Anti-sticking material bulk cargo storage bin

An anti-sticking material and bulk material technology, which is applied in the field of bulk material silo discharge, can solve the problems of easy damage to the next-level equipment, time-consuming and laborious, sticky materials, etc., achieve good anti-sticking effect, reduce labor intensity, and solve the problem of The effect of the sticky problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

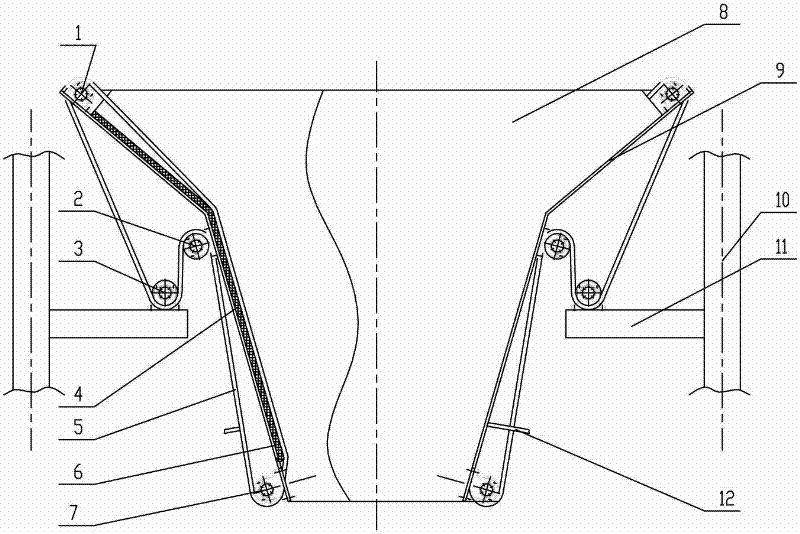

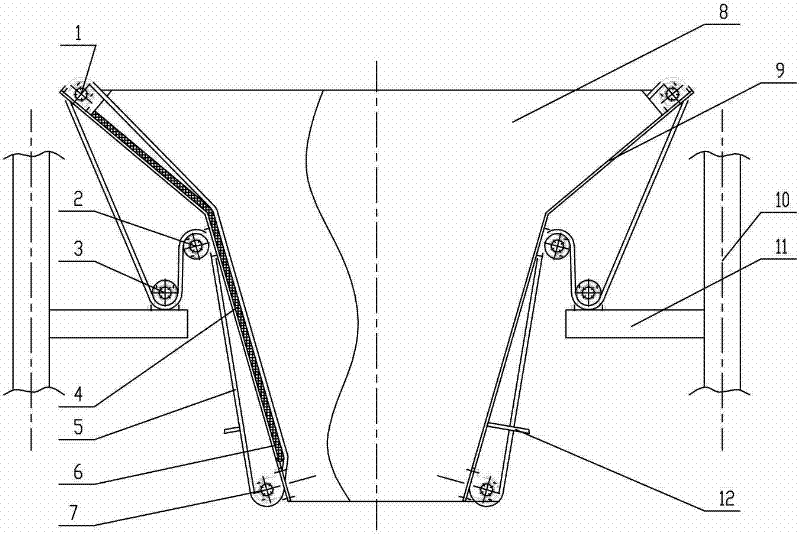

[0013] Such as figure 1 As shown, the bulk material silo of the anti-sticking material of the present invention includes a bulk material silo 8, columns 10 located on both sides of the bulk material silo 8, and is characterized in that the corresponding bulk material silo 8 Both side plates 6 are side plates 6 with a lower slope of 70° and an upper slope of 50°. The top and bottom ends of the two side plates 6 are respectively provided with a top guide hole and a bottom guide hole. The inwall of 6 is all provided with liner plate 4, and the material of this liner plate 4 is polyurethane plate, can prevent the direct wearing and tearing of belt and side plate inwall. Flanges 9 are arranged on the outer walls of the two side plates 6 along the material receiving direction, and the two side plates 6 are respectively provided with anti-adhesive material mechanisms,

[0014] The anti-adhesive mechanism includes a bracket 11 fixedly connected to the column 10, a tension roller 3 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com