Patents

Literature

34results about How to "Easy demoulding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

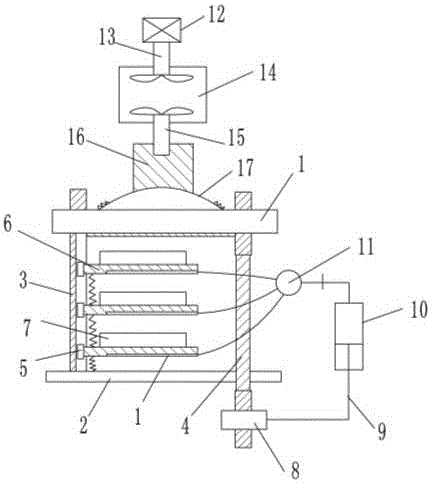

Injection mold for quick cooling and convenient demolding

InactiveCN108582637AImprove work efficiencyFreezing will not occurEngineeringInjection molding machine

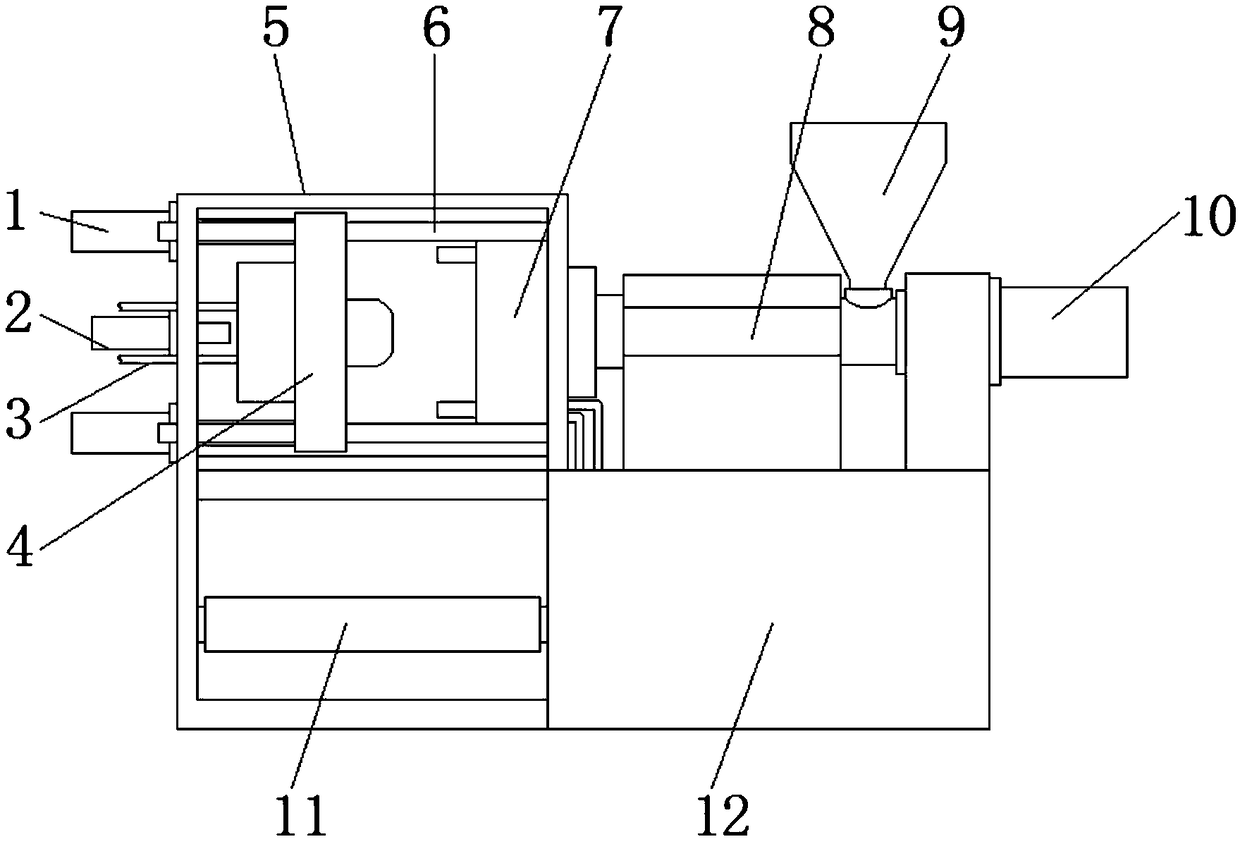

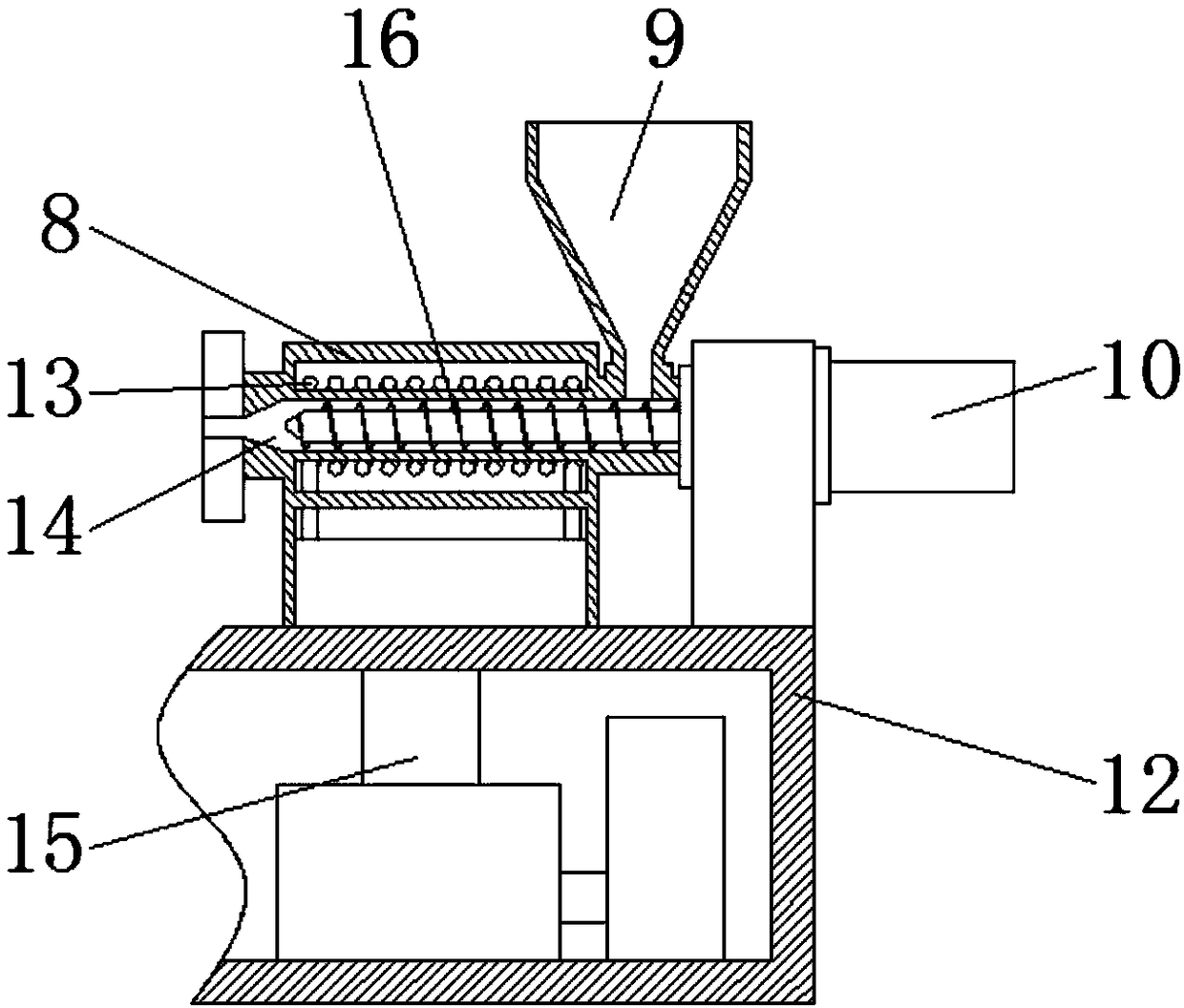

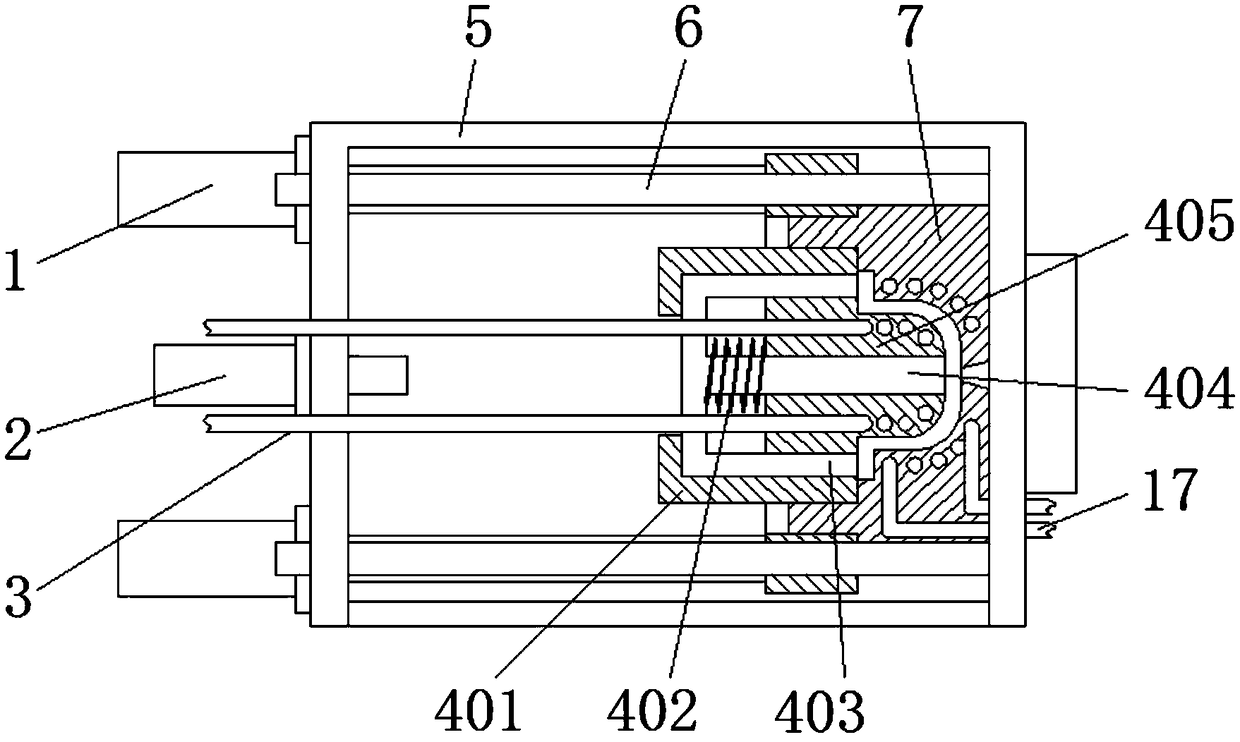

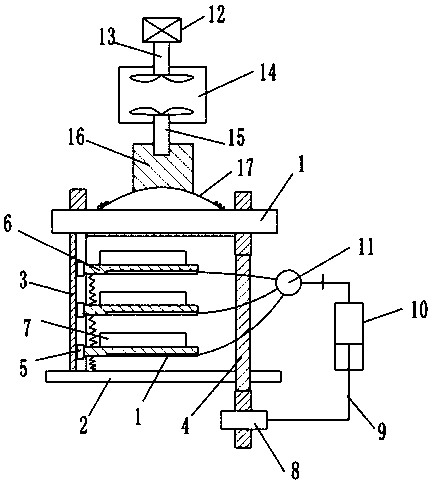

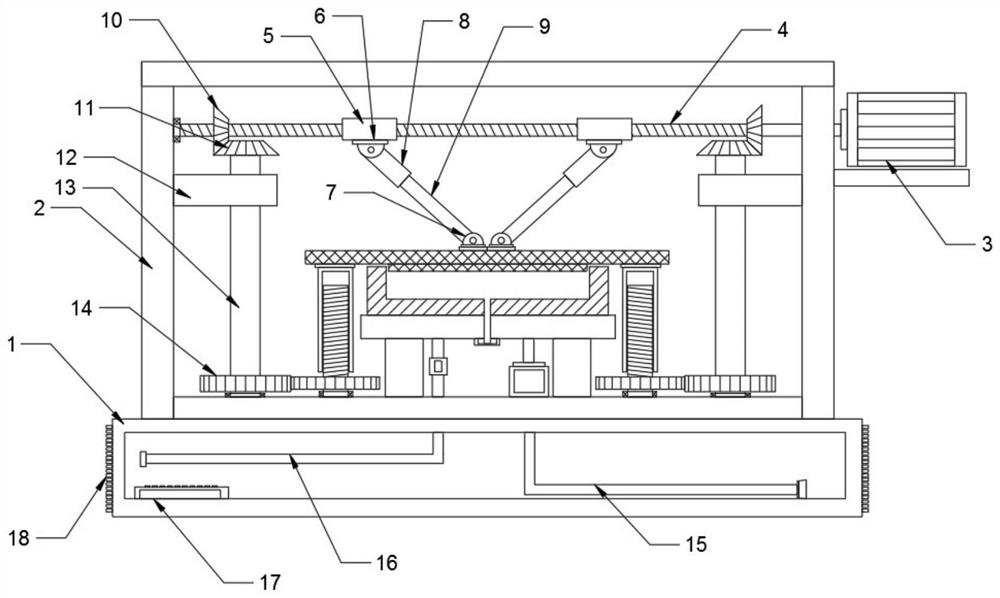

The invention discloses an injection mold for quick cooling and convenient demolding. The injection mold comprises a first electric extension rod, an unloading hopper and a limiting rod; a second electric extension rod is arranged in middle of the first electric extension rod; a first cooling pipe is arranged on the outer side of the second electric extension rod; the front end of the first cooling pipe is connected with a movable template; the outer side of the movable template is connected with a support frame through a slide rod; a fixed template is fixed on the inner side of the support frame; an injection molding pipe is connected to the back side of the fixed template; the lower end of the unloading hopper is connected with an injection molding pipe; a motor is mounted on the right side of the injection molding pipe; a support main body is arranged below the injection molding pipe; and a conveying belt is arranged on the left side of the support main body. The injection mold forquick cooling and convenient demolding is provided with a first cooling pipe and a second cooling pipe, and can accelerate the cooling molding work through the first cooling pipe and the second cooling pipe to improve the overall working efficiency and the overall functionality.

