Chimney and steel base body flue joint seam anti-corrosion layer structure and preparation method thereof

A technology of anti-corrosion layer and steel substrate, applied in combustion methods, lighting and heating equipment, combustion product treatment, etc., can solve problems such as poor use effect, high maintenance cost, damage to anti-corrosion layer, etc., and achieve resistance to thermal expansion and contraction. and vibration, good overall performance, good fracture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

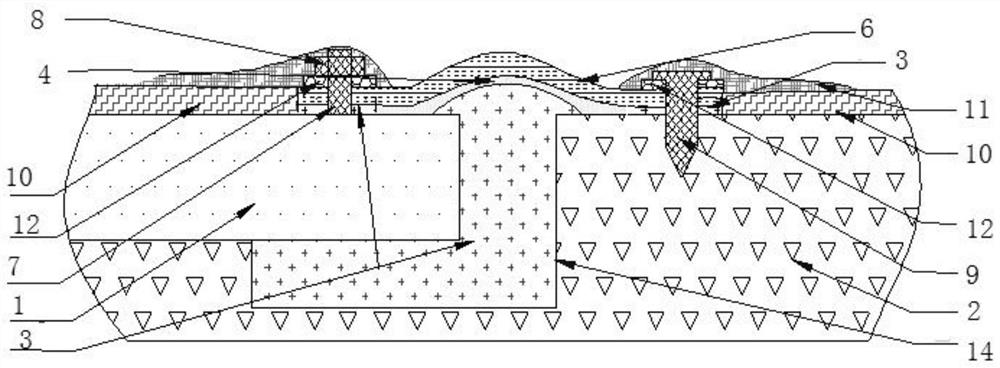

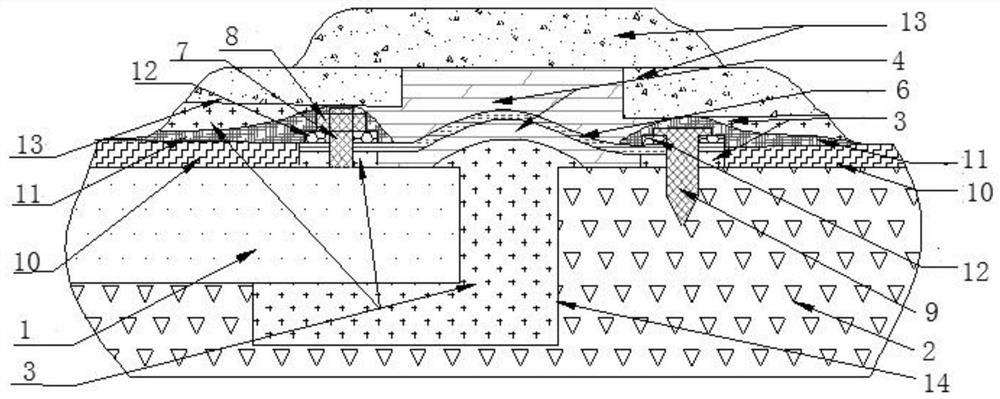

[0046] A kind of chimney and steel substrate flue junction anticorrosion layer structure, such as Figure 1-2 As shown, the anti-corrosion layer structure is arranged between the steel flue base body 1 and the concrete chimney base body 2 and on the inner side wall. The silica gel filling layer 3 in the seam 14, the top of the silica gel filling layer 3 is attached with a flexible filling layer 4 and a fluorine rubber skin 6 in sequence, the flexible filling layer 4 is attached to the silica gel filling layer 3, and the flexible filling layer 4 is attached to the silicone filling layer 3. One end of the filling layer 4 and the fluororubber skin 6 are both attached to the steel flue base 1 , and the other ends are attached to the concrete chimney base 2 to seal the gap between the steel flue base 1 and the concrete chimney base 2 .

[0047] Elastic silica gel is filled in the joint 14 to form the silica gel filling layer 3. As the anti-corrosion layer structure of the flue matr...

Embodiment 2

[0049] Based on Example 1, a silica gel filling layer 7 is provided between the flexible filling layer 4 and the fluororubber skin 6 near the steel flue base 1 and the concrete chimney base 2, and the silica gel filling layer 7 near the steel flue base 1 Fixing bolts 8 and nuts 9 are arranged on it, and firm screws 10 are arranged on the silica gel filling layer 7 near the concrete chimney base 2 . The design of the silica gel filling layer 7 improves the fixing stability of the flexible filling layer 4 and the fluororubber skin 6, and makes the side of the fluororubber skin 6 and the side of the anti-corrosion material layer 11 on the same horizontal line, which is convenient for subsequent installation of the screw material layer. Avoid leaving gaps to prevent acid intrusion and corrosion.

Embodiment 3

[0051] Based on Example 2, the inner side walls of the steel flue base body 1 and the concrete chimney base body 2 are also provided with an anti-corrosion material layer 10 .

[0052] A screw sealing layer 11 is provided above the fixing bolts 7 and the fixing screws 9 , and one end of the screw sealing layer 11 is attached to the anticorrosion material layer 10 , and the other end is attached to the fluororubber skin 6 . Screw sealing layer 11 is set on the surface of fixing bolt 7 and stabilizing screw 9, avoids the acidic liquid in the flue from causing corrosion to fixing bolt 7 and stabilizing screw 9, guarantees that its life-span is longer.

[0053] An FRP bead 12 is arranged near the fixing bolt 7 and the fixing screw 9 . The fixing bolts 7 and the fixing screws 9 are connected to the steel flue base 1 and the concrete flue base through the FRP bead 12 , and the FRP bead 12 is attached to the upper surface of the flexible filling layer 4 . With the above-mentioned st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com