Gear hobbing machining tool and gear hobbing machining method

A processing method and gear hobbing technology, which can be applied to metal processing equipment, gear tooth manufacturing devices, gear teeth, etc., can solve the problems of affecting processing accuracy and high cost of use, and achieve the advantages of increasing the contact area, facilitating disassembly and assembly, and saving costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

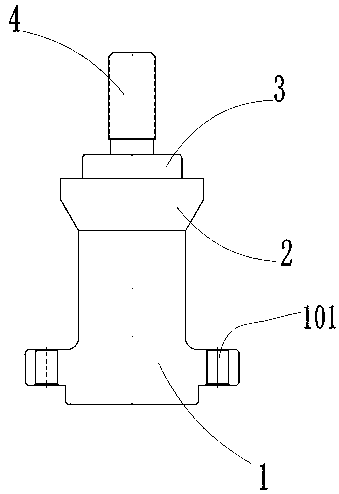

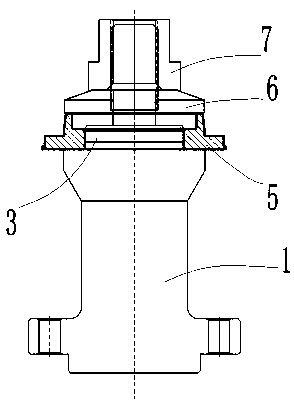

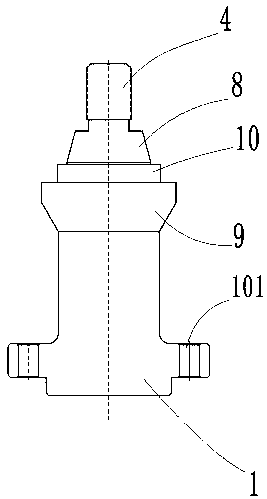

[0035] Such as Figure 1 to Figure 6 As shown, the gear hobbing tooling of this embodiment includes a columnar structure base 1 and an expansion sleeve 12 provided with the base 1, the expansion sleeve 12 is used to be sleeved on the cylinder of the base 1, and the base 1 It includes a section of expansion sleeve installation column 8 corresponding to the design of expansion sleeve 12. The contact surface of the expansion sleeve installation column 8 and expansion sleeve 12 is a conical surface that cooperates with each other. Multiple expansion holes 1201 are provided on the expansion sleeve 12. The outer ring surface of the expansion sleeve 12 is the tooth mounting surface corresponding to the processed product 5 .

[0036] The gear hobbing tooling of this embodiment is specially designed with the expansion sleeve installation column and the expansion sleeve. The expansion sleeve is directly in contact with the processed product. During processing, the product will not direc...

Embodiment 2

[0043] Such as Figure 1 to Figure 6 As shown, according to the gear hobbing tool described in Embodiment 1, the expansion hole 1201 of this embodiment includes a round hole penetrating through the wall of the expansion sleeve 12, and also includes a through groove communicating with the round hole, and the through groove extends to the expansion sleeve. 12 end faces. The design of the round hole of the expansion hole and the through groove extending to the end face of the expansion sleeve makes the wall of the expansion sleeve have a certain degree of expansion and cushioning, which is conducive to the firm combination of the expansion sleeve and the installation column of the expansion sleeve to ensure the stability of the installation of the processed product.

[0044] Further, the expansion sleeve 12 is provided with through grooves extending in two directions, respectively extending to the two end surfaces of the expansion sleeve 12 . The expansion sleeves are respective...

Embodiment 3

[0046] This embodiment provides a gear hobbing method. When the gear hobbing tool described in Embodiment 1 or Embodiment 2 is used for gear hobbing, the base 1 is first installed on the gear hobbing machine tool, and then the positioning plate 11 Install it on the positioning plate mounting platform 9 of the base 1 cylinder, then set the expansion sleeve 12 on the expansion sleeve installation column 8, and use the expansion hole 1201 to expand the expansion sleeve 12 to closely contact with the expansion sleeve installation column 8, and then install The processed product 5 and the lock nut 7 are hobbed by a gear hobbing machine tool.

[0047] In the gear hobbing processing method of this embodiment, by setting the expansion sleeve installation column and the expansion sleeve on the base cylinder, the processed product directly contacts with the expansion sleeve and does not directly contact the base cylinder, which avoids direct wear on the base cylinder and is convenient. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com