Owner:杨传平

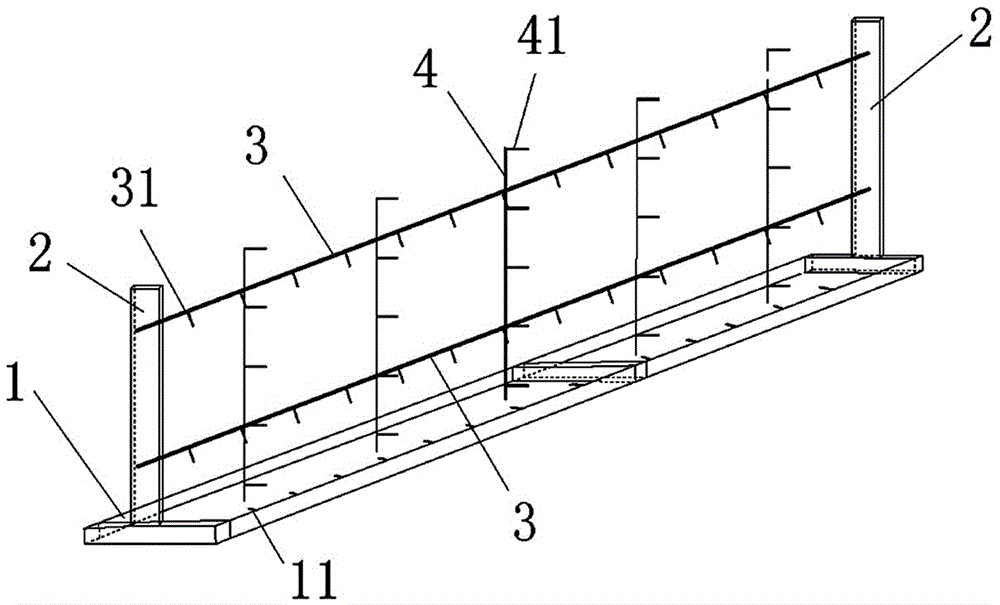

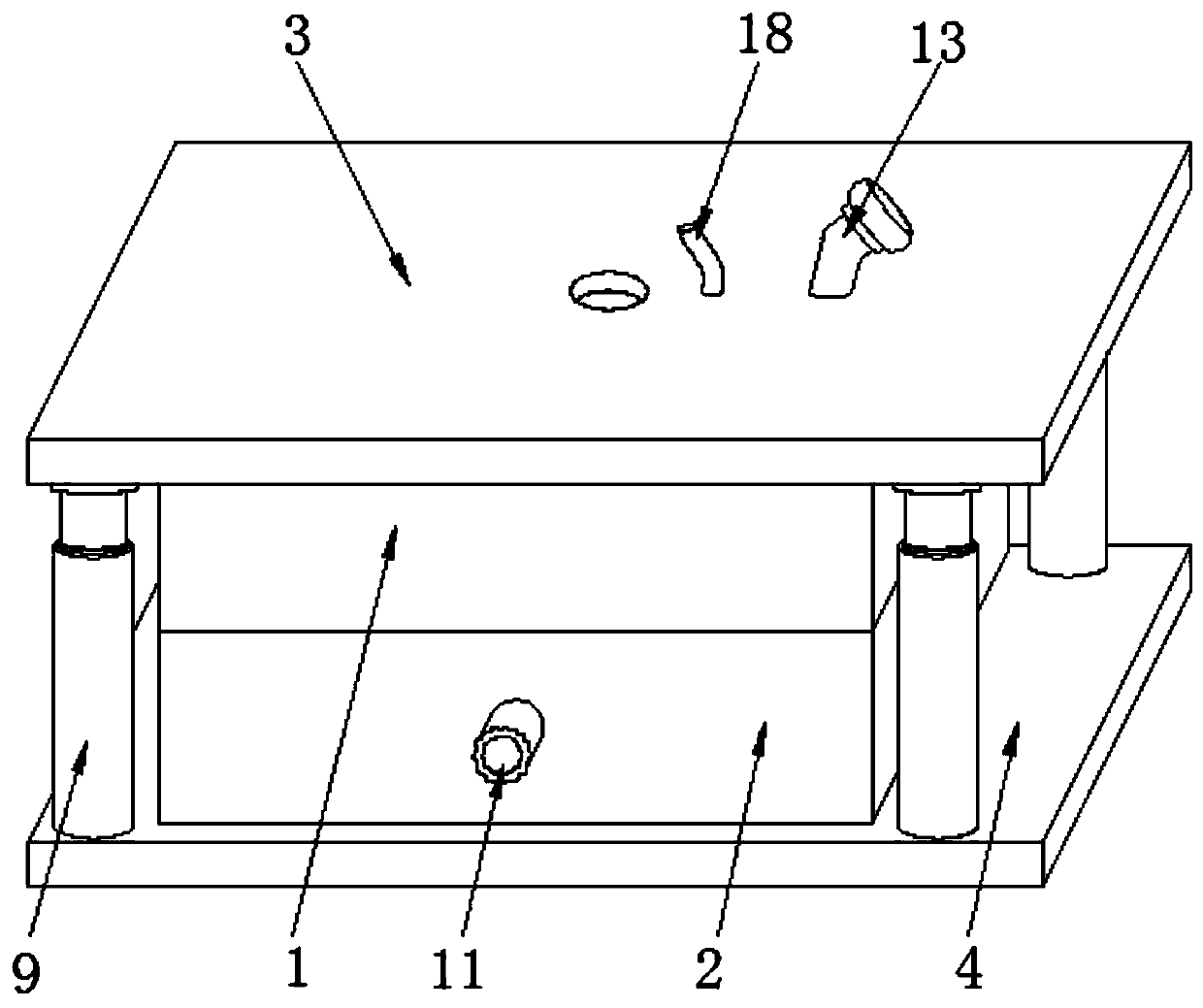

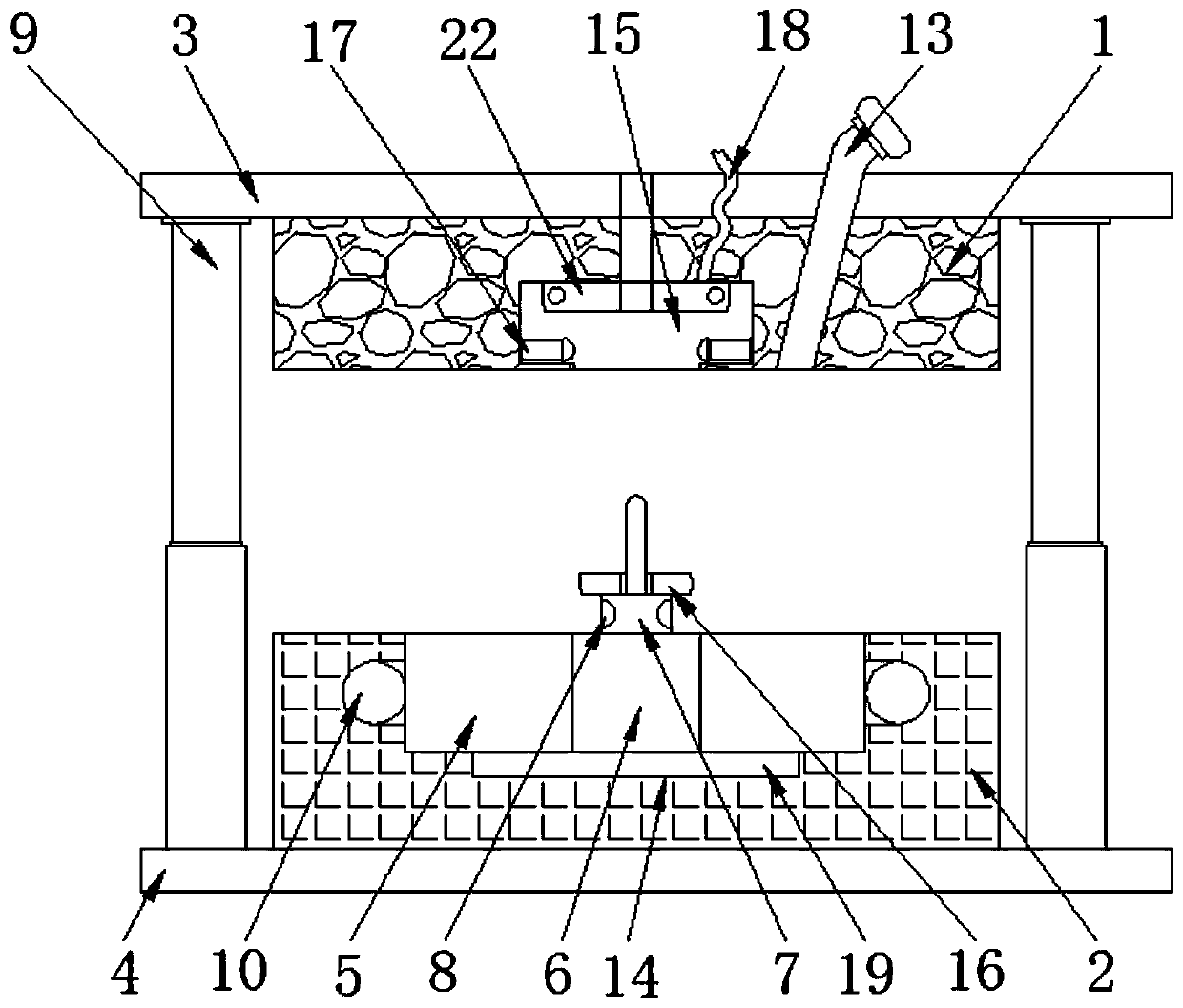

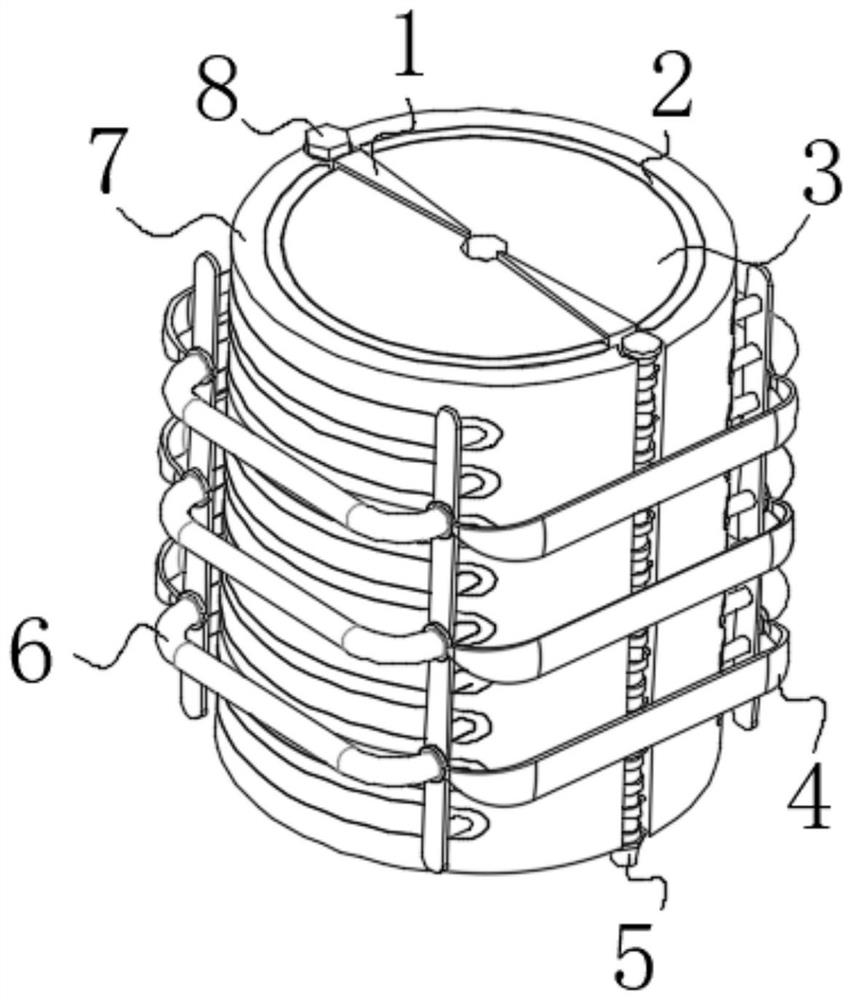

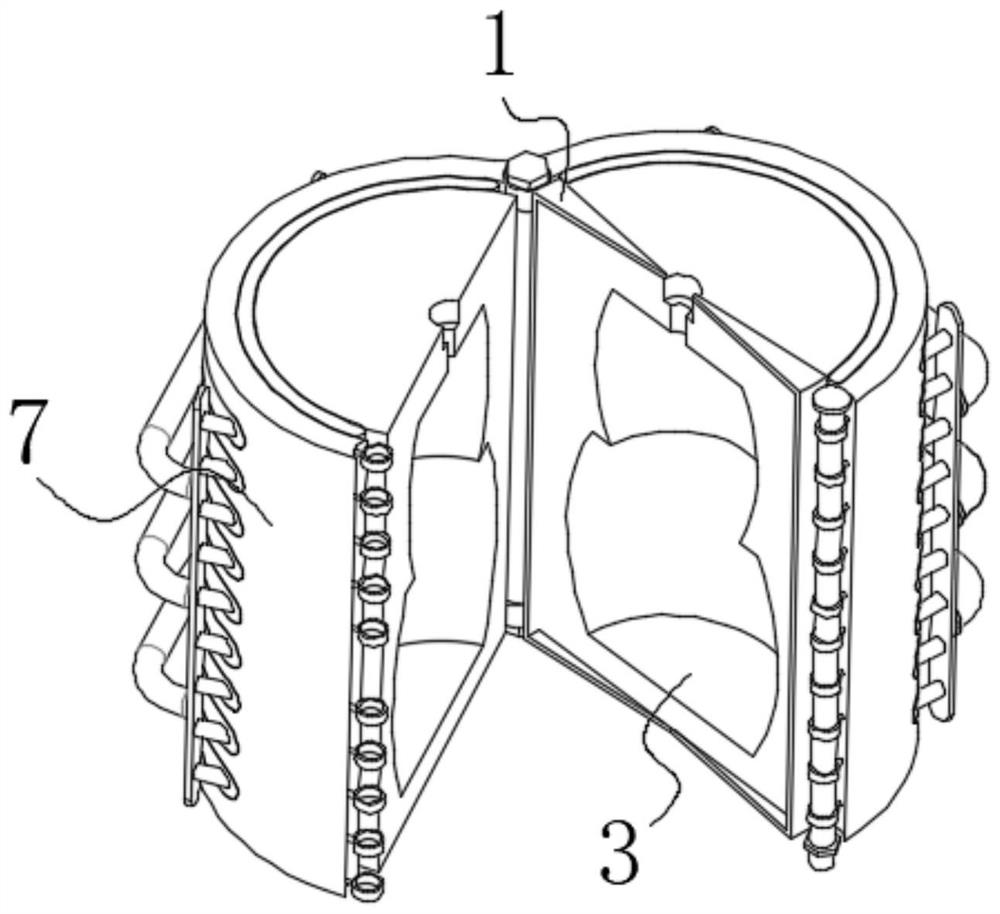

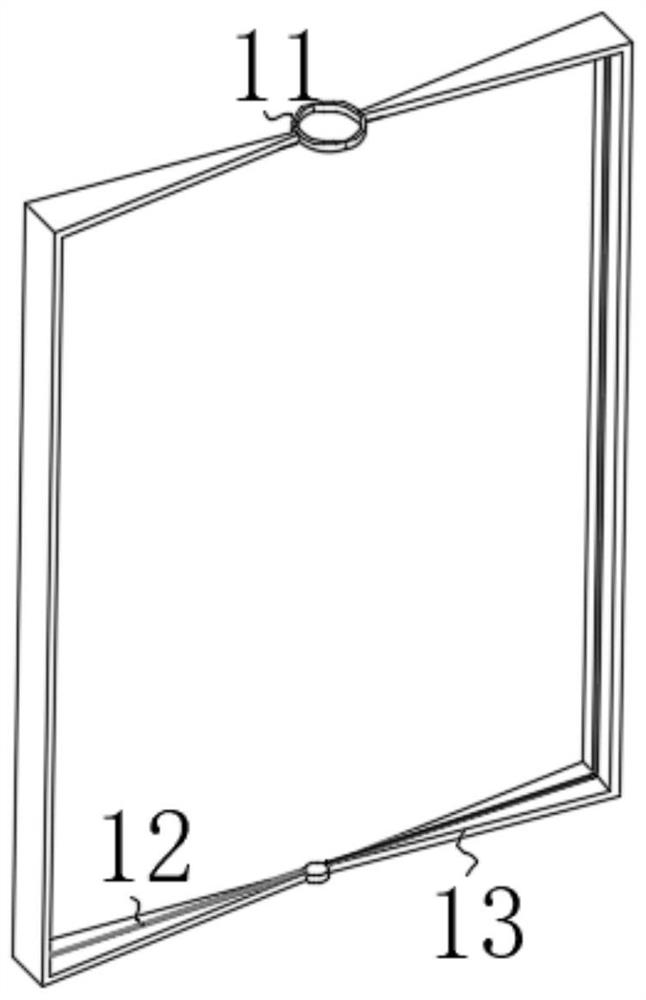

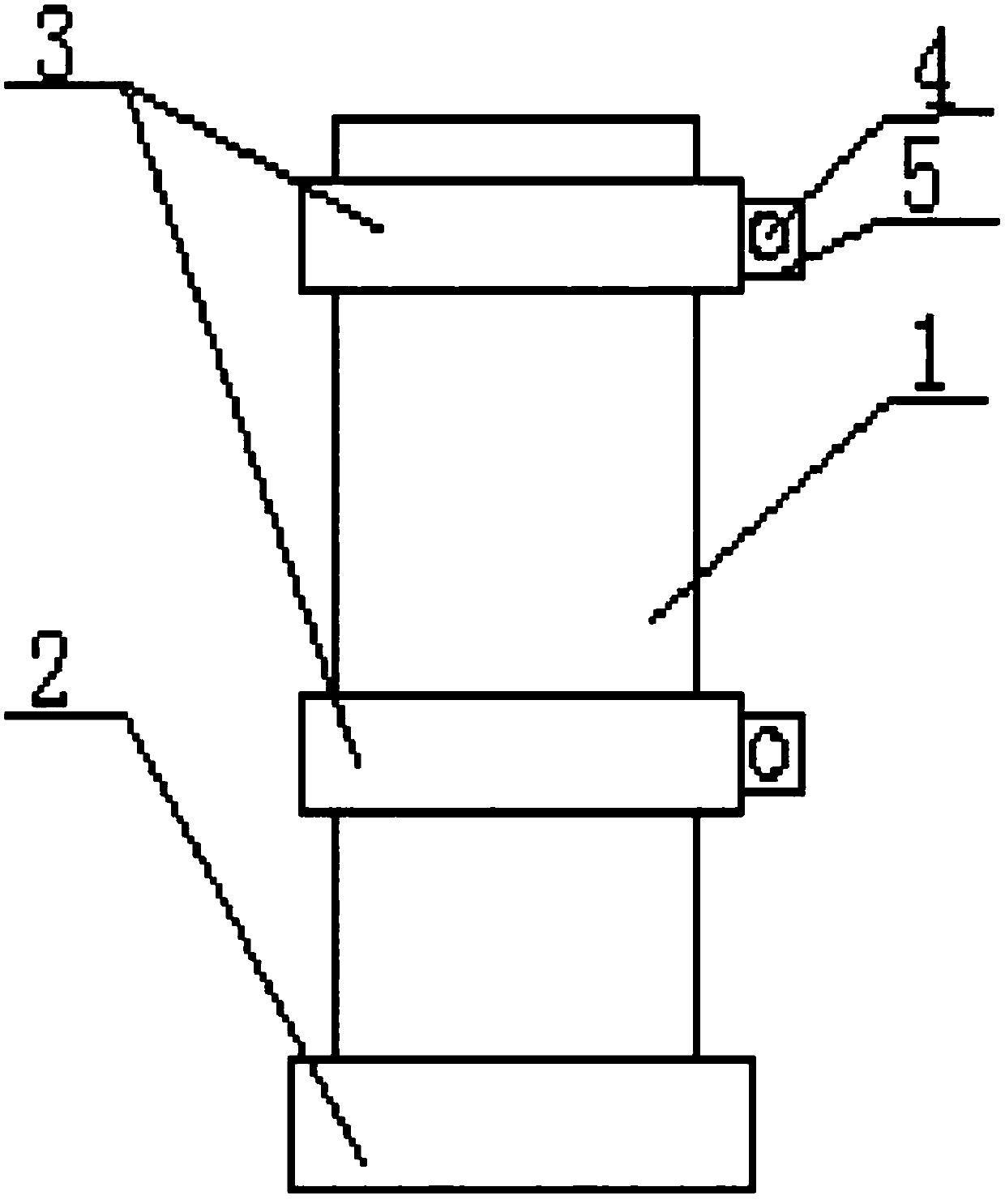

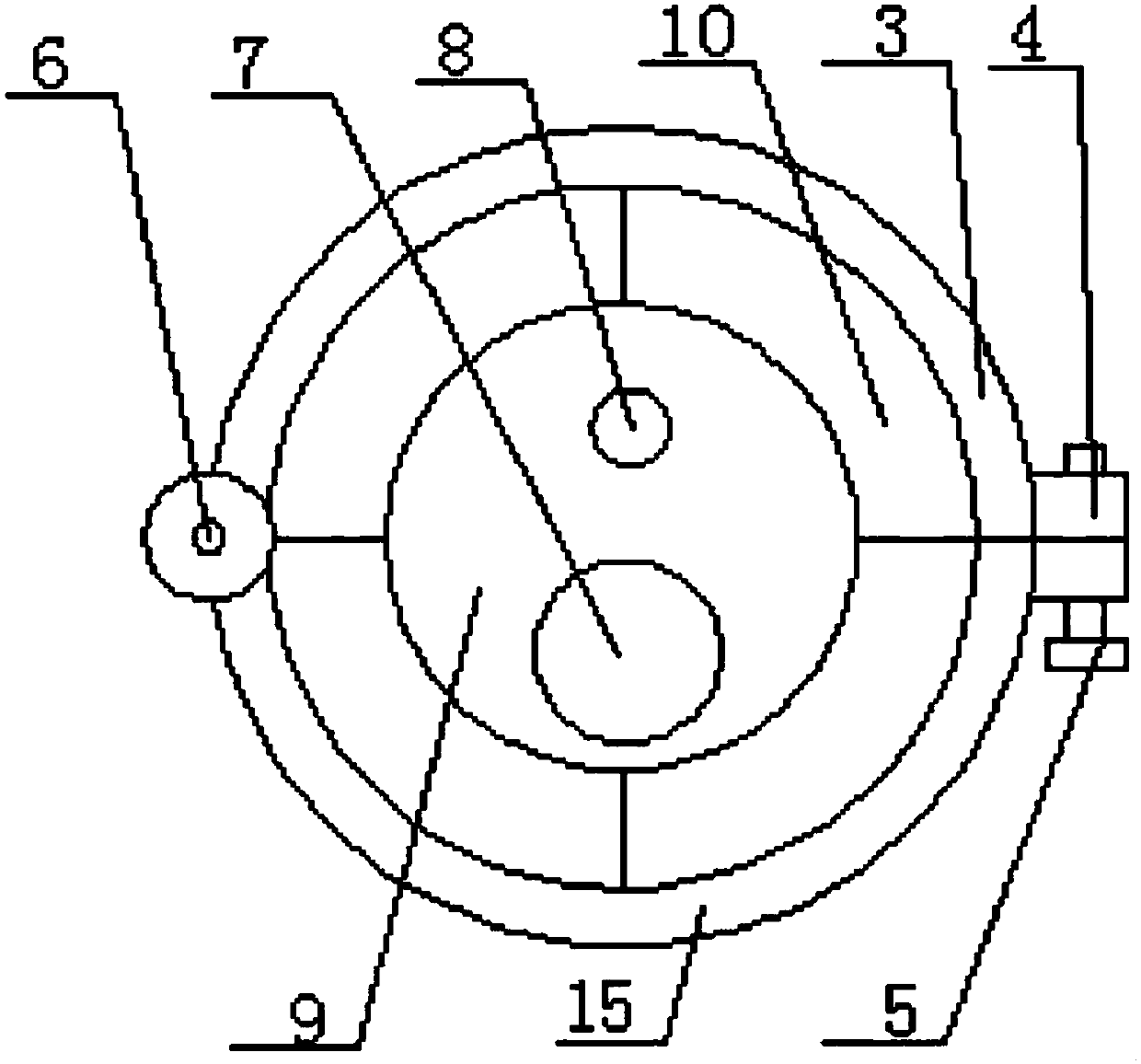

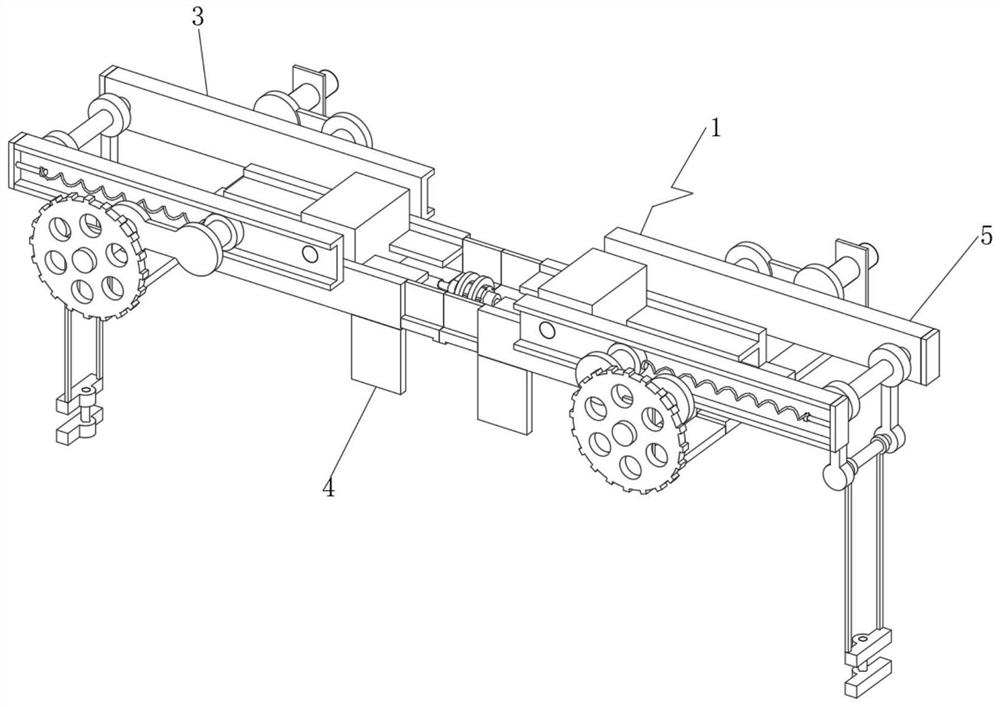

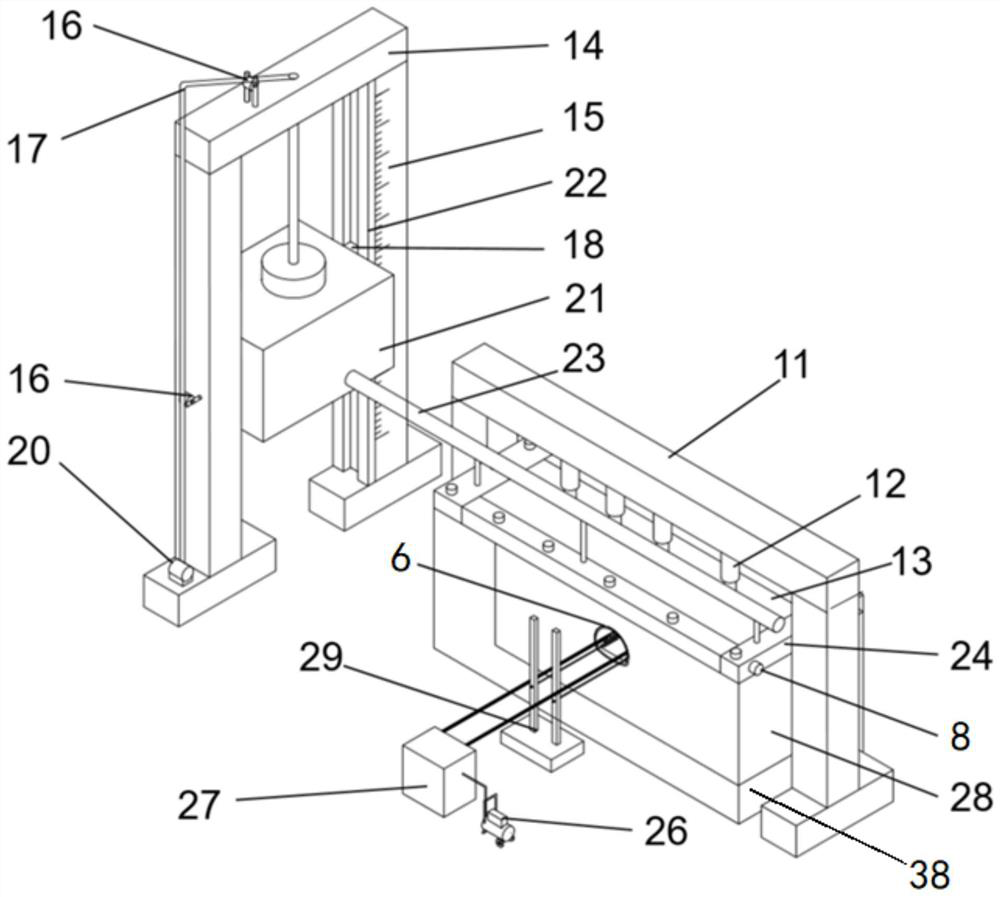

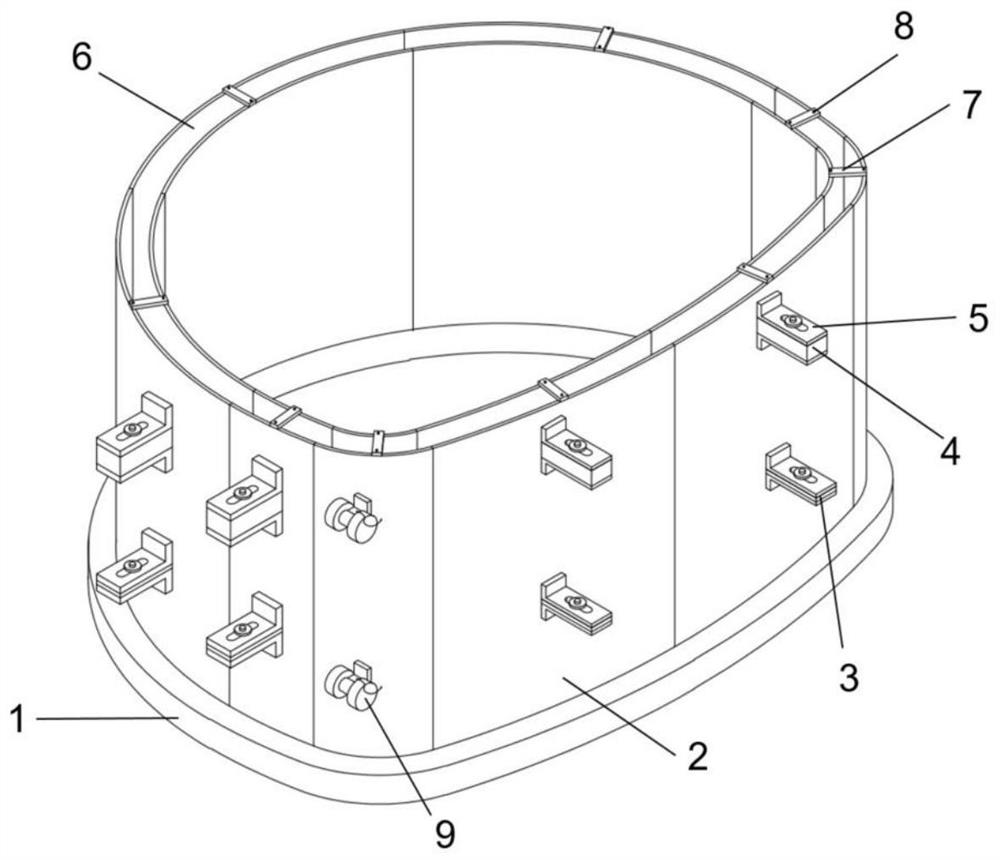

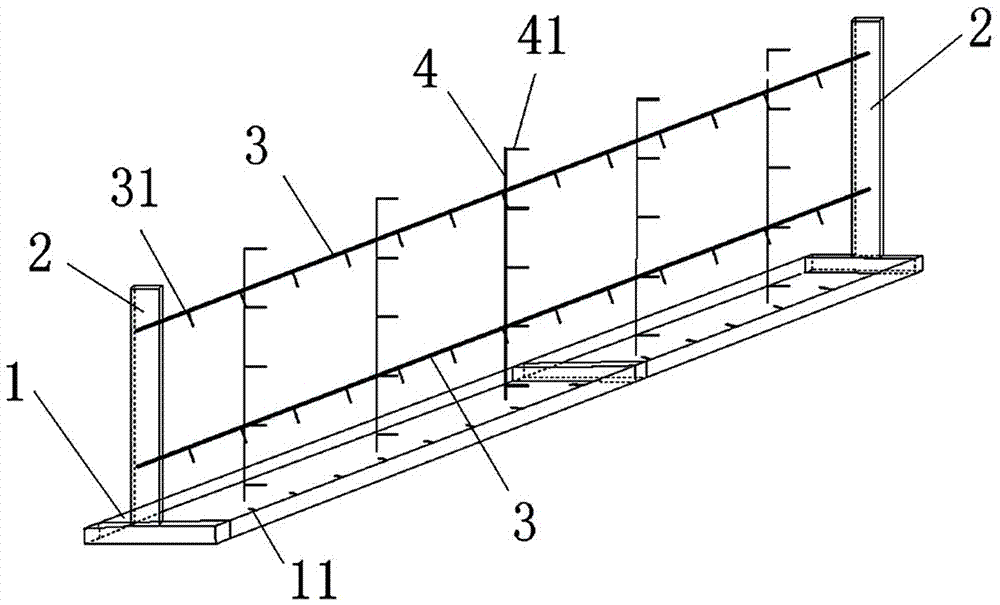

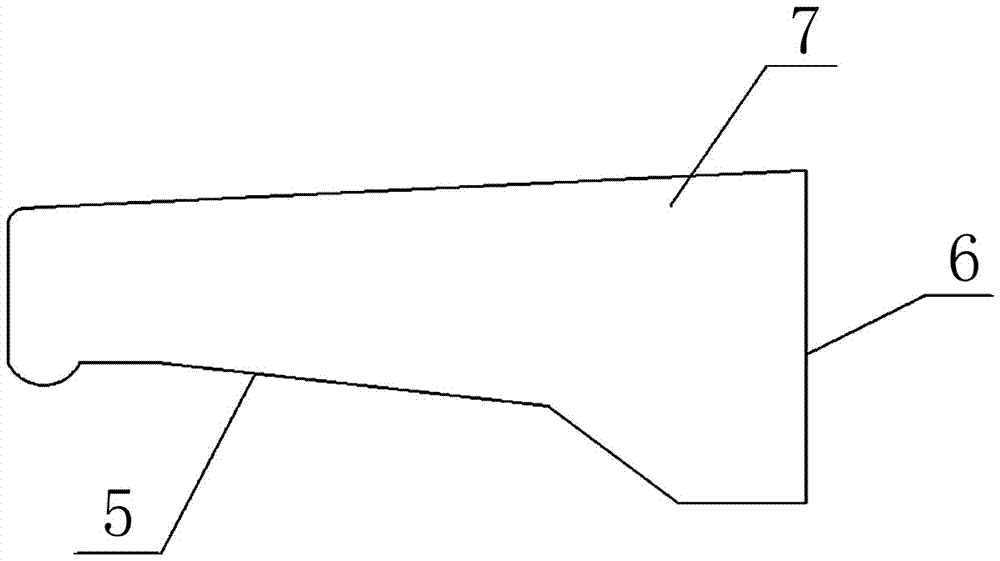

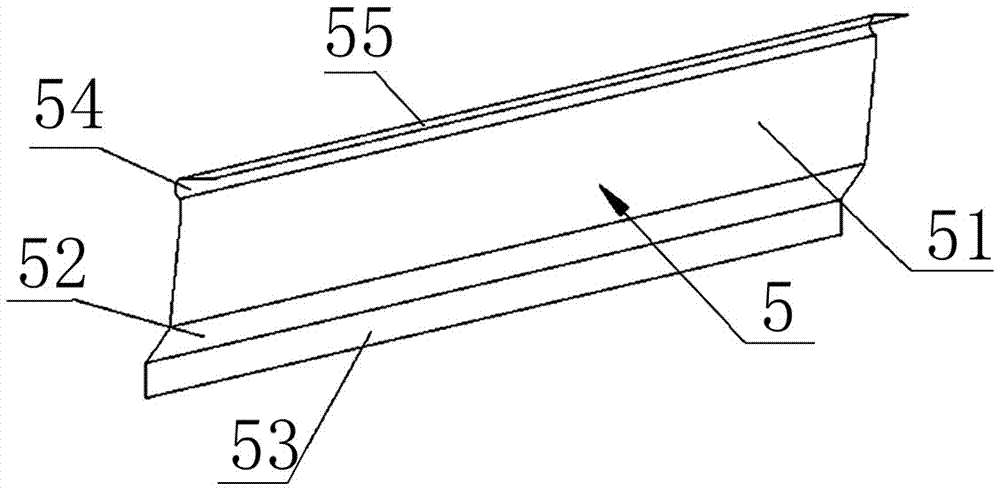

Jig frame for making guardrail rebars and construction method of guardrail

ActiveCN105603917AGuarantee product qualityReasonable designRoadway safety arrangementsEngineeringRebar

The invention provides a jig frame for making guardrail rebars and a construction method of a guardrail. The jig frame for making the guardrail rebars comprises a base, two supporting stand columns and two or more cross beams; the two supporting stand columns are fixedly connected to the two ends of the base respectively, the cross beams are parallel to the base, the two ends of each cross beam are fixedly connected to the two supporting stand columns respectively, and the cross beams are arranged in the vertical direction. The jig frame for making the guardrail rebars has the advantages that the design is reasonable, the structure is simple, a benchmark can be provided for making a rebar framework, the making quality of the rebar framework is guaranteed, the defective rate is decreased, and meanwhile the production efficiency can be improved.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

