Energetic thermoplastic elastomers for solid propellants

A thermoplastic elastomer and solid propellant technology, applied in organic chemistry and other fields, can solve problems such as high glass transition temperature, insufficient elasticity, and excess rigidity, and achieve good elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

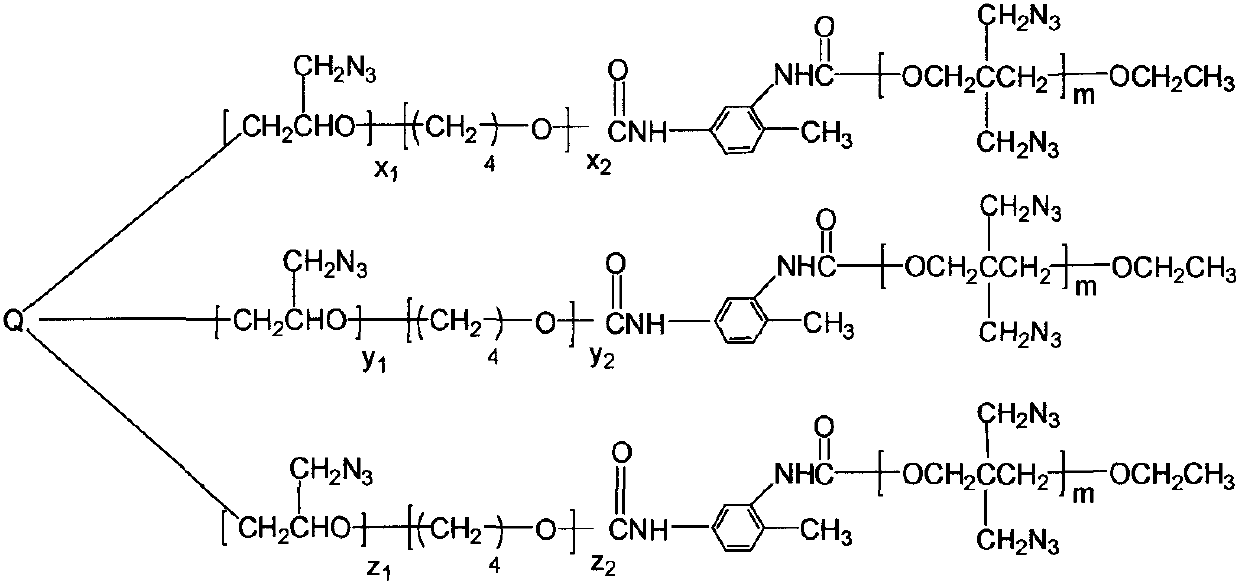

Image

Examples

example 1

[0040] Example 1, the synthesis of energetic thermoplastic elastomer TSETPE for solid propellant:

[0041] 1.1 Synthesis of CPP

[0042] Reaction formula:

[0043]

[0044] In a 500mL four-neck flask equipped with stirring, reflux condenser, thermometer and dropping funnel, add 13.05g (0.05mol) of initiator THEIC and 200mL of dispersant 1,2-dichloroethane. While stirring, the temperature was raised to 30-40°C, and the catalyst BF3 THF 1.0mL (0.008mol) was added dropwise. After the dispersion was uniform, 46.3g (0.5mol) of ECH monomer was added dropwise; when the solid of the initiator disappeared, the reaction liquid formed When homogeneous, lower the temperature slightly and control the reaction temperature between 20 and 30°C, and continue to add the monomer dropwise for a total of about 5 hours. After dropping, cool down to -2°C ~ 0°C, add dropwise a mixed monomer consisting of 54g (0.75mol) of THF and 92.5g (1.0mol) of remaining ECH monomer, the dropping time is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com