Water-proof coiled material without tire heat construction, manufacturing method and equipment thereof

A technology of waterproof roll material and production method, which is applied in chemical instruments and methods, infrastructure engineering, building insulation materials, etc., can solve problems such as wrinkles, polyolefin film deformation, tension, etc., and achieve fast and convenient construction and good elongation performance , is conducive to the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

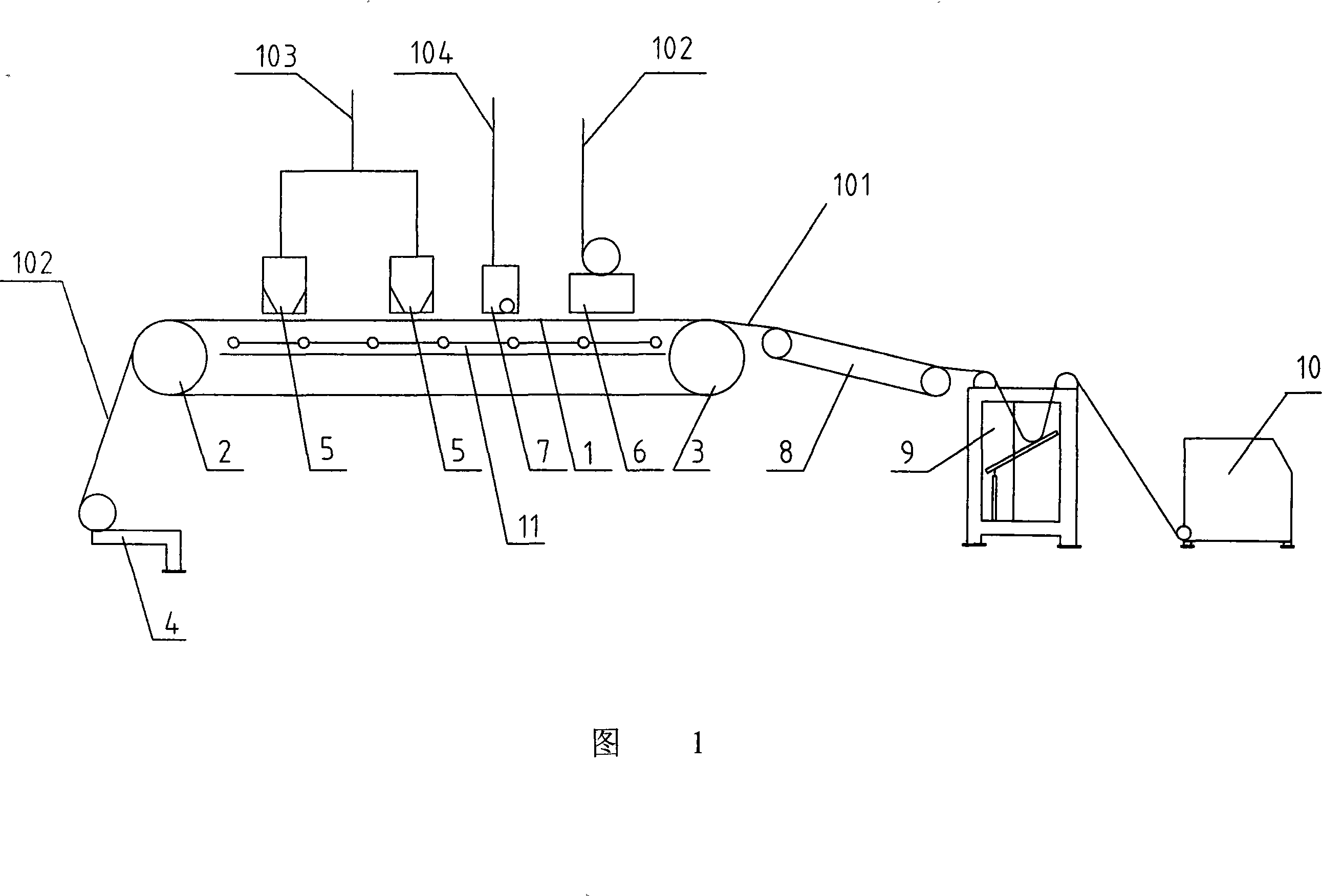