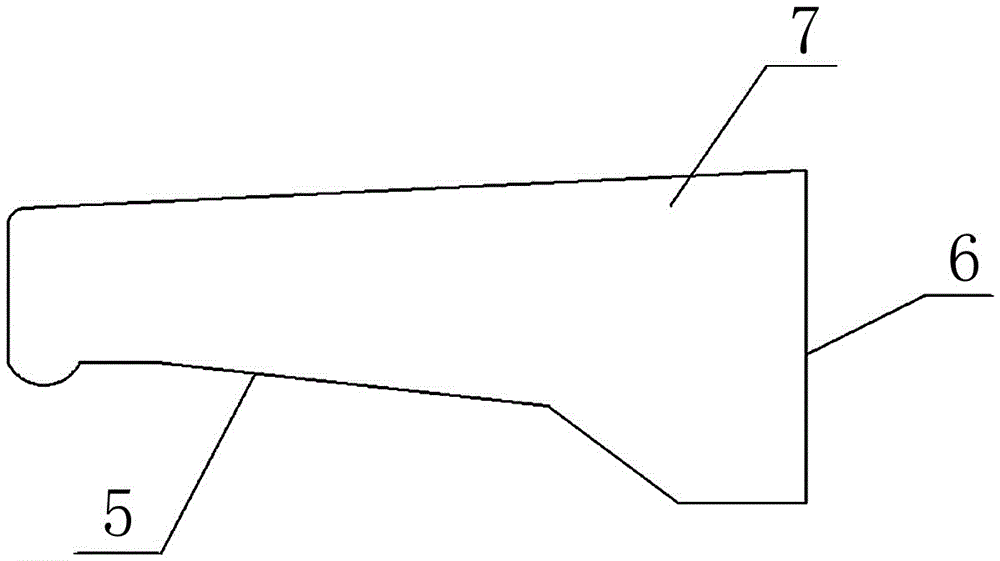

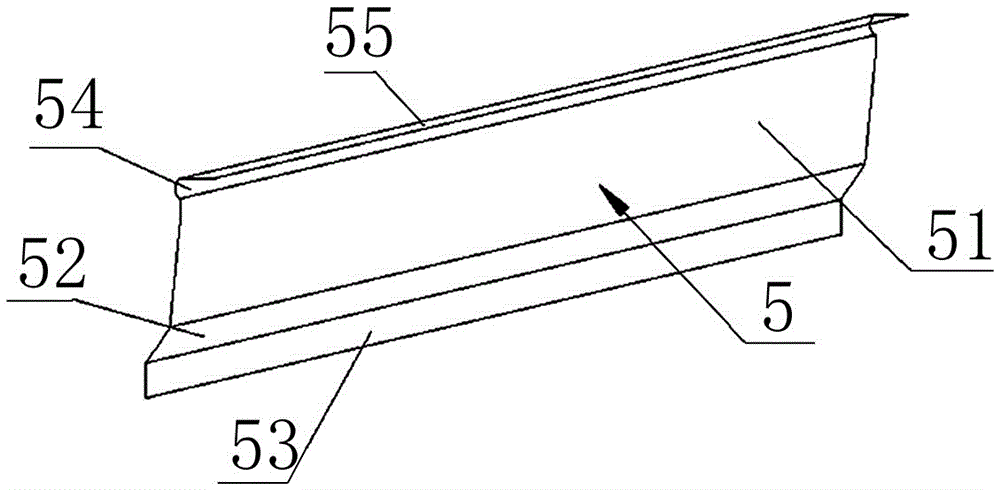

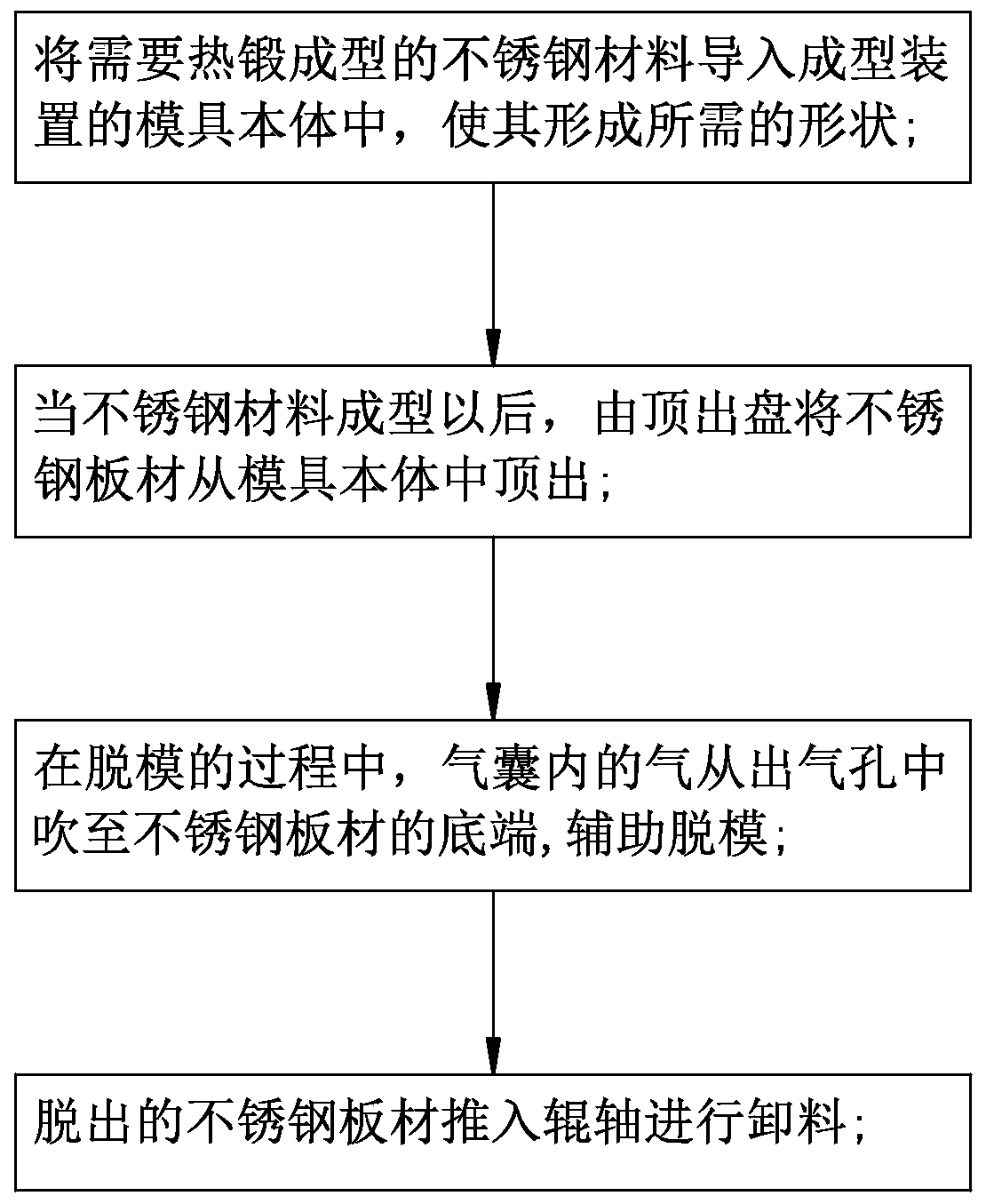

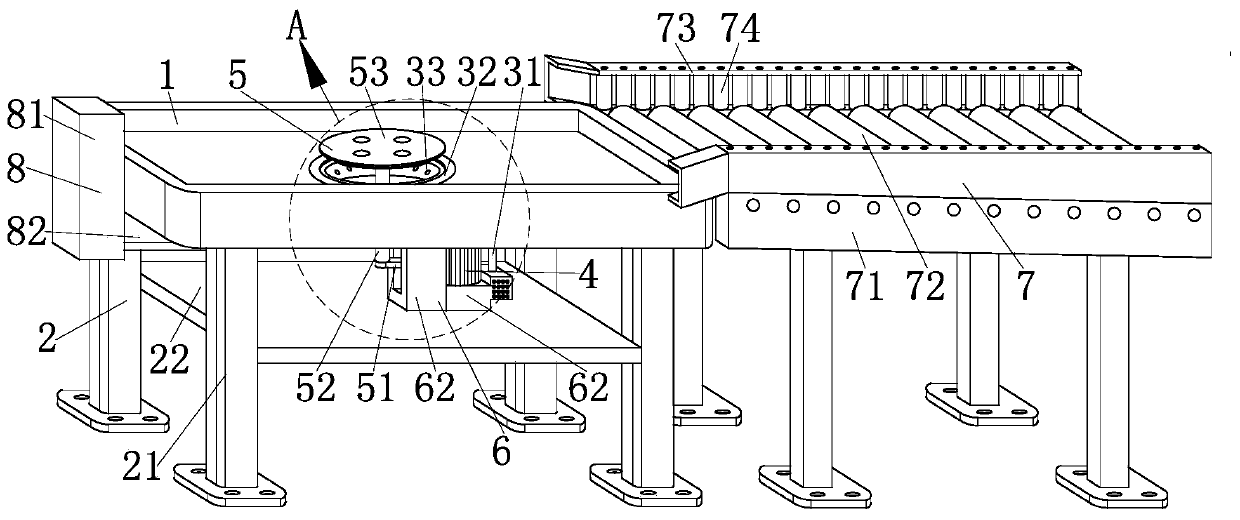

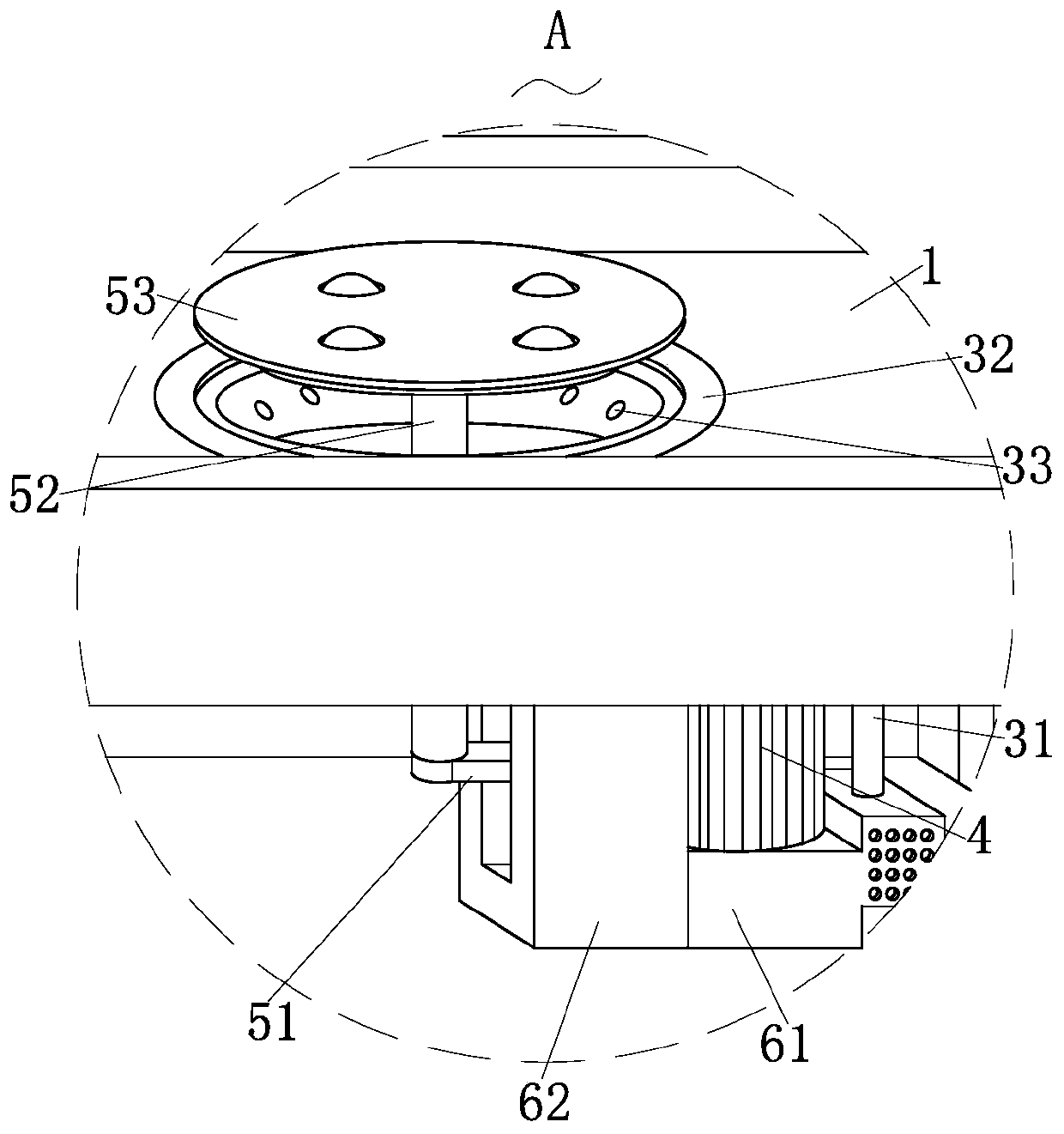

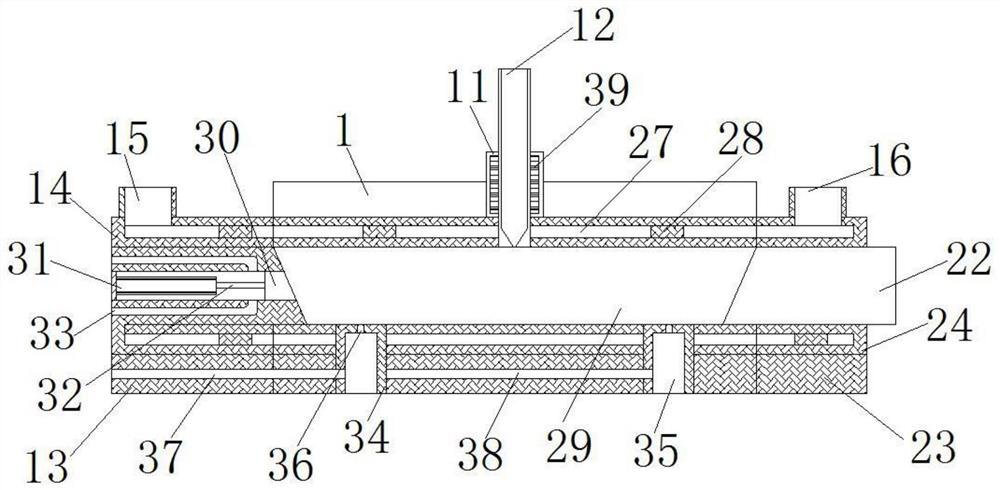

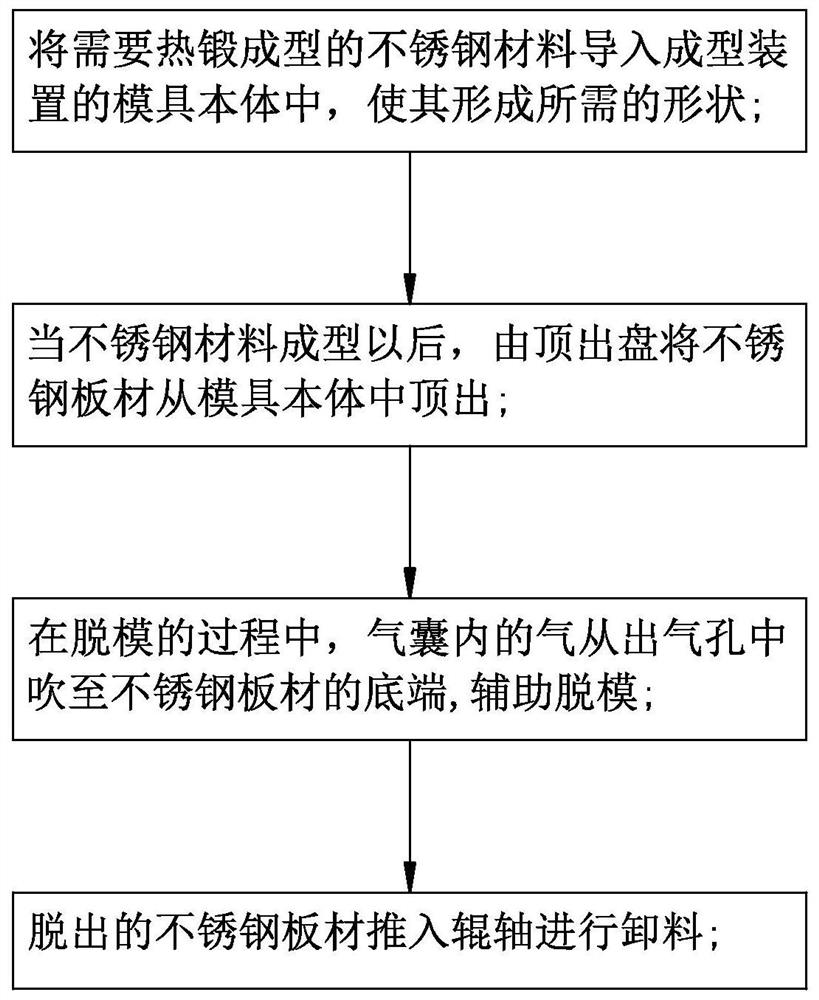

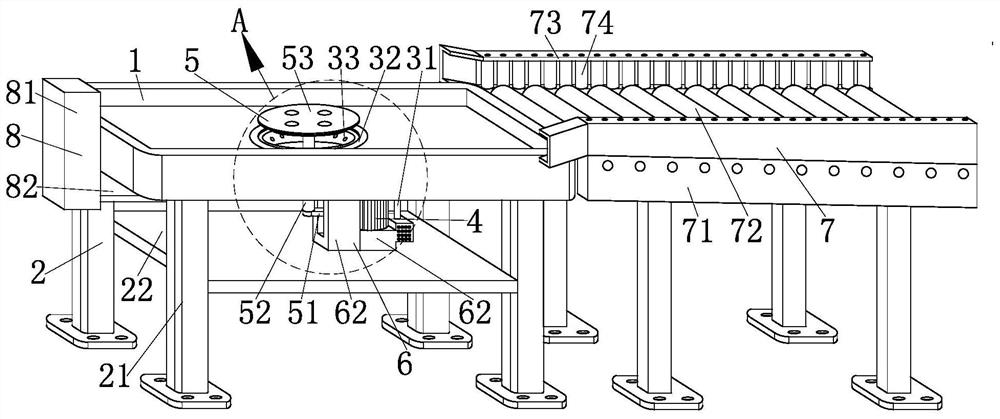

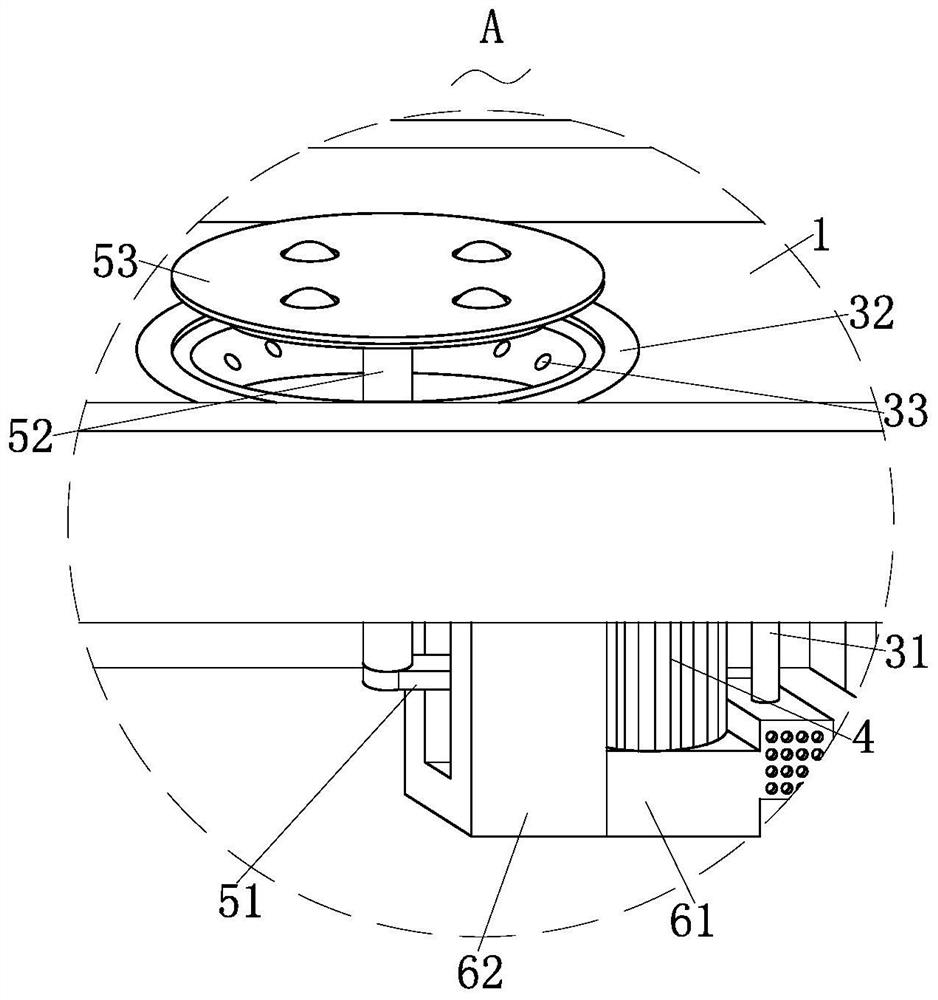

Stainless steel plate demoulding process

ActiveCN110328317AExtended service lifeReduce labor intensityForging/hammering/pressing machinesAirbagUltimate tensile strength

The invention relates to the field of hot forging equipment, in particular to a stainless steel plate demoulding process. The stainless steel plate demoulding process comprises the following steps that a stainless steel material needing hot forging forming is guided into a mold body of a molding device, and a needed shape of the stainless steel material is formed; after the stainless steel material is molded, a stainless steel plate is ejected out of the mold body through an ejection disc; in the demolding process, air in an airbag blows to the bottom end of the stainless steel plate from an air outlet hole to assist in demolding; and the demolded stainless steel plate is pushed into a roll shaft to be unloaded. The ejection structure can push the ejected material out of the mold body while ejection is carried out; meanwhile, due to the fact that a pushing structure can carry out fast pushing without enabling the ejection structure to bear long-term pressure, the service life of the ejection structure can be prolonged; and by means of linkage of the ejection structure and the pushing structure, ejection is convenient, pushing is convenient, and discharging is achieved, and therefore the labor intensity of workers can be greatly reduced.

