Processing method for large netting gear clothes of double-layer structure

A technology of double-layer structure and processing method, which is applied in knotting netting, knotting, textile and papermaking, etc. Anti-marine biofouling and other issues, to achieve the effect of improving service life and equipment level, improving anti-fouling performance, and reducing the number of screen changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

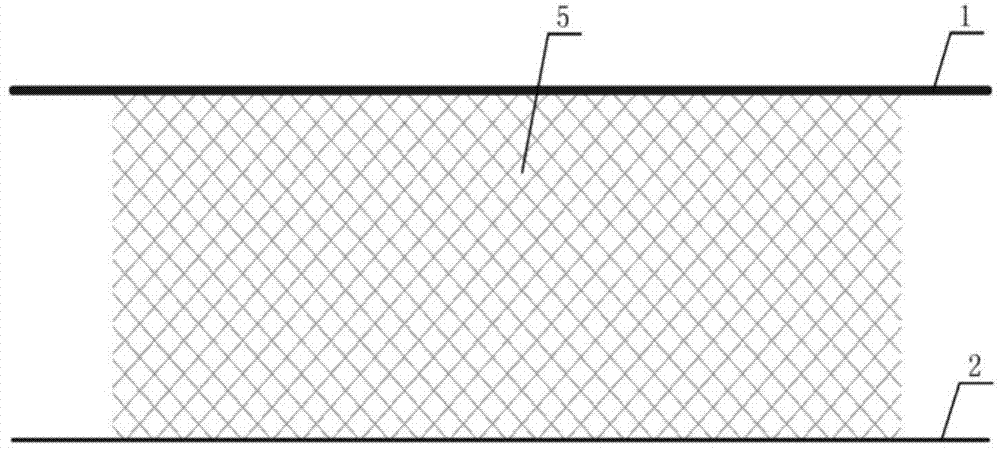

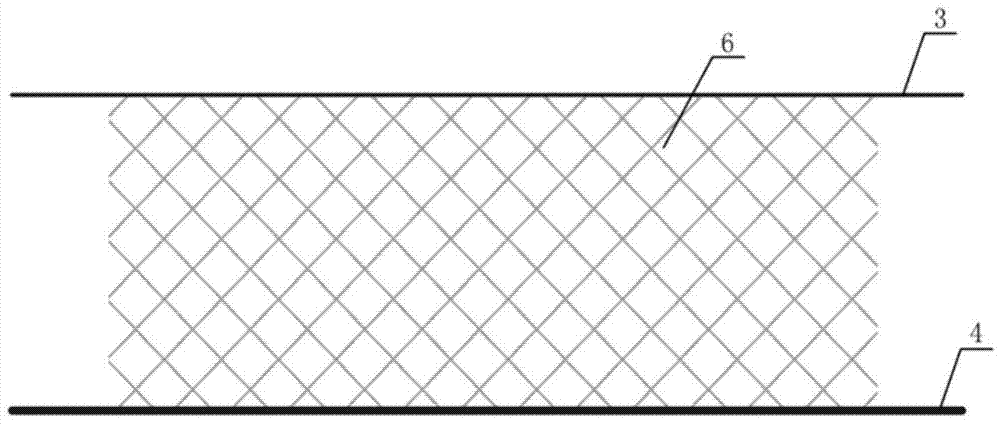

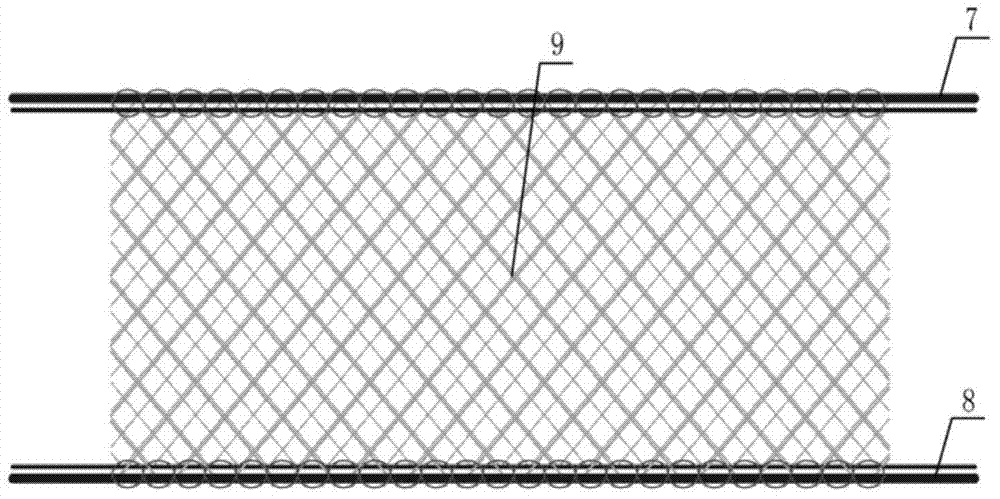

[0010] The invention adopts ultra-high molecular weight polyethylene fiber, ultra-high molecular weight polyethylene braided thread and fishing net antifouling agent, and is characterized in that the ultra-high molecular weight polyethylene fiber with a linear density of 1610D is warped into an ultra-high molecular weight polyethylene fiber with a linear density of 1610D. Vinyl fiber yarn, and then 16 ultra-high molecular weight polyethylene fiber yarns with a linear density of 1610D are used for warp The knitting machine is processed into a small-mesh ultra-high molecular weight polyethylene warp-knitted net with a specification of "UHMWPE-1610D×24-44"; the small-mesh ultra-high molecular weight polyethylene warp-knitted net is treated with antifouling agent for fishing nets, After drying, the antifouling treated small-mesh ultra-high molecular weight pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com