Device and technology for smelting and processing secondary lead materials to generate lead bullion by adopting bottom blowing furnace hearth

A molten pool smelting and regenerated lead technology, which is applied in the field of non-ferrous metallurgy, can solve problems such as relatively difficult application, and achieve the effects of convenient operation, long furnace life, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

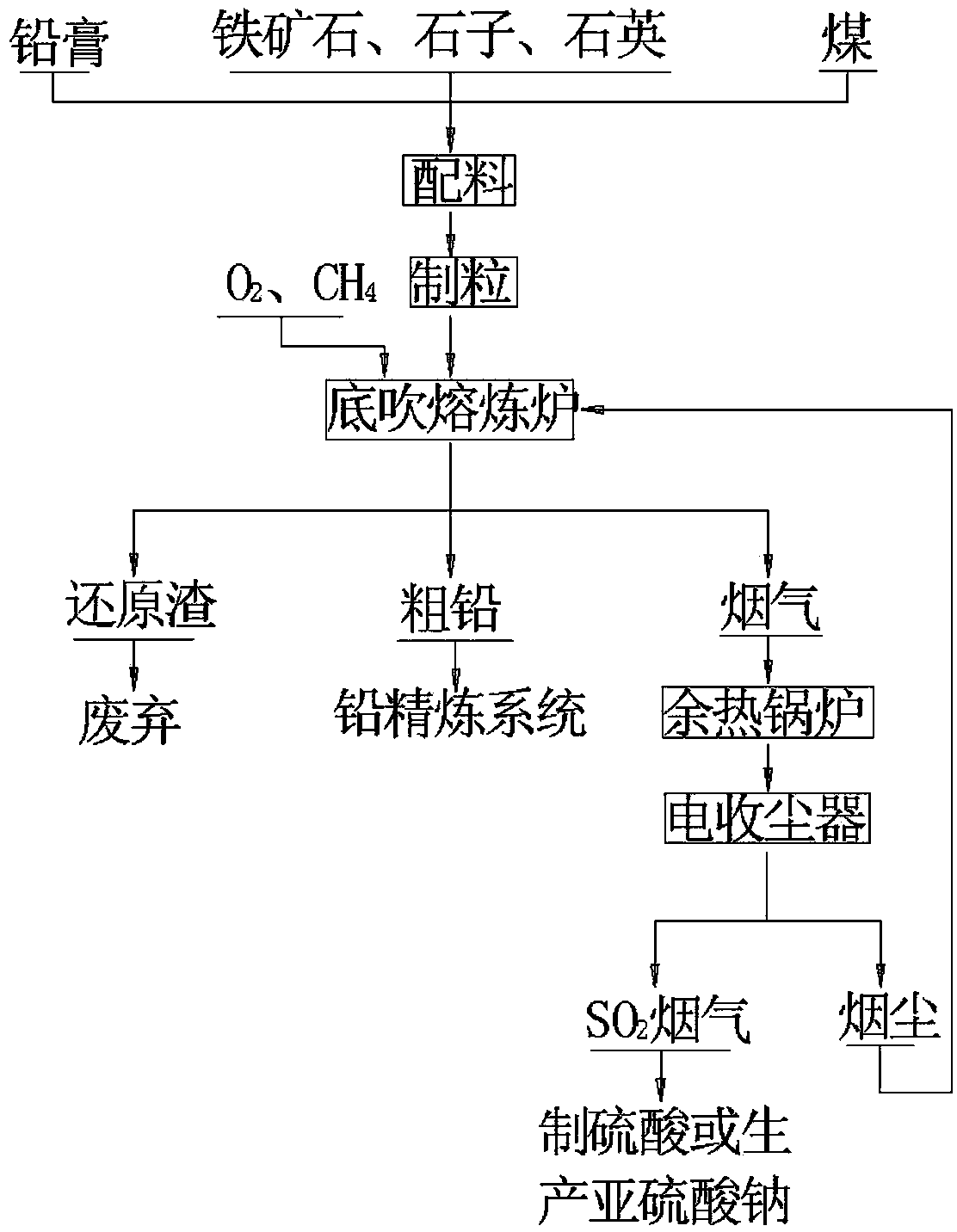

[0044] A process for producing crude lead from secondary lead materials by smelting in a bottom-blown molten pool, comprising the following steps:

[0045] Step 1), mix the lead sulfate paste separated from waste lead-acid batteries with coal powder, iron ore, stone or quartz with a particle size of 1-10mm, and the amount of iron ore, stone or quartz added meets the following iron making Calcium silicon slag needs: FeO / SiO 2 / CaO=1:1:0.5, the amount of lead-containing scrap, coal powder, iron ore, stone or quartz should be added so that the main components after mixing the ingredients are: the mass percentage of Pb is 40%; the mass of S The percentage is 5%; the mass percentage of Fe is 15%; SiO 2 The mass percent of CaO is 15%; The mass percent of CaO is 7.5%, and granulation obtains pellet, for subsequent use;