Owner:陈光贡

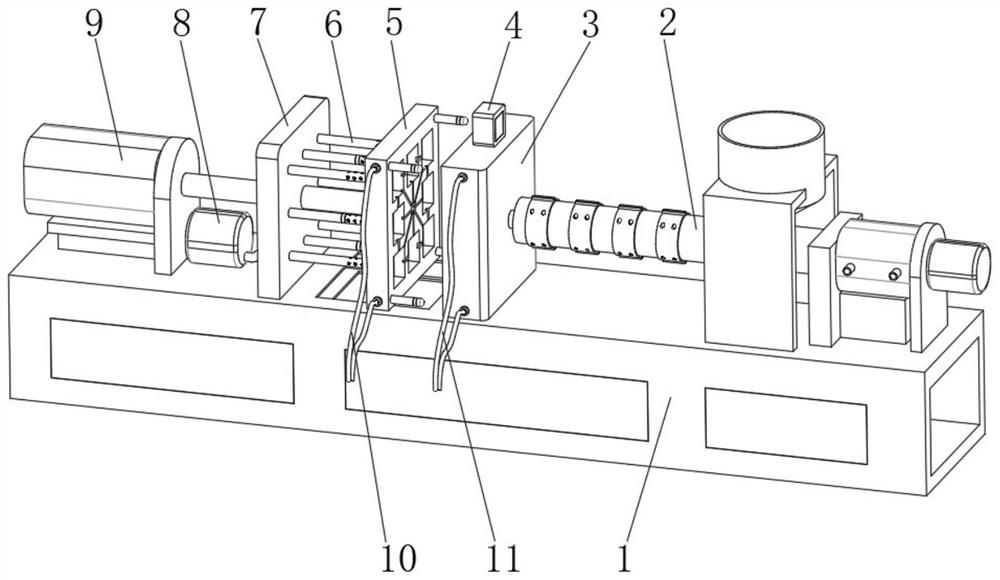

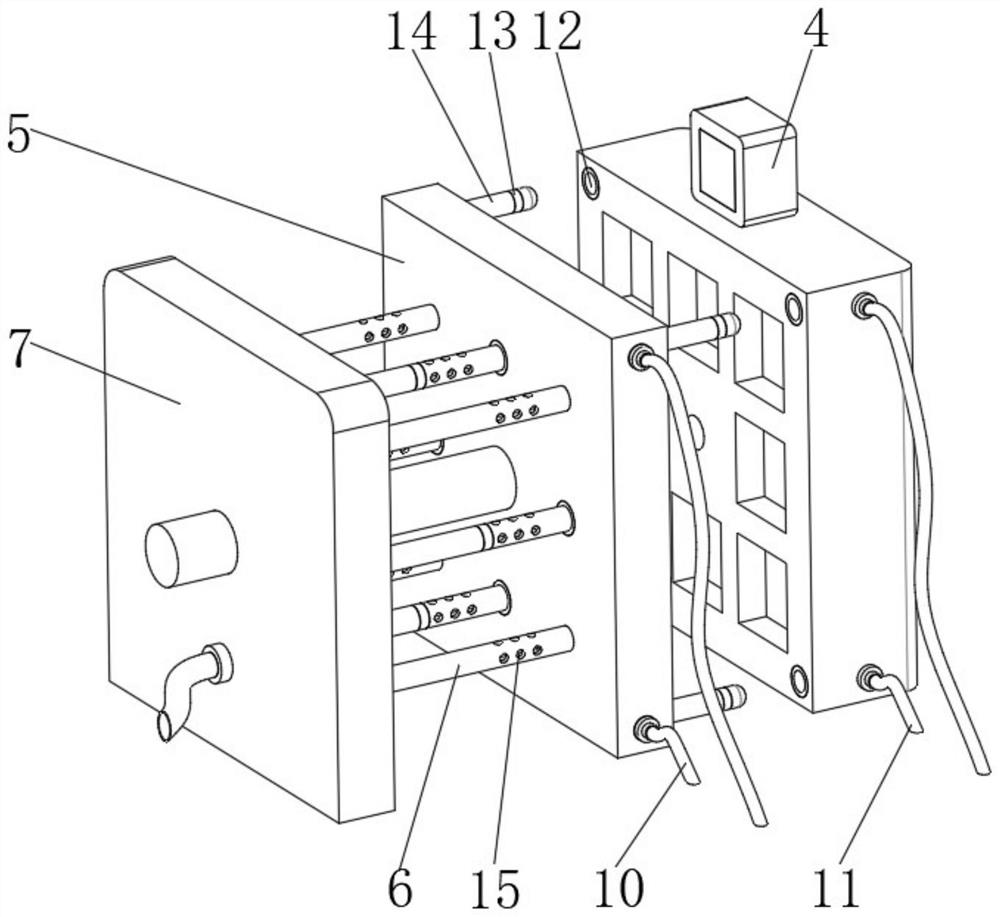

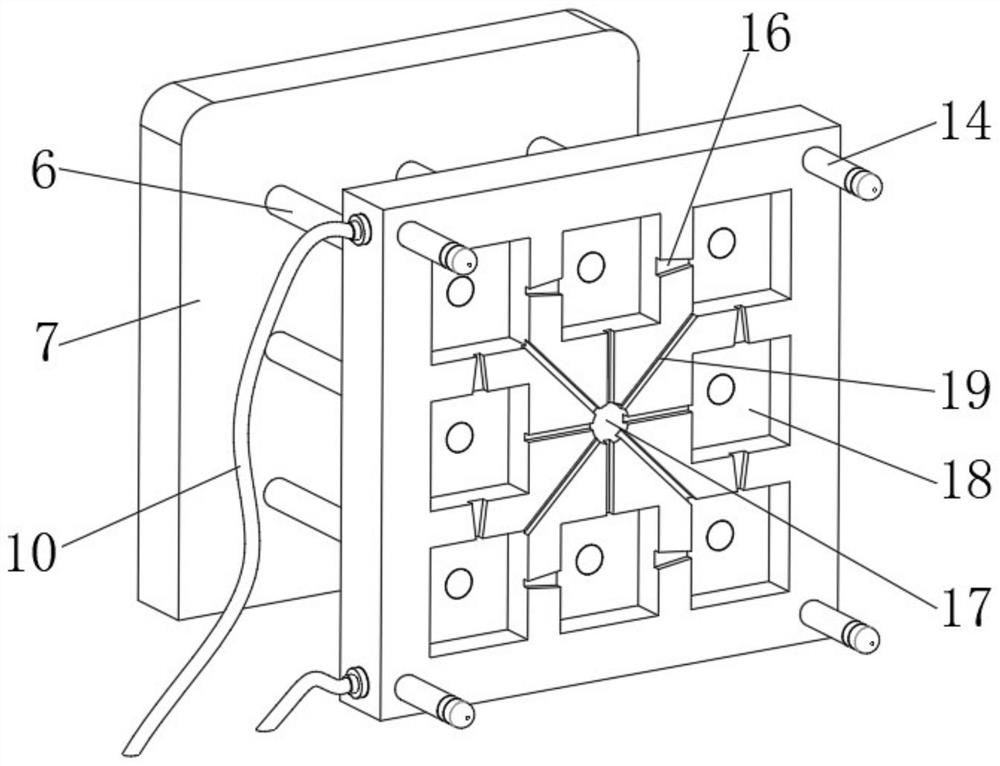

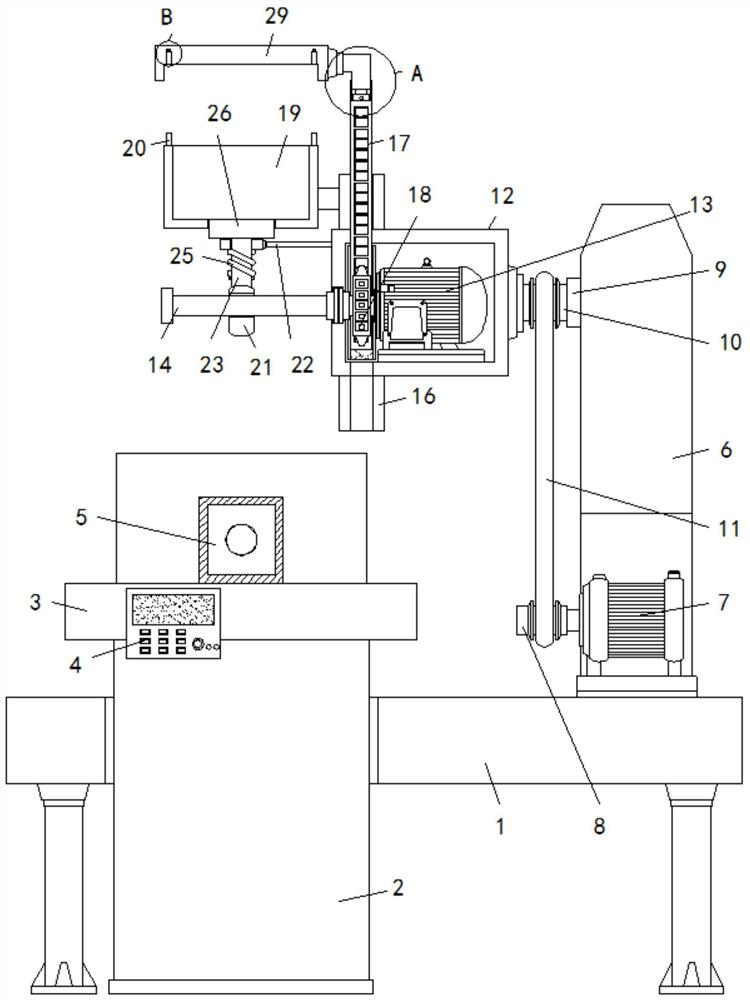

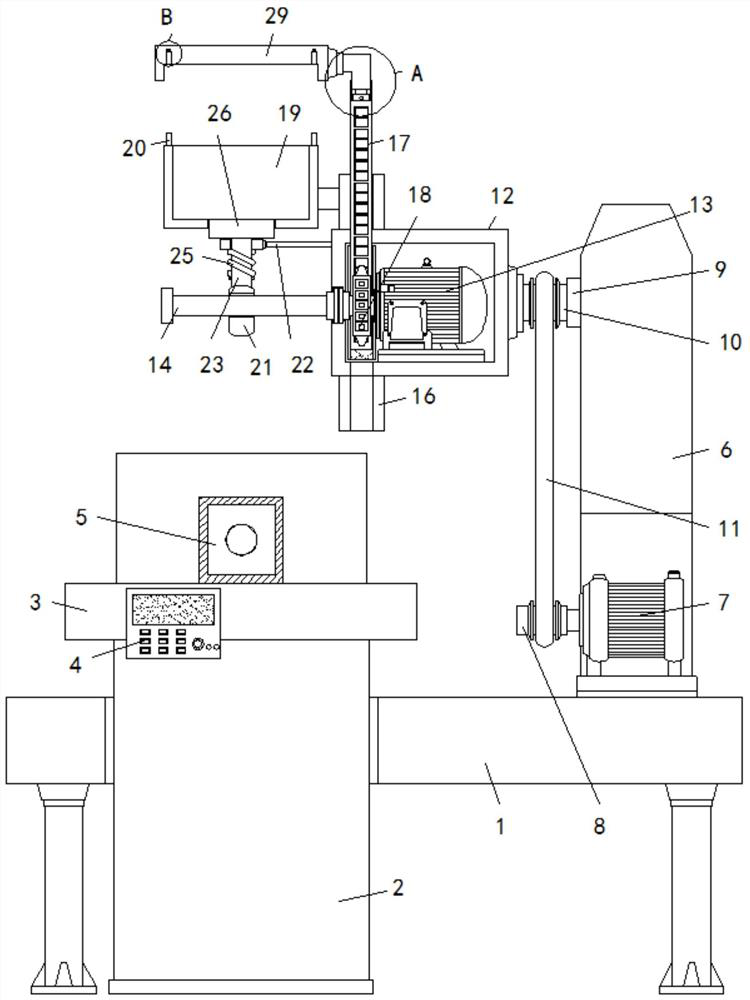

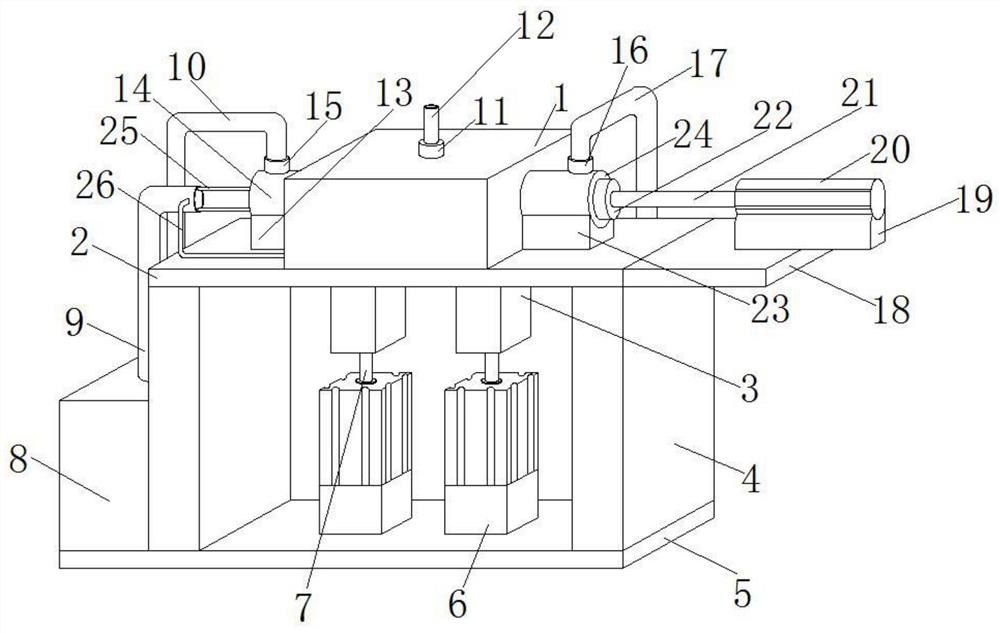

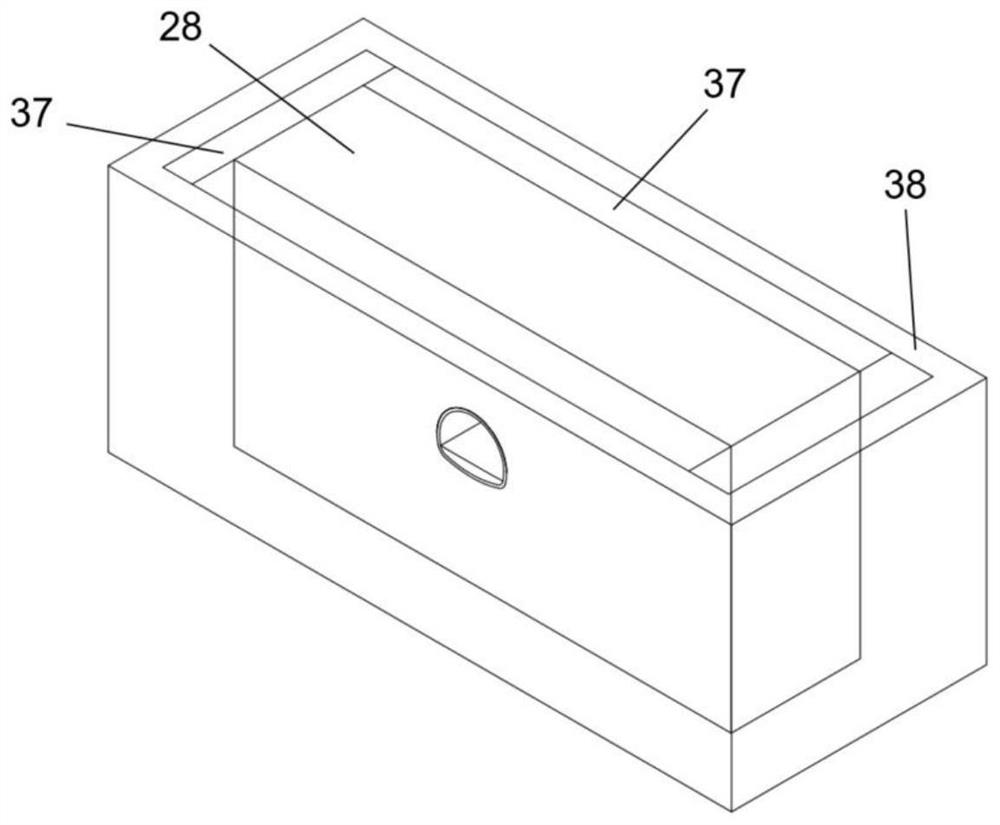

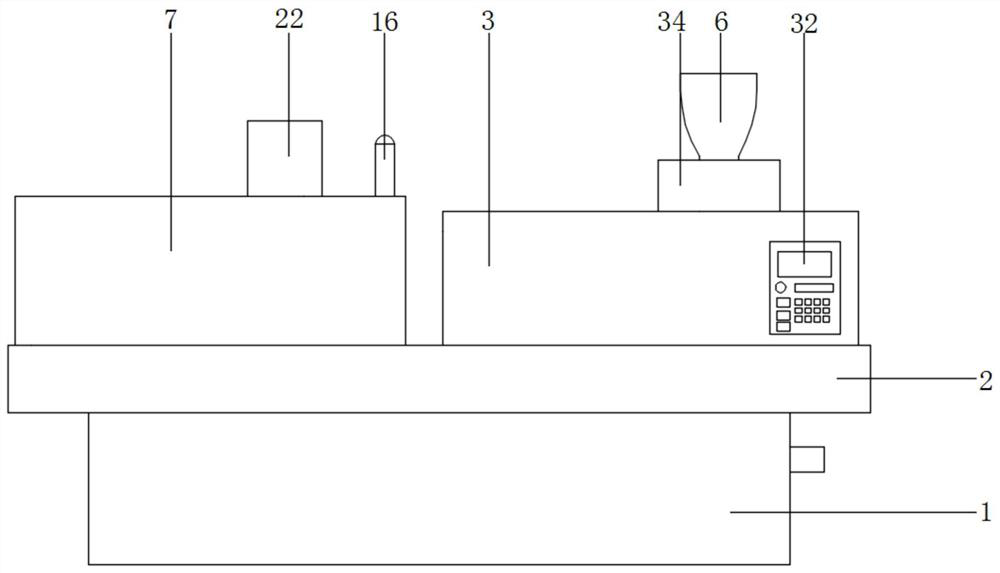

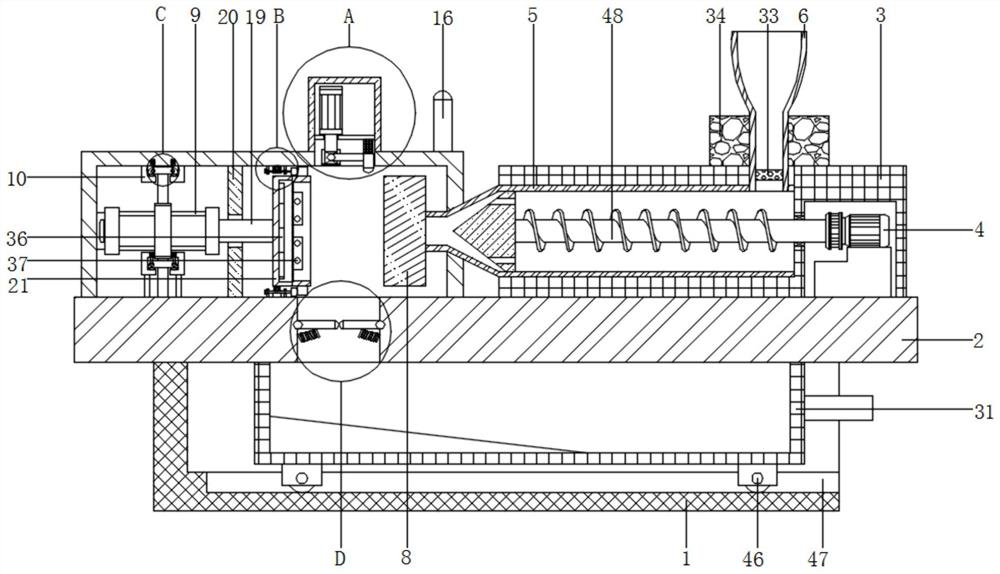

Injection molding machine and control method of injection molding machine

InactiveCN112223699AGuarantee processing qualityRealize automatic blowingTemperature controlMolding machine

The invention discloses an injection molding machine and a control method of the injection molding machine, and relates to the technical field of injection molding machines. The purpose of the invention is to improve the quality of injection molding products. The injection molding machine comprises a workbench; an injection molding mechanism and a mold mechanism are installed on the outer wall ofthe top of the workbench; a control module is arranged in the workbench; the mold mechanism comprises a movable injection mold and a fixed injection mold; and the inner wall of one side of the fixed injection mold is connected to the output end of the injection molding mechanism. The control method of the injection molding machine comprises the following steps: the injection molding mechanism works to extrude materials into a mold core; and in the extrusion process, a timer performs timing synchronously, and an electric control temperature liquid tank performs heat preservation through a firsttemperature control pipeline and a second temperature control pipeline. According to the invention, an air blowing hole and an air pump are arranged; during de-molding, the air pump is used for inflating a hollow ejector rod, and the inner wall of the mold core is cleaned through the air blowing hole; and therefore, the machining quality of the products is guaranteed, the purpose of automatic airblowing is achieved based on the de-molding position of the injection molding movable mold, and convenience and practicability are improved.

Owner:苏州思捷精密模具有限公司

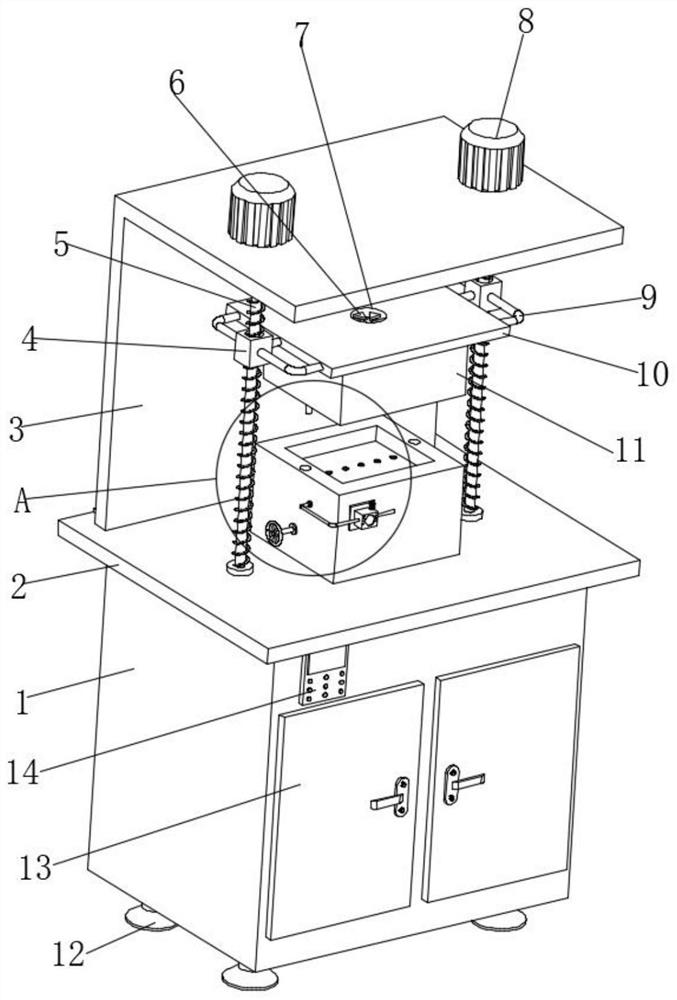

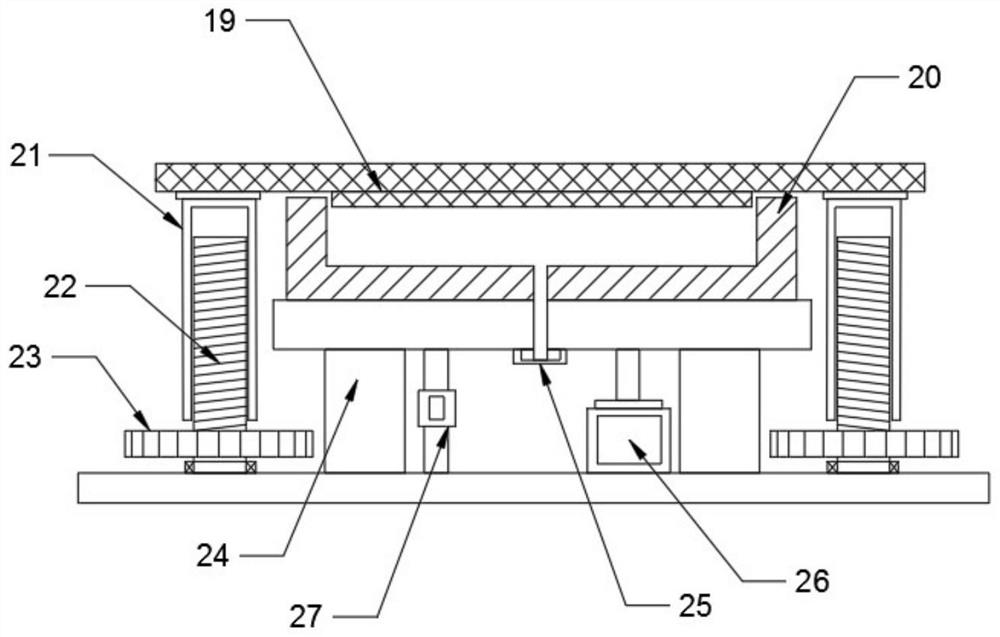

Hot press with demolding function

InactiveCN106827120AEven by forceConvenient pressing workPlywood pressesVeneer pressesMechanical engineeringWater tanks

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

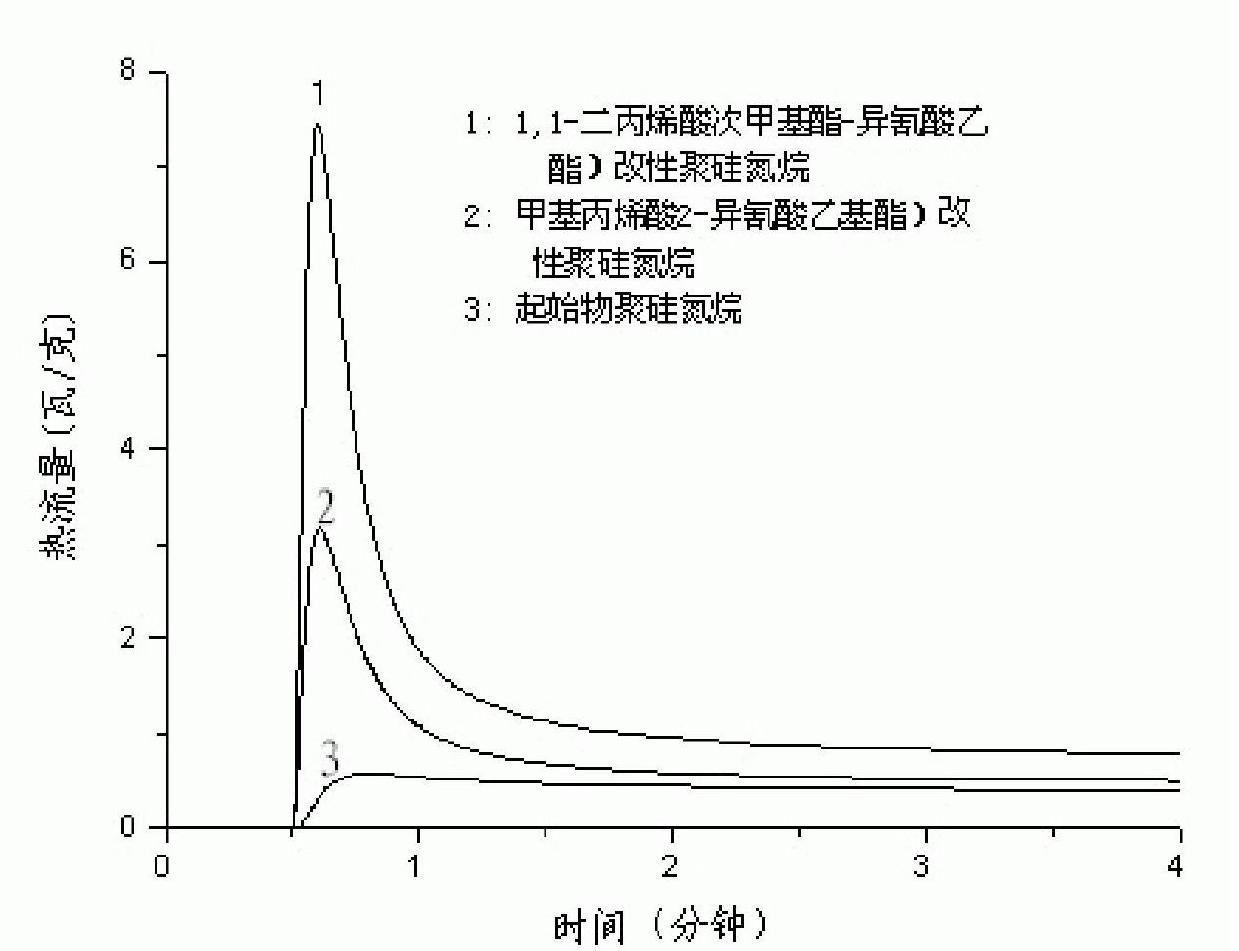

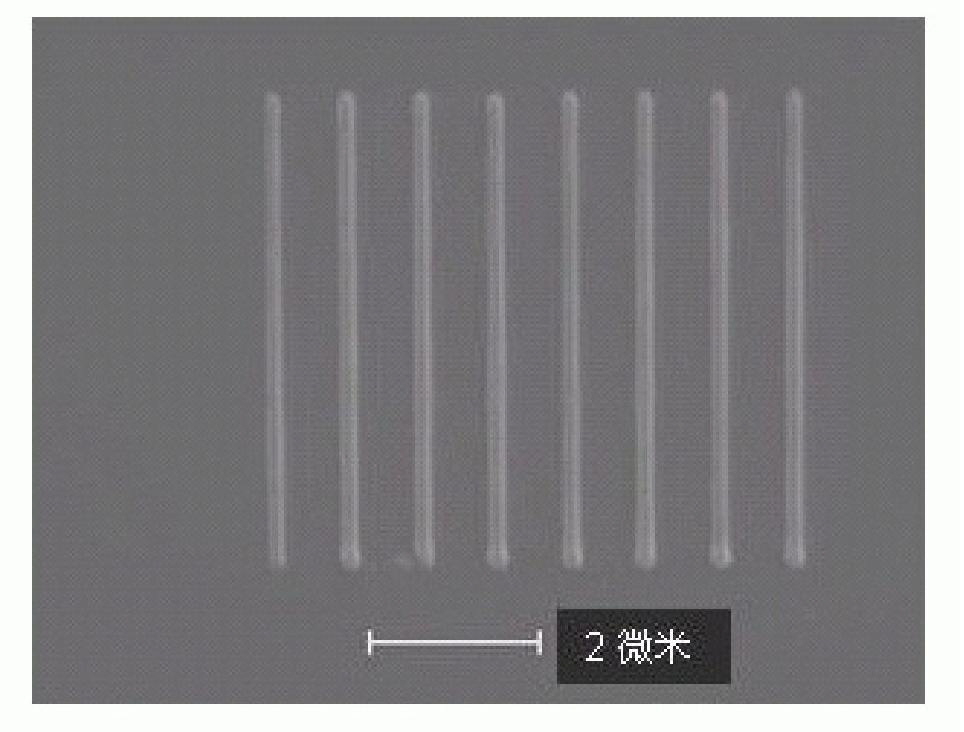

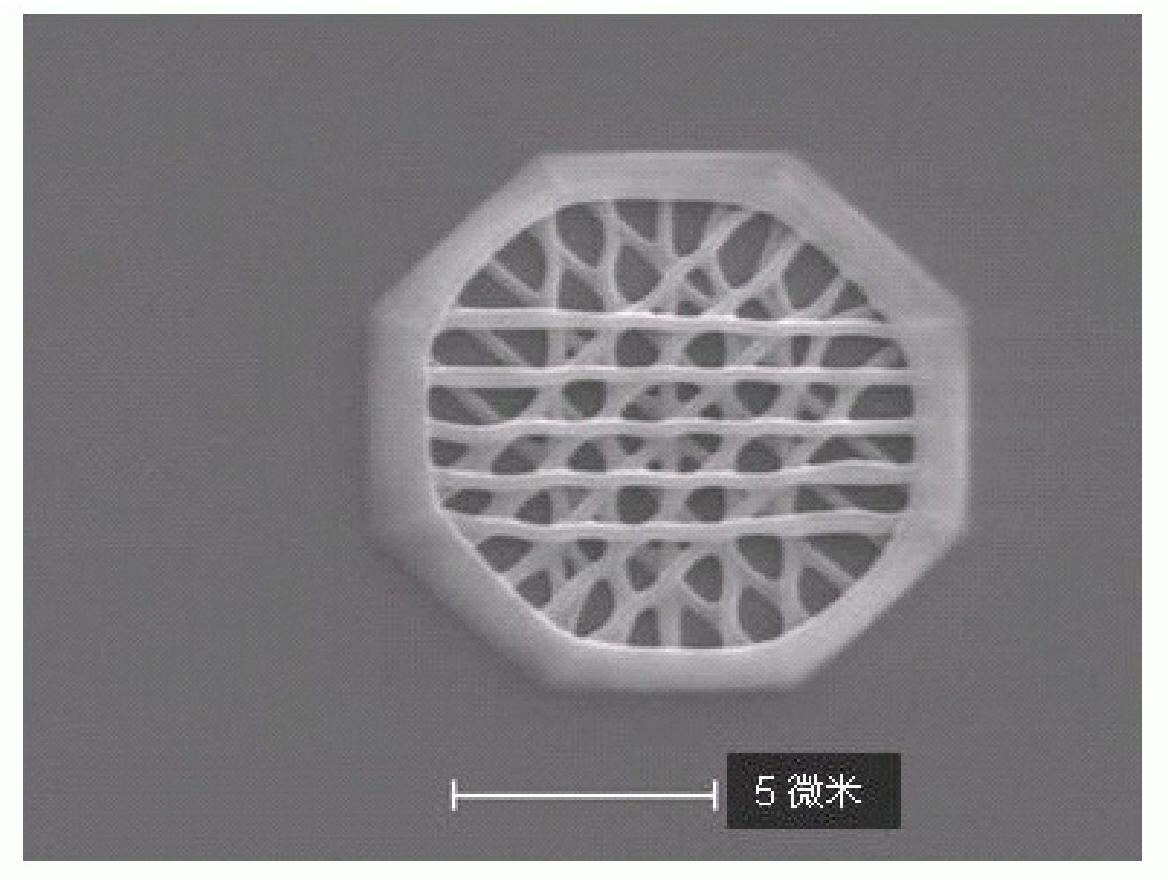

Precursor polymer for manufacturing fine ceramic components and synthesis method thereof

The invention discloses a precursor polymer for manufacturing fine ceramic components and a synthesis method thereof; by utilizing pure chemical reaction between -NCO in optical activity compound and secondary amine group on a silazane precursor without by-product generation, photocrosslinking group is linked to a polysilazane molecule framework, so as to improve the optical activity of the synthesized precursor; by adopting a precursor conversion method, two-photon absorption three-dimension etching technology is applied to the programming design manufacturing of a three-dimension ceramic fine structure, such as the processing of a microfluidic chip complex ceramic component and the like; in the invention, the optical activity of the synthesized precursor is greatly improved, the photocrosslinking curing speed is improved rapidly, the curing time is rapidly reduced to within 1s from more than 100min, the precursor body and a mold can not be adhered and can not carry out swelling, so as to bring great convenience to the follow-up demoulding operation, and the precision of the manufactured microflow control component structure is greatly improved.

Owner:NAT UNIV OF DEFENSE TECH

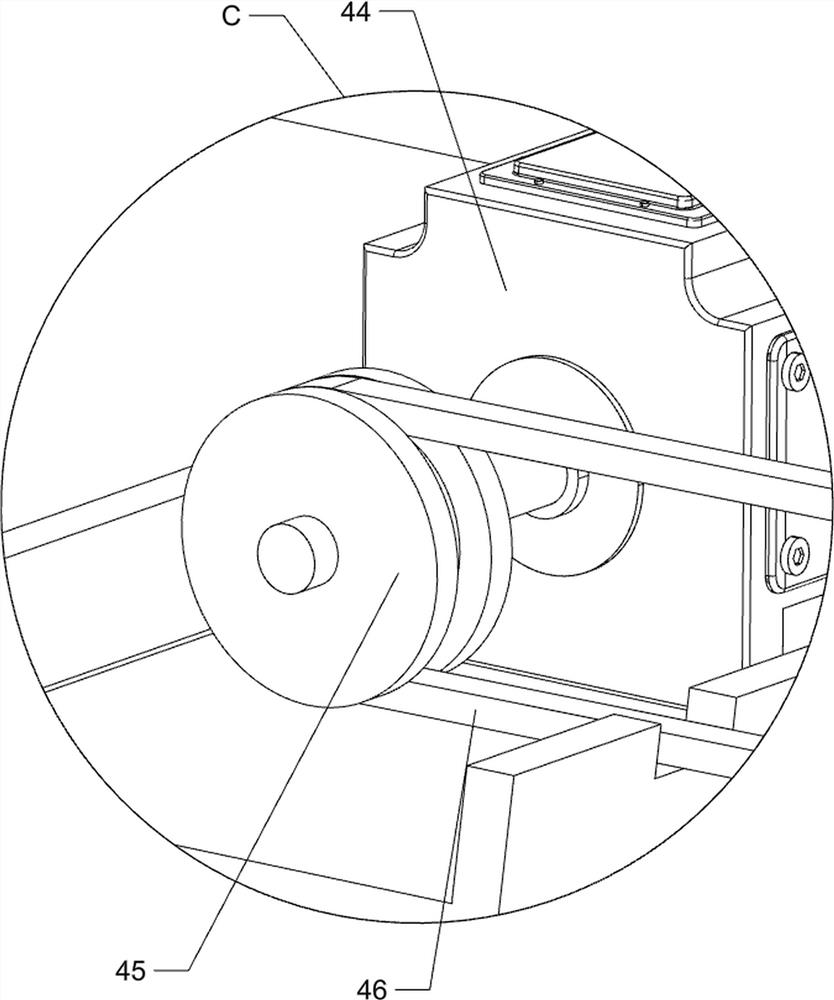

Device for assisting injection molding machine in demolding injection product

The invention relates to the technical field of injection molding auxiliary demolding devices, and discloses a device for assisting an injection molding machine in demolding an injection product. The device comprises a base and a demolding component, wherein electric telescopic rods are fixedly arranged on the inner wall of the top of the base; an injection molding table is movably connected to the outer wall of the electric telescopic rod; all structures in the demolding component are matched for use, so that after injection molding is completed, once the injection molding table ascends, a formed object in a mold can be pushed out, and the demolding work is more convenient and faster; through the cooperation of all structures in a rolling wheel component, when swing rods drive a supporting disc to enable ejector rods to demold the object, the ejector rod does not ascend stably and rotates along with the rotation of two second pulleys, and ejector pins in the two second pulleys are controlled to be ejected out in a staggered mode, so that a supporting plate is pushed to swing and ascend like a seesaw, the ejector rods are further made to swing leftwards and rightwards around the center of the supporting plate, the object in the mold is pushed out of the mold and moves upwards in a staggered mode, and it is guaranteed that the ejector rods can conduct demolding more smoothly.

