Rotor pump and assembly method thereof

An assembly method and technology of rotor pumps, which are applied to rotary piston pumps, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as increased labor intensity, high processing costs, and rotor jamming, and achieve reduction Labor intensity, reduce processing cost, and avoid the effect of excessive clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

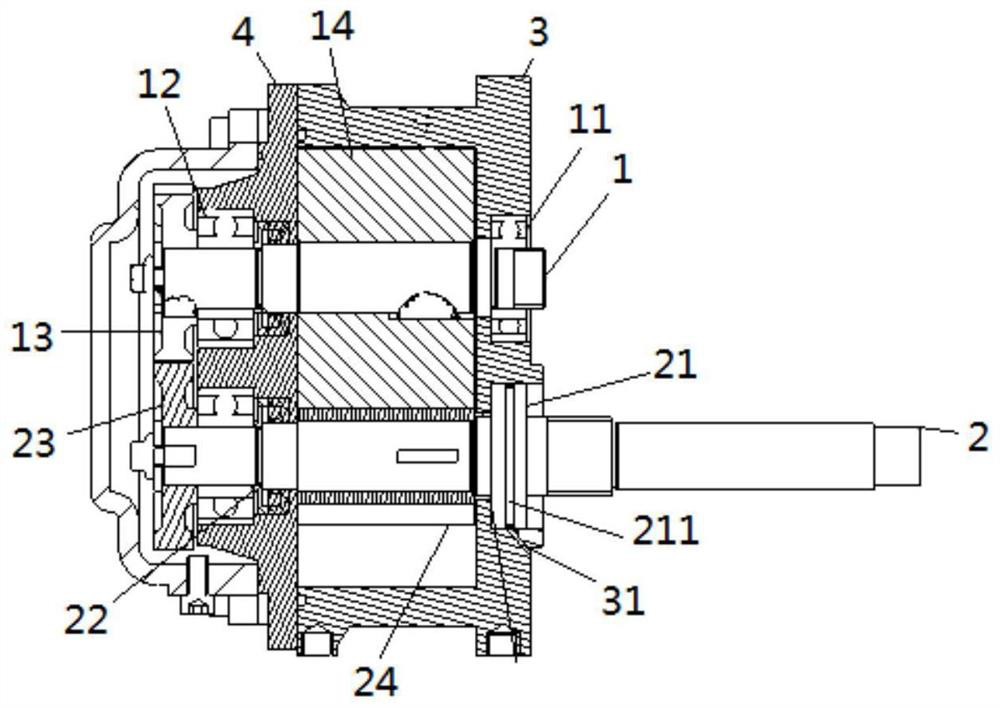

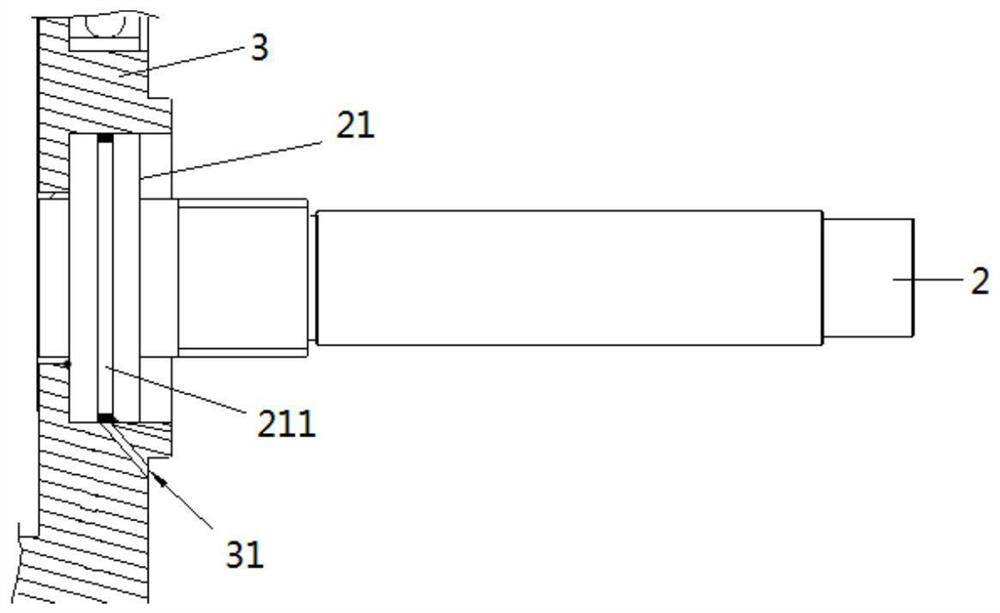

[0041] This embodiment proposes a rotor pump for transporting items to be transported, such as figure 1 As shown, the rotor pump includes a housing 3 , a first transmission shaft 1 and a second transmission shaft 2 . Wherein, one end of the first transmission shaft 1 is pierced with a first bearing 11, and the first bearing 11 is arranged in a first bearing seat on the casing 3, and a first rotor 14 is also arranged on the first transmission shaft 1; The two transmission shafts 2 are driven in parallel with the first transmission shaft 1, and the second transmission shaft 2 is meshed with the first transmission shaft 1 for transmission. One end of the second transmission shaft 2 is pierced with a second bearing 21, and the second bearing 21 is arranged on In the second bearing seat on the casing 3 , a second rotor 24 is also provided on the second transmission shaft 2 , and the second rotor 24 and the first rotor 14 can rotate synchronously and in opposite directions.

