Stirring equipment for broken plastic

A mixing equipment and plastic technology, which is applied in the field of waste plastic reprocessing equipment, can solve the problems of unfavorable dust and moisture discharge, high manpower and material cost, and difficult moisture discharge, so as to reduce manpower and material cost and feed the effect Good, easy to disassemble and connect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

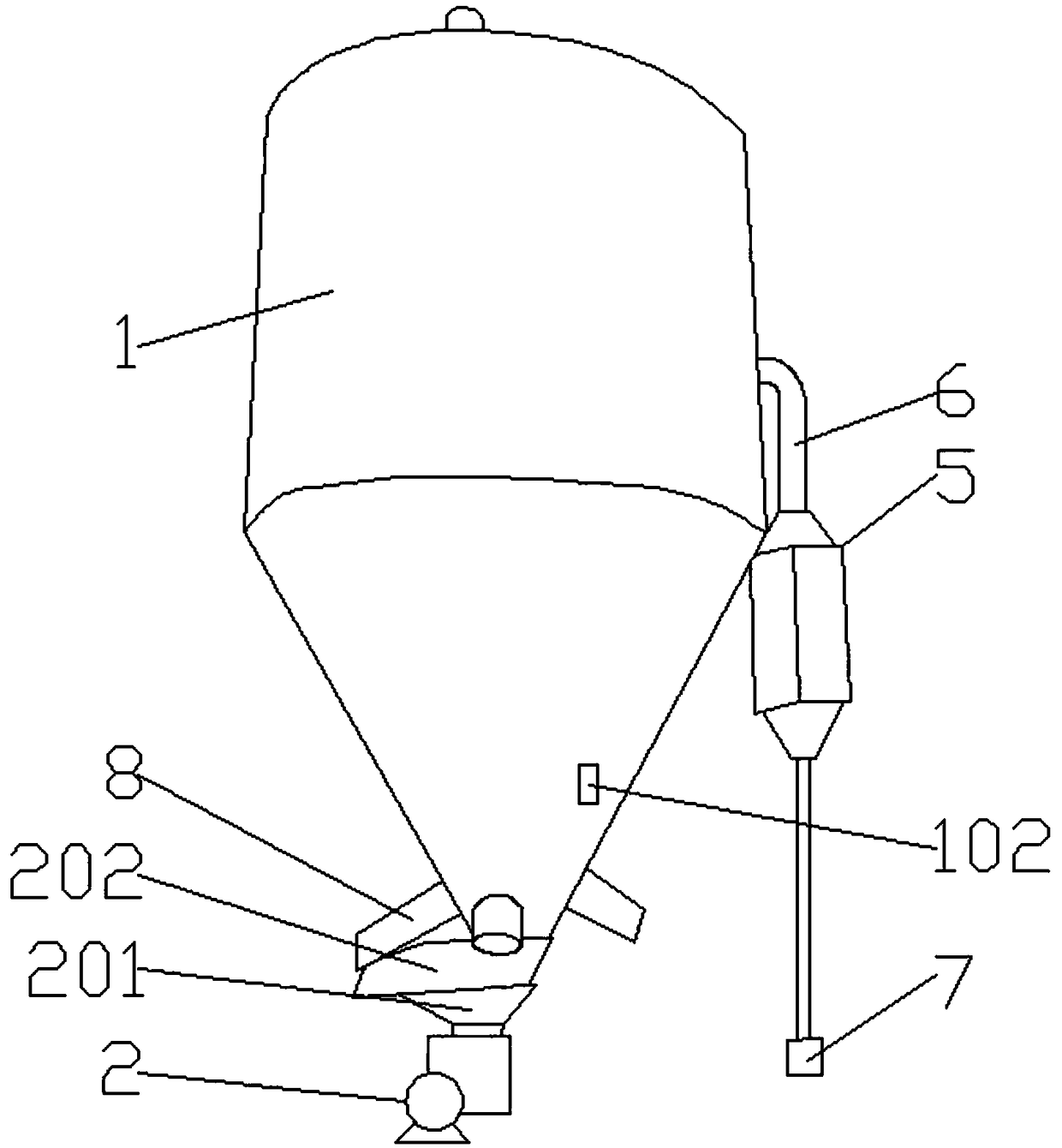