Owner:施诞

Injection mold and demolding mechanism thereof

The invention discloses an injection mold. The injection mold comprises an upper mold base, a lower mold base, a top plate fixedly connected to the top of the upper mold base, a bottom plate fixedly connected to the bottom of the lower mold base and a groove formed in the top of the lower mold base, a sleeve is movably connected to the inner part of the groove, a limiting mechanism is movably connected to the inner part of the sleeve; the limiting mechanism comprises a fixing column, a through hole is formed in the inner part of the fixing column, a lifting rod is movably connected in the inner part of the through hole, and through grooves are formed in the positions, located on the periphery of the through hole, of the inner part of the fixing column. According to the injection mold and ademolding mechanism thereof, limiting and fixing sleeves with different diameter specifications are carried out, the sleeves which need the corresponding diameter specifications are arranged on the fixing column in a sleeving mode, the fact that plastic circular rings with different hole diameters can be machined on the injection mold in an injection molding mode can be realized, and molds with other sizes do not need to be additionally used, so that the application range of the injection mold is widened, and meanwhile certain economic cost is reduced.

Owner:郑晓璇

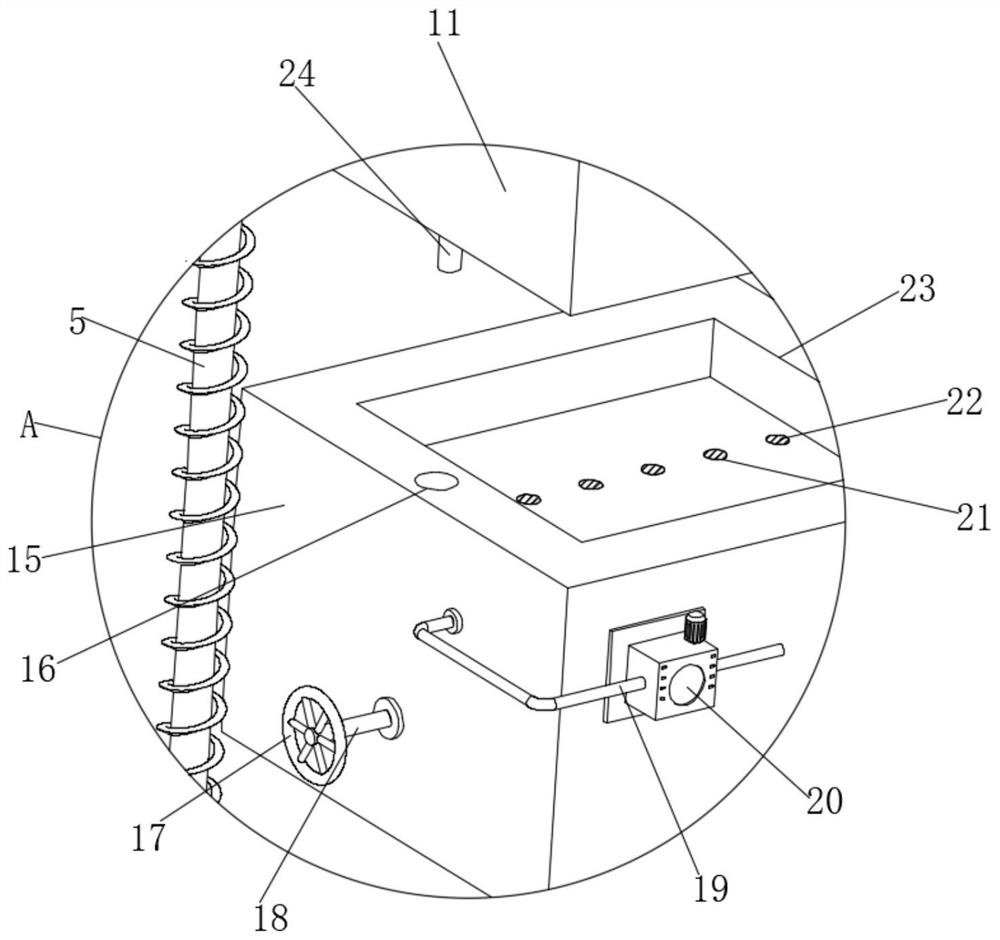

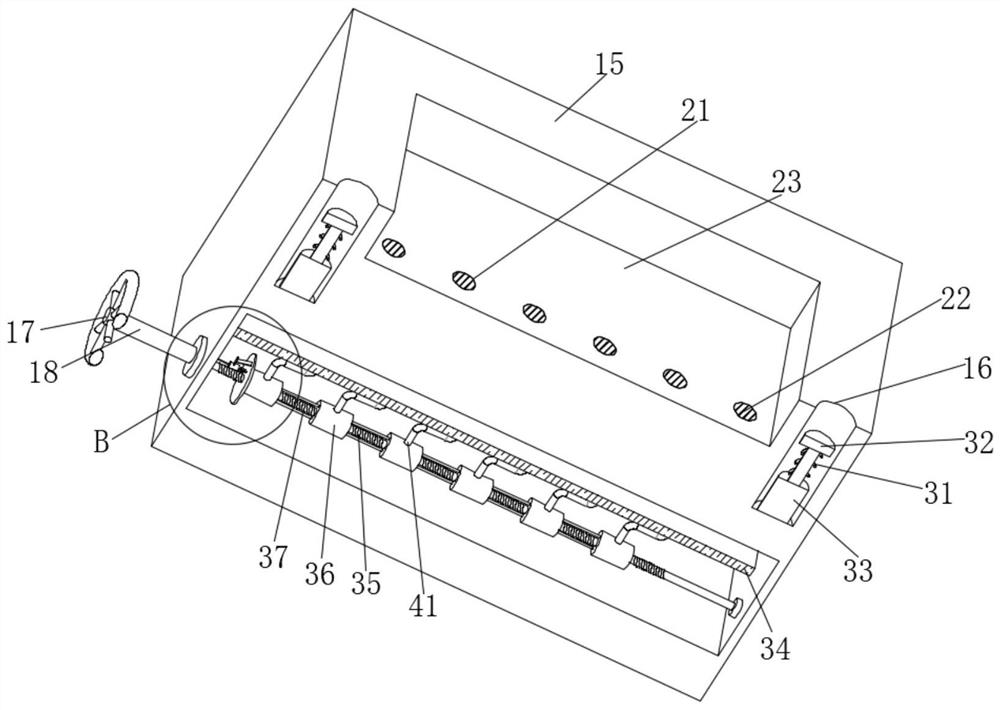

Metal casting demolding and discharging equipment

The invention relates to metal casting demolding and discharging equipment. The metal casting demolding and discharging equipment comprises a desk body, a mounting box is fixedly connected to the interior of the desk body, the top of the mounting box is fixedly connected with a discharging table, a control panel is fixedly mounted on the front face of the discharging table, the top of the discharging table is fixedly connected with a hydraulic push rod, the right side of the top of the desk body is fixedly connected with a fixing plate and a driving motor, an output shaft of the driving motoris fixedly connected with a driving rod, the top of the left side of the fixing plate is fixedly connected with a first bearing, the inner side of the first bearing is fixedly connected with a transmission rod, the outer sides of the transmission rod and the driving rod are in transmission connection with a conveying belt, the left side of the transmission rod is fixedly connected with a fixing box, and the inner bottom wall of the fixing box is fixedly connected with a servo motor. The metal casting demolding and discharging equipment is simple in overall structure, the purpose that the discharging equipment is convenient to use is achieved, the structure is compact, operation is easy, the discharging efficiency and quality are improved, and the practicability is high.

Owner:TIANCHANG TIANXIANG GRP

Glass bottle forming die applied to glass bottle blowing process

The glass bottle forming die applied to the glass bottle blowing process comprises an outer frame, a rotating column is arranged in the outer frame, the inner wall of the outer frame is movably connected with the outer surface of the rotating column, fastening devices are symmetrically arranged in the outer frame, and the outer surfaces of the fastening devices are fixedly connected with the inner wall of the outer frame. A mold is arranged in the fastening device, the outer surface of the mold is movably connected with the inner wall of the fastening device, a sealing device is arranged on the outer surface of the mold, the inner wall of the sealing device is movably connected with the outer surface of the mold, a heat insulation device is arranged in the outer frame, and the inner wall of the outer frame is movably connected with the outer surface of the heat insulation device. In order to overcome the defects in the prior art, the invention provides the glass bottle forming die applied to the glass bottle blowing process, and the problems that a traditional glass bottle blowing process is slow in forming and affects the working efficiency are solved.

Owner:江苏晶瑞玻璃有限公司

Automatic assembling and detecting equipment for metal packsack pendant

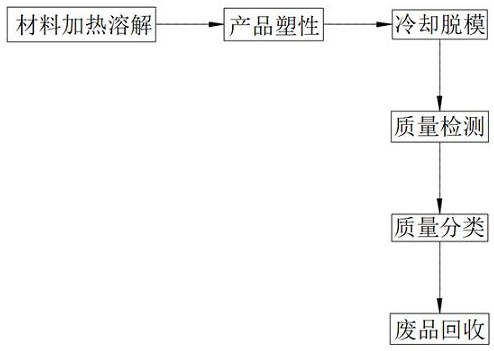

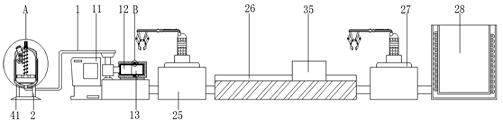

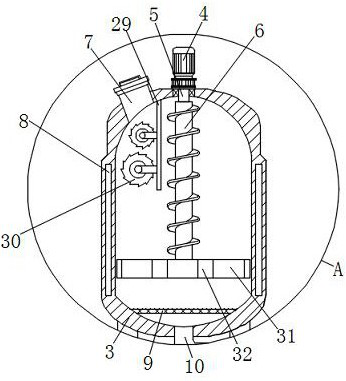

InactiveCN112354627AIncrease the degree of fragmentationStir to dissolve thoroughly and evenlyMachine part testingFoundry mouldsThermodynamicsWaste product

The invention relates to automatic assembling and detecting equipment for a metal packsack pendant. An automatic device body comprises a supporting leg, and the upper surface of the supporting leg isfixedly connected with a dissolving tank. A driving machine is fixedly arranged on the upper surface of the dissolving tank, and the output end of the driving machine is fixedly connected with a rotating rod. The bottom end of the rotating rod penetrates into the dissolving tank and is fixedly connected with a stirring rod. The top, close to the left side of the dissolving tank, of the dissolvingtank is fixedly connected with a feeding pipe, and the inner wall of the dissolving tank is fixedly connected with a temperature-adjustable heating plate. By the coordination of the structures, the dissolution of raw materials is accelerated, and a plastic machine can quickly cool and demold products. Thus, waste recycling work of a user is facilitated, convenience is brought to follow-up productquality screening work of the user, the production efficiency of the product production process is improved, and convenience is brought to the user.

Owner:重庆新禹智能科技有限公司

A kind of metal casting demoulding blanking equipment

The invention relates to a metal casting demoulding blanking equipment, comprising a table body, the inside of the table body is fixedly connected with an installation box, the top of the installation box is fixedly connected with a blanking platform, and the front of the blanking platform is fixedly installed with a control panel , the top of the unloading table is fixedly connected with a hydraulic push rod, the right side of the top of the table body is respectively fixedly connected with a fixed plate and a drive motor, the output shaft of the drive motor is fixedly connected with a drive rod, and the left side of the fixed plate The top of the first bearing is fixedly connected with a first bearing, the inner side of the first bearing is fixedly connected with a transmission rod, the transmission rod and the outer side of the drive rod are connected with a conveyor belt, the left side of the transmission rod is fixedly connected with a fixed box, and the inner bottom of the fixed box The wall is fixedly connected with a servo motor. The metal casting stripping blanking equipment has a simple overall structure, realizes the purpose of the blanking equipment being easy to use, has a compact structure and is easy to operate, improves the efficiency and quality of blanking, and has high practicability.

Owner:TIANCHANG TIANXIANG GRP

Separated type hardware mold

Owner:长兴恒腾机械设备有限公司

Ecological stone demolding equipment for building

The invention relates to demolding equipment, in particular to ecological stone demolding equipment for a building. The ecological stone demolding equipment for the building provided by the inventionis easy to operate and capable of saving time and labor. The ecological stone demolding equipment for the building comprises a base, and a mounting rack is connected to the middle part of the base; ademolding mechanism mounted on the mounting rack; and a moving mechanism mounted on the base, and the moving mechanism is in transmission connection with the demolding mechanism. According to the ecological stone demolding equipment for the building provided by the invention, a mold with ecological stone can be conveyed leftwards through the moving mechanism, demolding can be conducted on the ecological stone through the demolding mechanism, the ecological stone is moved out of the mold, the moving mechanism and the demolding mechanism can automatically switch power to work through an automatic power switching mechanism, and guiding can be conducted through a reinforcing structure; and demolding work is facilitated, and therefore, the ecological stone does not need to be manually taken outof the mold, time and labor can be saved, and the operation is simple.

Owner:傅海冬

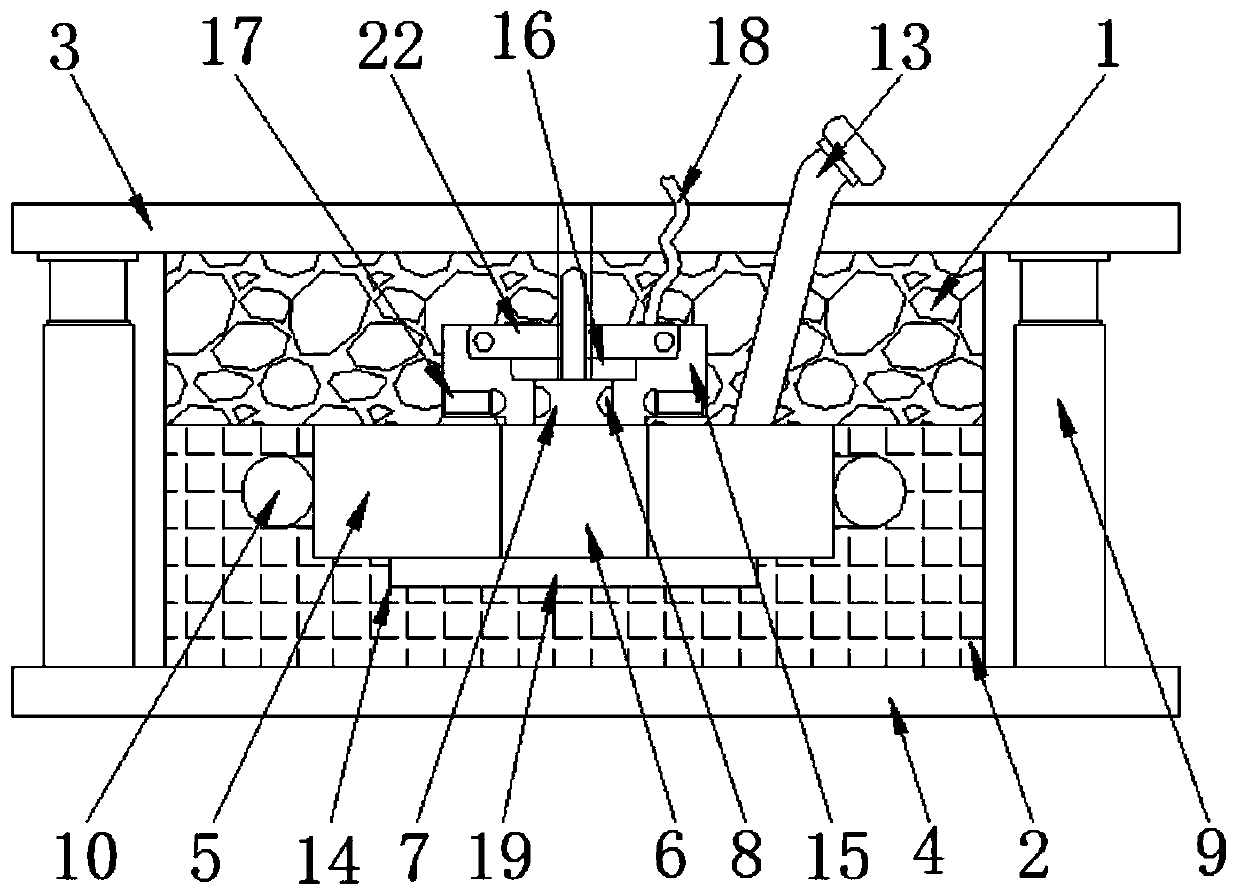

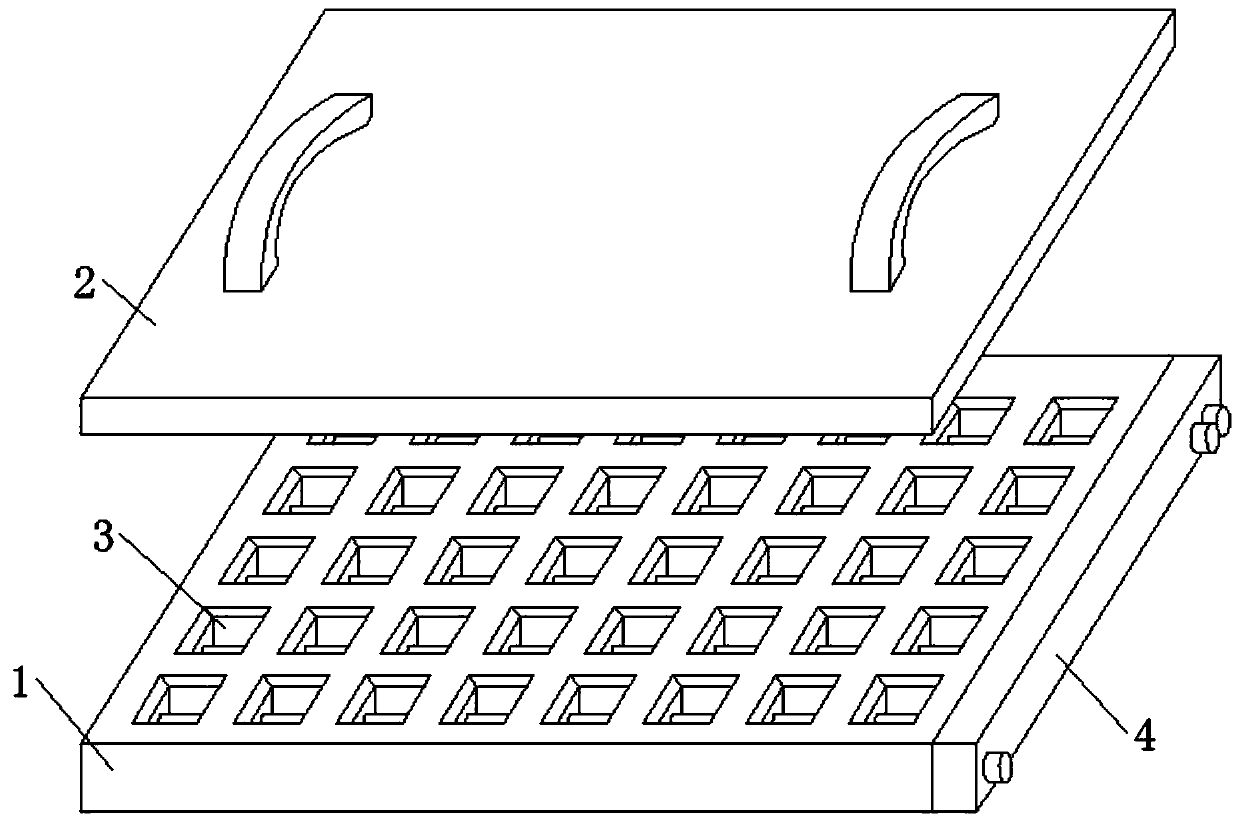

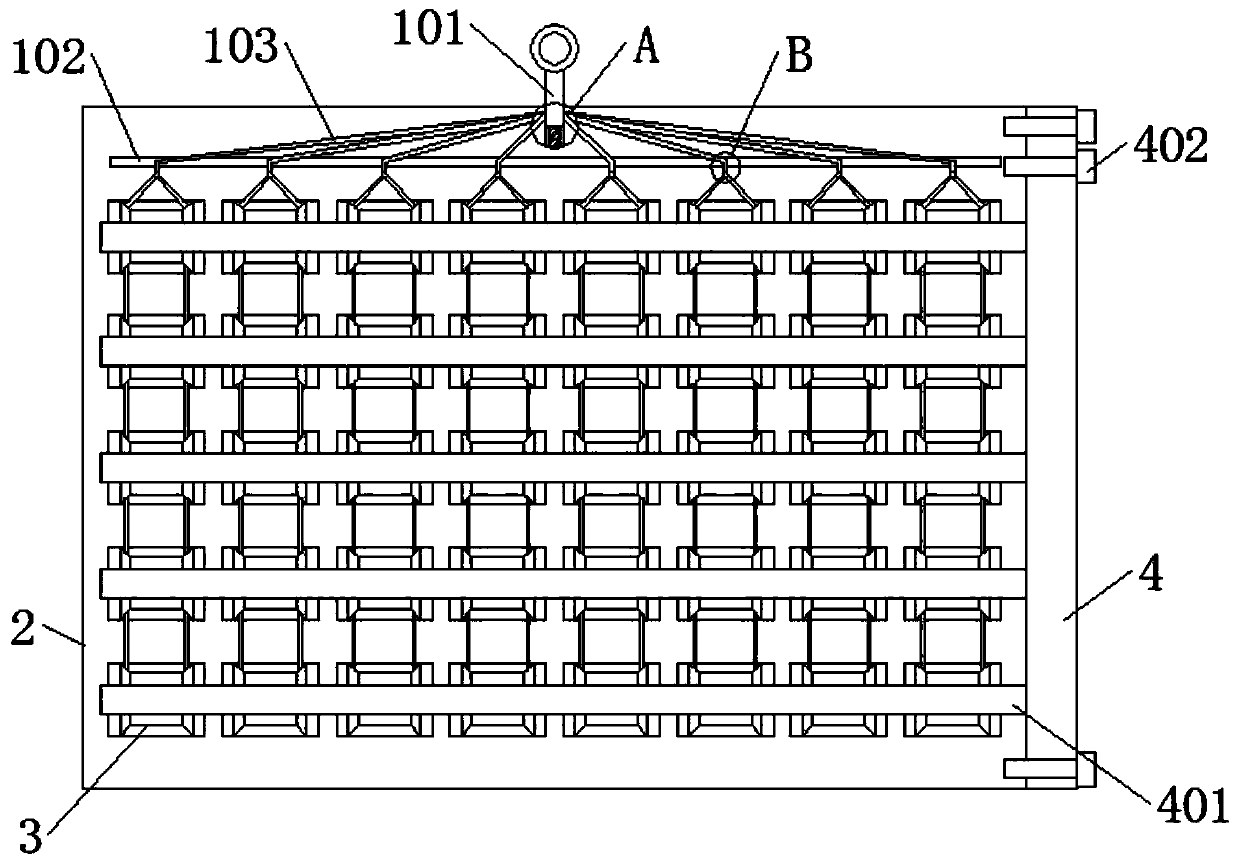

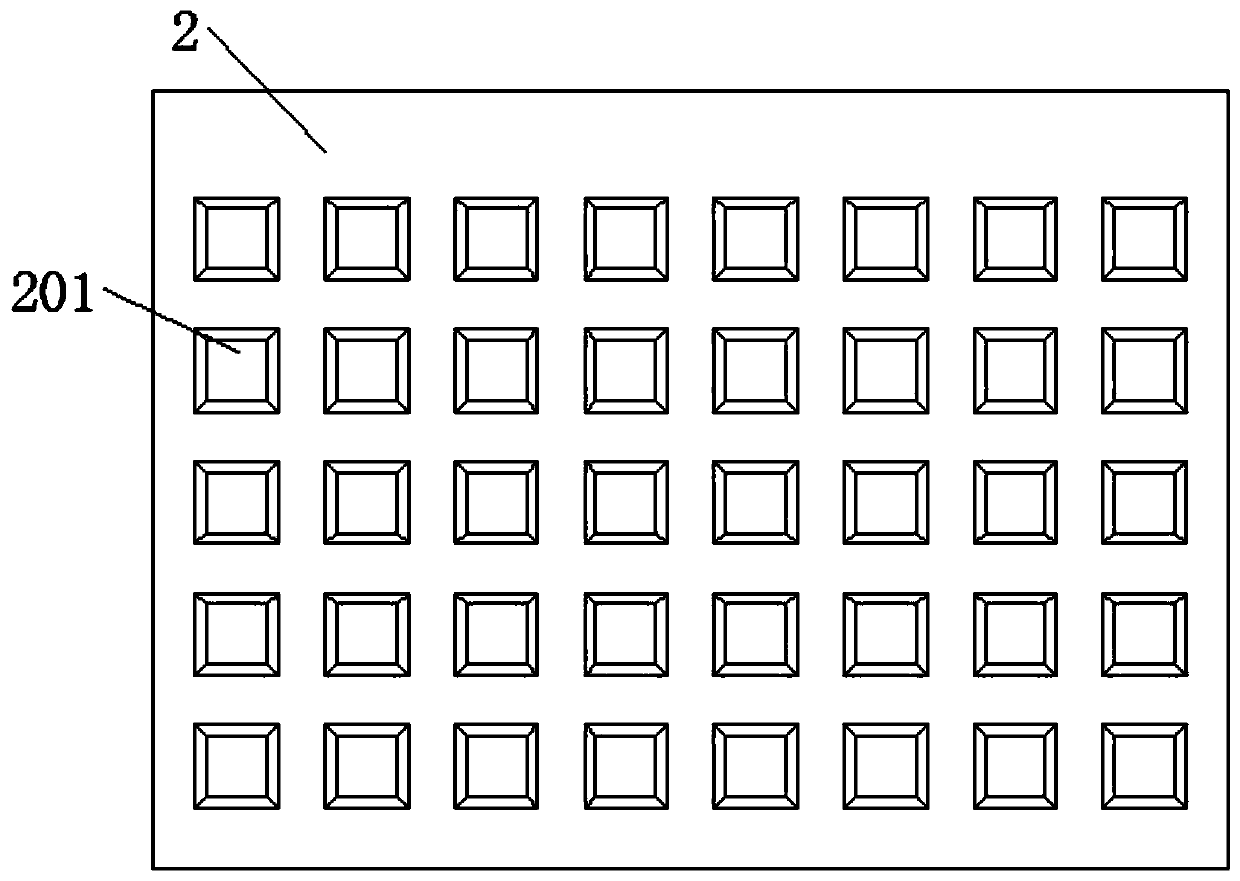

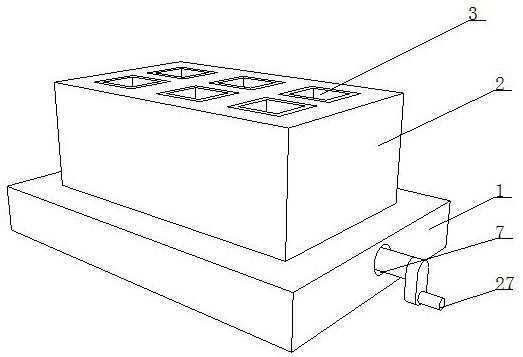

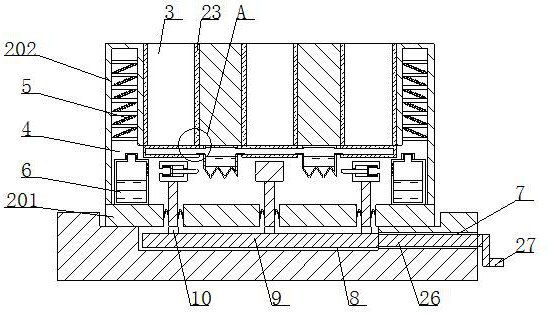

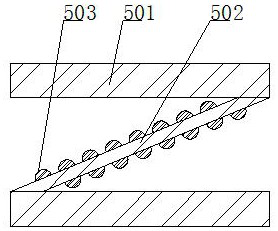

A grid hollow brick filling frame fitted with centripetal compaction

ActiveCN110154216BEasy to shapeEasy to useFeeding arrangmentsShaping press ramBrickClassical mechanics

The invention provides a grid hollow brick filling frame capable of fitting to centripetal compacting. The grid hollow brick filling frame comprises a mould frame, an extrusion cover, a pressure plate, a shaping slot and a pushing plate, wherein the extrusion cover is arranged at the top end of the mould frame; the bottom end surface of the extrusion cover is integrally equipped with the pressureplate; the shaping slot is embedded into the middle part of the mould frame; and the right side of the mould frame is equipped with the pushing plate. The grid hollow brick filling frame is stable instructure, enables brick blocks to be more compacted, is convenient and quick in use operation, is convenient in de-moulding, and is good in stabilizing effect.

