Improved sealing ring structure for horizontal middle opening double suction pump

A sealing ring and double-suction pump technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pumps, etc., can solve the problems of impeller wear and tear, avoid direct wear and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

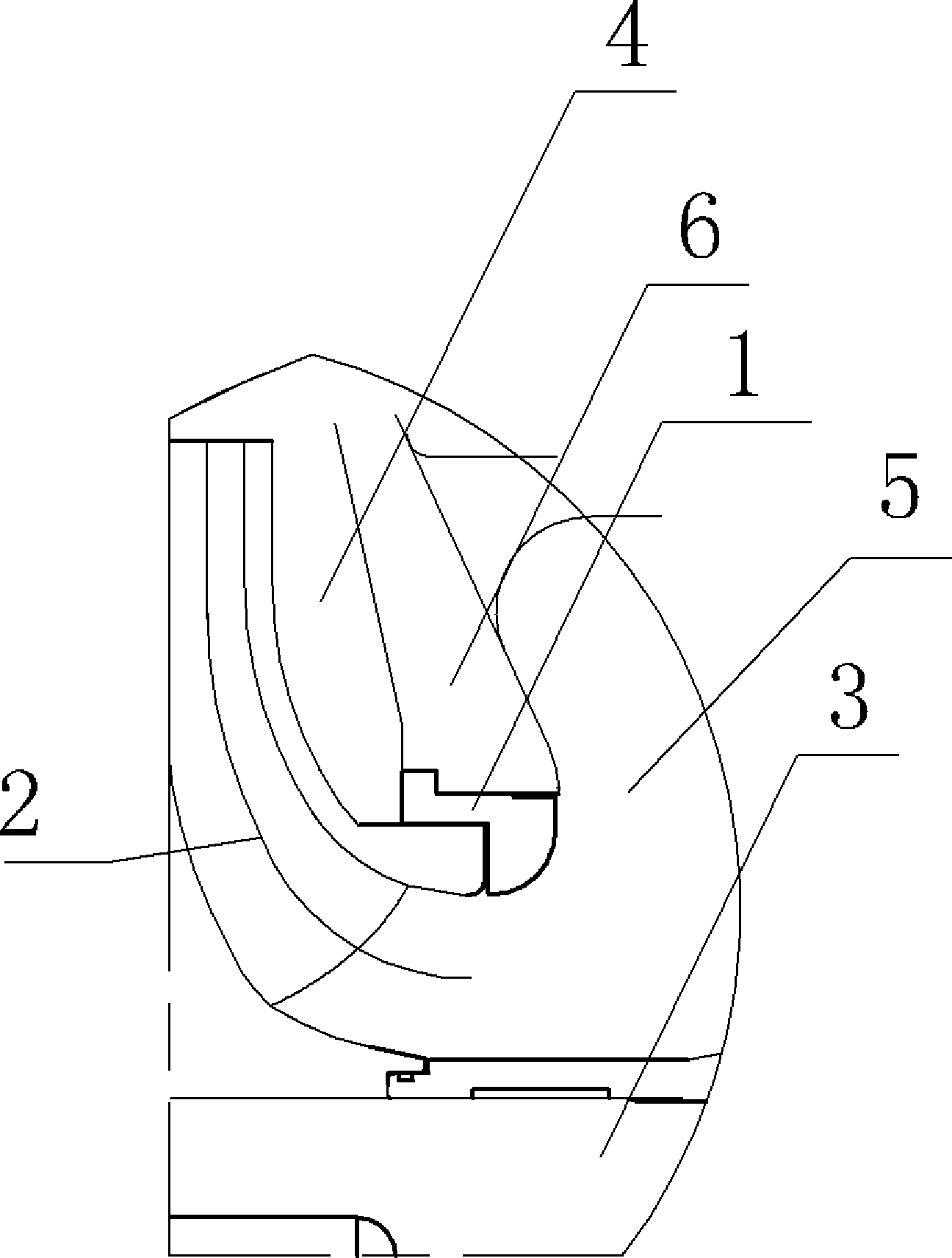

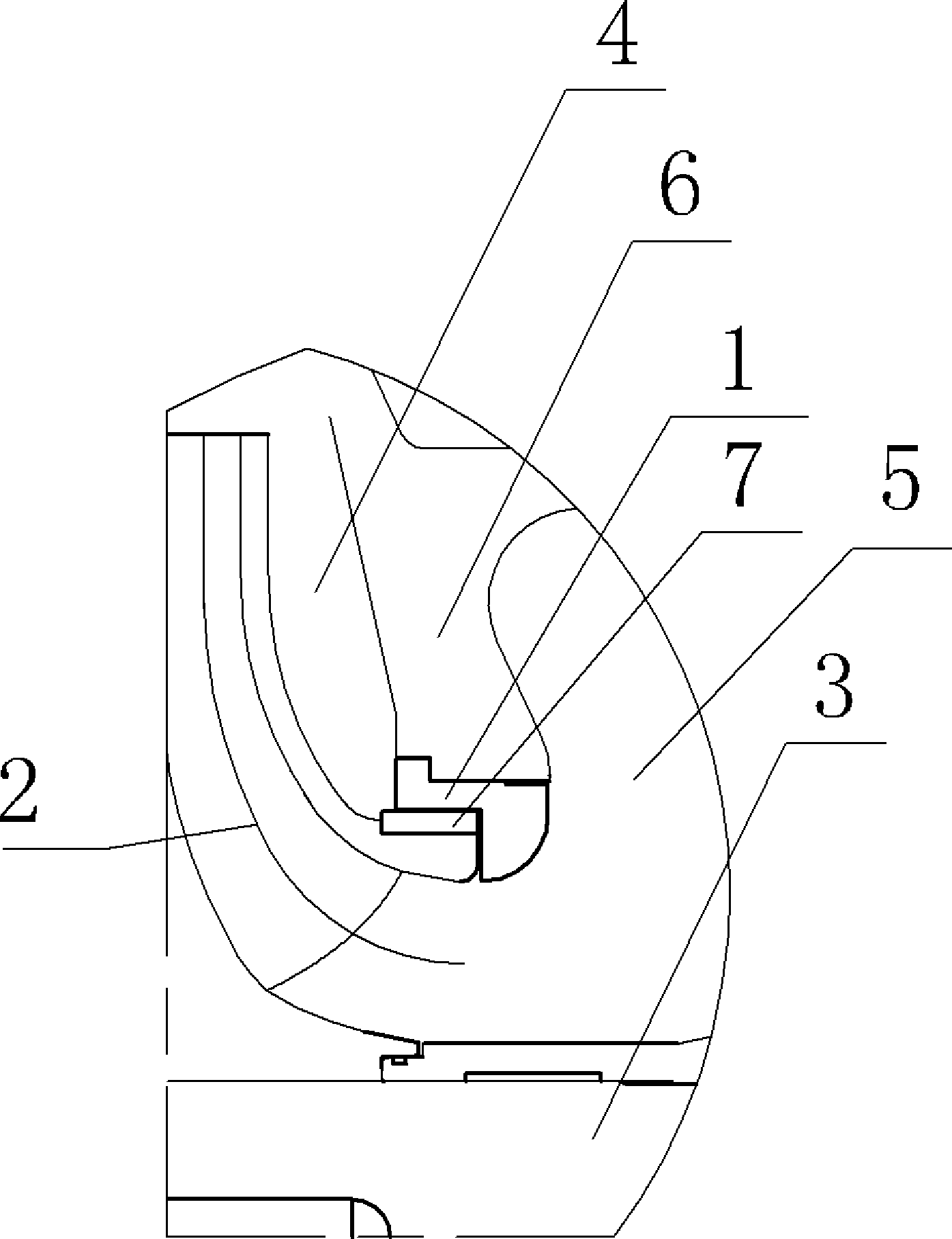

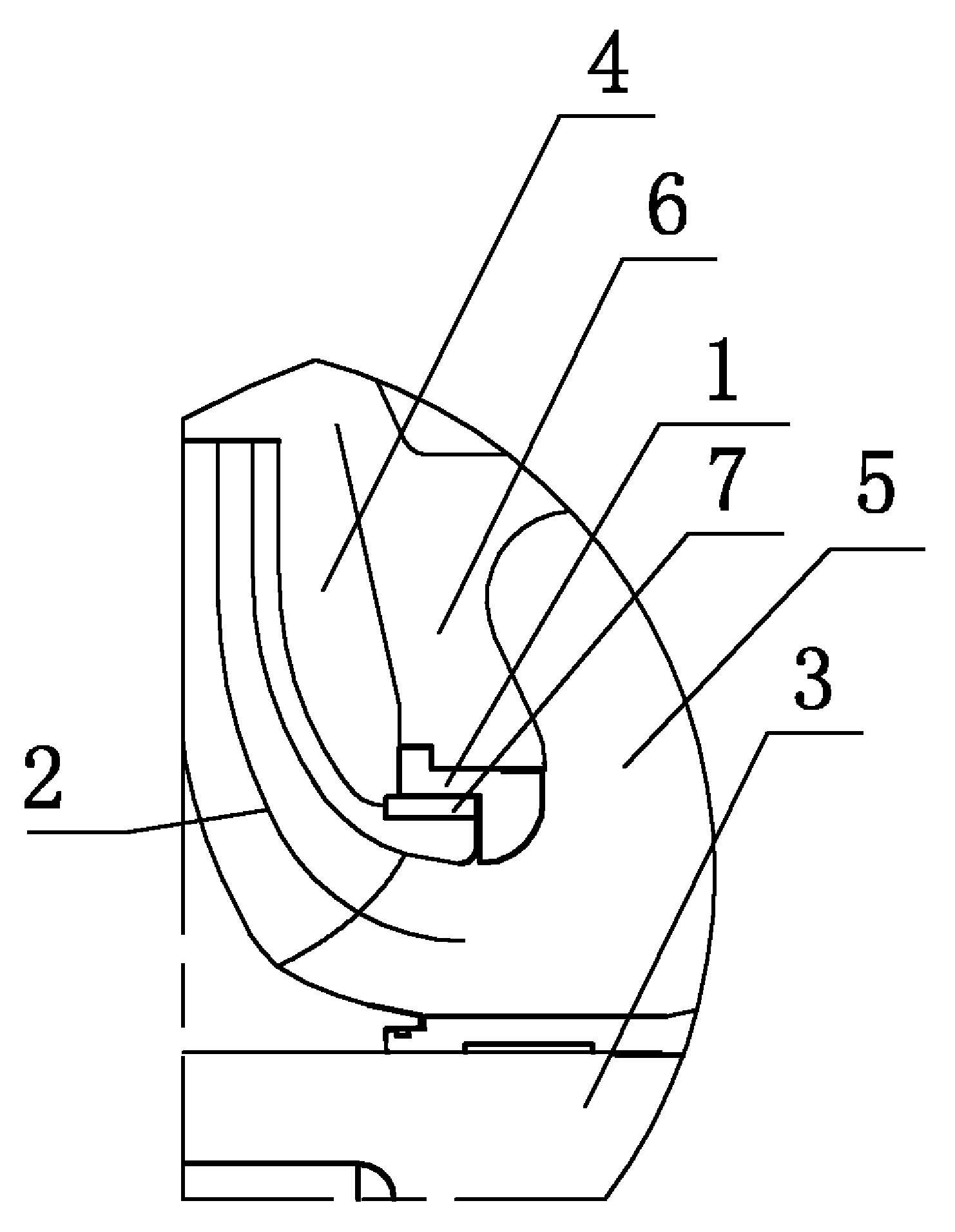

[0009] See figure 2 , The structure of the present invention includes a seal ring 1, the seal ring 1 is installed at the inlet of the impeller 2, an impeller wear-resistant ring 7 is installed between the seal ring 1 and the impeller 2, and the gap fit between the seal ring 2 and the impeller wear-resistant ring 7. The impeller wear-resistant ring 7 is fixed to the impeller 2 by fastening screws; the surface hardness of the sealing ring 1 reaches HRC40.5-46, and the surface hardness of the impeller wear-resistant ring 7 reaches HRC60-68. Among them, the sealing ring material can be precipitated martensitic stainless steel, the outer circle of the impeller wear ring is made of hard alloy Co-Wc for supersonic thermal spraying, and the coating hardness is HV1200-1500, which improves the surface hardness of the impeller wear ring 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com