Automatic assembling and detecting equipment for metal packsack pendant

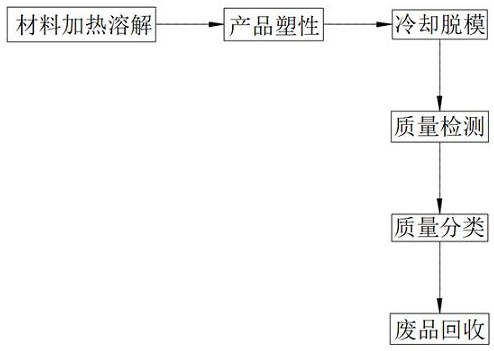

A technology of automatic assembly and testing equipment, applied in metal processing equipment, testing of mechanical parts, testing of machine/structural parts, etc. Inconvenient work and other problems, to achieve the effect of facilitating multi-directional detection, reducing waste and leak detection, and stirring and dissolving thoroughly and evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

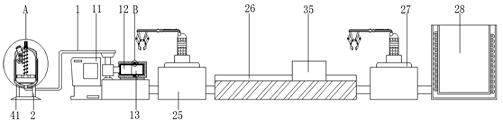

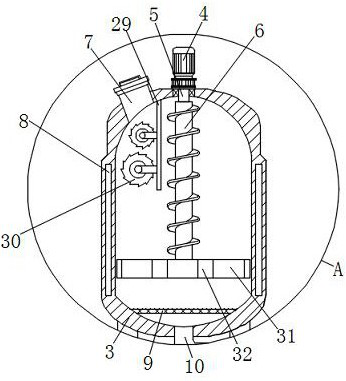

[0029] Such as Figure 1-7As shown, a kind of automatic assembly detection equipment of metal backpack pendant comprises automation device body 1, and described automation device body 1 comprises support leg 2, and the upper surface of described support leg 2 is fixedly connected with dissolving tank 3, and described dissolving tank The upper surface of 3 is fixedly equipped with a driver 4, the output end of the driver 4 is fixedly connected with a rotating rod 5, and the bottom end of the rotating rod 5 penetrates into the inside of the dissolution tank 3 and is fixedly connected with a stirring rod 6, so A feeding pipe 7 is fixedly connected to the top near the left side of the dissolving tank 3, a temperature-adjustable heating plate 8 is fixedly connected to the inner wall of the dissolving tank 3, and a side surface near the bottom of the inner wall of the dissolving tank 3 is fixedly connected There is a screen 9, the bottom of the dissolving tank 3 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com