Water-based non-asphalt-based waterproof coating, preparation method thereof and waterproof laminate

A non-asphalt-based, waterproof coating technology, applied in coatings, conjugated diene coatings, roofs using flexible materials, etc., can solve problems such as poor adhesion, high cohesion, and limited use range, and achieve excellent high resistance Low temperature performance, excellent elongation performance, and the effect of avoiding water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

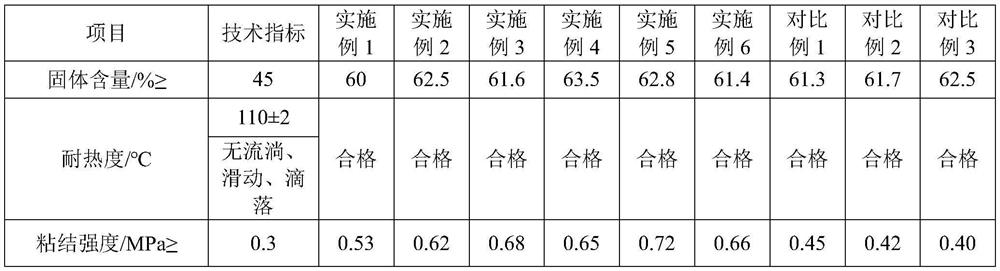

Examples

Embodiment 1

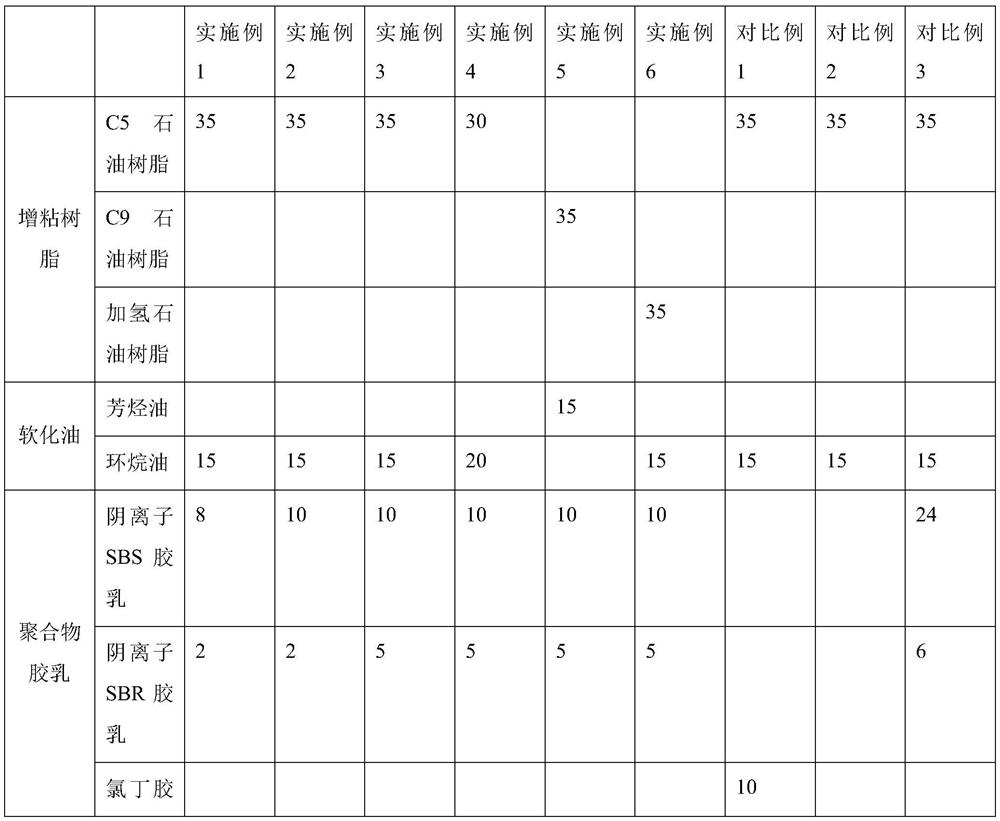

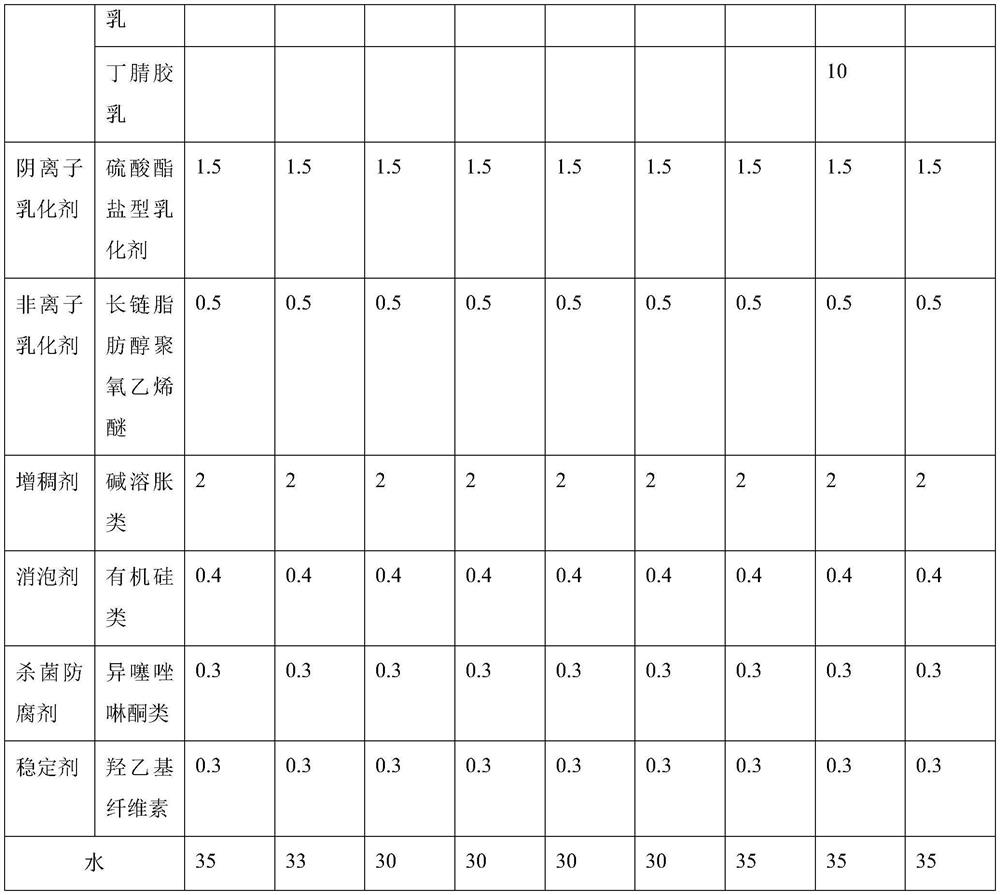

[0050] This example provides a water-based non-asphalt-based waterproof coating, and its raw material composition is shown in Table 1, and the preparation method is as follows:

[0051] Dissolve anionic emulsifier, nonionic emulsifier and stabilizer in water to prepare soap solution, and heat to 50°C for later use; mix C5 petroleum resin and aromatic hydrocarbon oil and heat to 120°C, stir evenly to obtain sizing material; sizing material and soap At the same time, a colloid mill is used to prepare an emulsified rubber compound with stable performance; the defoaming agent, bactericidal preservative, anionic SBS latex, anionic SBR latex and the emulsified rubber compound are mixed, stirred evenly, and the thickener is slowly added to reach the set viscosity. 13000mPa . s, to obtain a water-based non-asphalt-based waterproof coating.

Embodiment 2

[0053] This example provides a water-based non-asphalt-based waterproof coating, the preparation process of which is the same as that of Example 1, the difference is only in that the composition of its raw materials is different from that of Example 1, and its specific composition is shown in Table 1.

Embodiment 3

[0055] This example provides a water-based non-asphalt-based waterproof coating, the preparation process of which is the same as that of Example 1, the difference is only in that the composition of its raw materials is different from that of Example 1, and its specific composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com