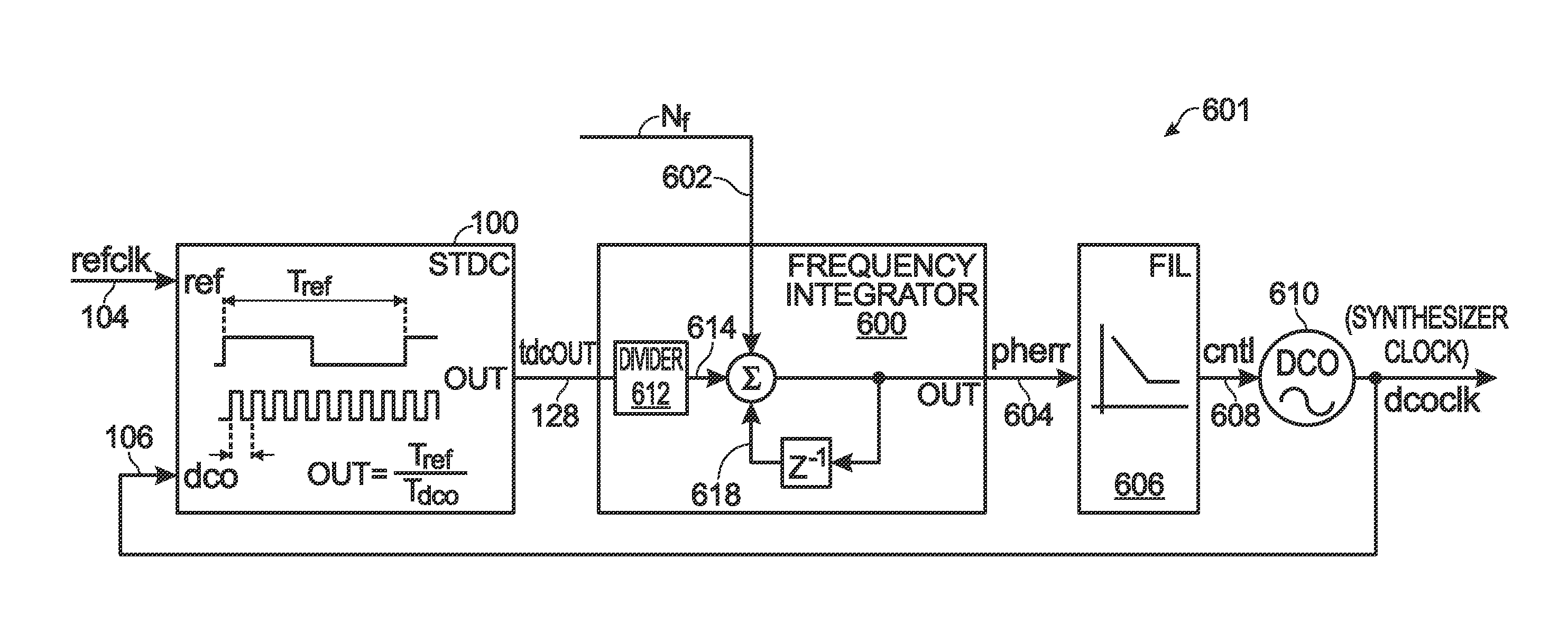

Frequency integrator with digital phase error message for phase-locked loop applications

ActiveUS8264388B1Reduce power consumptionPromote high performanceAnalogue/digital conversionElectric signal transmission systemsIntegratorEngineering

A digital phase-locked loop (DPLL), a supporting digital frequency integrator, and a method are provided for deriving a digital phase error signal in a DPLL. A digital frequency integrator periodically accepts a digital tdcOUT message from a Time-to-Digital Converter (TDC) representing a measured ratio of a reference clock (Tref) period to a synthesizer clock (Tdco) period. Also accepted is a digital message selecting a first ratio (Nf). In response, a digital phase error (pherr) message is periodically supplied that is proportional to an error in phase between the reference clock and the (synthesizer clock*Nf).

