Bucket lifting mechanism and engineering vehicle using same

A lifting mechanism and bucket technology, applied in the field of mixer trucks, can solve the problems of increasing construction costs, consuming manpower and material resources, occupying space, etc., and achieve the effects of prolonging service life, reducing maintenance costs, and increasing overturning angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

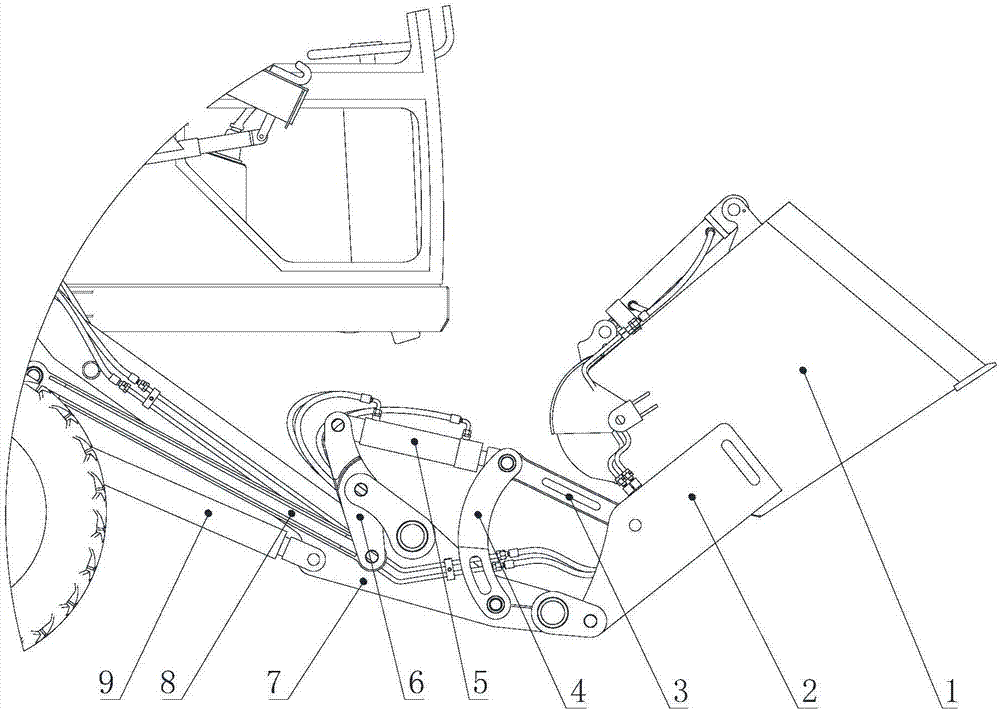

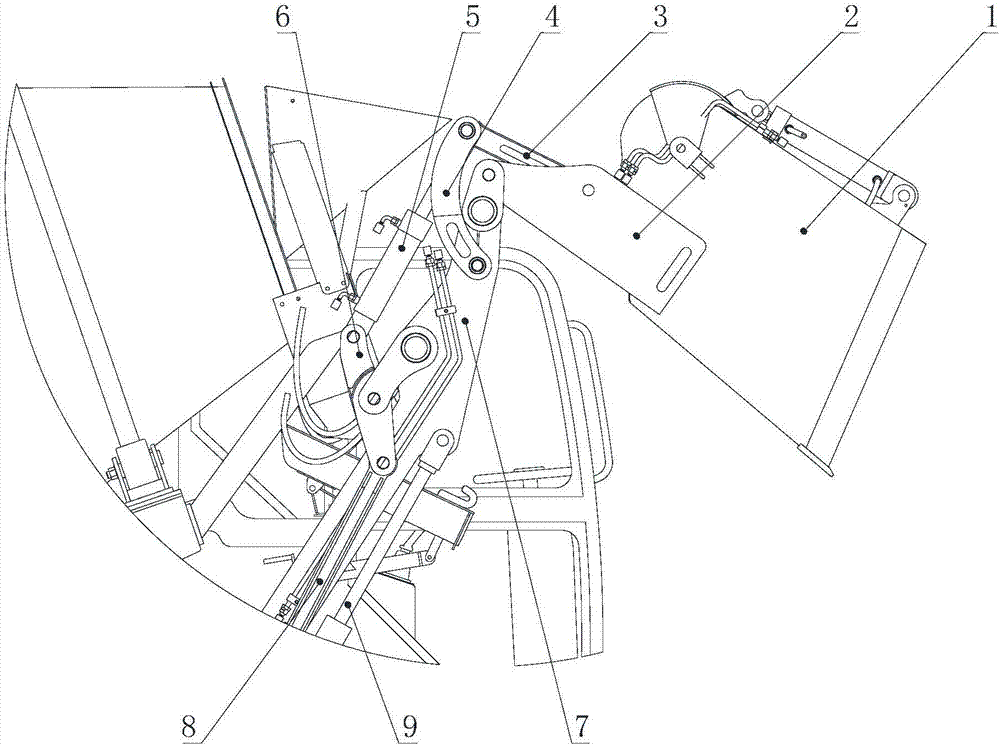

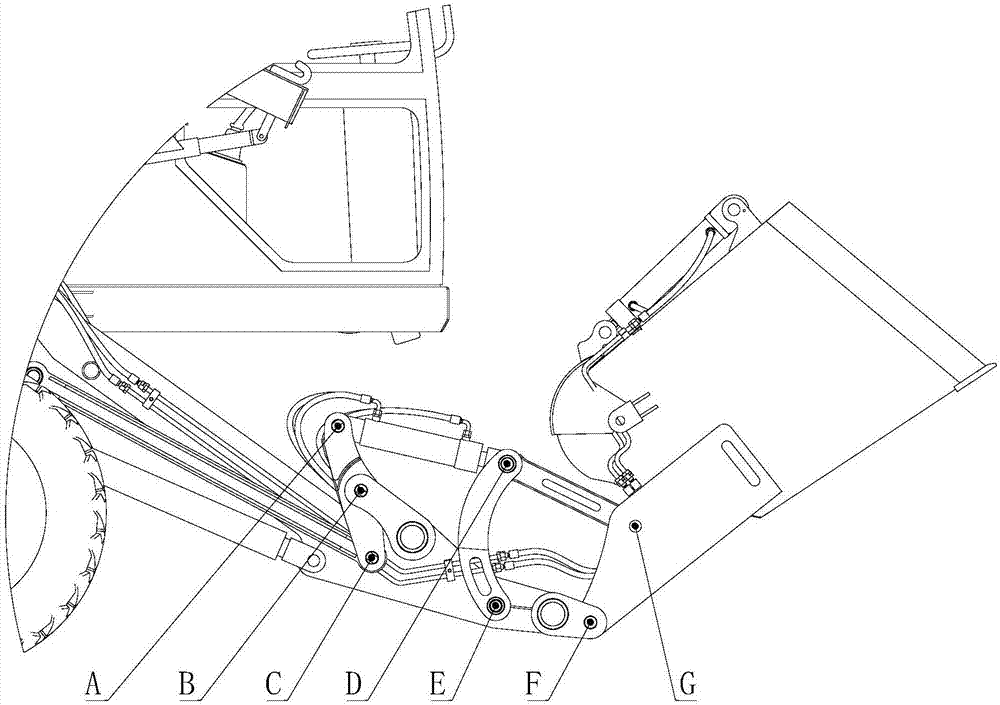

[0031] A bucket lifting mechanism, including a boom 7, a lifting power device, a pull rod 8, and a lifting and overturning device 11 for driving and tipping a bucket 1 in a lifted state, the action executing parts of the lifting power device are hinged On the boom 7, the end of the boom 7 is provided with the lifting and tilting device 11, one side of the lifting and tilting device 11 is hinged with one end of the pull rod 8, and the other side of the lifting and tilting device 11 is hinged. One side is used to connect the bucket 1, wherein the lifting power device is set on the second type of general chassis provided by the manufacturer, which will not be repeated here. The use of this lifting and tilting device 11 can make the bucket 1 in the lifting state. Comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com