Sliding nozzle device

A sliding nozzle and pulley technology, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve problems such as many operating errors and mistakes, unreasonable operating mechanisms, and inaccurate control, and achieve cost reduction and structure simplification. , control the precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

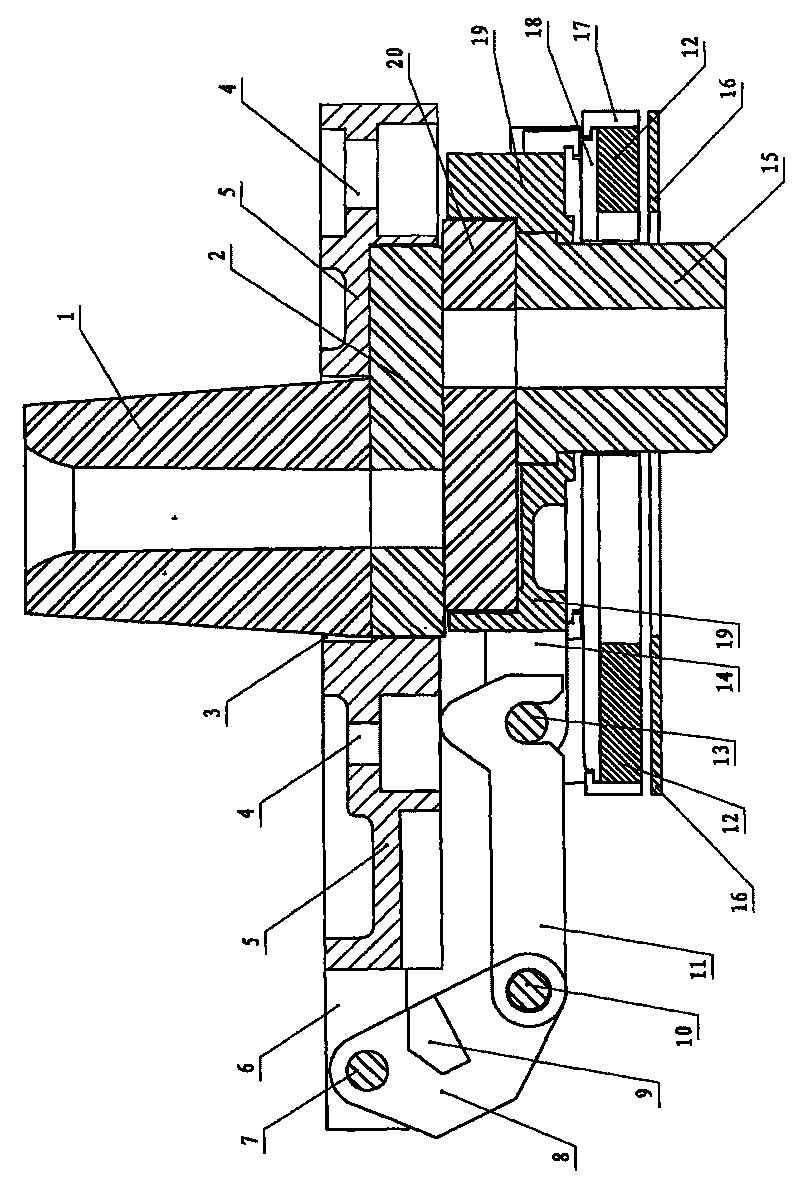

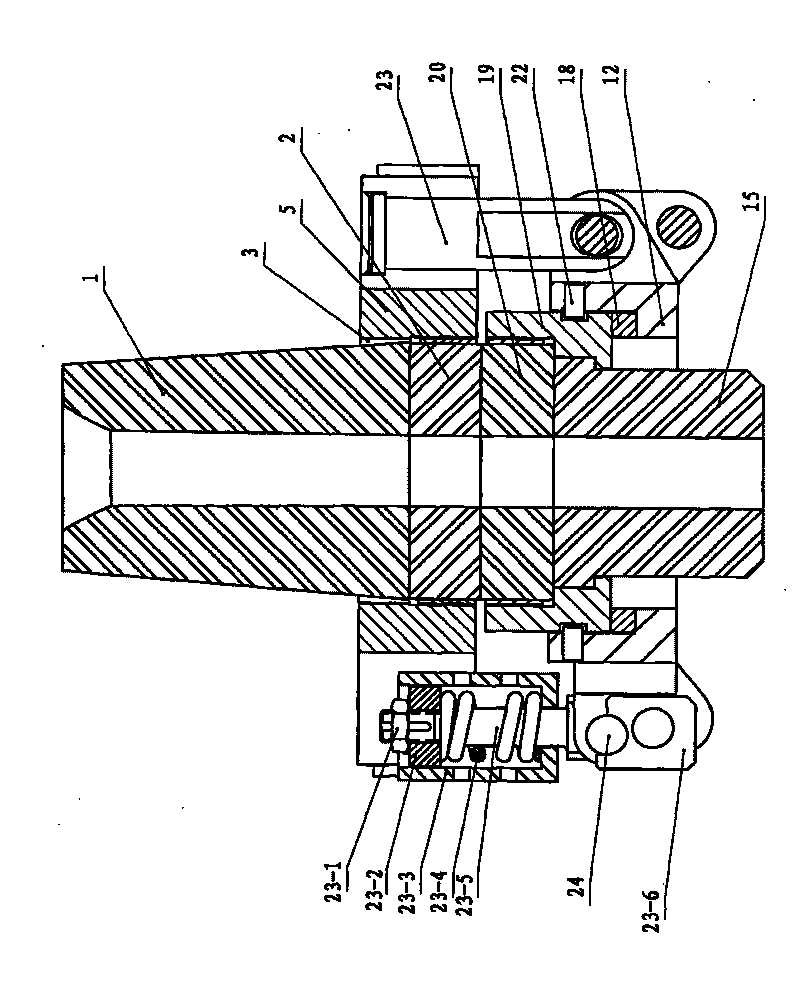

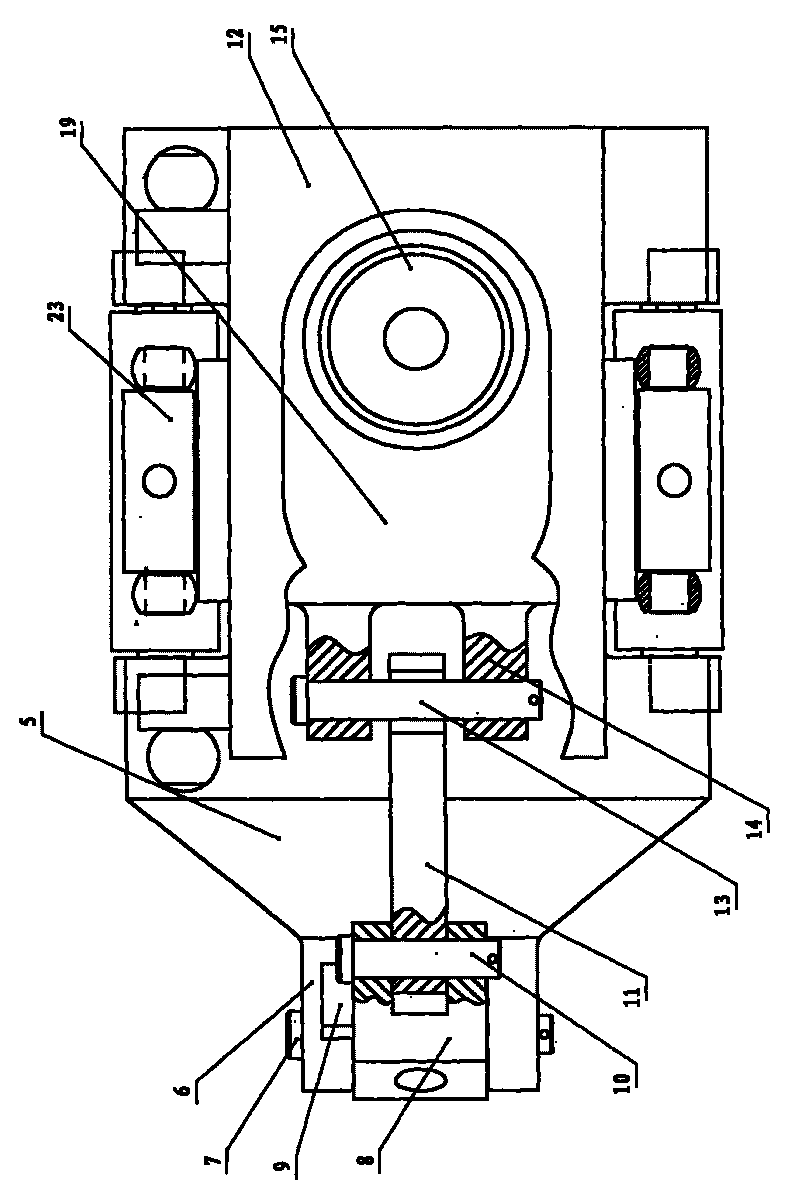

[0030] Example: see Figure 1-Figure 10 , in the figure 1. Upper nozzle, 2. Upper slide brick, 3. Upper nozzle hole, 4. Mounting hole, 5. Base, 6. Hinged ear A, 7. Hinged shaft A, 8. Rocker arm, 9. Limit Block, 10. Winged shaft B, 11. Hook bar, 12. Sliding bracket, 13. Cross bar, 14. Hinged ear B, 15. Water outlet, 16. Protective plate, 17. Compression bar, 18. Slider, 19. pulley, 20. sliding plate brick, 22. sliding pin, 23, spring locking mechanism, 24. pressing shaft.

[0031] Among them, 23-1. Compression nut, 23-2. Press plate, 23-3. Spring box, 23-4. Spring, 23-5. Pull rod, 23-6. Compression elbow, 19-1. Lower plate brick cavity , 19-2. Step snap ring, 19-3. Drain installation hole, 19-4. Chute, 8-1. Operating hole, 8-2. Hinged hole, 8-3. Hinged hole, 9-1 . Limiting surface.

[0032] A sliding nozzle device, including a base 5, a sliding brick and a sliding bracket 12, a pulley 19 is provided between the base 6 and the sliding bracket 12, and a spring locking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com