Owner:浏阳市常丰墙材有限公司

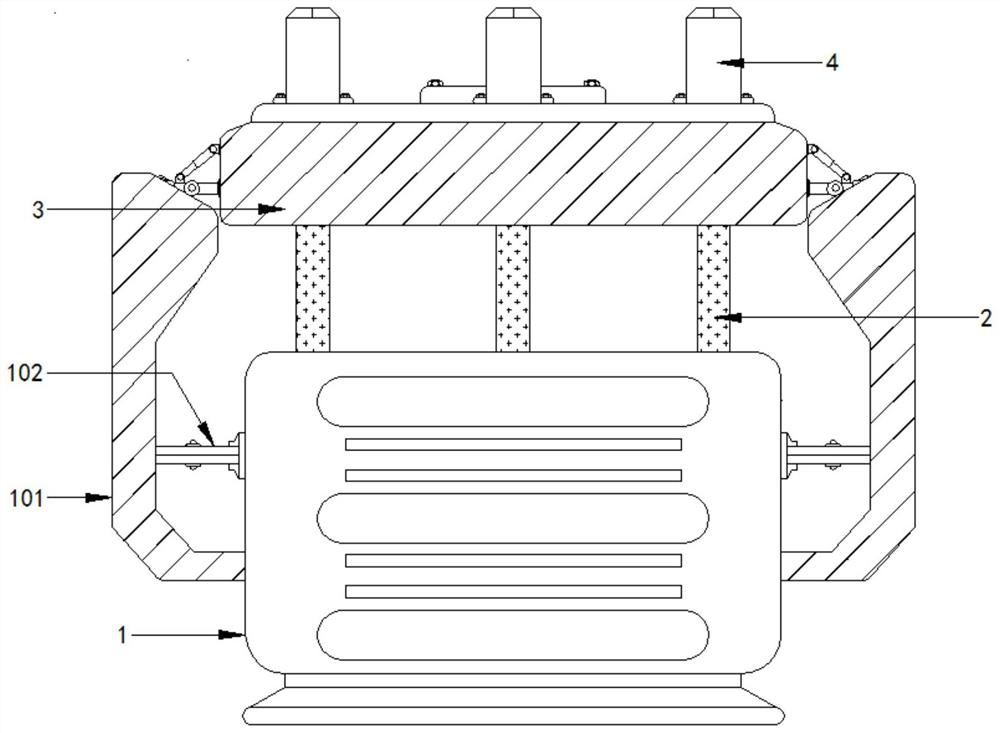

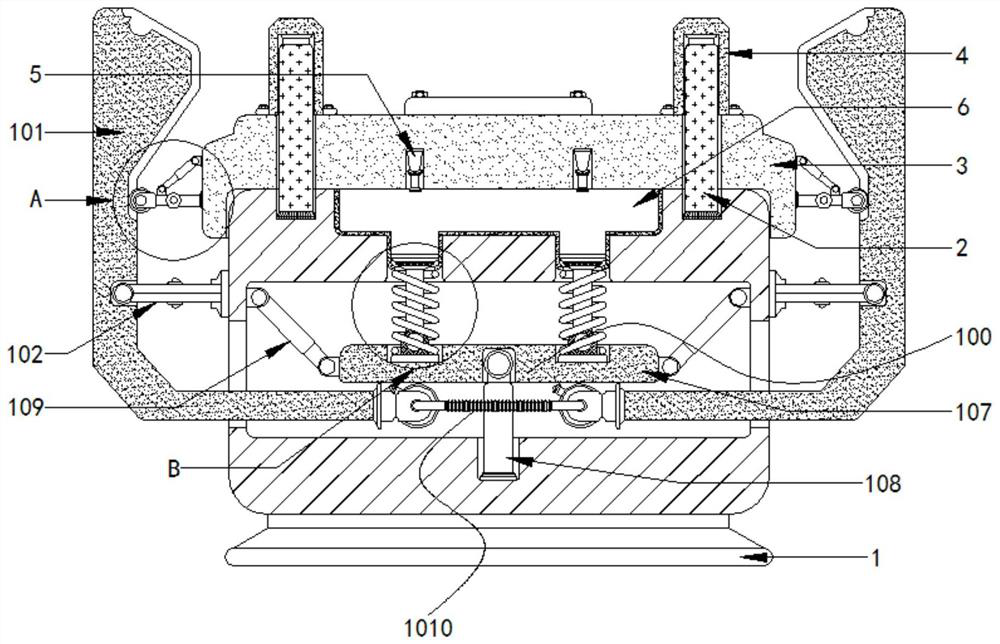

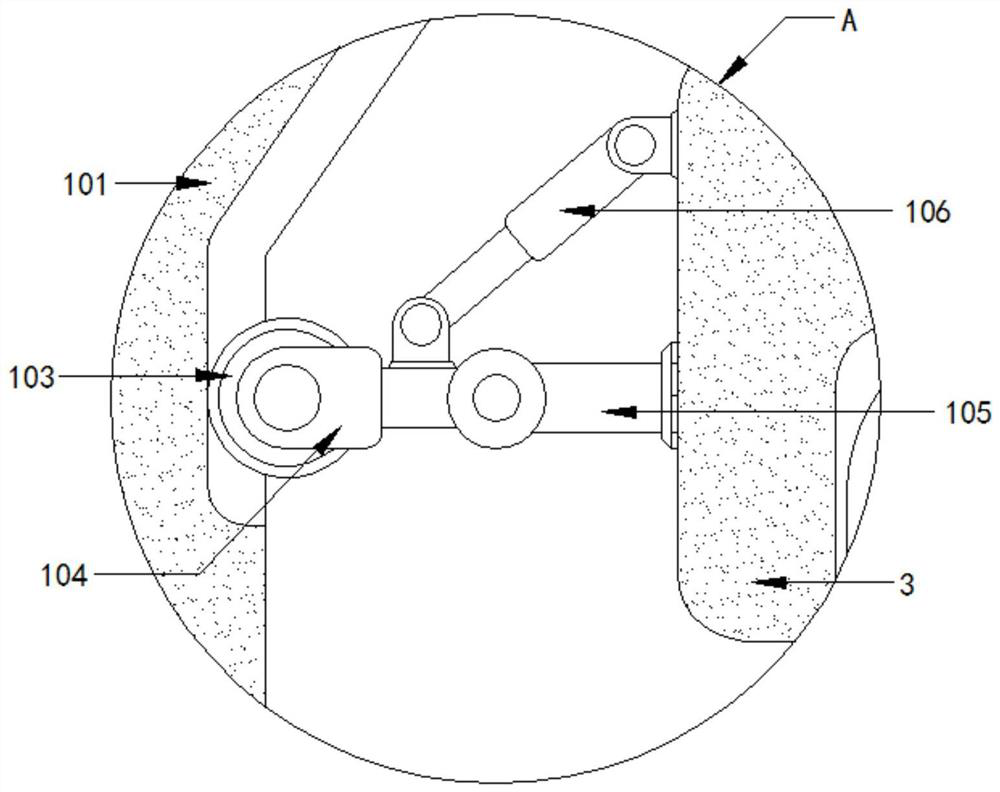

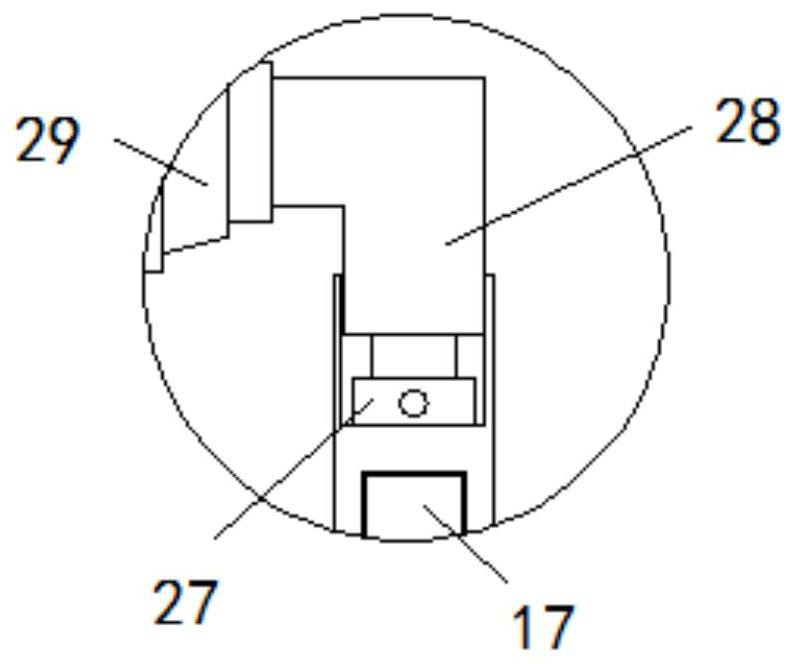

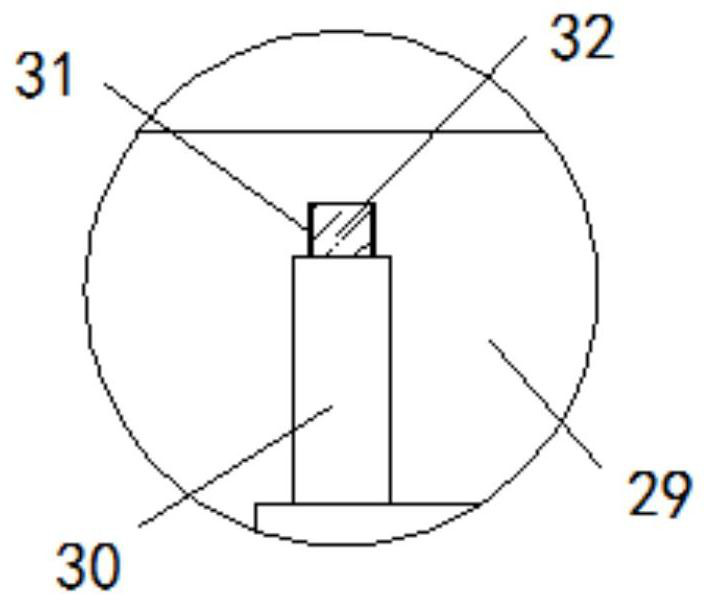

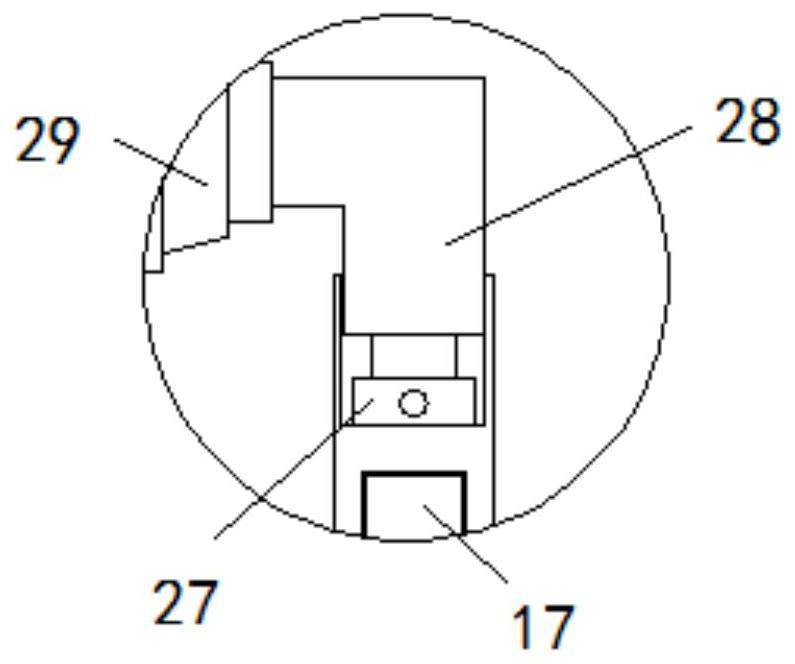

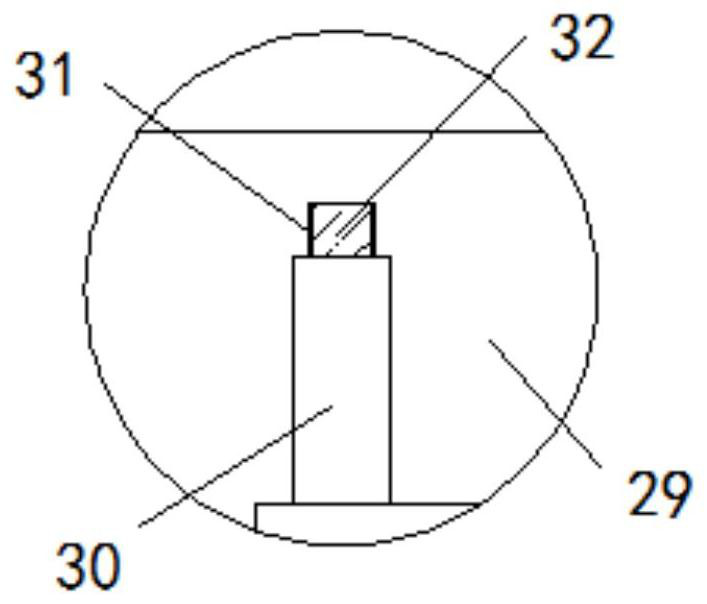

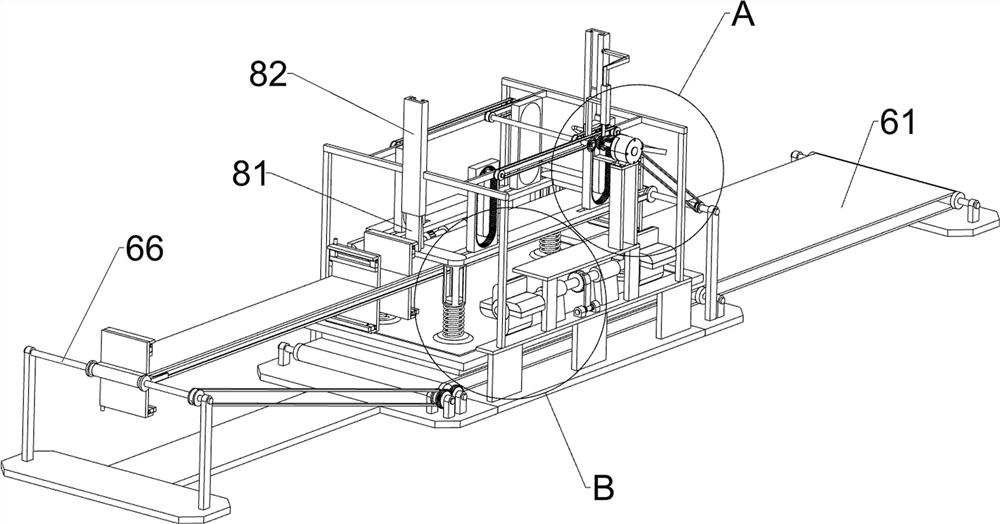

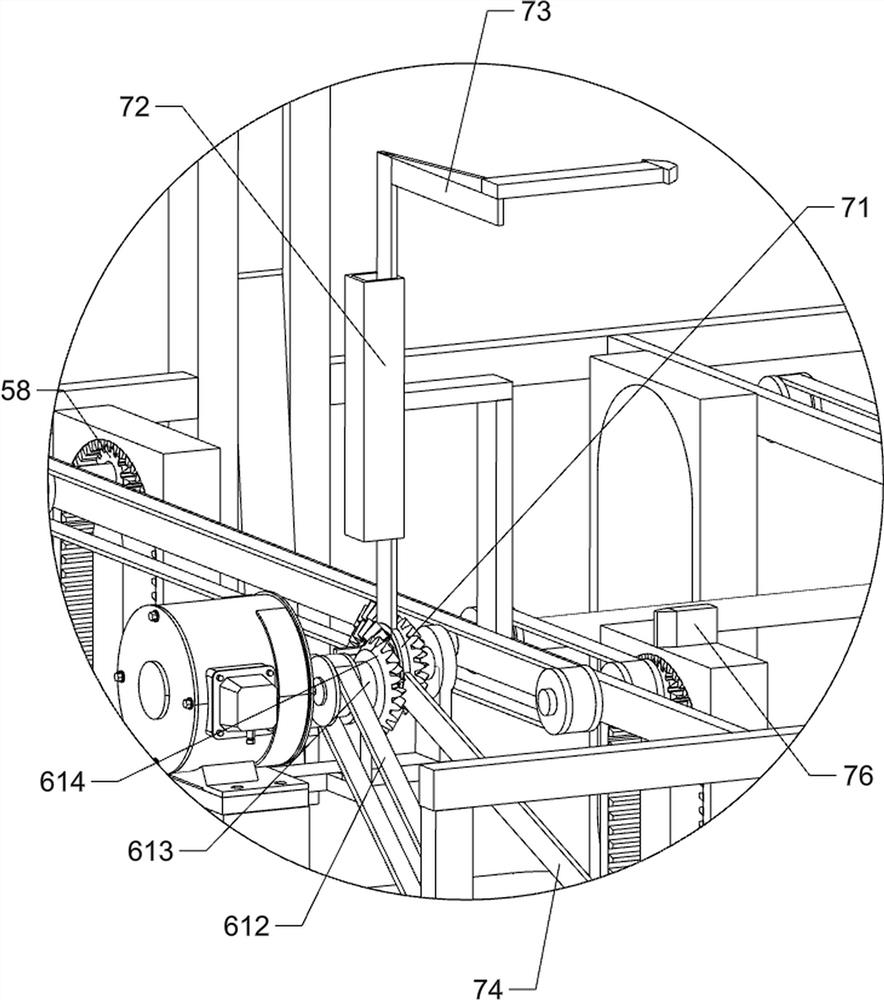

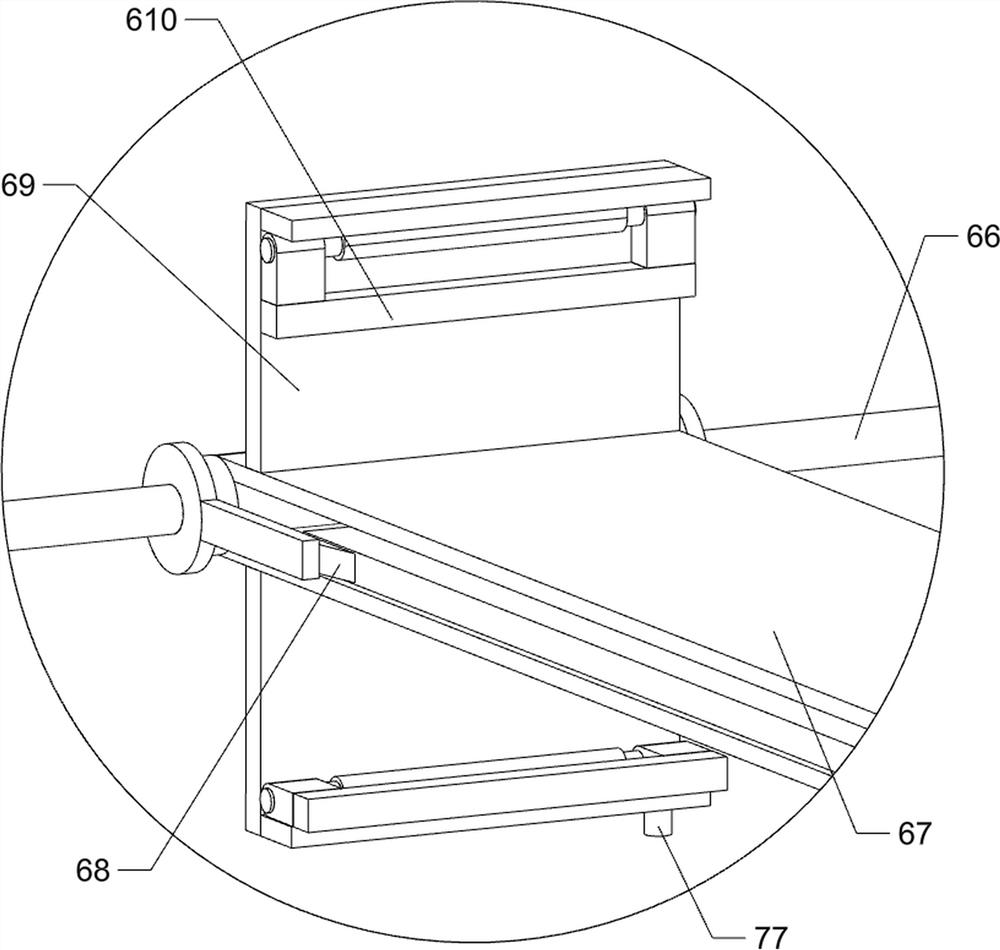

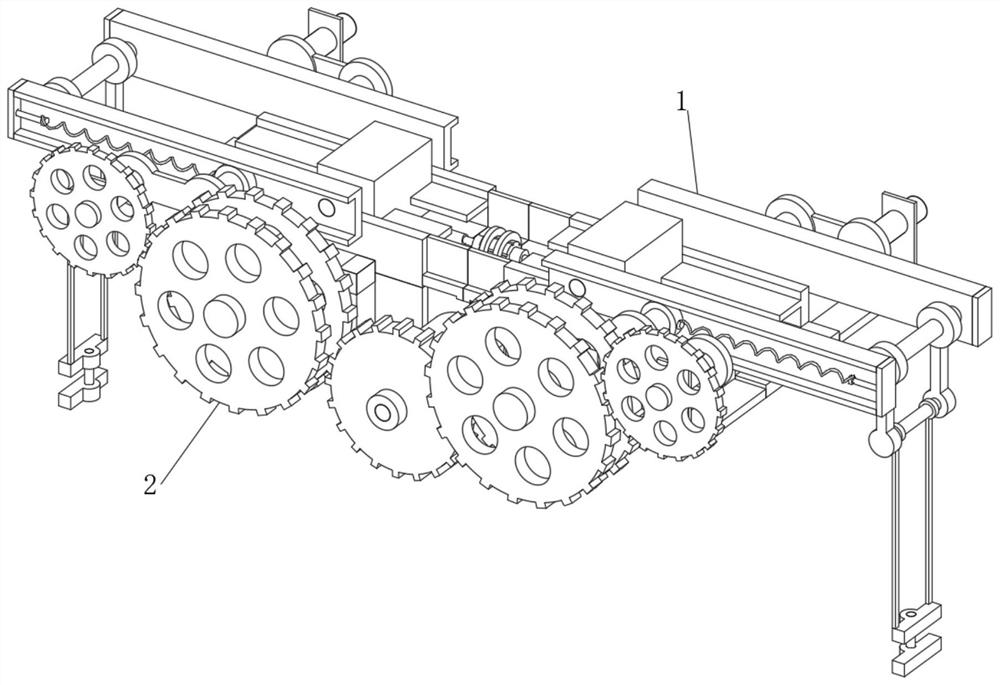

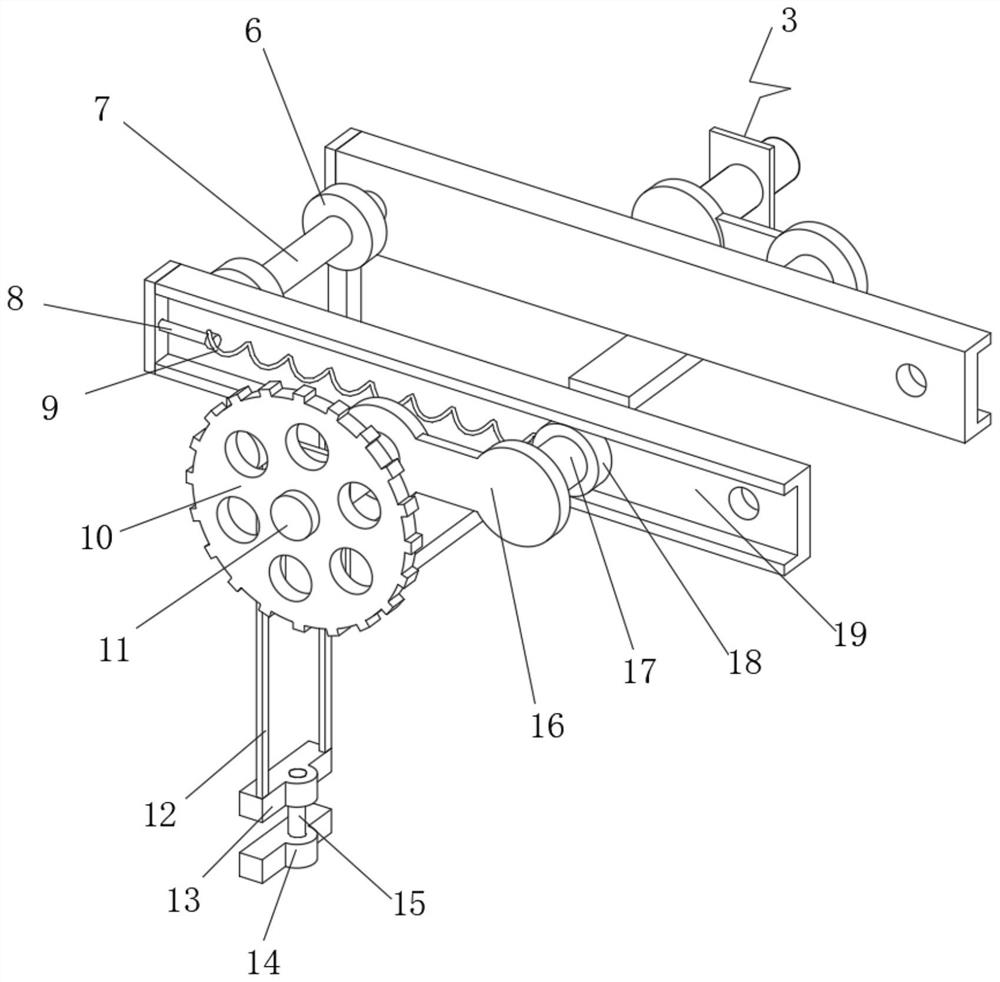

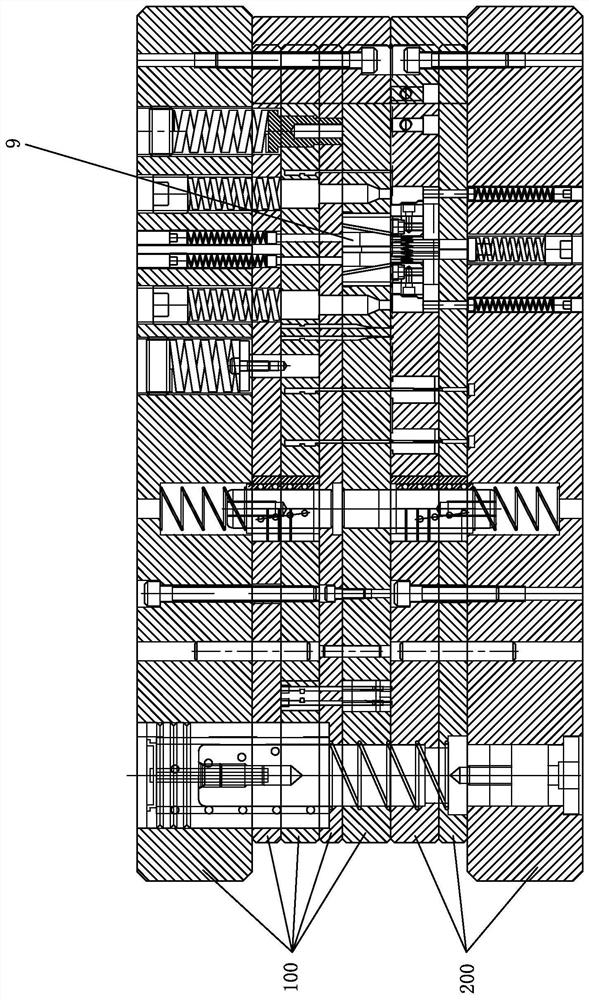

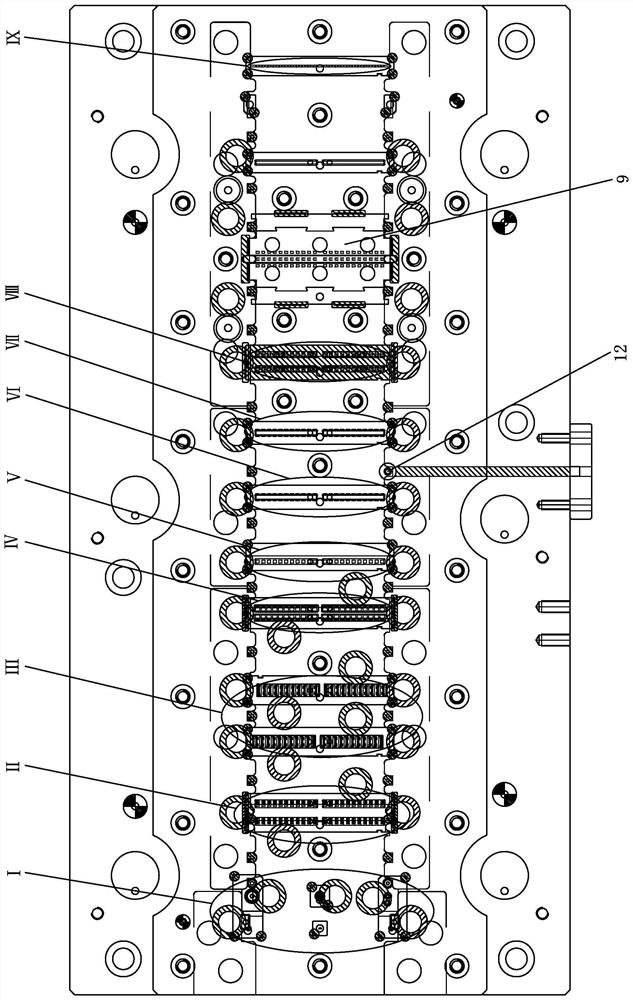

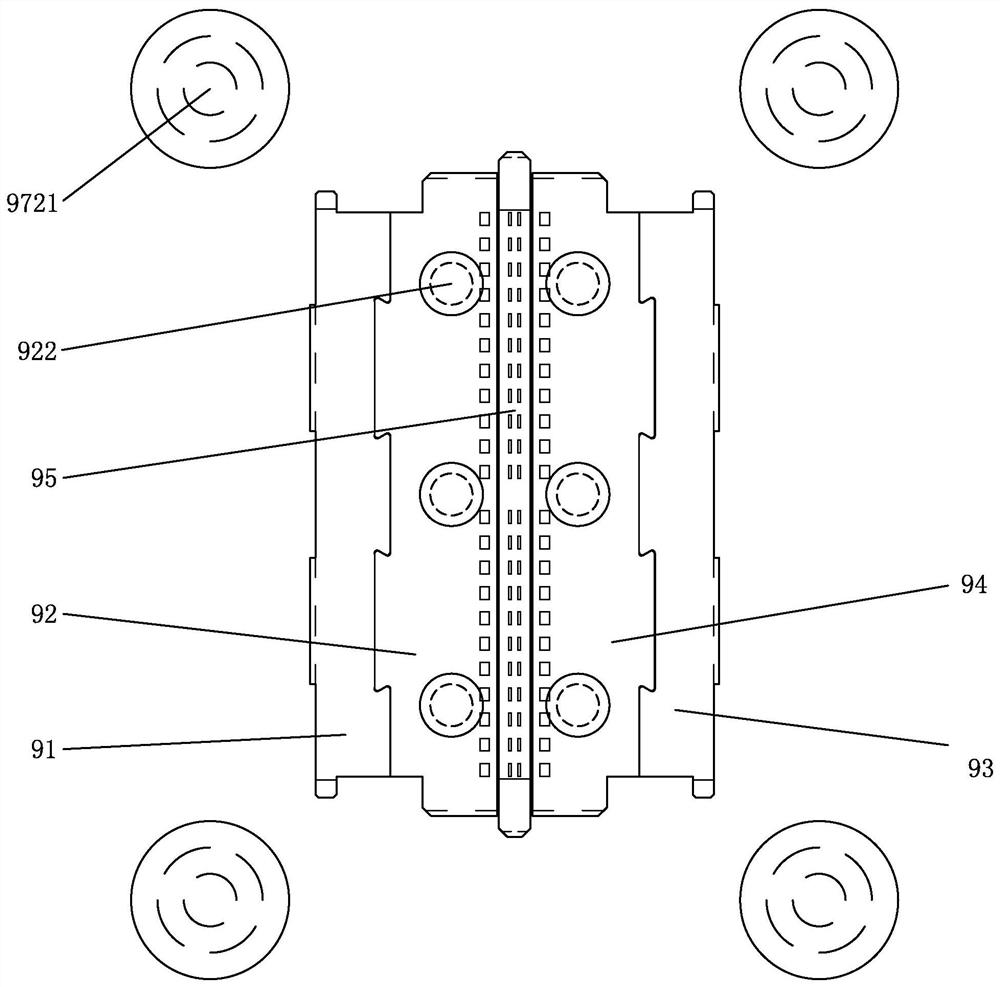

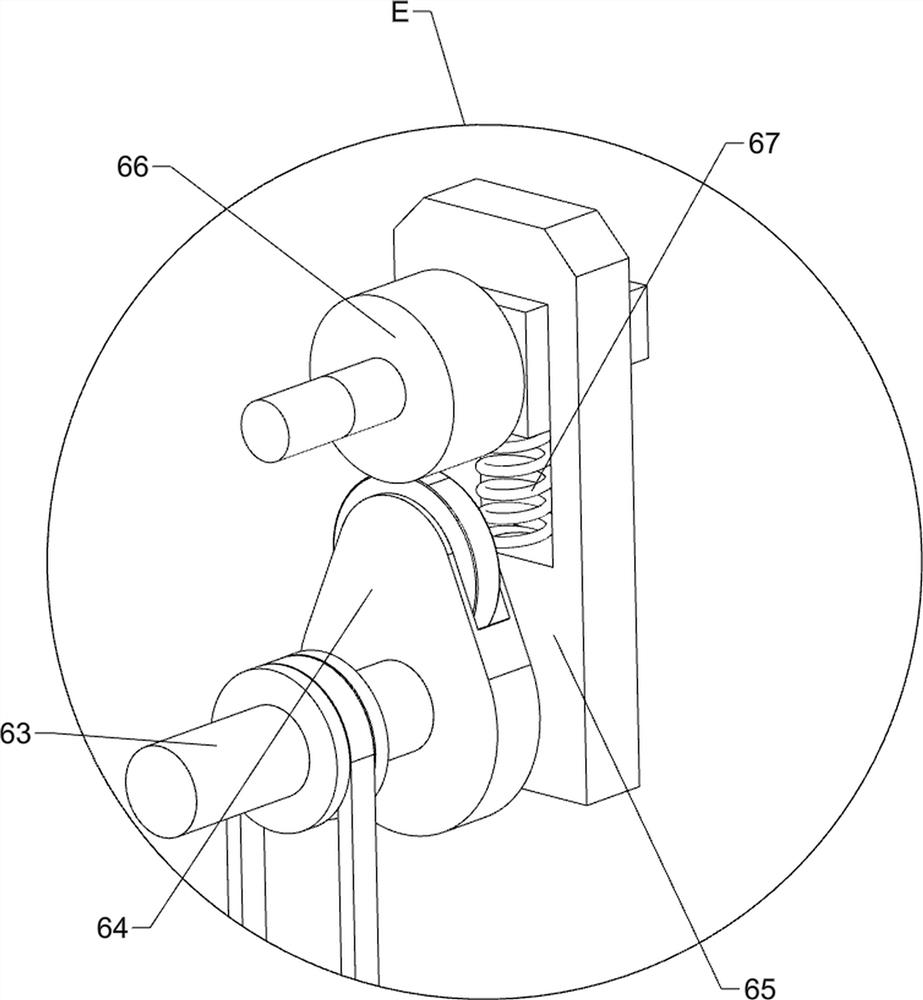

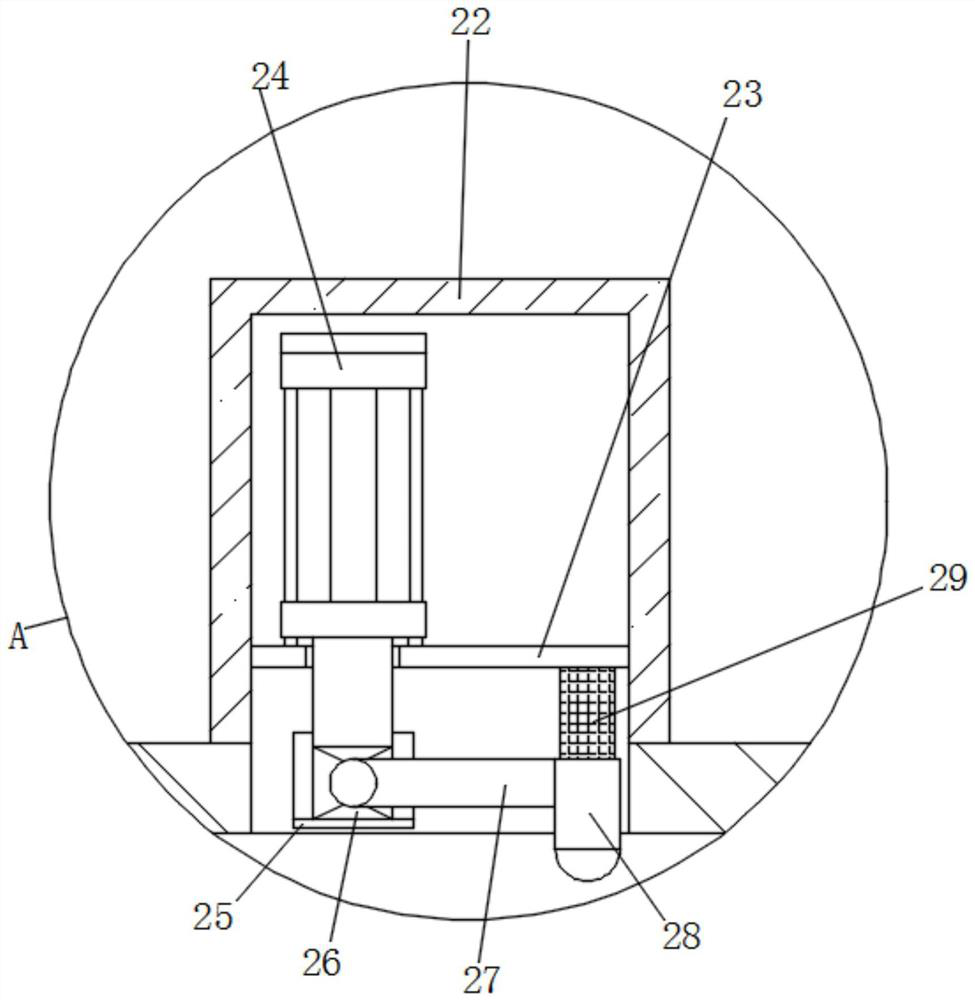

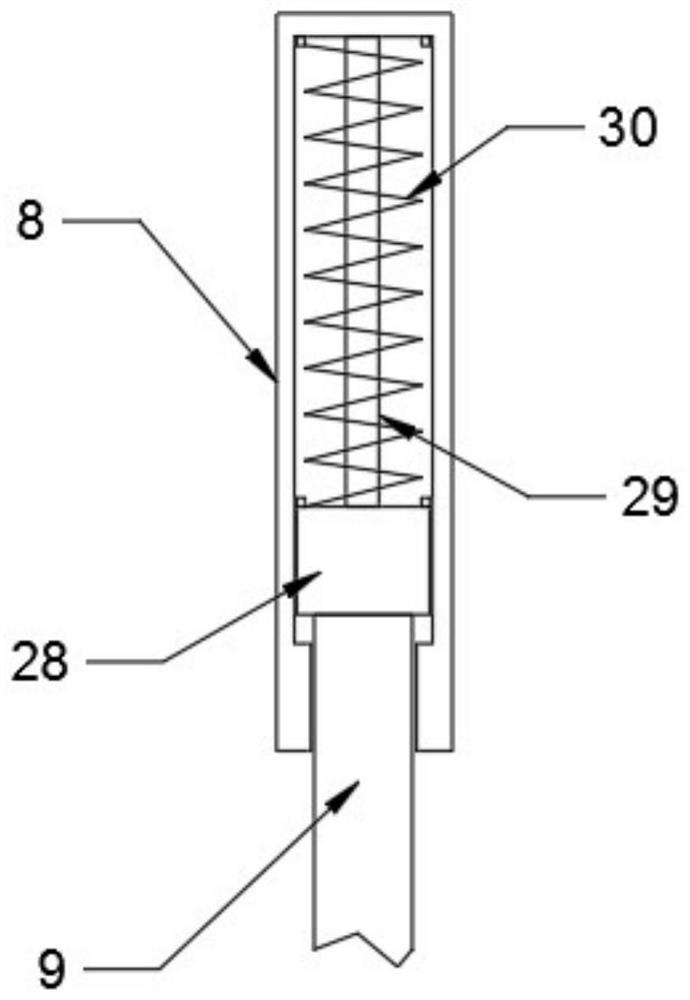

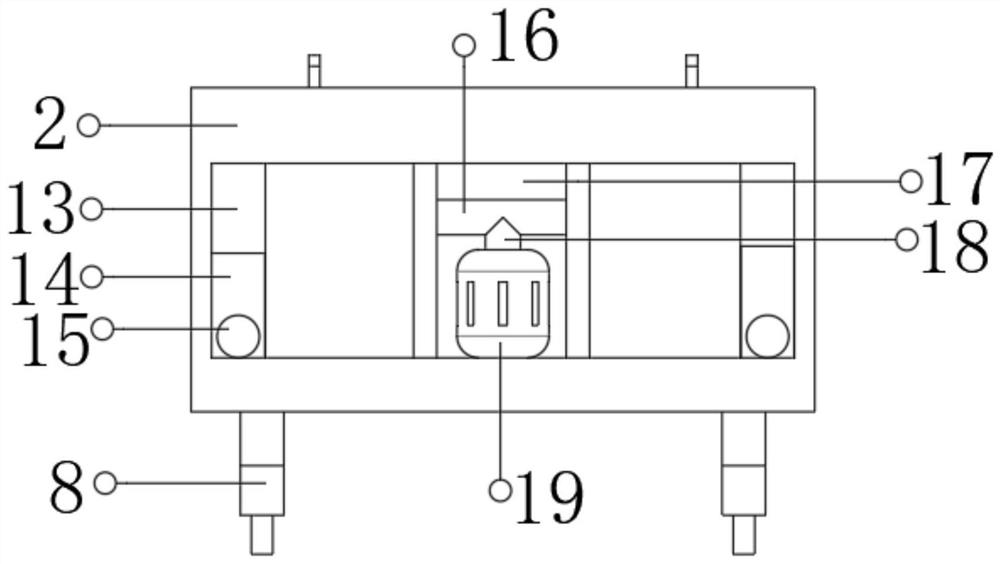

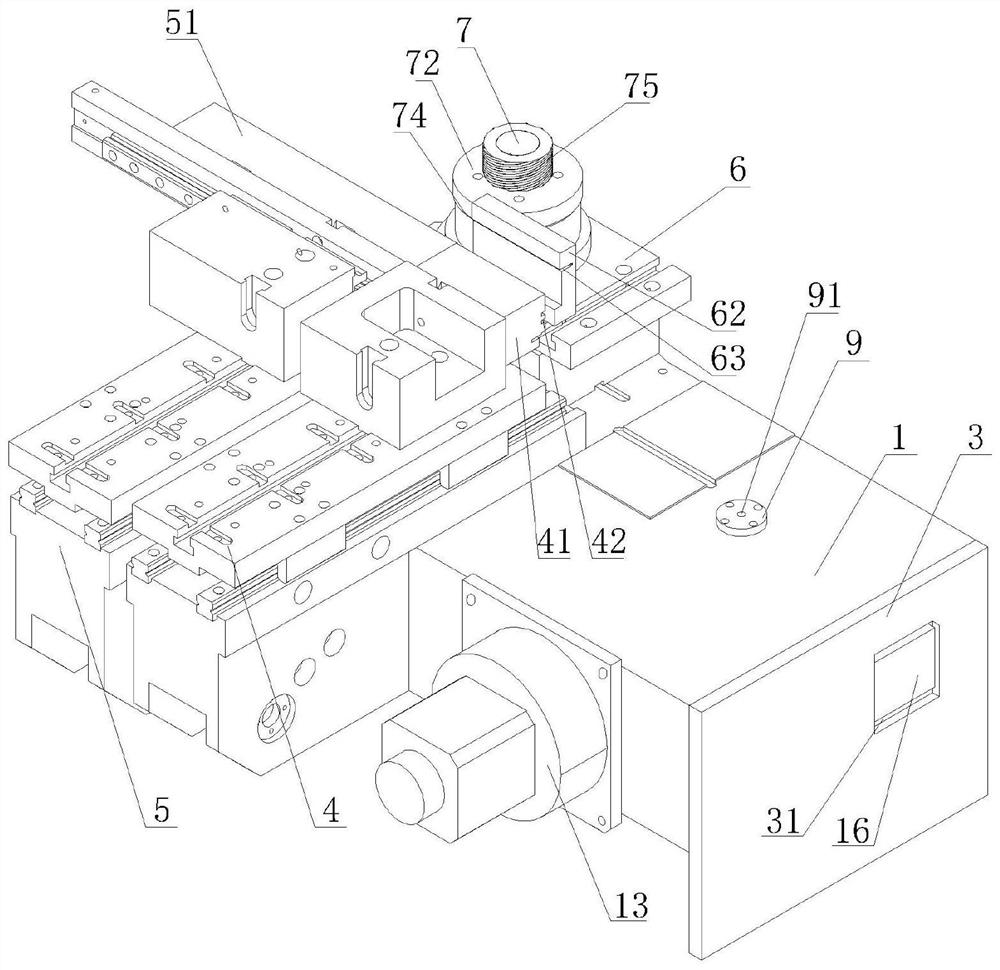

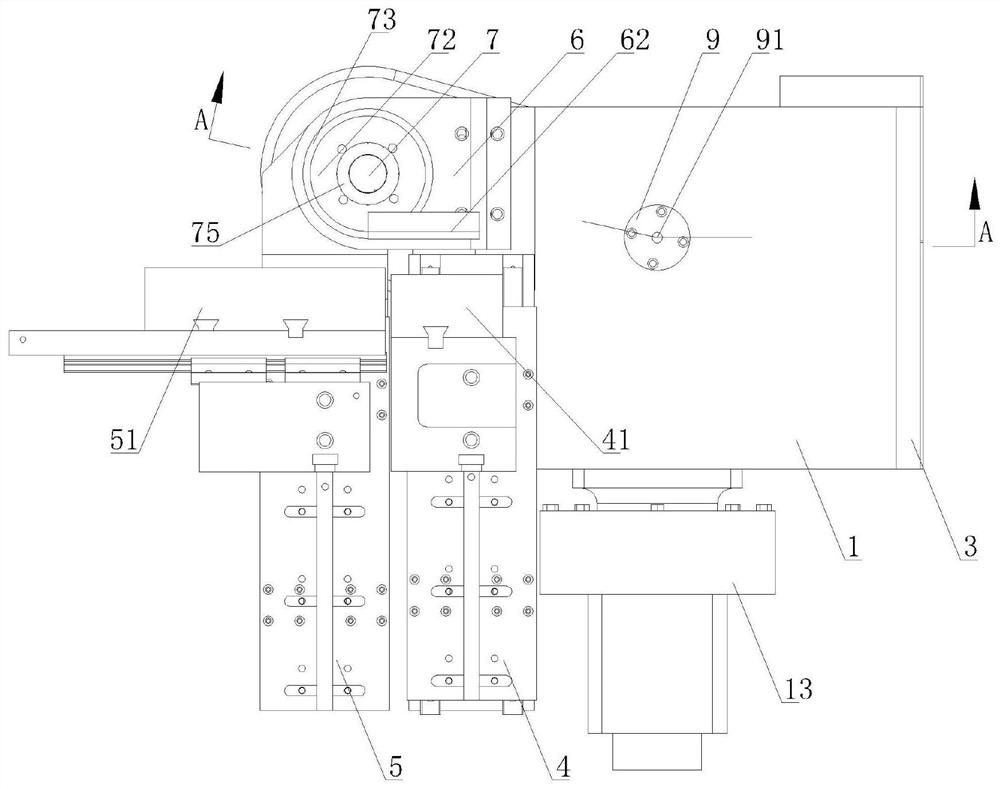

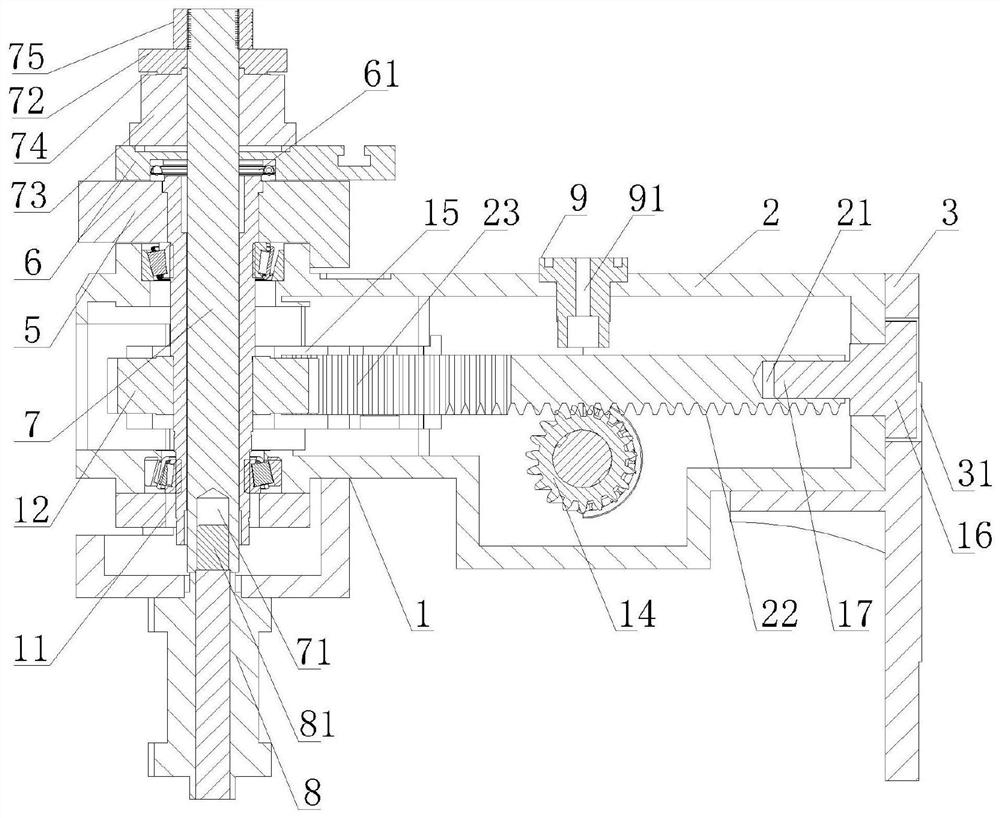

Gear demolding mechanism

InactiveCN114192688AFacilitate automatic regulationEasy demoulding workStripping-off devicesGear wheelsGear wheelControl theory

Owner:毛燕青

Clean injection mold forming blowing mechanism with high-pressure spraying function

ActiveCN112549470ARealize the effect of high-pressure ejectionTo achieve the effect of excisionTool bitAir pump

The invention discloses a clean injection mold forming blowing mechanism with a high-pressure spraying function. The mechanism comprises a mold body, a bearing plate is fixedly installed at the lowerend of the mold body, symmetrical fixing blocks are fixedly installed at the lower end of the bearing plate, and symmetrical first supporting blocks are fixedly installed at the left edge and the right edge of the lower end of the bearing plate. A bottom plate is fixedly installed at the lower ends of the first supporting blocks, and symmetrical first air cylinders are fixedly installed at the upper end of the bottom plate. According to the clean injection mold forming blowing mechanism with the high-pressure spraying function, by arranging multiple air conveying pipes, the effect of high-pressure