Owner:MACOM CONNECTIVITY SOLUTIONS LLC

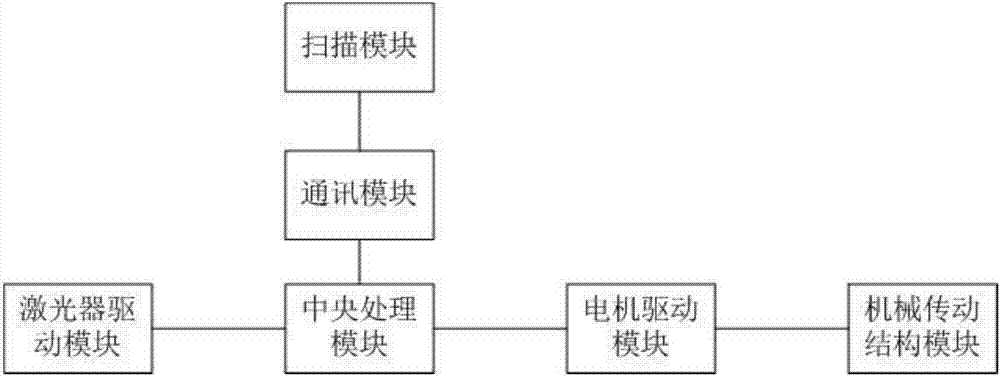

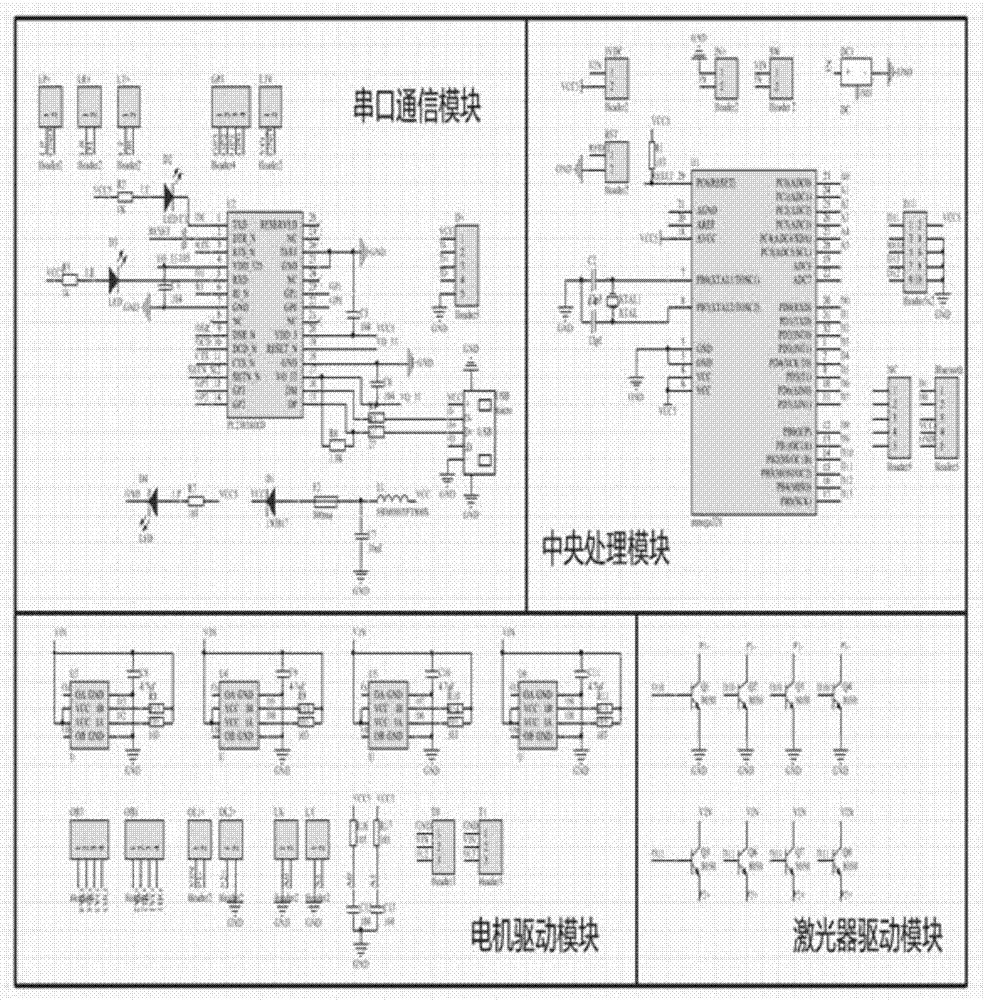

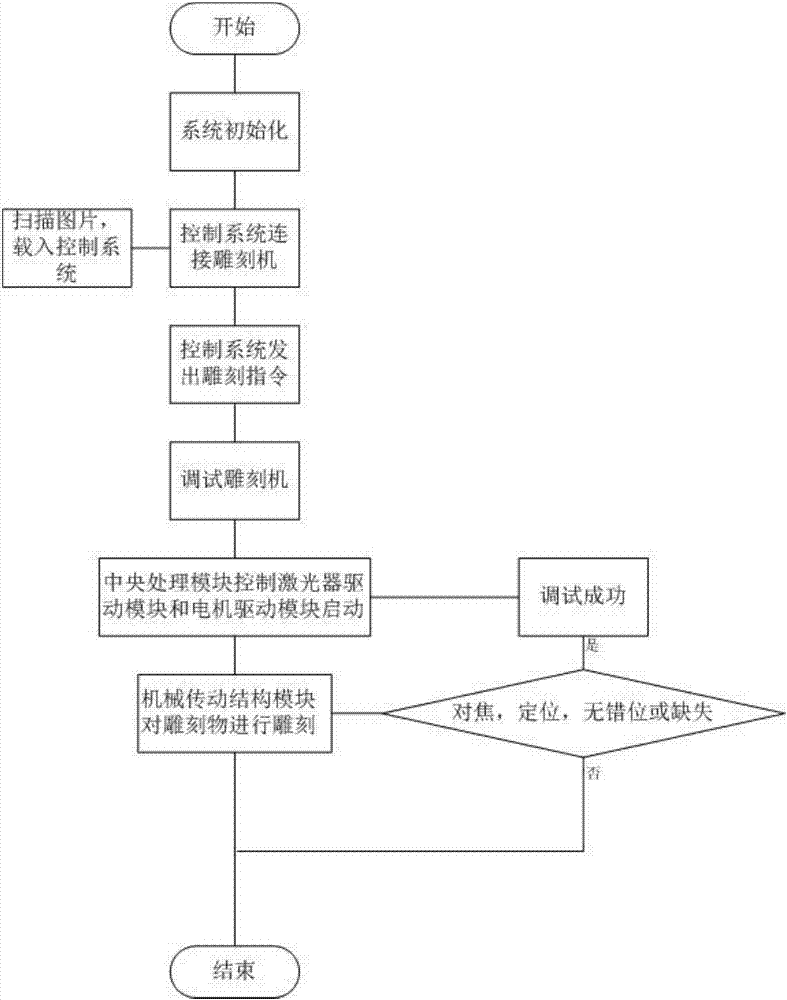

Laser engraving machine, control system of laser engraving machine and operation method of laser engraving machine and control system

InactiveCN107470780AAbsenceRealize direct identificationLaser beam welding apparatusMachine controlMotor drive

The invention discloses a laser engraving machine. The laser engraving machine comprises a communication module, a scanning module, a central processing module, a motor driving module, a laser device driving module and a mechanical transmission structure module. The communication module is connected with the scanning module and the central processing module. The central processing module is connected with the motor driving module and the laser device driving module. The motor driving module is connected with the mechanical transmission structure module. The invention further discloses a control system of the laser engraving machine. The control system comprises an image editing module and an engraving machine control module, the image editing module is connected with the engraving machine control module, and the engraving machine control module is in communication connection with the engraving machine. The invention further discloses an operation of the laser engraving machine and the control system. A hardware part of the whole laser engraving machine is small in size, portable, stable in working, high in precision, low in cost and flexible in application, and secondary development is facilitated; and a software part of the laser engraving machine is easy to operate and humanized, convenience is provided for non-professional users, and the users can learn to operate the laser engraving machine easily.

Owner:NANJING INST OF MECHATRONIC TECH

Flexible imaging member seam treatment apparatus

InactiveUS20030222078A1Good seam region physical continuityImprove surface morphologyElectrography/magnetographyDomestic articlesEngineeringMechanical engineering

A belt seam treatment apparatus includes a support element with a smooth surface that supports the seam region of the belt and a heat and pressure source that heats a treatment strip and the belt seam region and that forces the treatment strip against the belt seam region. The support element can be a tube over which the belt hangs and can include a vacuum belt hold system that secures the seam region against the tube during treatment. The heat and pressure source can be a heated pressure bar engaging the entire seam region or a heated pressure wheel traversing the seam region of the entire belt width.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com