A starting device of a model shield machine with a movable counter force support

A technology of reaction force bearing and shield machine, which is applied in teaching models, instruments, mining equipment, etc., can solve the complex assembly process of negative segment, the difficulty in assembling the negative segment, and the small distance between the negative segment and the shield tail, etc. problems, to achieve the effect of saving test costs, simplifying the process, and reducing the space occupied by the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

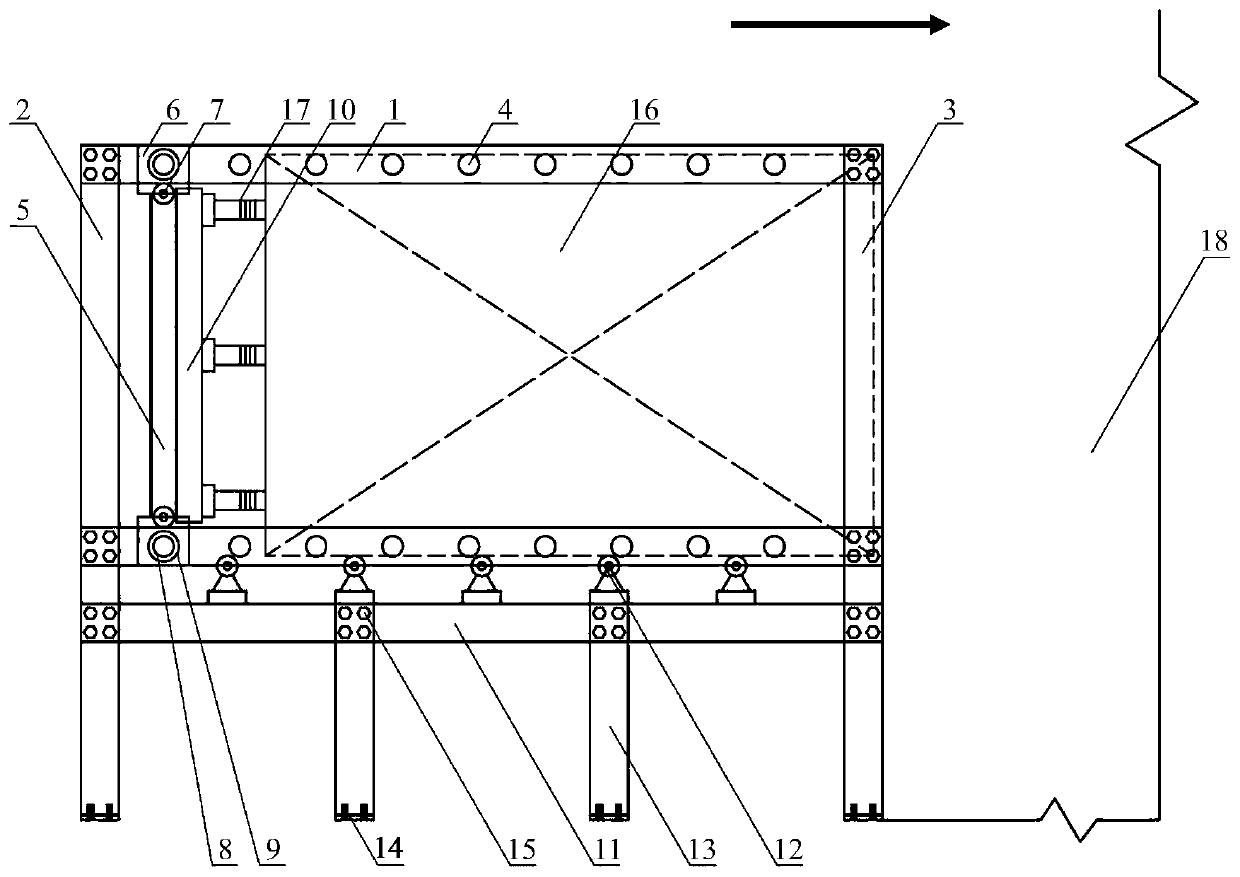

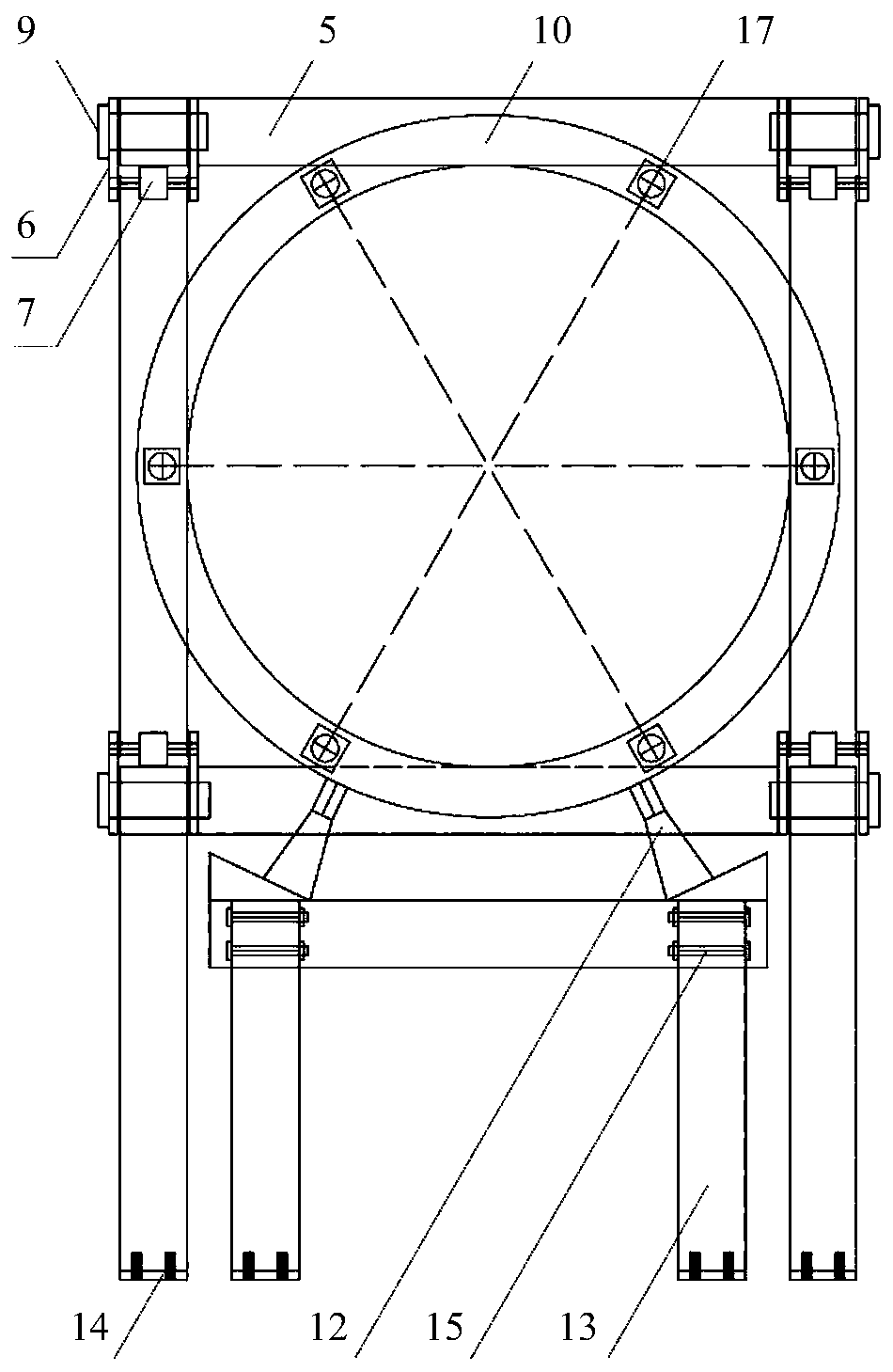

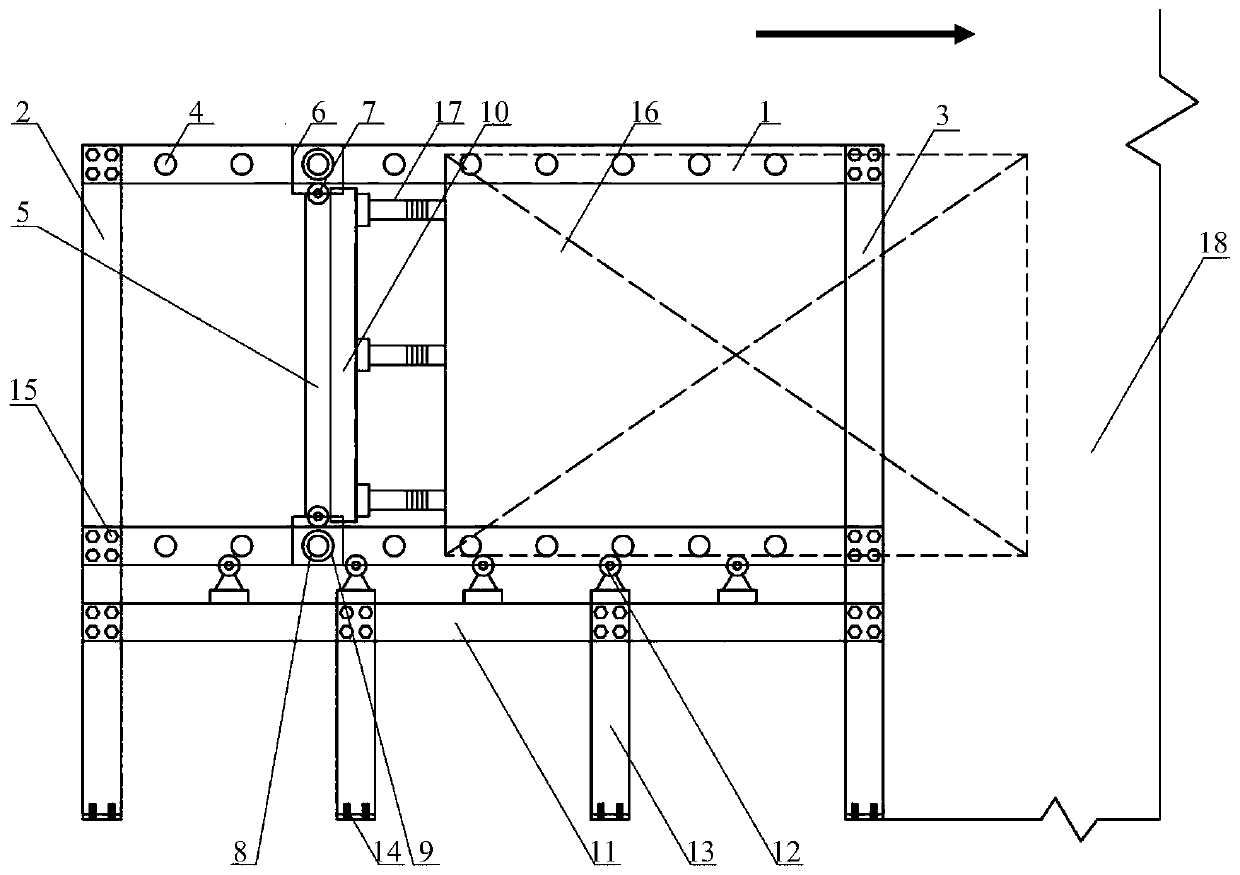

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] Such as figure 1 , figure 2 , image 3 As shown, in the starting device of the model shield machine that can realize the movement of the reaction force support of the present invention, it consists of:

[0023] The reaction force support guide rail 1 is provided with a reaction force support positioning hole 4, and its front and rear ends are respectively connected to the front support frame 3 and the rear support frame 2, and the front support frame 3 is connected to the outer shell of the test soil box 18;

[0024] The front of the bottom plate 5 is connected with the reaction piece 10, and the four corners are designed as U-shaped slots 6, and the U-shaped slot 6 and the normal contact position of the reaction support guide rail 1 are installed with bearings 7, so that the reaction support can move along the direction of the reaction force. The guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com