spraying of a plastic mold through the air pressure of an air pump is achieved, by arranging a water gap groove and a tool bit, the effect of firstly cutting off a water gap of the plastic mold through a third air cylinder is achieved, one-time forming of the plastic mold is facilitated, the effect of automatically cutting the water gap in the spraying process of the plastic mold is achieved,and use is convenient.

Owner:惠州市兴利嘉科技有限公司

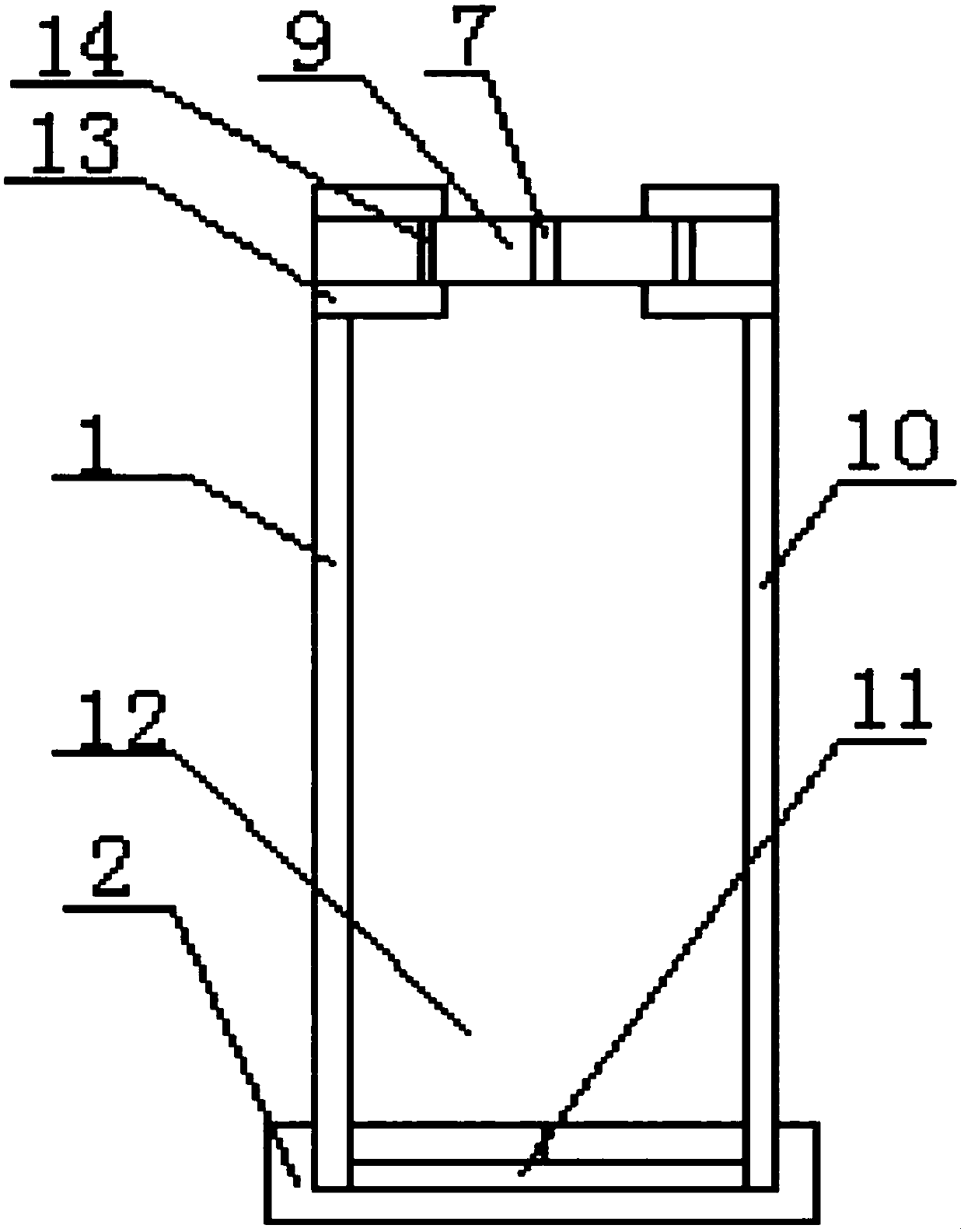

Neodymium iron boron pressed blank isostatic pressing die body

The invention discloses a neodymium iron boron pressed blank isostatic pressing die body, and relates to the technical field of neodymium iron boron processing. The neodymium iron boron pressed blank isostatic pressing die body comprises a rectangular fixing base, a die body structure, a containing groove, a work cavity, heat transfer mechanisms and a boiling mechanism. The inner wall of the rectangular fixing base is movably connected with the die body structure. The die body structure comprises a bottom plate and a die main body. The die main body is arranged on the top of the bottom plate. The containing groove is formed in the top of the die main body. The work cavity is formed in the bottom of the die main body. The heat transfer mechanisms are separately arranged at the left end and the right end of the top of the inner wall of the work cavity. According to the neodymium iron boron pressed blank isostatic pressing die body, a neodymium iron boron pressed blank is rapidly heated, the heat transferred by the heat transfer mechanisms can make an acetone solution arranged in the boiling mechanism boiled, generated airflow enables an extrusion rod to extrude a storage bag, cooling liquid in the storage bag cools the neodymium iron boron pressed blank, the pressed blank forming effect is improved, a balance block can impact the bottom of the containing groove, the neodymium iron boron pressed blank can be conveniently taken out, and outer package of the pressed blank and interior of the containing groove can be prevented from being bonded.

