Resourceful treatment method of coal tar residues

A treatment method and technology for coal tar, which are applied in the field of resource treatment of coal tar residue, can solve problems such as reducing economic efficiency, waste of water resources, and affecting product quality, etc., so as to solve the problem of environmental pollution, realize resource utilization, eliminate The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

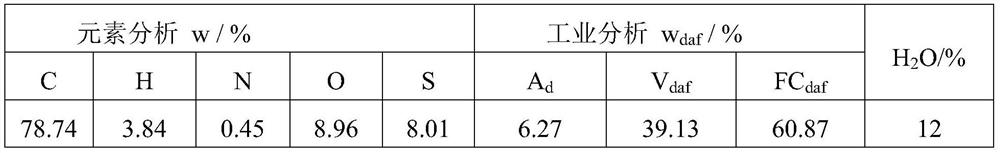

[0033] The tar residue from a coal gasification company in Xinjiang was taken, and the tar residue was subjected to elemental analysis and industrial analysis. The results are shown in Table 1.

[0034] Table 1

[0035]

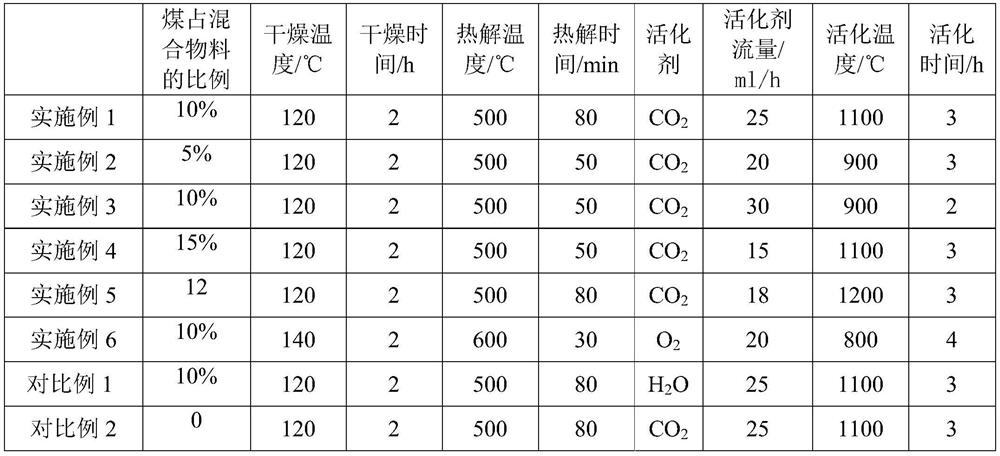

[0036] 90g of tar residue was mixed with 10g of anthracite to obtain a mixture. The mixed material was dried and pretreated at 120° C. for 2 hours to obtain a dried material. Among them, the condensable gas is condensed and collected, and the non-condensable gas is subjected to high-temperature combustion treatment after being adsorbed by an acidic solution.

[0037] Put the pulverized dry material into extruder and extrude it into a columnar material with a diameter of 2.5mm. The columnar material is subjected to low-temperature pyrolysis at 500°C for 80min under a nitrogen atmosphere to obtain thermal solution material. The gases produced during the pyrolysis process are mixed with those produced during the drying process for centralized treatment. T...

Embodiment 2-4

[0041] The method of Examples 2-4 is the same as that of Example 1, except that the process parameters are different, see Table 3 for details, the yield of each product is shown in Table 4, and the properties of the prepared activated carbon products are shown in Table 5.

Embodiment 5-6

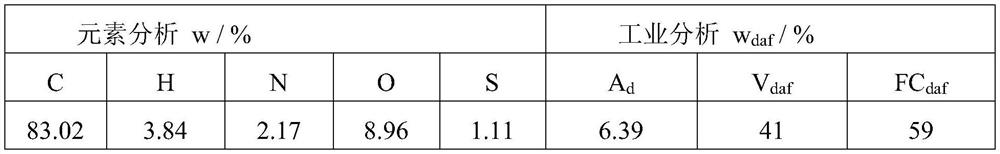

[0043] The raw material of coal tar slag used in Examples 5-6 is coal pyrolysis tar slag from a coking plant in Shandong, and its water content is 3%. The physical parameters after dehydration are shown in Table 2.

[0044] Table 2

[0045]

[0046] The method of Examples 5-6 is the same as that of Example 1, except that the process parameters are different, see Table 3 for details, the yield of each product is shown in Table 4, and the properties of the prepared activated carbon products are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com