Electric shaver

A technology of electric razors and razors, which is applied in metal processing and other fields, can solve the problems of increased overall weight, and achieve the effect of reducing production costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

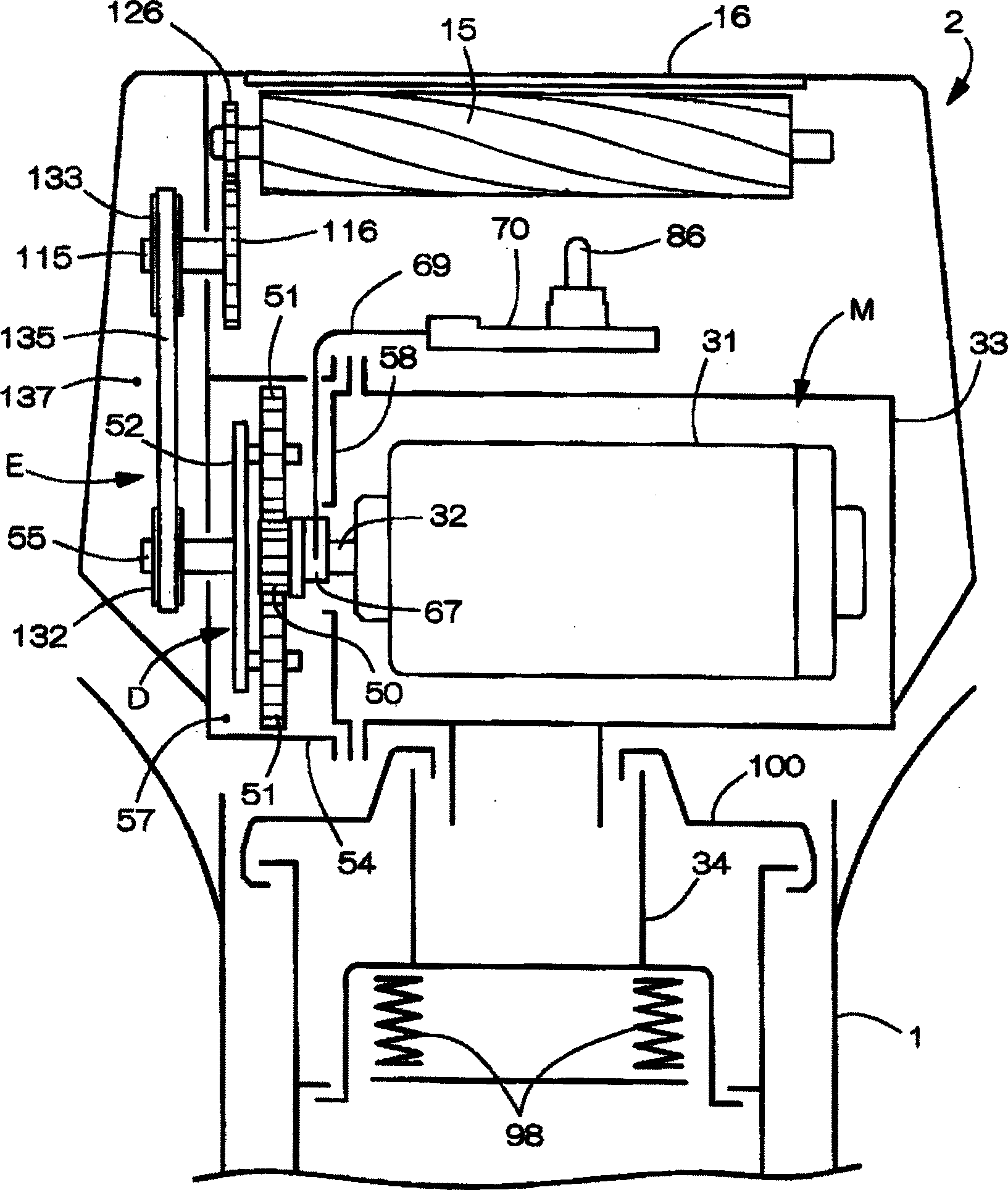

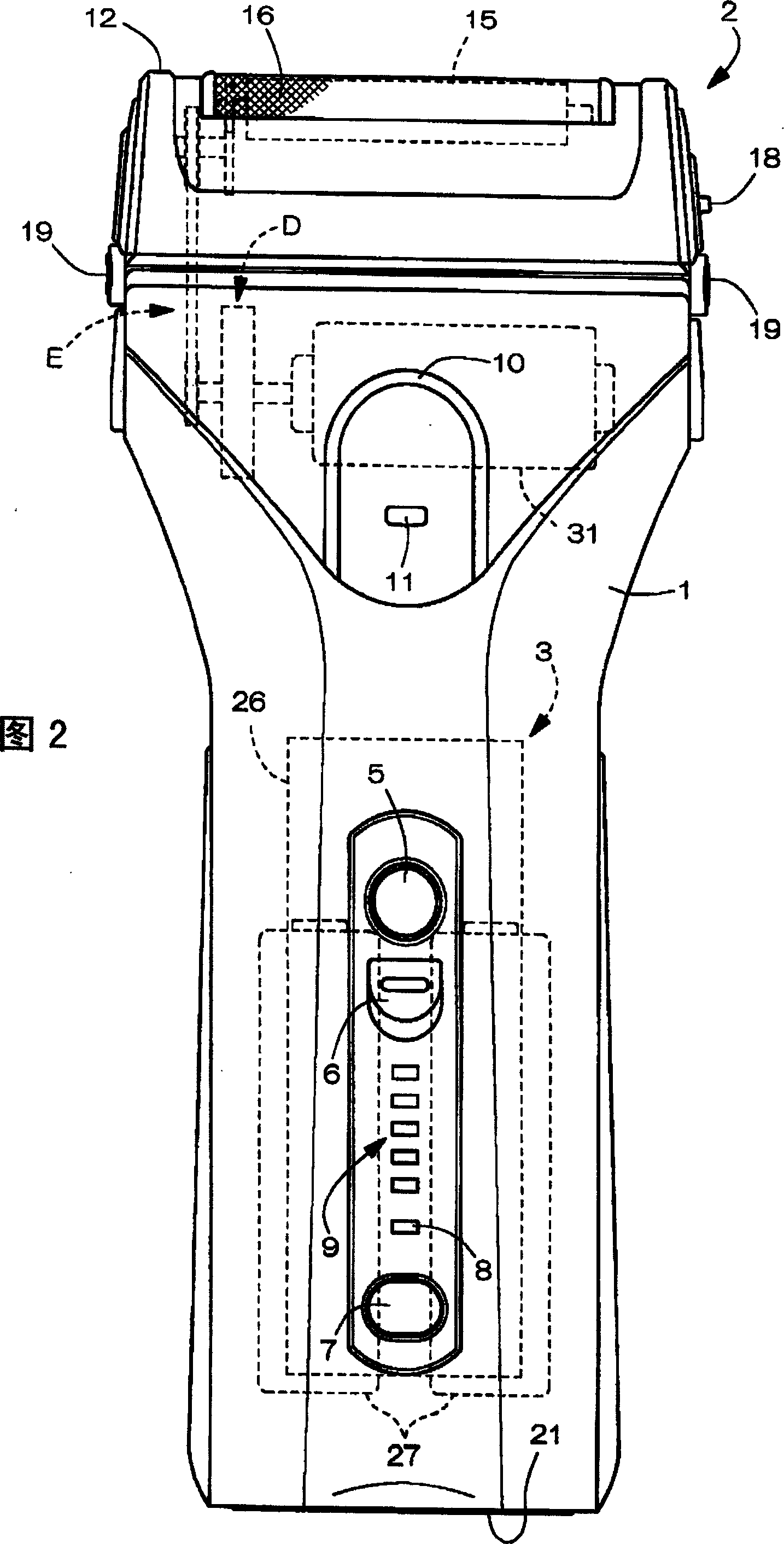

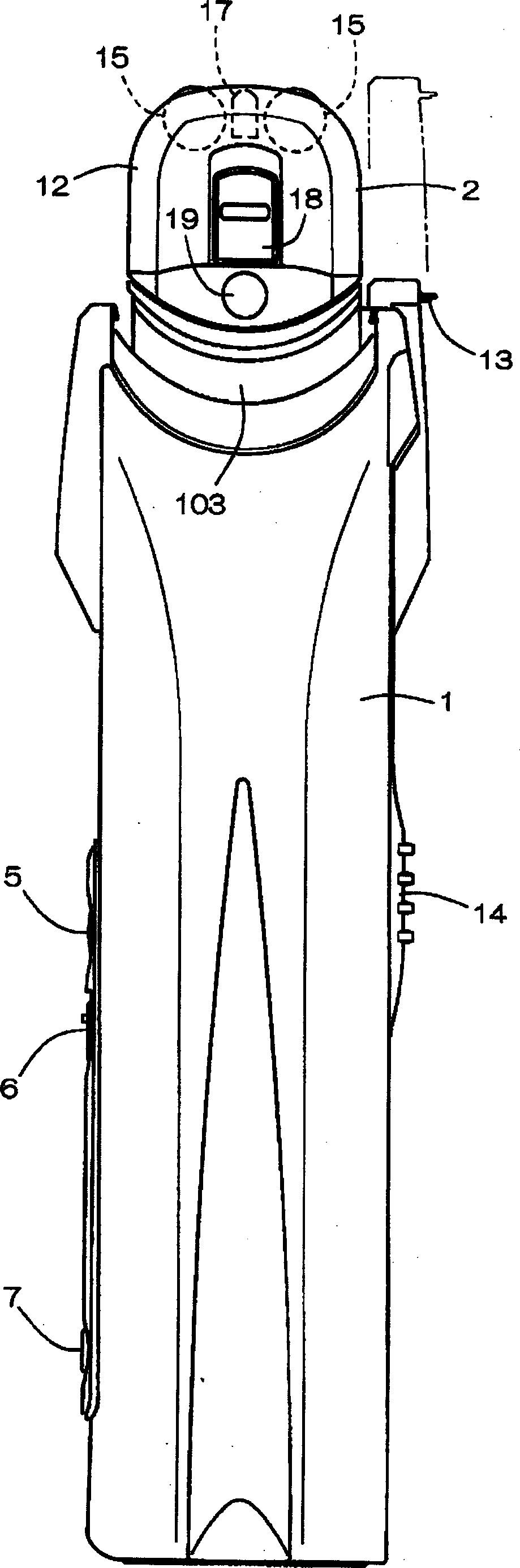

[0077] Figure 1 to Figure 3A vote of 0 indicates an embodiment in which the present invention is applied to a rotor type electric shaver. The structure of the electric shaver among Fig. 2 to Fig. 4 is to have the main structural components such as the main casing 1, the shaver head 2 that is arranged on the top of the main casing 1, and the electrical device unit 3 accommodated in the main casing 1.

[0078] In the front of the main casing 1, there are switching operation components such as a switch button 5 for starting the motor, a locking button 6, a selection button 7 for switching operation modes, and the like; and a display component. The display part includes four kinds of lights: the charging light 8 on the upper side of the selection button 7, the remaining battery level display light 9, the inverted U-shaped mode display light 10 on the upper part of the casing that can change color corresponding to the operating mode and The sensor lamp 11 which lights up in conju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com