Owner:GANZHOU FORTUNE ELECTRONICS

Inverted cone led bracket step-by-step side push molding method

The application discloses a step-by-step side-pushing forming method for an inverted-cone LED bracket. The method comprises the following steps that S1, punching forming is conducted on a side-pushingLED bracket so that the left side of a positive-cone LED bracket is provided with a first slope tilting leftwards and the right side of the positive-cone LED bracket is provided with a second slope tilting rightwards; S2, punching cutting is conducted on the bottom of the positive-cone LED bracket so that a punched water pit is formed; S3, push-pressing forming is conducted on the first slope tilting leftwards on the left side of the positive-cone LED bracket to be the first slope tilting rightwards; and S4, push-pressing forming is conducted on the second slope tilting leftwards on the rightside of the positive-cone LED bracket to be the second slope tilting leftwards, so that the positive-cone bracket is formed to be the inverted-cone LED bracket. By means of the step-by-step side-pushing forming method, the inverted-cone LED bracket with smaller specifications and higher moisture resistance and high anti-aging light decay and other high-quality requirements can be processed and formed, so that the step-by-step side-pushing forming method can meet production of smaller-pitch outdoor full-color lamp beads so as to further improve the resolution ratio of an LED display, and the display technology of the outdoor LED display goes up a storey still higher accordingly.

Owner:ZHONGSHAN MULINSEN ELECTRONICS CO LTD +1

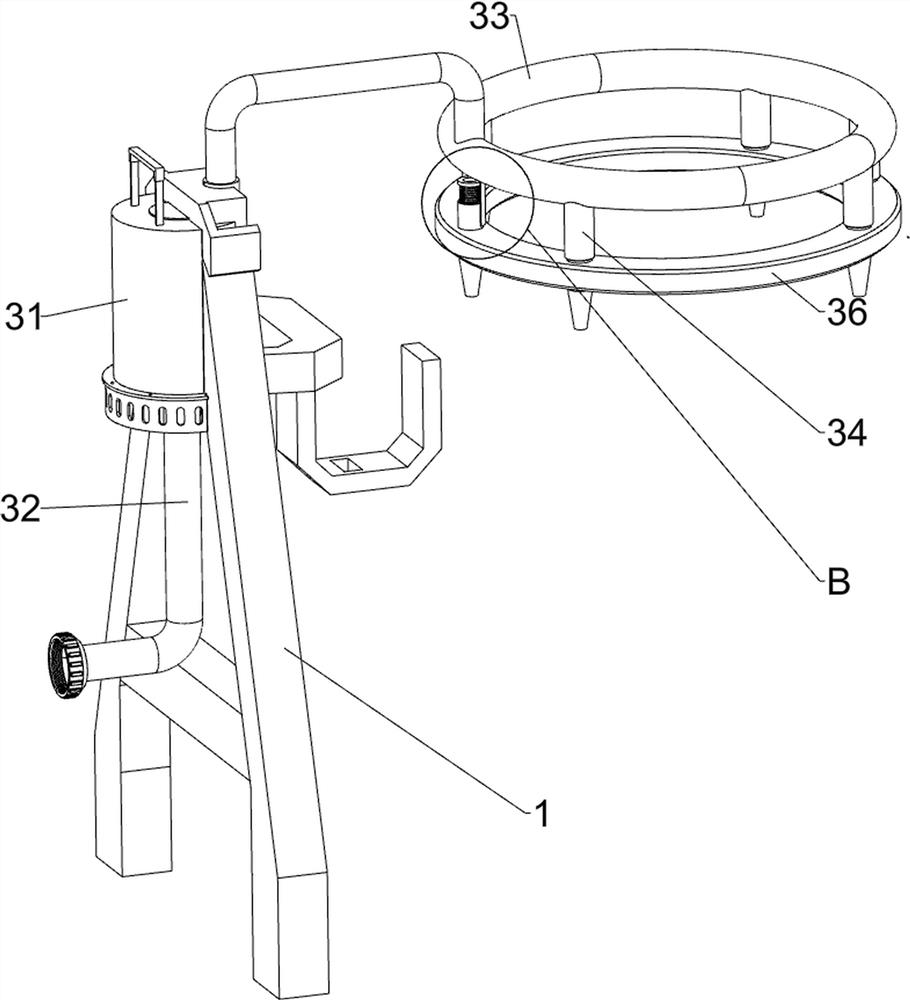

Water injection auxiliary demolding device for plastic product processing and forming

The invention relates to a demolding device, in particular to a water injection auxiliary demolding device for plastic product processing and forming. The technical problem to be solved is how to provide the water injection auxiliary demolding device for plastic product processing and molding, which can automatically spray water between a mold and a plastic part. The water injection auxiliary demolding device for plastic product processing and forming comprises a mounting frame, a water injection device, water injection pipes and a conveying device, wherein the water injection device is mounted on one side of the upper portion of the mounting frame, the multiple water injection pipes are slidably mounted on the water injection device at intervals, and the conveying device is mounted at the lower part of the mounting frame. According to the water injection auxiliary demolding device for plastic product processing and forming, with a driving motor serving as driving force, a conveying belt can be driven to rotate intermittently, so that the intermittent feeding function of the mold is completed; and then, an external water source is sprayed between the mold and the product through a water suction pump, so that the demolding work is completed.

Owner:惠州市大路科技有限公司

Heat press machine with demoulding function

InactiveCN106827120BEven by forceConvenient pressing workPlywood pressesVeneer pressesElectric machineryEngineering

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

Model test device and method for operating highway tunnel lining disease evolution rule

PendingCN114199686AEasy to processEasy demoulding workPreparing sample for investigationMaterial strength using tensile/compressive forcesStrain gaugePressure sensor

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Double-color plastic part injection molding device and injection molding technology

PendingCN112536972AGuaranteed Plastic IntegrityLabor savingNon-electrical signal transmission systemsAlarmsProcess engineeringWorkbench

The invention discloses a double-color plastic part injection molding device and injection molding technology. The double-color plastic part injection molding device comprises a bottom table, whereinan injection molding workbench is fixedly connected with the upper surface of the bottom table, a stirring table is fixedly connected with the portion, close to the right side of the injection moldingworkbench, of the top of the injection molding workbench, a concave opening is formed in the portion, close to the right side of the stirring table, of the bottom of the stirring table, a driver is fixedly installed at the bottom of an inner wall of the concave opening through a support, a flow-guiding rod is fixedly connected with an output end of the driver, a transportation pipe is fixedly connected with the interior of the stirring table, the end, away from the driver, of the flow-guiding rod penetrates the transportation pipe, and a feeding pipe is fixedly connected with the portion, close to the right side of the stirring table, of the top of the stirring table. According to the double-color plastic part injection molding device and injection molding technology, through cooperationof the structures and the like, plastification work conducted on double-color plastic parts can be automatically completed by controlling a controller, a worker can conveniently conduct recovery workon a mould after plastification is conducted, the safety is high, the production efficiency is effectively improved, and convenience is brought to the worker.

Owner:苏州开元模具有限公司

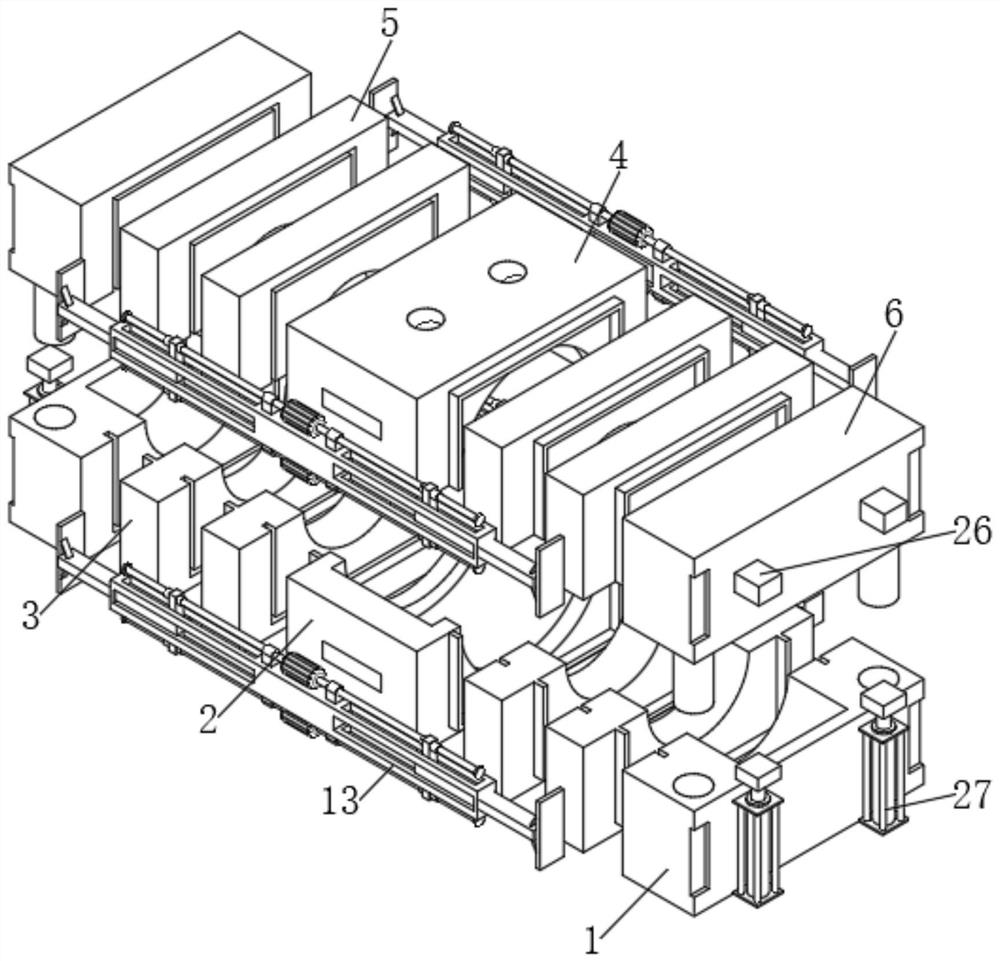

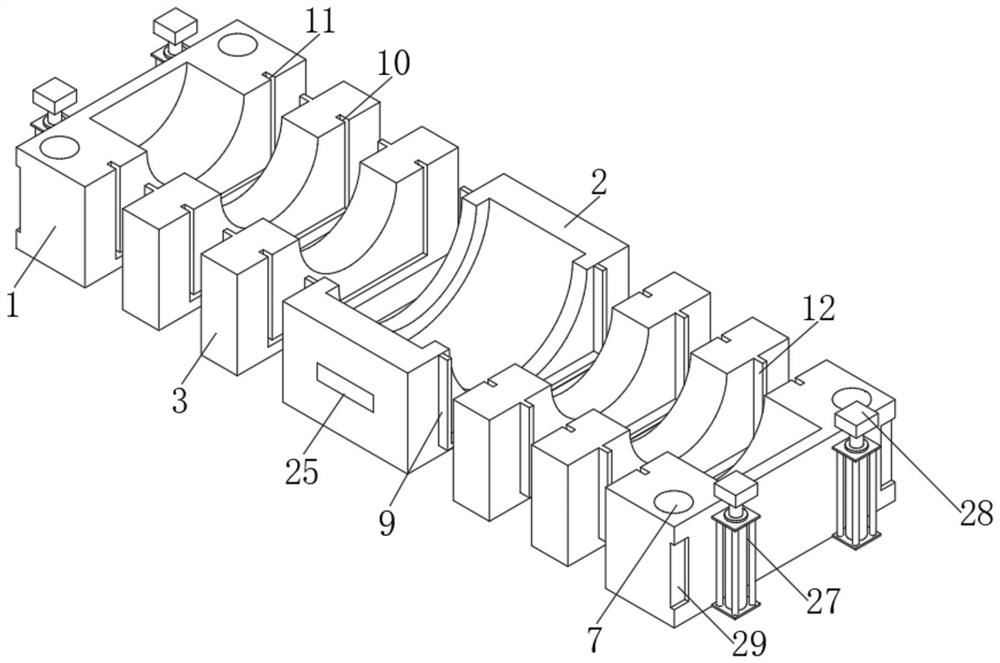

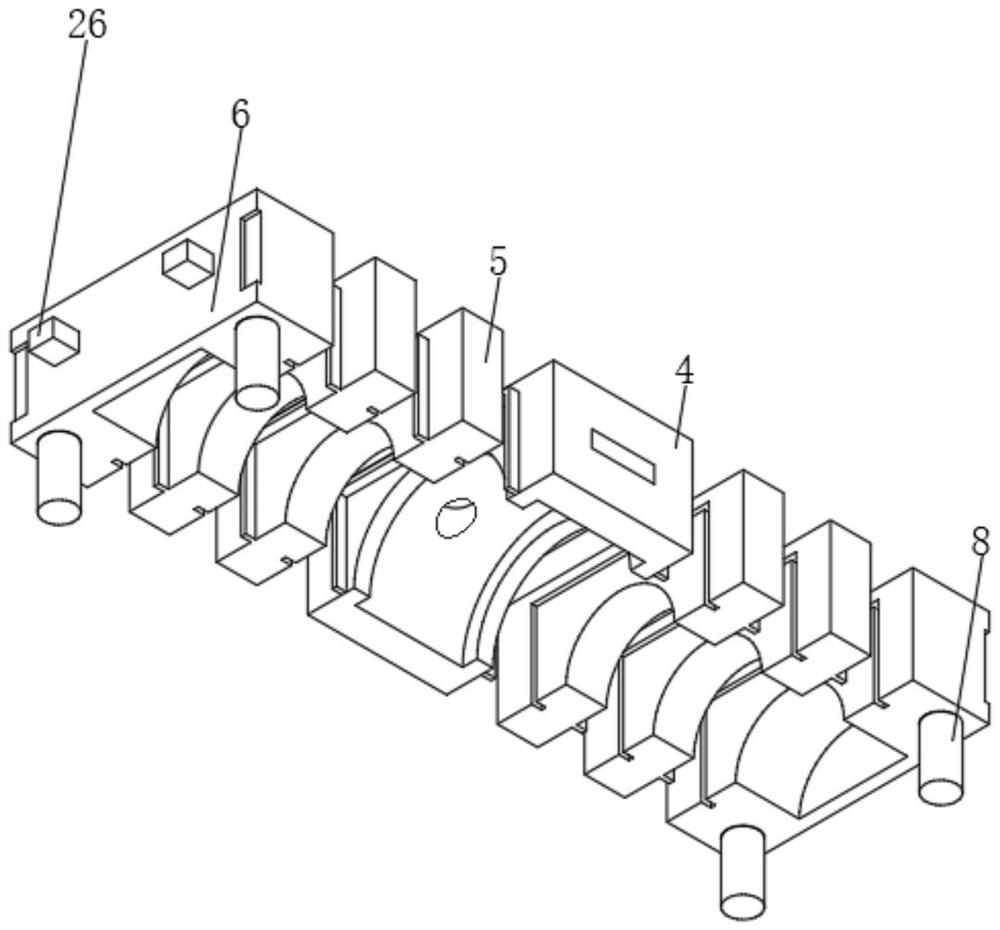

Hardware bathroom part forming mold and using method thereof

PendingCN114101598AImprove stabilityImprove efficiencyFoundry mouldsFoundry coresButt jointEngineering

The invention belongs to the technical field of molds, and particularly relates to a hardware bathroom part forming mold which comprises a lower end mold shell, a lower middle end mold shell, a lower shaft rod mold shell, an upper middle end mold shell, an upper shaft rod mold shell and an upper end mold shell. A butt joint inserting rod is fixedly connected to the lower end surface of the upper end mold shell, first sealing inserting pieces are fixedly connected to the surfaces of the two sides of the lower middle end mold shell and the surfaces of the two sides of the upper middle end mold shell correspondingly, and first sealing inserting grooves are formed in the surface of one side of the lower shaft rod part mold shell and the surface of one side of the upper shaft rod part mold shell correspondingly. Second sealing insertion grooves are formed in the surfaces of one sides of the lower end mold shell and the upper end mold shell correspondingly. By arranging the fastening mechanism, the whole mold can have better stability after being spliced, and after the whole mold has the detachable property, the later demolding work is more convenient, so that the use efficiency of the whole mold is improved.

Owner:江门市艾米卫浴科技有限公司

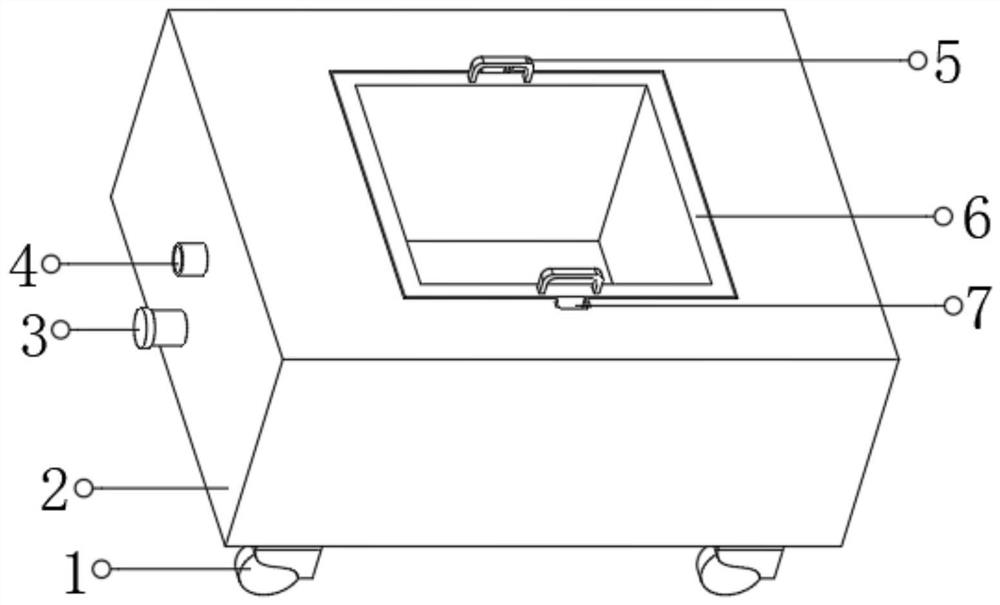

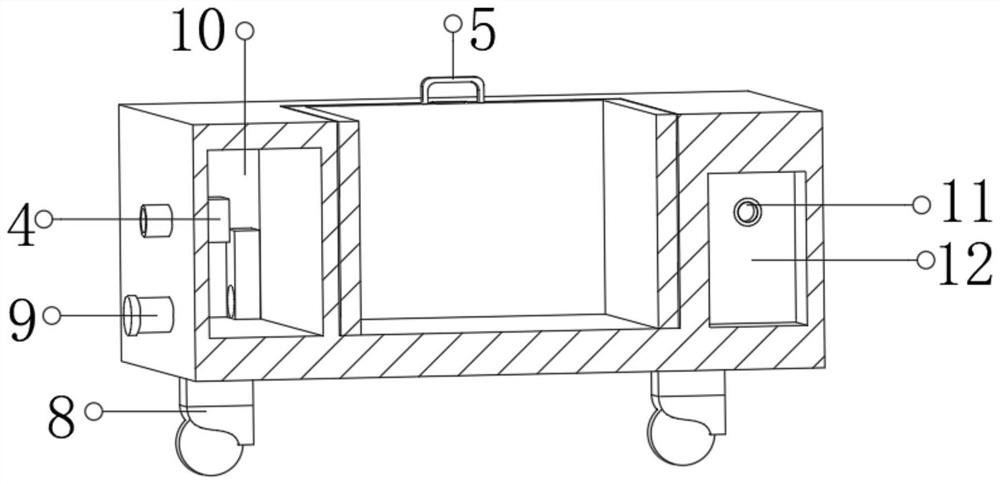

Injection molding machine convenient to demold and capable of preventing adhesion

The invention belongs to the technical field of injection molding machines, and particularly relates to an injection molding machine convenient to demold and capable of preventing adhesion. The following scheme is provided aiming at the problems that an existing injection molding machine cannot be quickly demolded after injection molding work is completed, and meanwhile, the injection molding machine and an injection molding product are prone to being damaged to different degrees during demolding. The injection molding machine comprises a table body, a base, a box door and a control panel, wherein the top of the table body is fixedly connected with a top plate, the top of the top plate is fixedly connected with a baffle, the top of the baffle is fixedly connected with a motor, one end of an output shaft of the motor is fixedly connected with a first threaded screw rod, the circumferential outer wall of the first threaded screw rod is sleeved with a first threaded sleeve, and the two sides of the first threaded sleeve are fixedly connected with fixing frames. According to the injection molding machine, an ejection assembly is arranged, so that the demolding work of people is facilitated, and meanwhile, the situation that the injection molding product is adhered to the inner wall of an injection molding groove due to the fact that the demolding work is not successfully carried out for a long time is avoided.

Owner:杜小虎

Injection mold facilitating stable demolding

The invention discloses an injection mold facilitating stable demolding. The injection mold comprises a mold, and a processing device connected with the mold and used for shaping and demolding an injection molding part on the inner side of the mold. The processing device comprises a supporting device connected with one side of the mold and used for supporting one side of the mold and limiting the moving track of the mold, a displacement device located on the other side of the mold and used for driving one side of the mold to move, and a cooling device located on the inner side of the mold and used for reducing the temperature of the injection molding part on the inner side of the mold, the supporting device in the processing device can support one side of the mold and limit the moving track of the mold, and the working effect of the mold can be effectively improved; the displacement device can also support the mold, so that the mold is conveniently driven to move, shaping and demolding of the injection molding part are conveniently completed, and the working efficiency is effectively improved; and the cooling device can effectively cool the inner side of the mold, and demolding work is facilitated.

Owner:深圳市恒大伟业塑胶有限公司

Injection mould with water blowing device

The invention discloses an injection mould with a water blowing device. The injection mould comprises a mould body, and a groove is formed in the outer wall of the top of the mould body. Sliding chutes are formed in the inner walls of the two ends of the groove, and the outer wall of one side of each of the two sliding chutes is glidingly connected with a mould chamber. A water storage tank is arranged in one end of the mould body, and water channels are formed in the two ends of the mould body. Water baffles are arranged between the water channels and the water storage tank, and circular holes are formed in the positions, close to the bottoms, of the outer walls of one sides of the two water baffles. Vertical plates are fixedly arranged on the outer walls of one sides of the gathering ends of the two water channels, and air inlets are formed in the surfaces of the vertical plates. An air pressure box is arranged between the two vertical plates, and a pressure pump is fixedly arrangedon the inner wall of the bottom of the air pressure box. An air guide tube is fixedly arranged on the outer wall of the top of the pressure pump, and a horizontal tube is fixedly arranged on the outerwall of the top of the air guide tube. The injection mould can make use of air pressure to treat water attached to the surfaces of the water channels, so that the water can be treated completely to avoid rust inside the water channels, and meanwhile demoulding operation is conveniently carried out through a pull ring.

Owner:YANCHENG INST OF TECH

High-precision aluminum profile bending mechanism

PendingCN112742920AExtended service lifeImprove wear resistanceMetal-working feeding devicesPositioning devicesGear wheelSlide plate

The invention discloses a high-precision aluminum profile bending mechanism which comprises a rack, a main shaft tube arranged on the rack, a first gear arranged on the main shaft tube, a servo motor arranged on the rack, a second gear connected to the servo motor and a rack plate slidably arranged in the rack, wherein a first rack meshed with the second gear is arranged at the bottom of the rack plate, and a second rack meshed with the first gear is arranged at the left end of the rack plate; a sliding plate die is arranged on the outer side of the rack; and a mounting seat is arranged on the rack, a bearing is arranged in the mounting seat, the main shaft tube is in close fit to the bearing, a rotating shaft is arranged in the main shaft tube in a penetrating manner, the lower end of the rotating shaft is connected to a lifting mechanism, a wheel die group consisting of a plurality of mutually independent wheel dies is sleeved at the upper end of the rotating shaft, and a pressing and blocking mechanism is arranged at the top of the rotating shaft. The high-precision aluminum profile bending mechanism has the advantages that the service life is prolonged, aluminum profile demolding is facilitated, and the bending precision and the bending quality of the aluminum profile are greatly improved.

Owner:张家港市和力机械制造有限公司

A kind of demoulding process of stainless steel plate

ActiveCN110328317BExtended service lifeReduce labor intensityForging/hammering/pressing machinesMetallurgySS - Stainless steel

The present invention relates to the field of hot forging equipment, specifically a stainless steel plate demoulding process, which includes the following steps: introducing the stainless steel material that needs to be hot forged into the mold body of the forming device to form the desired shape; After the stainless steel material is formed, the stainless steel sheet is ejected from the mold body by the ejector plate; during the demoulding process, the air in the air bag is blown from the air outlet hole to the bottom of the stainless steel sheet to assist demoulding; the ejected stainless steel The plate is pushed into the roller shaft for unloading; the ejection structure can also push the ejected material out of the mold body while ejecting the material, and at the same time, because the pushing structure can quickly push the material, it will not make the ejection structure Under long-term pressure, the service life of the ejection structure can be extended. Through the linkage of the ejection structure and the pushing structure, it is not only convenient for ejecting materials, but also convenient for pushing materials to realize unloading, which can greatly reduce the labor intensity of workers. .

Owner:陈光贡

A tire frame for making guardrail steel bars and a construction method for guardrails

ActiveCN105603917BGuarantee product qualityReasonable designRoadway safety arrangementsRebarMechanical engineering

The invention provides a jig frame for making guardrail rebars and a construction method of a guardrail. The jig frame for making the guardrail rebars comprises a base, two supporting stand columns and two or more cross beams; the two supporting stand columns are fixedly connected to the two ends of the base respectively, the cross beams are parallel to the base, the two ends of each cross beam are fixedly connected to the two supporting stand columns respectively, and the cross beams are arranged in the vertical direction. The jig frame for making the guardrail rebars has the advantages that the design is reasonable, the structure is simple, a benchmark can be provided for making a rebar framework, the making quality of the rebar framework is guaranteed, the defective rate is decreased, and meanwhile the production efficiency can be improved.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com