[0042...

Embodiment 2

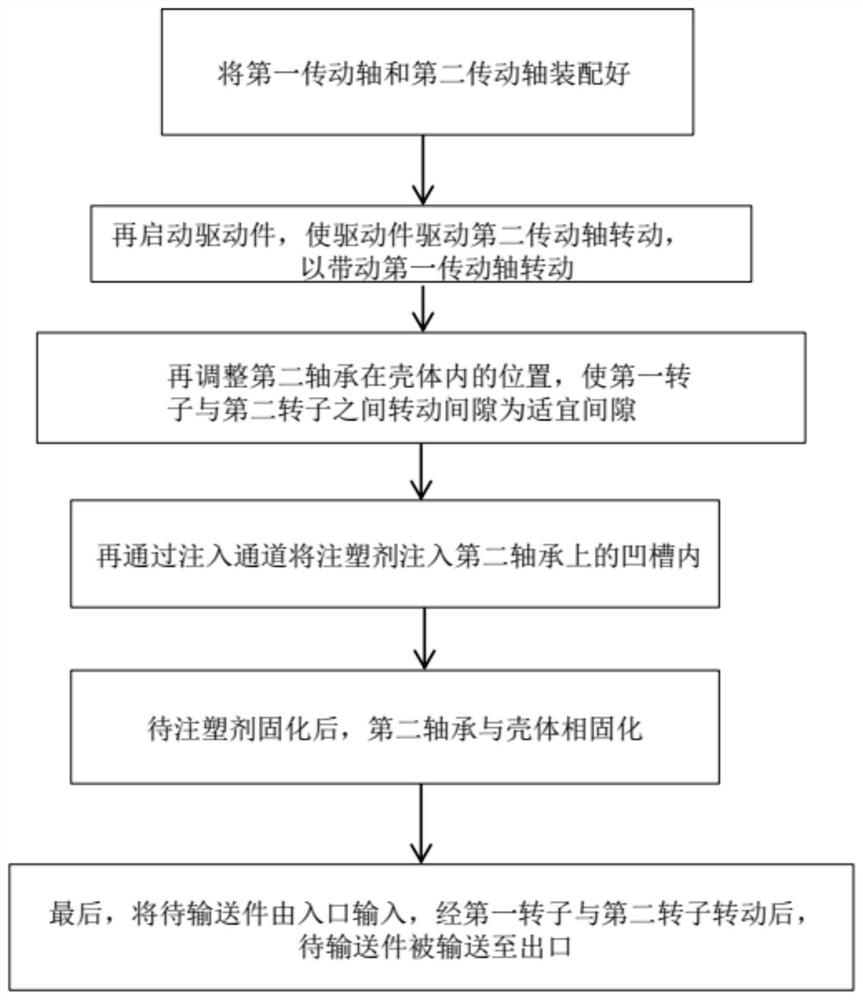

[0048] In this embodiment, a method for assembling the rotor pump is proposed, which is used for assembling the rotor pump in the first embodiment. Specifically, the assembly method of the rotor pump includes the following steps: Step 10: respectively assembling the first transmission shaft 1 and the second transmission shaft 2 on the casing 3, so that the first transmission shaft 1 and the second transmission shaft 2 are meshed for transmission; Step 20: Drive the second transmission shaft 2 to rotate to drive the first transmission shaft 1 to rotate, so that the first rotor 14 and the second rotor 24 rotate in opposite directions, and adjust the position of the second bearing 21 relative to the housing 3, To adjust the rotation gap between the first rotor 14 and the second rotor 24 to an appropriate gap; Step 30: inject the injection molding agent into the injection molding groove 211, and wait for the injection molding agent to solidify to solidify the second bearing 21 rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com