A method for converting blade non-contact vibration stress measurement value

A vibration stress, non-contact technology used in vibration testing, measuring devices, measurement of elastic deformation forces by measuring gauges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

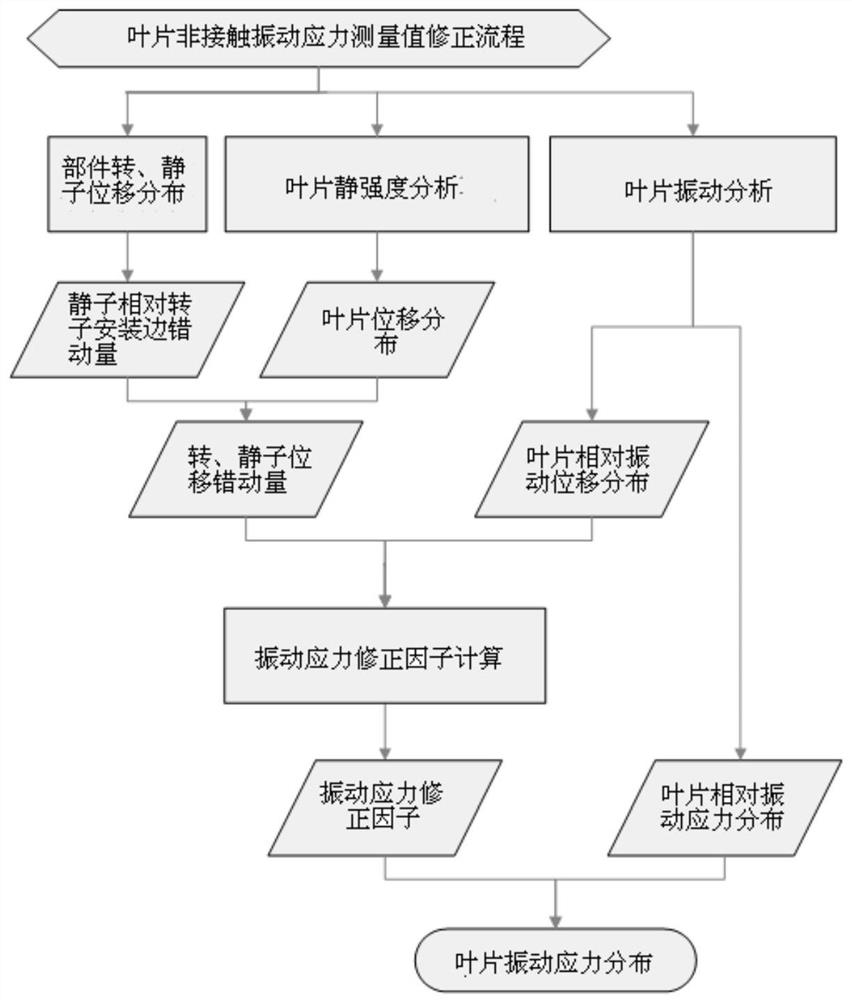

[0030] The specific process of the correction of the blade non-contact vibration stress measurement value is as follows: figure 1 shown.

[0031] It can be seen from the above figure that the correction of the non-contact vibration stress measurement value of the blade needs to be corrected in terms of the axial misalignment of the rotor stator and the vibration deformation of the blade. Here, taking the first-stage rotor blade of a certain engine fan component as an example, the correction method Make an introduction:

[0032] 1) Correction for axial misalignment of rotor and stator

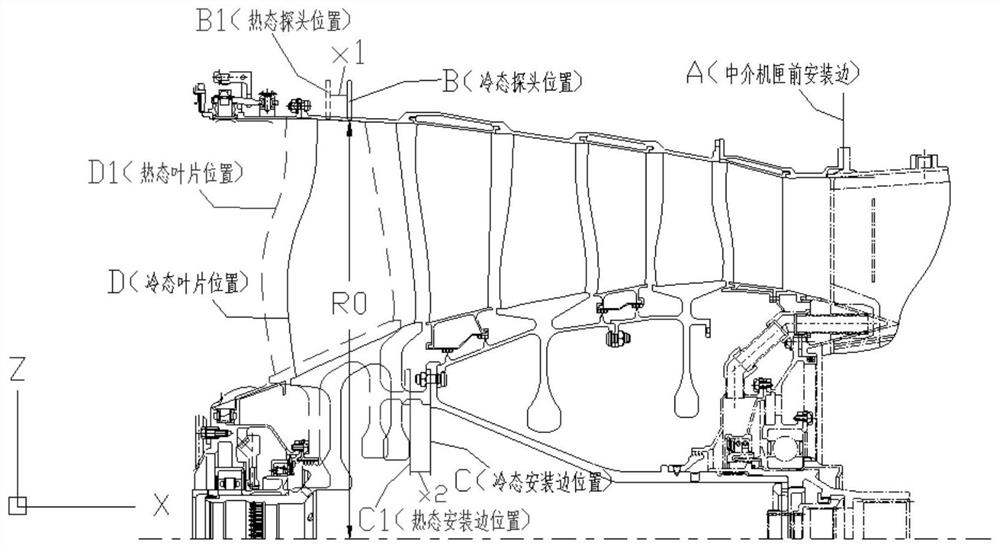

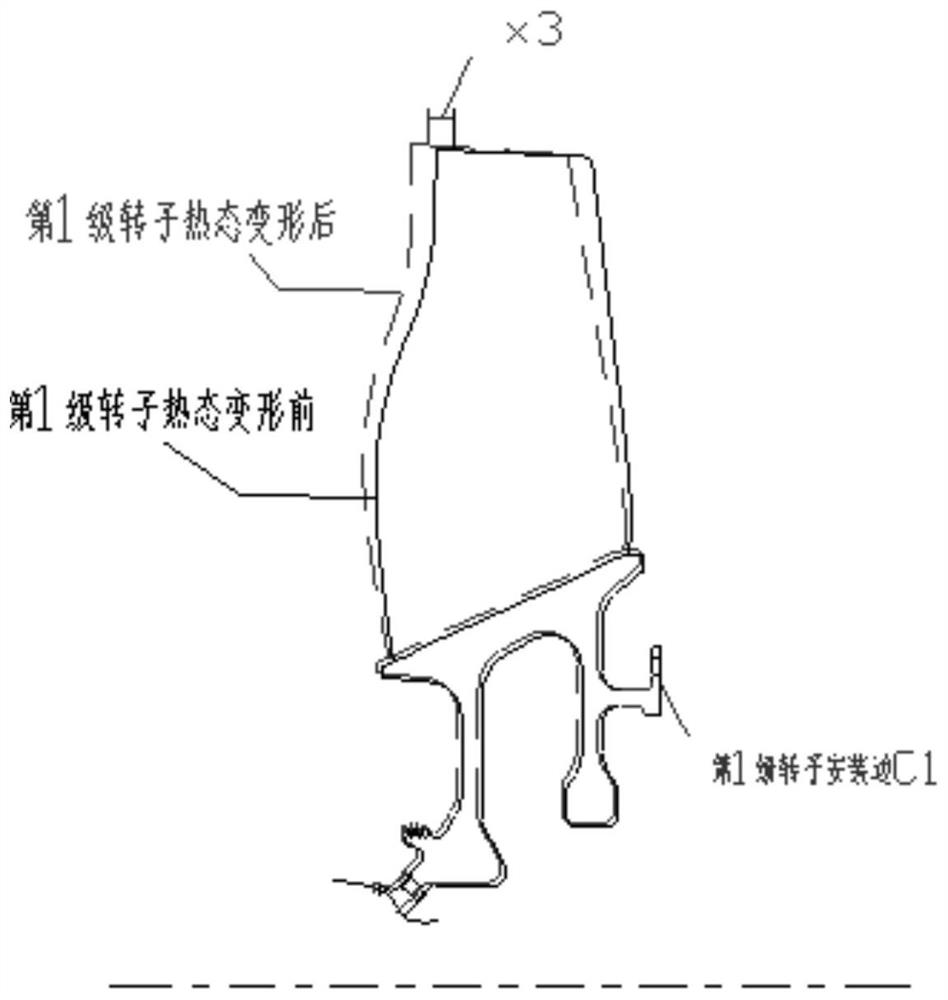

[0033] The engine coordinate system is defined as a right-handed Cartesian coordinate system: X is along the axial direction of the engine, positive along the airflow direction, Z is vertical along the engine, positive vertically upward, and the Y axis is determined by the right-hand rule. Figure 2a-2b It is a schematic diagram of thermal axial deformation of fan rotor and stator components o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com