Tooth shaped structure of screwing tool

A polygonal structure and tool technology, used in the manufacture of tools, screwdrivers, wrenches, etc., can solve the problems of stress concentration, difficult to form, and difficult to manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

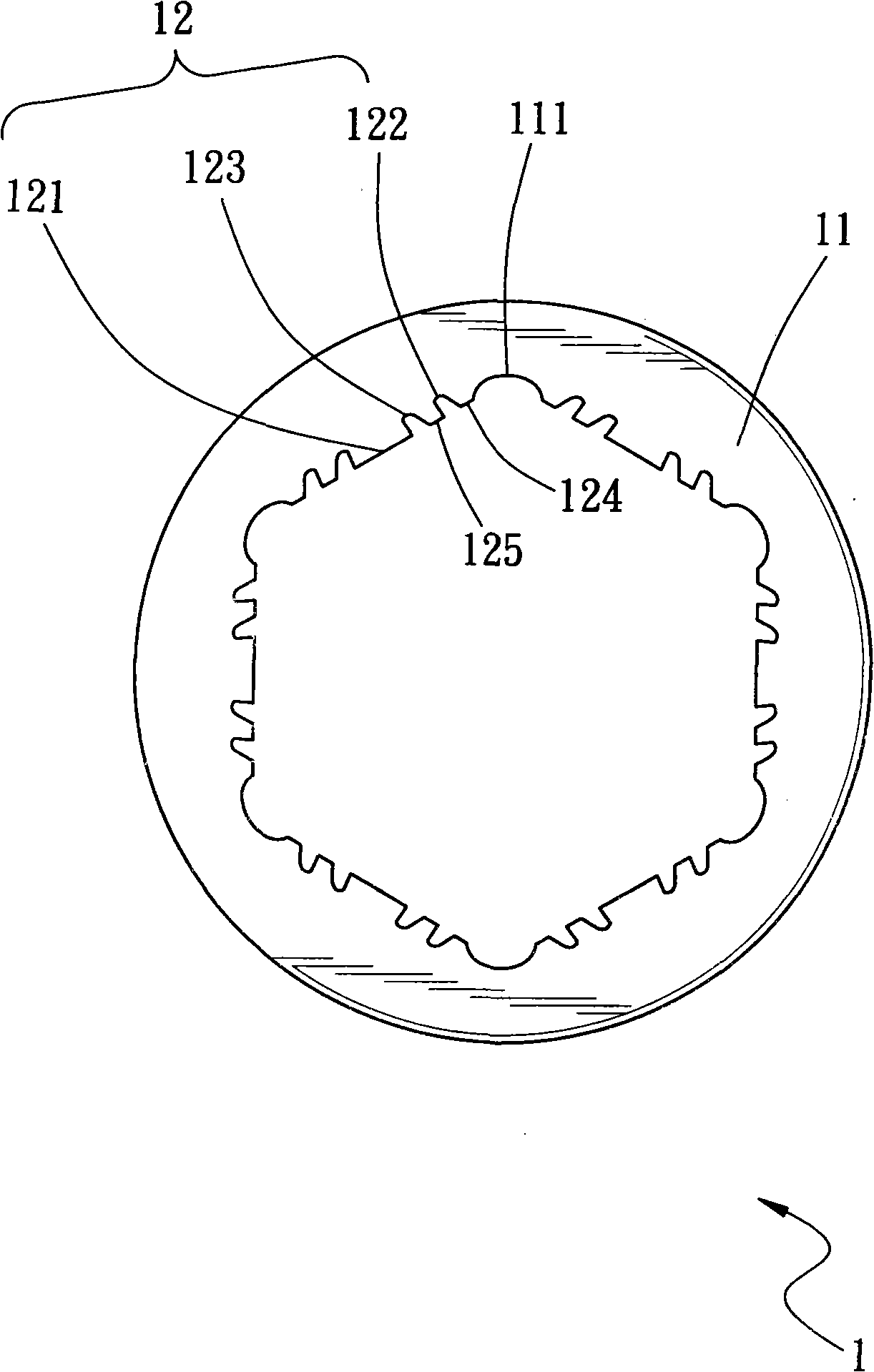

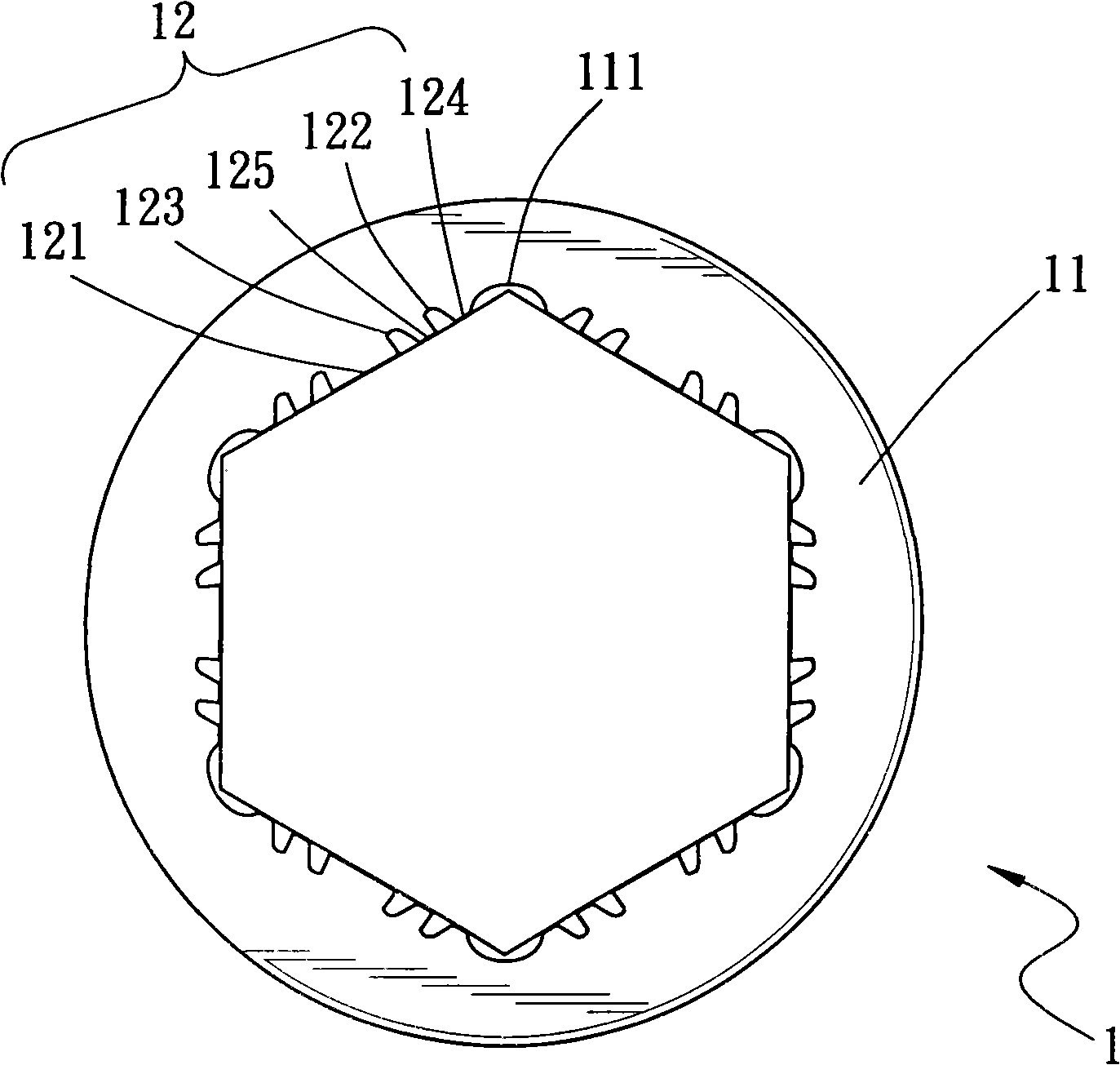

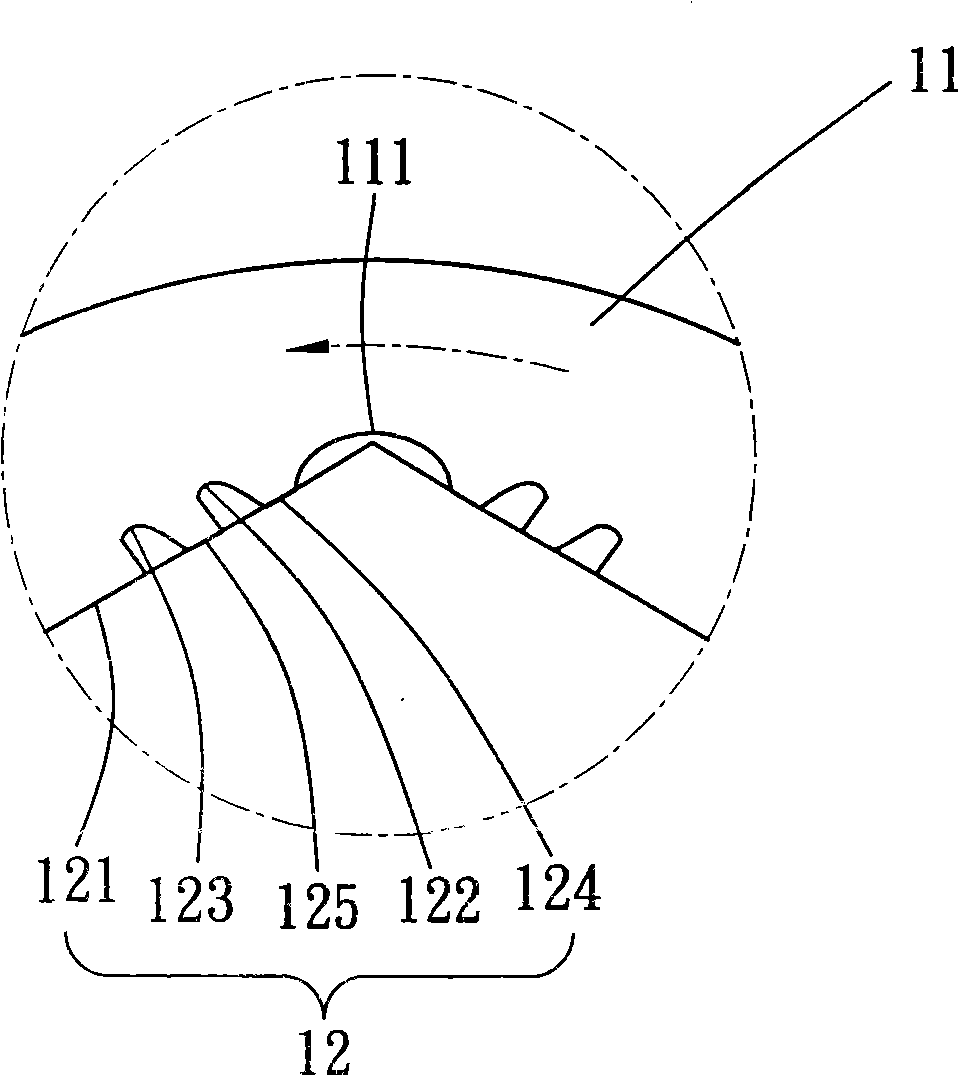

[0032] The present invention relates to a screw tool tooth structure, please refer to figure 1 As shown, the toothed structure of this kind of screw fixing tool mainly includes a driving part 1, and a set of mouth parts 11 is pierced in the driving part 1, wherein:

[0033] The socket portion 11 is a hollow structure recessed in the driving portion 1, and the socket portion 11 is generally in a regular hexagonal structure. Avoidance grooves 111 are respectively provided at the corners of the sides of the regular hexagonal structure of the socket portion 11, totaling There are six avoidance grooves 111. The avoidance grooves 111 are concave arc-shaped structures. The openings of the avoidance grooves 111 are connected with the openings of adjacent avoidance grooves 111 with straight sides 12. The adjacent avoidance grooves 111 are connected The distance between the straight sides 12 is equal in length, and the avoidance groove 111 is used for accommodating each corner of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com