Advanced ceramic pipe type defueling pump

A technology of ceramic tubes and oil well pumps, which is applied in variable capacity pump parts, pumps, pump components, etc., can solve the problems of broken ceramic sleeves, low impact resistance, cracking and misalignment, etc., and achieves improved opening and closing speeds, The effect of increasing the area of the liquid flow channel and increasing the degree of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

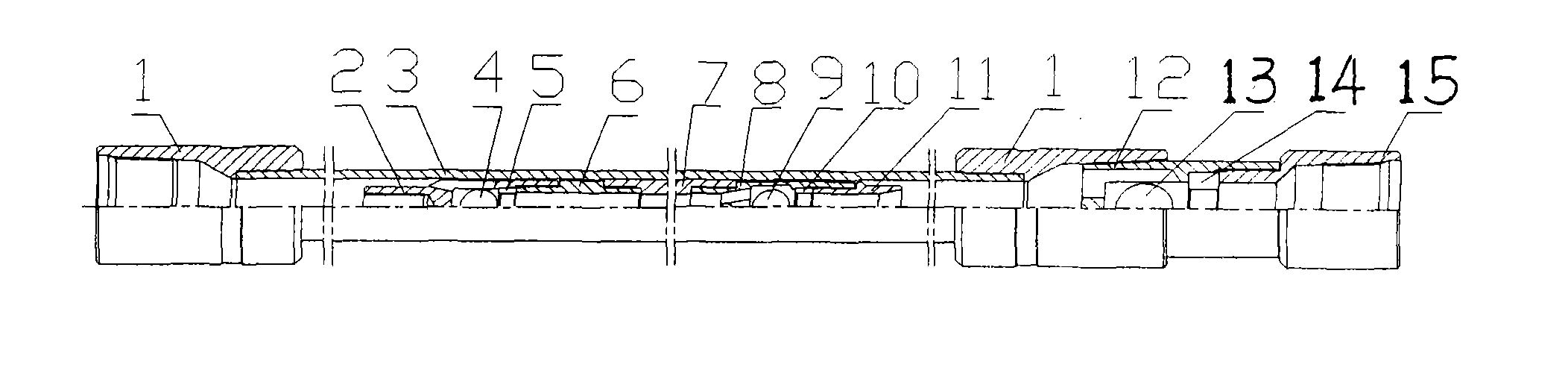

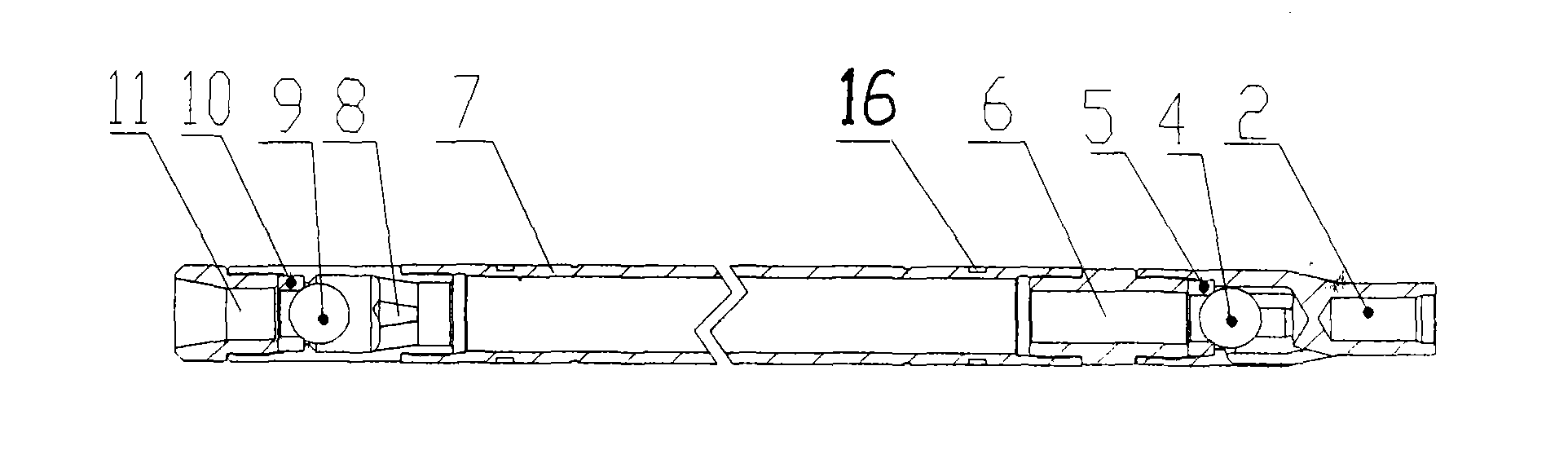

[0017] refer to figure 1 , figure 2 , 1. Pump barrel collar, 2. Upstream floating valve cover, 3. Ceramic pump barrel, 4. Upstream floating valve ball, 5. Upstream floating valve seat, 6 Plunger joint 7. Plunger, 8. Downstream Moving valve cover, 9. Downstream