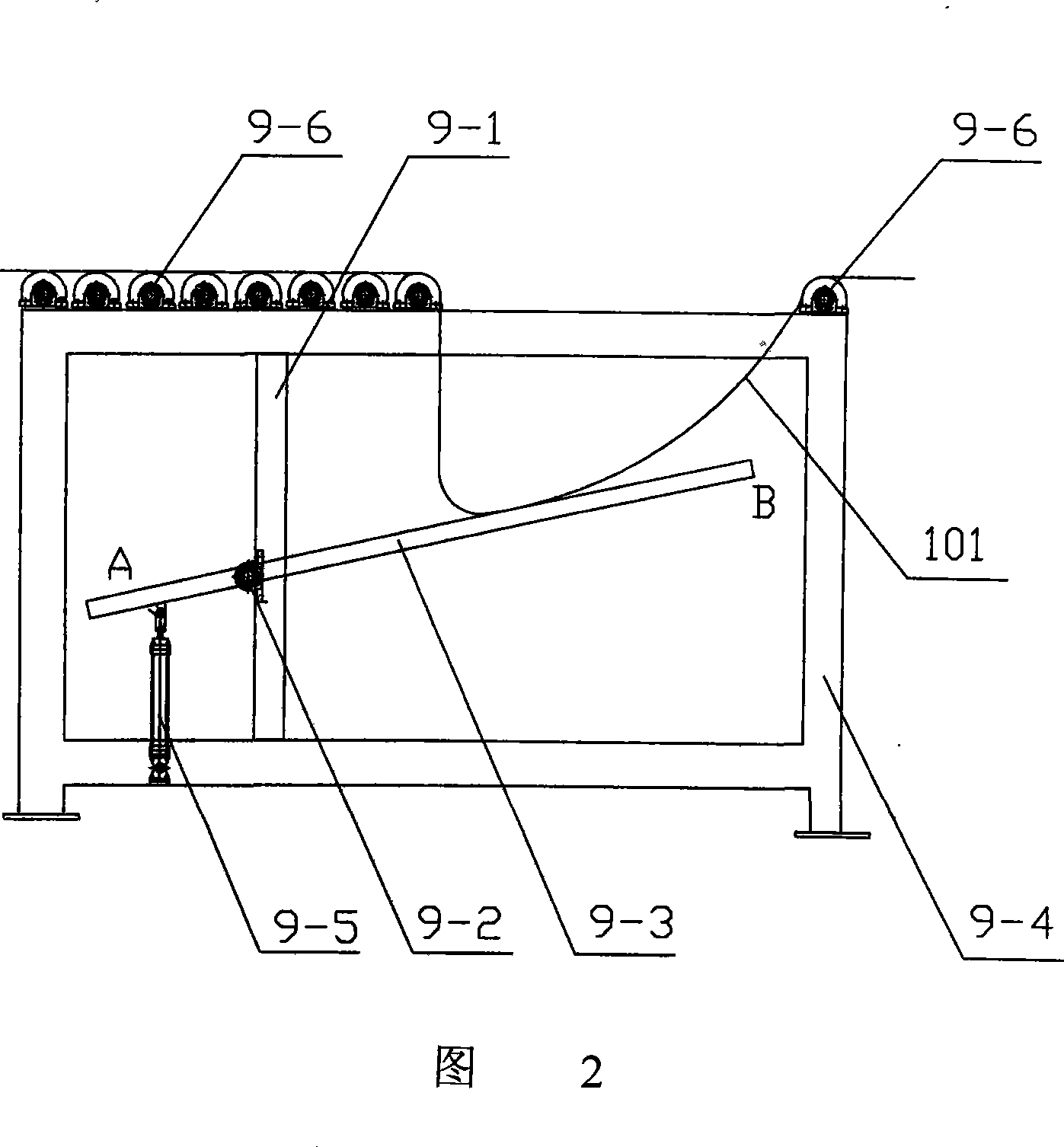

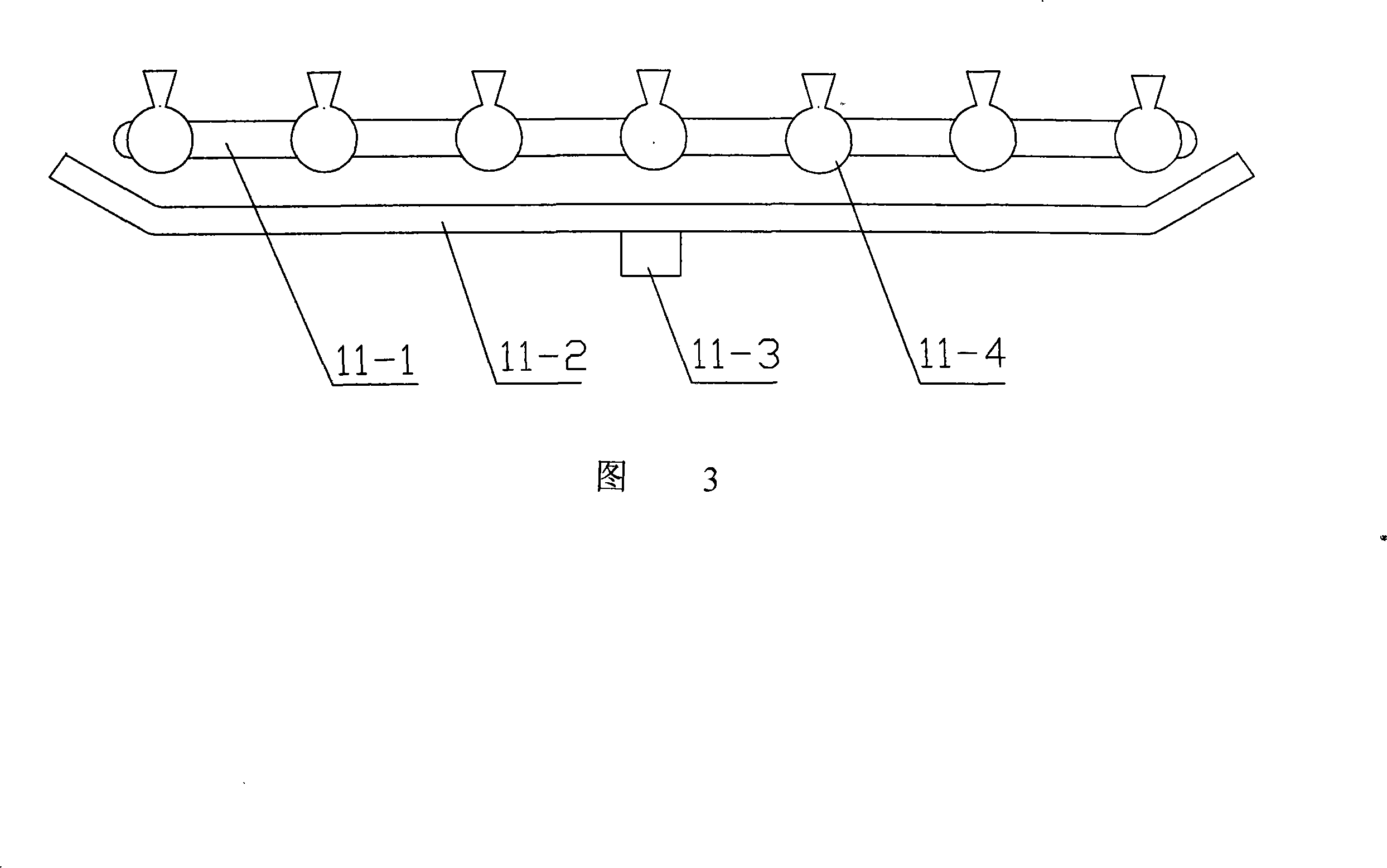

[0029] Embodiment: as shown in Fig. 1~Fig. 3. The tireless thermal construction waterproof roll material 101 is a roll material with a certain size formed by high-density polyethylene film (PE film) 102 on the upper and lower sides, and modified asphalt 103 sandwiched in the middle; It can be a coil with a certain size formed by a high-density polyethylene film (PE film) 102 on the bottom, modified asphalt 103 sandwiched in the middle, and sand 104 on the modified asphalt 103 . When using this membrane for waterproofing, hot application methods should be used. The thickness of the product is 3mm.

[0030]The method for making the waterproof coiled material 101 for hot construction without tires includes introducing the polyethylene film (PE film) 102 on the roll by the film unwinding device 4 and laying it on the outer surface of the transmission steel belt 1, and the transmission steel belt 1 to drive the polyethylene film (PE film) 102 to move forward together, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com