Manufacturing process for green harmless precise wires used for household appliances

A manufacturing process and home appliance technology, applied in metal rolling and other directions, can solve the problems that bare copper wires are difficult to meet the performance of green home appliances, and achieve the effects of good recrystallization effect, stable elongation rate, and best elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

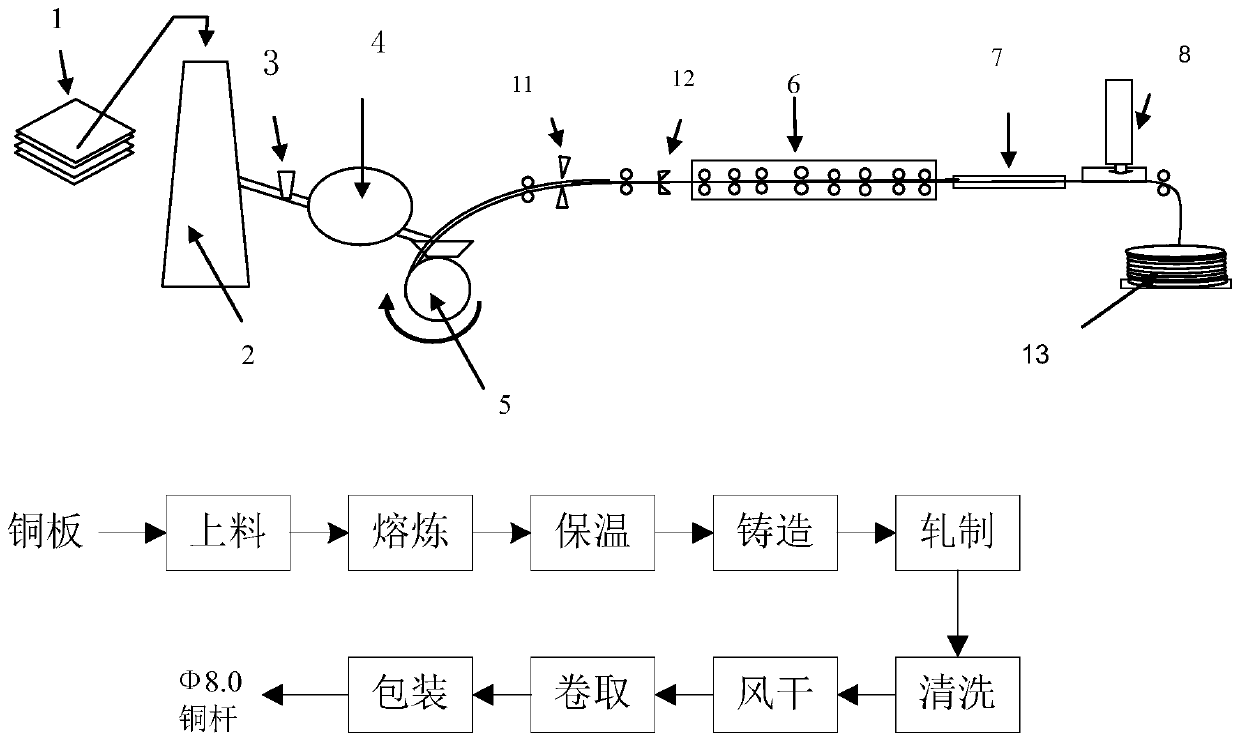

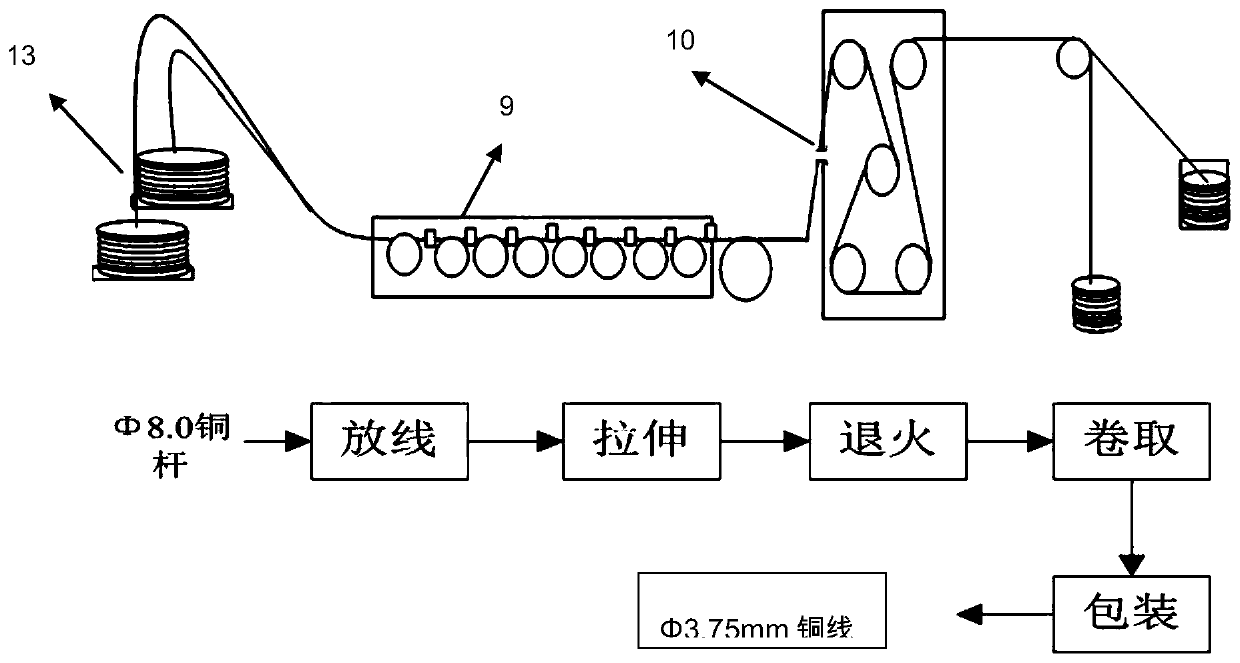

[0029] Such as Figure 1-2 As shown, the manufacturing process of precision wires for green and harmless household appliances includes the following steps:

[0030] S1: Prepare electrolytic cathode copper plate 1;

[0031] S2: The electrolytic cathode copper plate 1 is fed to the shaft furnace 2 for smelting to prepare molten copper;

[0032] S3: After the molten copper passes through the slag box 3 and filters the slag, it is diverted to the holding furnace 4 for heat preservation to keep the molten copper in a liquid state, remove harmful impurities in the molten copper, and reduce the impurity content inside the copper billet crystal. The composition of the copper rod is analyzed by a high-precision spectrometer Conduct testing to ensure high voltage and high current requirements;

[0033] S4: the copper liquid in the holding furnace 4 is drained to the casting wheel 5, and the copper rod 13 is cast into a billet;

[0034] S5: The billet copper rod 13 is rolled by the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com