Cable splicing operation platform

An operation platform and optical cable splice box technology, which is applied in the coupling of optical waveguides, can solve the problems of low welding quality, low efficiency, and poor stability, and achieve the effects of improving efficiency, ensuring quality, and quickly installing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

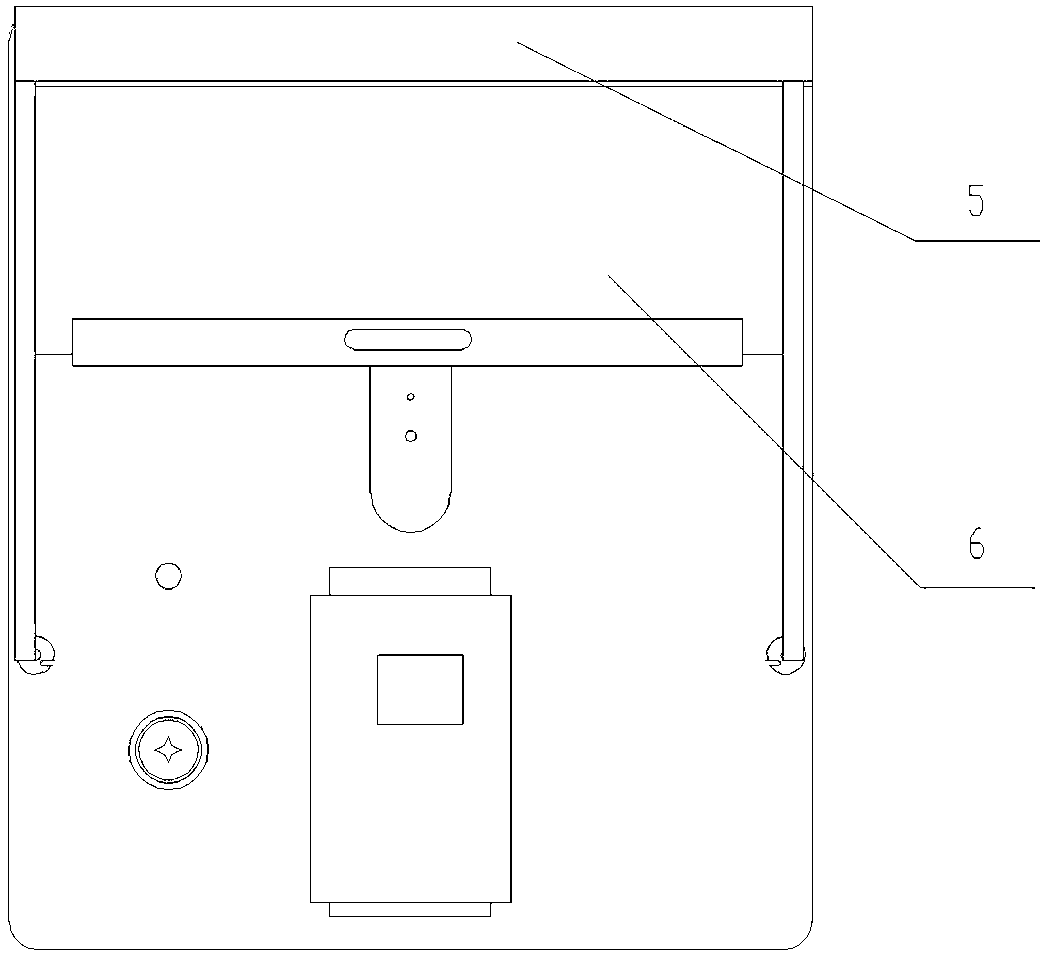

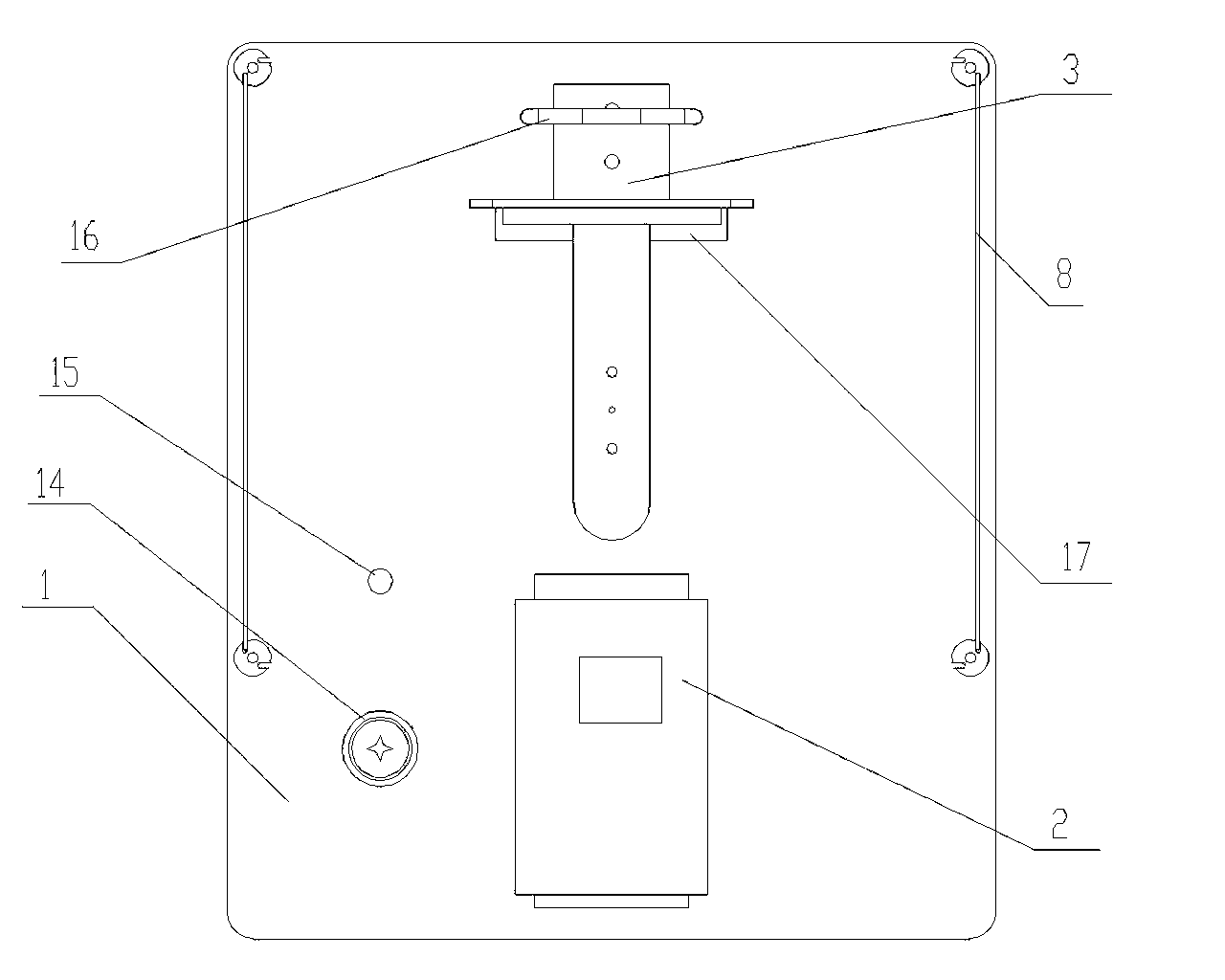

[0024] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the optical cable fusion operation platform provided by the present invention includes a workbench 1 with legs 11, and the two ends in the horizontal direction of the workbench are respectively provided with a groove 13 for placing a fusion splicer 2 and a fixed optical cable splice box 3 The U-shaped clamping plate 16 of the U-shaped clamping plate 16 offers a rectangular fixing groove 17 that cooperates with the optical cable splice box 3 disk parts on the inner side of the U-shaped clamping plate 16, and a groove 14 for placing a spirit level and an umbrella hole 15 are also provided on the workbench surface. . The optical cable entrance limit of workbench 1 is provided with rear windshield 4, and adjacent two sides are provided with side windshield 8, and the bottom edge of rear windshield 4 has the notch that passes through optical cable, see Figure 8 , Figure 9 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com