moving valve ball, 10. Downstream moving valve seat, 11. Pipe plug, 12. Fixed valve cover, 13. Fixed valve ball, 14. Fixed valve seat, 15. Lower coupling.

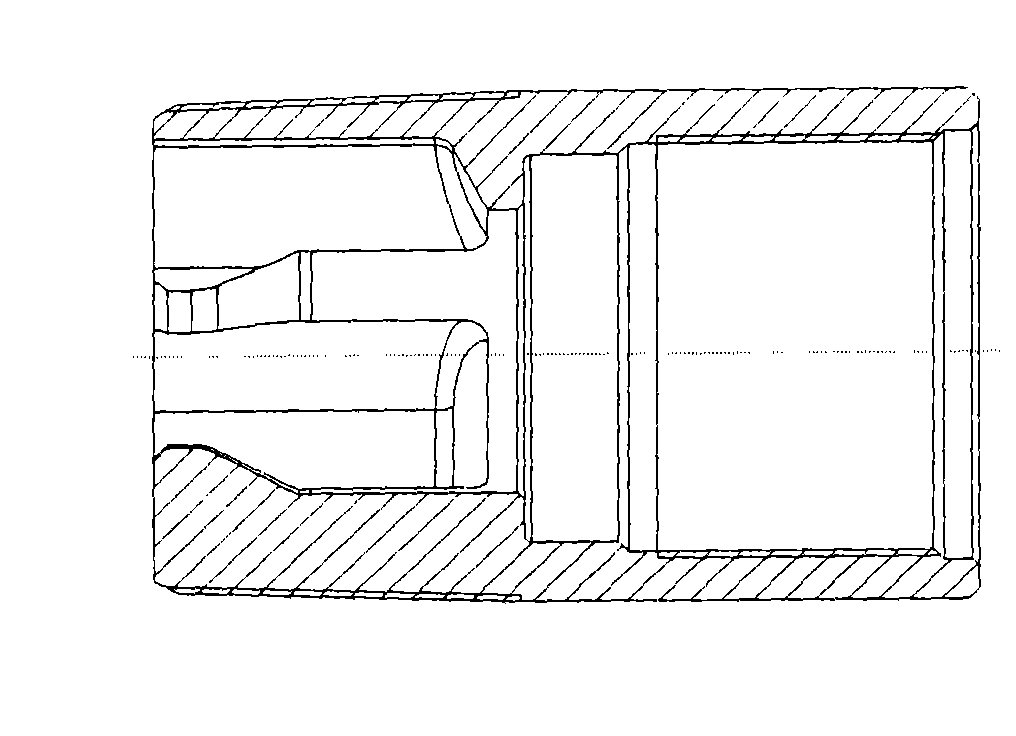

[0018] The body of the ceramic pump barrel oil pumping plunger 7 of the present invention is a tubing-shaped cylinder with a certain length. The outer layer of the ceramic pump barrel is a steel pump barrel, and the inner layer is in contact with the plunger, and the friction part is combined with the pump barrel. The integrated advanced ceramic layer is lined with grinding technology to make the smoothness and straightness of the ceramic layer on the inner wall of the pump barrel meet the requirements of use, while the plunger 7 is a steel cylinder, and the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com