Wet-type sintering desulfurization flue gas deep purification device

A technology of flue gas deep purification and gas distribution device, which is applied in the direction of electrode conveying device, electrode structure, steam flow control, etc., can solve the problems of poor pollutant removal effect, improve the level of environmental protection equipment, reduce corrosion speed, Arrange flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

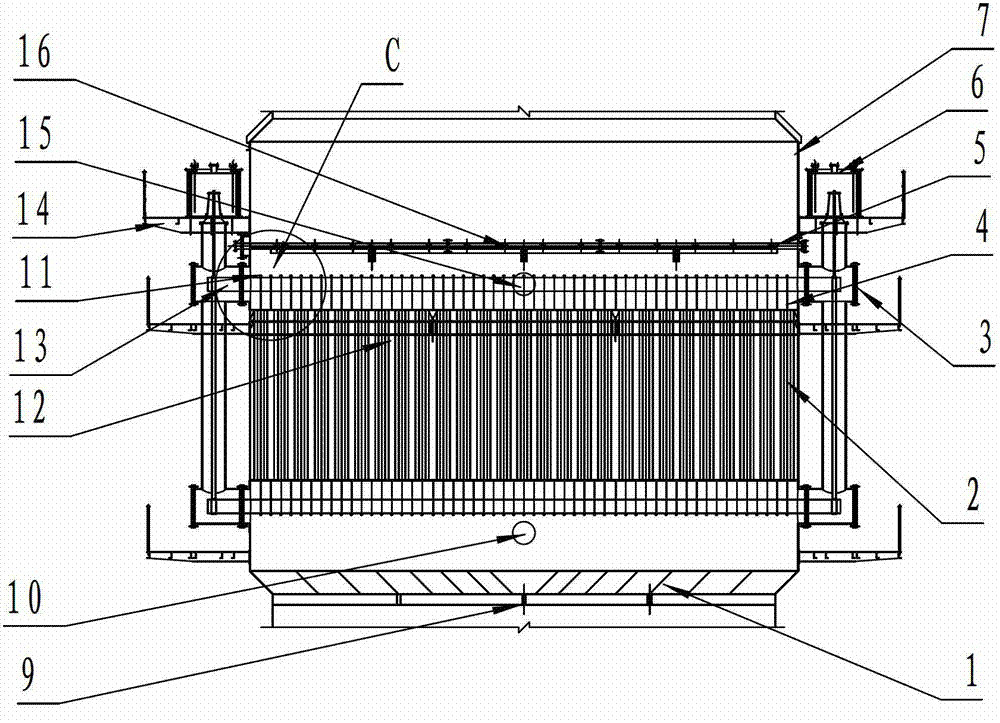

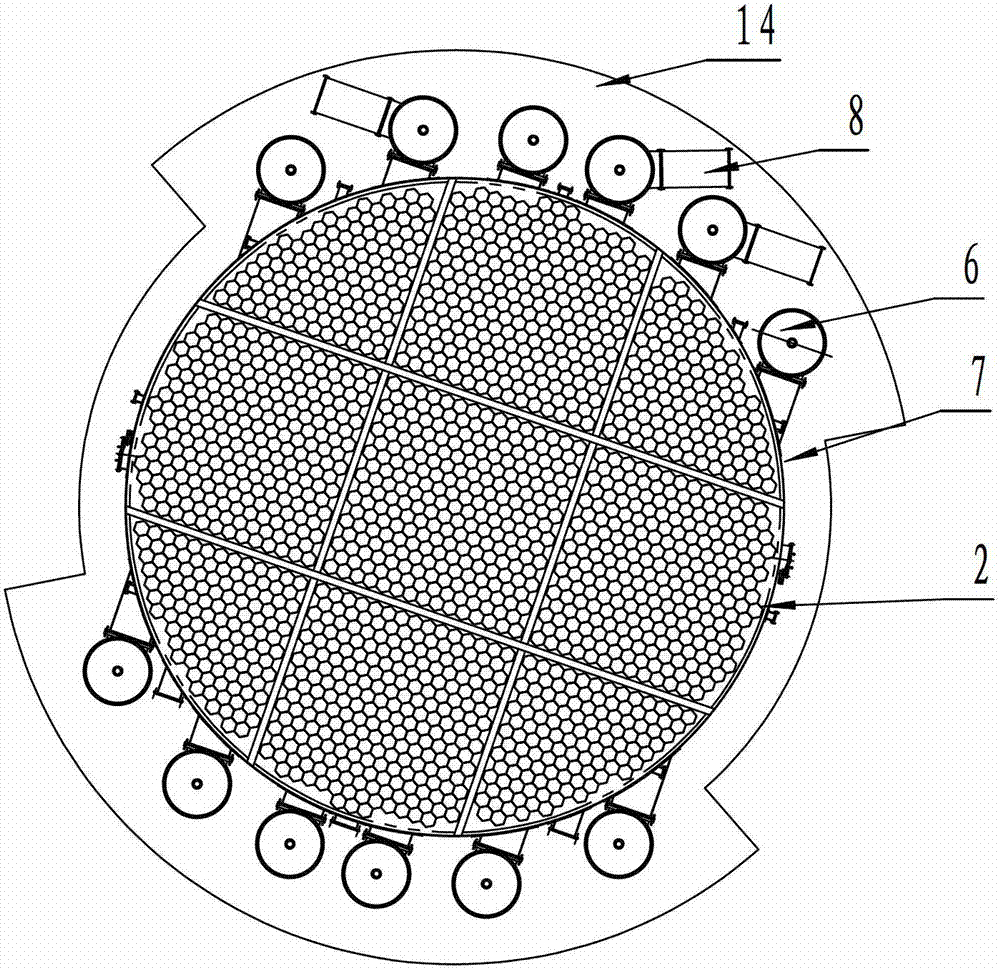

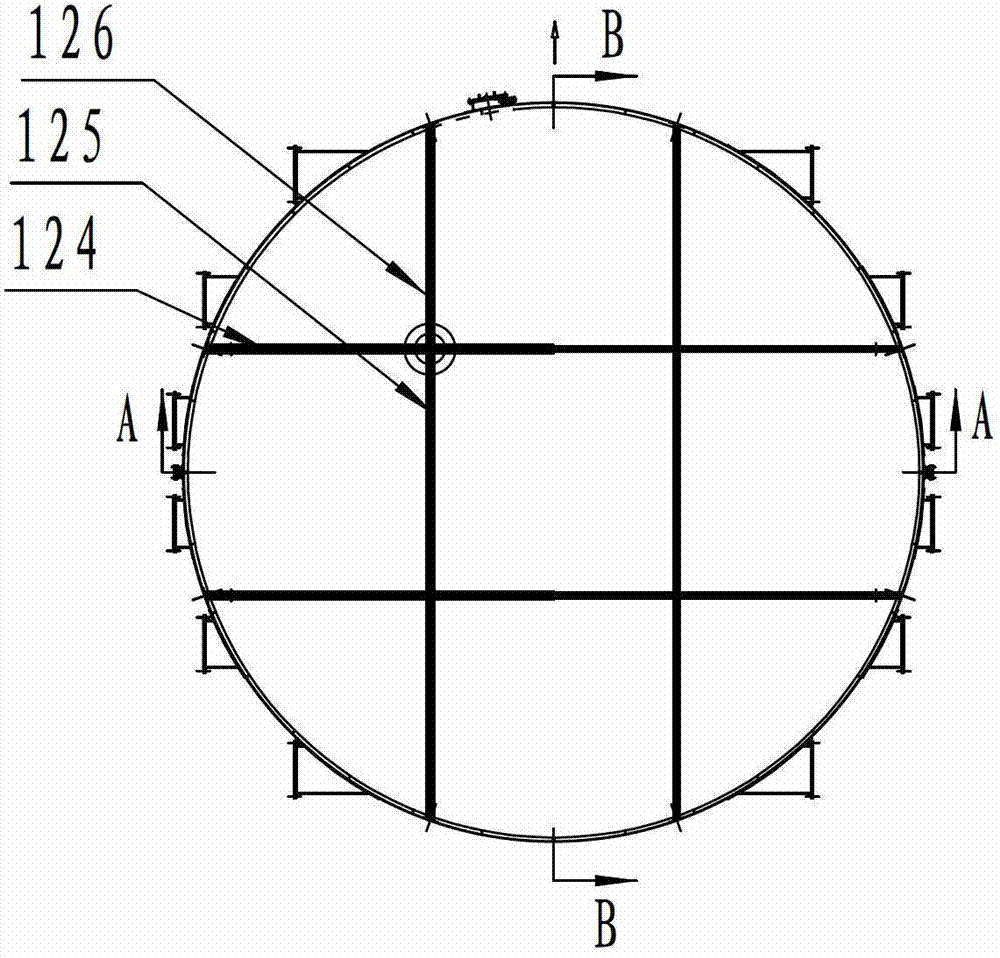

[0024] Embodiment 1, a wet-type sintering desulfurization flue gas deep purification device, including a housing 7 installed on the upper part of the desulfurization tower and a part of the desulfurization tower body, characterized in that there are vertically installed sedimentation anode tube bundles 2 and corona electrodes 4 in the housing , the sedimentation electrode tube bundle is supported and fixed in the shell by the tube bundle in the tower, the upper and lower ends of the corona electrode are respectively connected to the electrode beam 11 on the upper and lower sides of the corona electrode beam 13, and the two ends of the corona electrode beam are in the side pipe 3 Hanging on the boom 64, there is a flushing device and an upper air chamber above the sedimentation electrode, a gas distribution device is provided at the lower part of the shell, and a lower air chamber is between the sedimentation electrode and the gas distribution device; 12 insulating boxes are inst...

Embodiment 2

[0025] Embodiment 2, a wet-type sintering desulfurization flue gas deep purification device, including a shell 7 installed on the upper part of the desulfurization tower and a part of the desulfurization tower body, characterized in that there are vertically installed sedimentation anode tube bundles 2 and corona electrodes 4 in the shell , the sedimentation electrode tube bundle is supported and fixed in the shell by the tube bundle in the tower, the upper and lower ends of the corona electrode are respectively connected to the electrode beam 11 on the upper and lower sides of the corona electrode beam 13, and the two ends of the corona electrode beam are in the side pipe 3 Hanging on the boom 64, there is a flushing device and an upper air chamber above the sedimentation electrode, a gas distribution device is provided at the lower part of the shell, and a lower air chamber is between the sedimentation electrode and the gas distribution device; 12 insulating boxes are installe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com