Ferri-catalyzing desulfurization device for sintering flue gas and kiln flue gas and method

A technology of sintering flue gas and catalytic desulfurization, which is applied in chemical instruments and methods, separation methods, ferric sulfate, etc., can solve problems such as equipment corrosion, secondary pollution, and accumulation of desulfurized gypsum, and achieves reduced floor space, resource conservation, and The effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

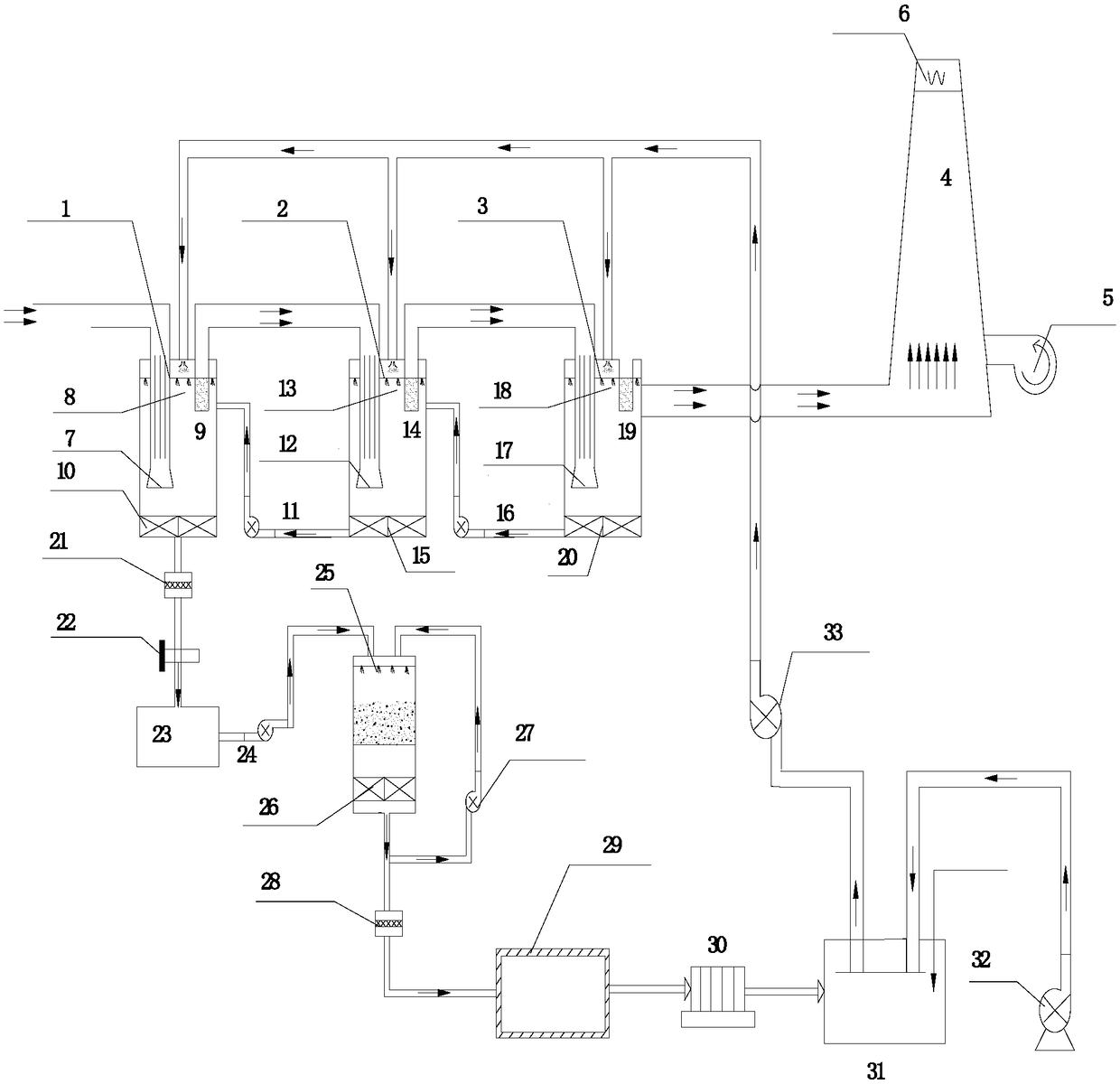

[0031] Example 1: When the flue gas volume is 150,000 to 200,000 Nm 3 , the flue gas with a temperature of 130-150°C passes through the first flue gas inlet pipe 7 and enters the first-stage absorption desulfurization tower 1 after being dedusted by the dust collector. The temperature of the flue gas is reduced to 110-120°C. 3+ The ion filtrate is sprayed into the primary absorption desulfurization tower 1, the filtrate is in contact with the flue gas for 3-4 seconds, and the SO 2 Efficiently oxidized to SO 3 , directly contact with the solution to generate dilute sulfuric acid, and the flue gas reacted in the primary absorption desulfurization tower 1 continues to enter the secondary absorption desulfurization tower 2 through the first flue gas outlet pipe 9, and the temperature of the flue gas will drop to 90-110°C. The same is the use of high-pressure spray gun will contain Fe 3+ The filtrate of ions is sprayed into the secondary absorption desulfurization tower 2, and th...

Embodiment 2

[0032] Example 2: When the flue gas volume is 400,000 to 450,000 Nm 3 , the flue gas with a temperature of 130-150°C is dedusted by the dust collector and then enters the first-stage absorption desulfurization tower 1 through the flue gas inlet pipe 7. After the flue gas temperature drops to 115-123°C, the Fe-containing 3+ The filtrate of ions is sprayed into the primary absorption desulfurization tower 1, and the filtrate is contacted with the flue gas for 3-5 seconds, and the SO 2 Efficiently oxidized to SO 3 , directly contact with the aqueous solution to generate dilute sulfuric acid, and the flue gas reacted in the primary absorption desulfurization tower 1 continues to enter the secondary absorption desulfurization tower 2 through the first flue gas outlet pipe 9, and the temperature of the flue gas will drop to 92-115°C. The same is the use of high-pressure spray gun will contain Fe 3+ The filtrate of ions is sprayed into the secondary absorption desulfurization tower...

Embodiment 3

[0033] Example 3: When the flue gas volume is 1 to 1.1 million Nm 3 , the flue gas with a temperature of 130-150°C passes through the first flue gas inlet pipe 7 and enters the first-stage absorption desulfurization tower 1 after being dedusted by the dust collector. After the flue gas temperature drops to 105-125°C, the Fe-containing 3+ The filtrate of ions is sprayed into the primary absorption desulfurization tower 1, and the filtrate is contacted with the flue gas for 4-5 seconds, and the SO 2 Efficiently oxidized to SO 3 , directly contact with the solution to generate dilute sulfuric acid, and the flue gas reacted in the primary absorption desulfurization tower 1 continues to enter the secondary absorption desulfurization tower 2 through the first flue gas outlet pipe 9, and the temperature of the flue gas will drop to 90-110°C. The same is the use of high-pressure spray gun will contain Fe 3+ The filtrate of the ion is sprayed into the secondary absorption desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com