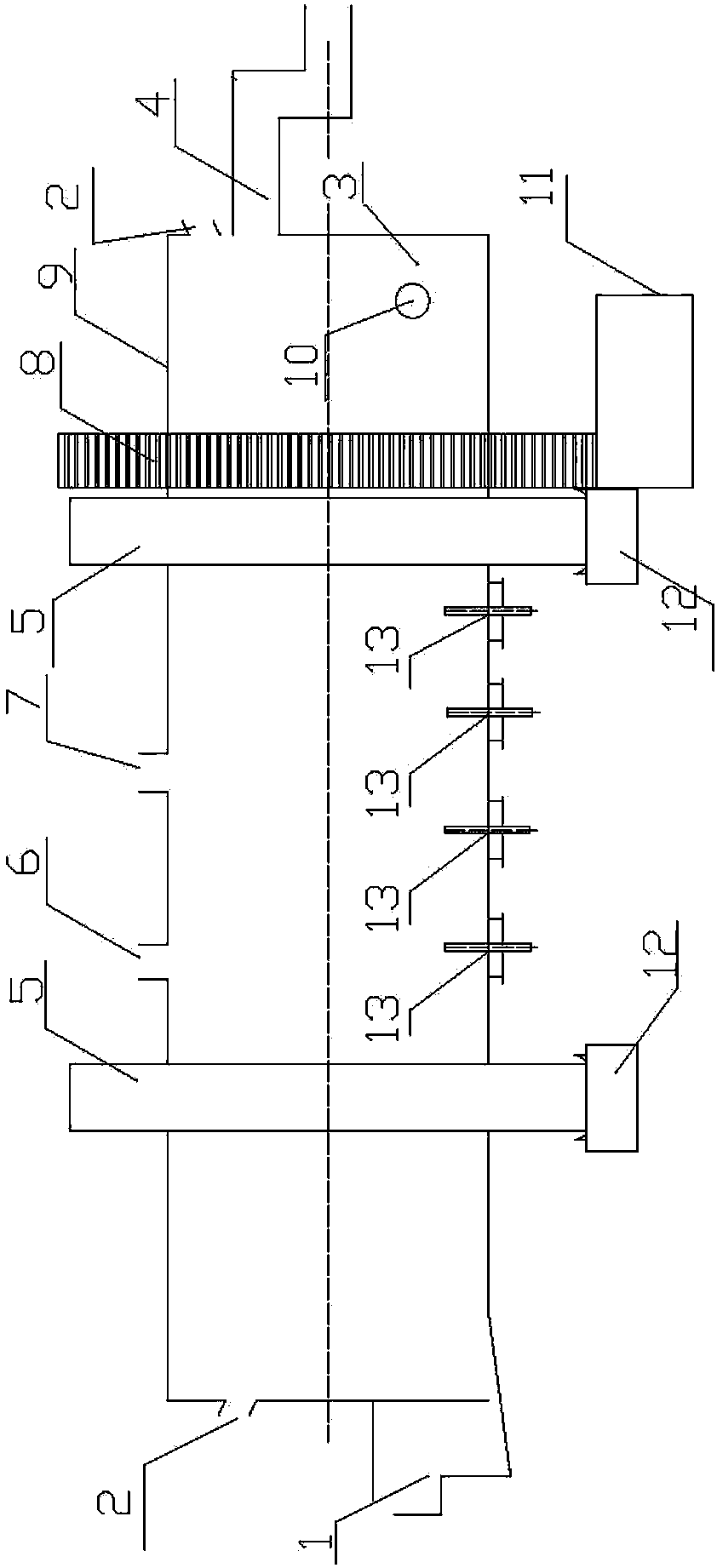

[0046] Step 2), the pellets prepared in step 1) are obtained from such as figure 1 The material feeding port of the device shown is continuously and quantitativel...

Embodiment 2

[0056] A process for producing crude lead from secondary lead materials by smelting in a bottom-blown molten pool, comprising the following steps:

[0057] Step 1) Mix the lead-containing scrap produced in the production process of lead-acid batteries with coal powder, iron ore, stone or quartz with a particle size of 1-10 mm. The amount of iron ore, stone or quartz added meets the following requirements Iron-silicon-calcium slag needs: FeO / SiO 2 / CaO=1.5:1:0.5, the amount of lead-containing scrap, coal powder, iron ore, stone or quartz should be added so that the main components after mixing the ingredients are: the mass percentage of Pb is 40%; the mass of S The percentage is 5%; the mass percentage of Fe is 15%; SiO 2 The mass percent of CaO is 10%; The mass percent of CaO is 5%, and granulation obtains pellet, for subsequent use;

[0058] Step 2), the pellets prepared in step 1) are obtained from such as figure 1 The material feeding port of the device shown is continuo...

Embodiment 3

[0068] A process for producing crude lead from secondary lead materials by smelting in a bottom-blown molten pool, comprising the following steps:

[0069] Step 1), the regenerated lead material is lead sulfate paste separated from waste lead-acid batteries and the lead-containing scraps produced in the production process of lead-acid batteries are simultaneously treated with coal powder, iron ore, stone or quartz with a particle size of 1-10mm Mixed ingredients, the amount of iron ore, stones or quartz added to meet the following requirements for making iron-silicon-calcium slag: FeO / SiO 2 / CaO=1.5:1:0.8, the amount of lead-containing scrap and lead sulfate plaster, coal powder, iron ore, stone or quartz should be such that the main components of the mixed ingredients are: the mass percentage of Pb is 40%; the mass of S The percentage is 5%; the mass percentage of Fe is 15%; SiO 2 The mass percent of CaO is 10%; The mass percent of CaO is 8%, and granulation obtains pellet, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com