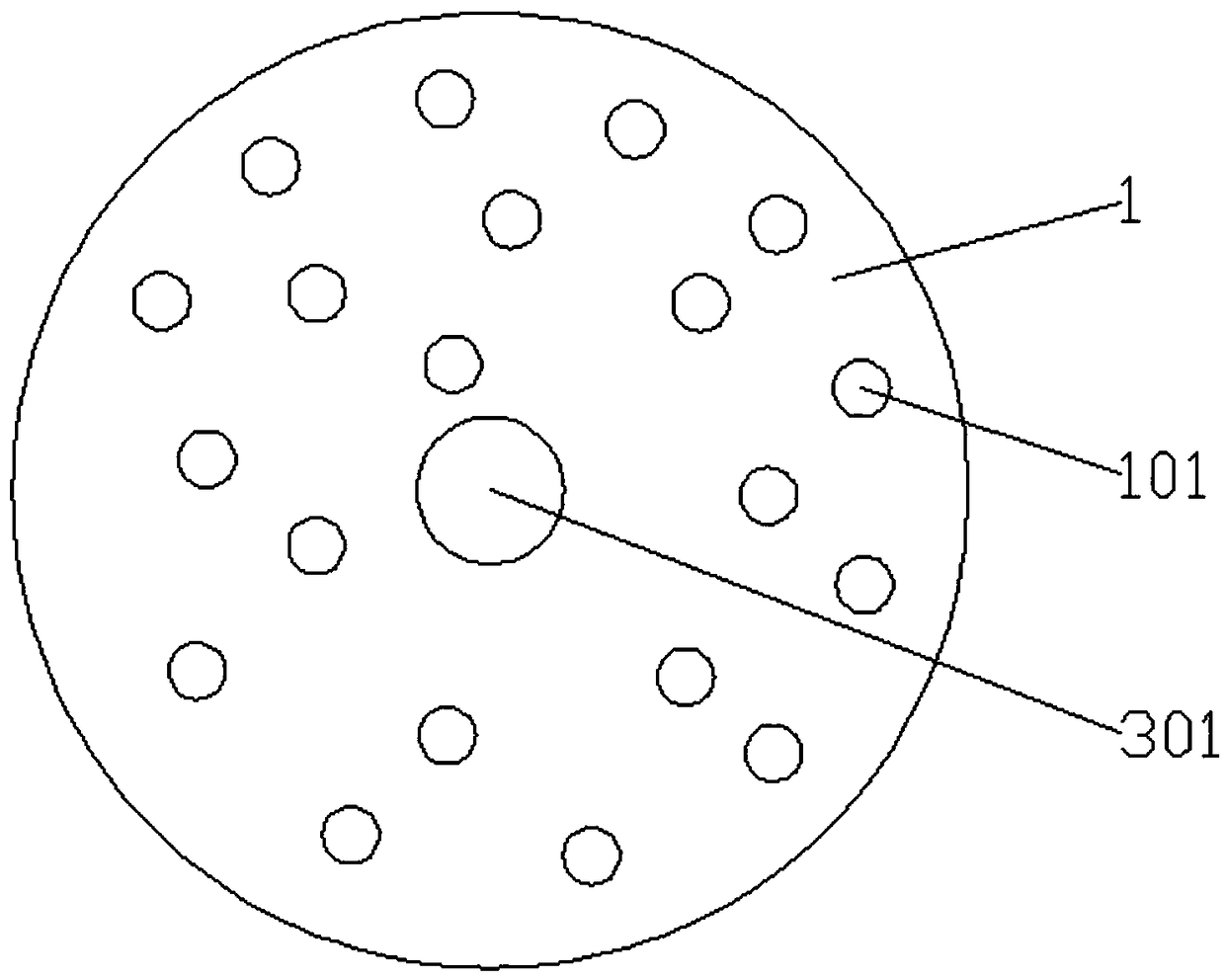

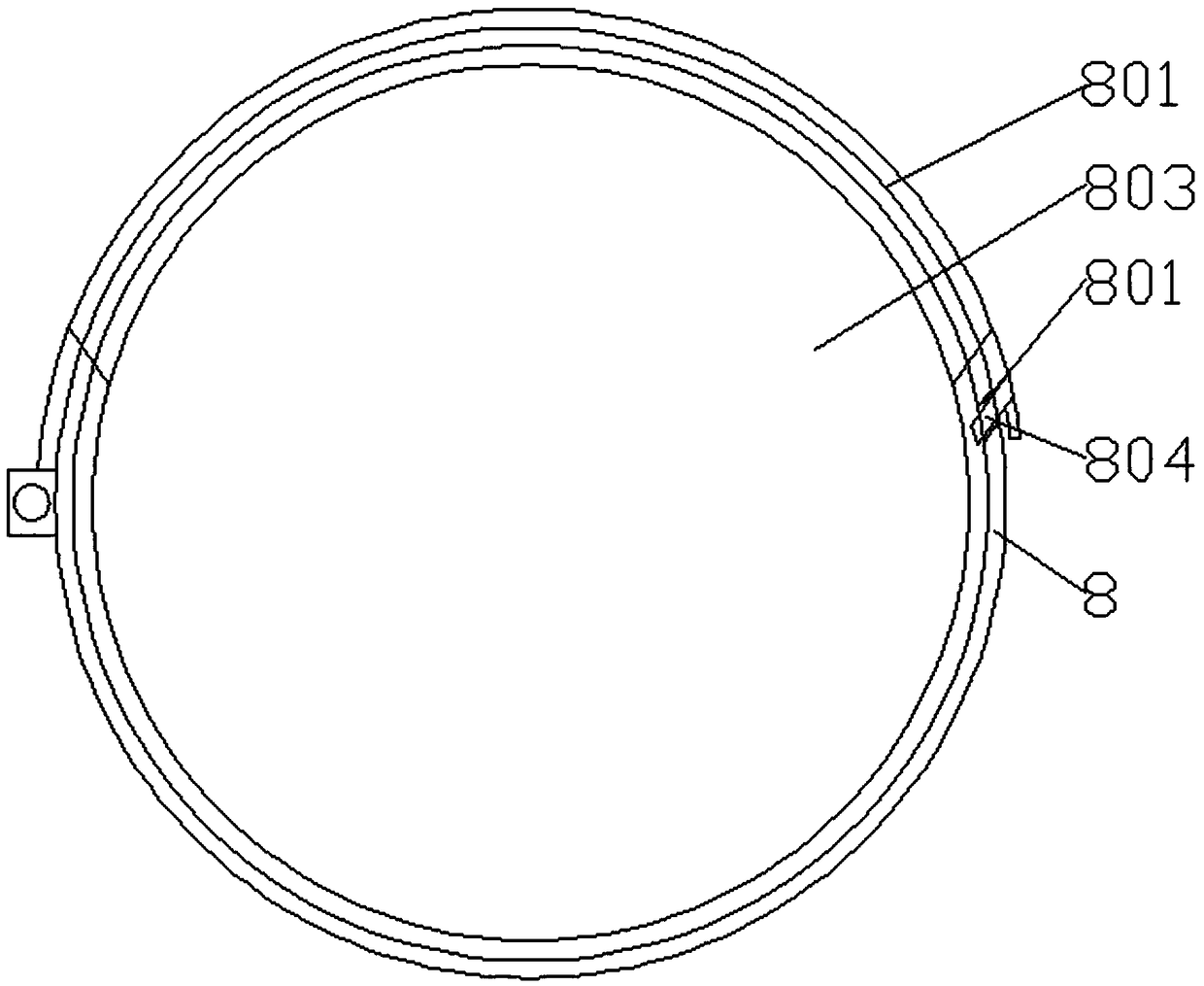

[0049] Such as figure 1 The broken plastic mixing equipment shown includes a barrel 1, a feeding device 2 arranged at the bottom of the barrel, and a device such as Figure 10 The mixing device 3 shown is arranged on the inner wall of the barrel, such as Figure 16 Shown air equalizer 4 and be arranged on the outside of barrel such as Figure 13 The temperature raising device 5 shown is connected with a centrifugal fan 7 through the ventilation pipeline 6 on the air uniforming device, the temperature raising device is arranged on the ventilation pipeline, and the centrifugal fan is located outside the barrel; the feeding device includes a feeding bin 201 and a Two feeding hoppers 202 are arranged oppositely on the top of the warehouse, the bottom of the feeding cylinder is located between the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com