Patents

Literature

34results about How to "Convenient sorting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

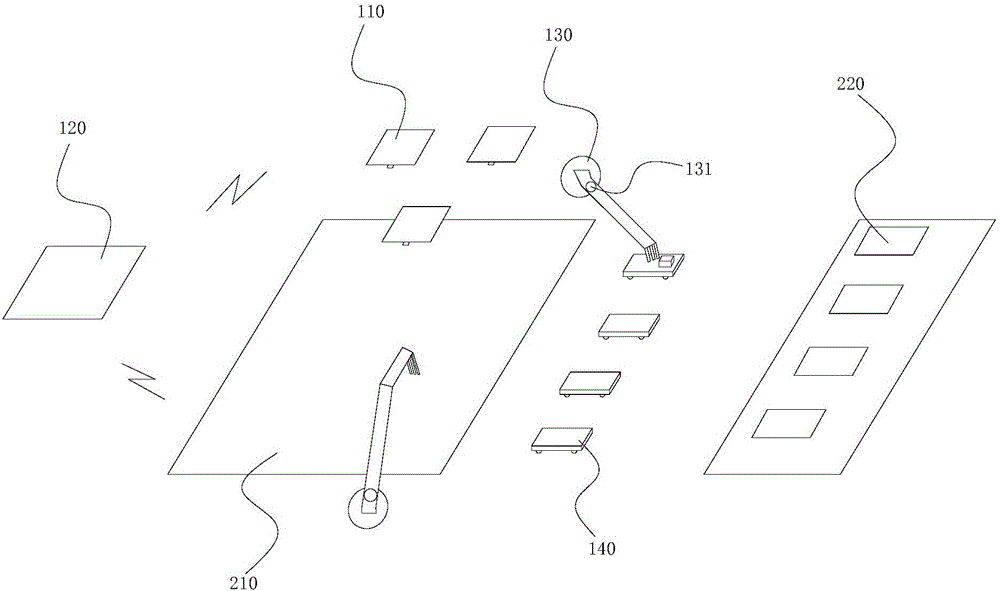

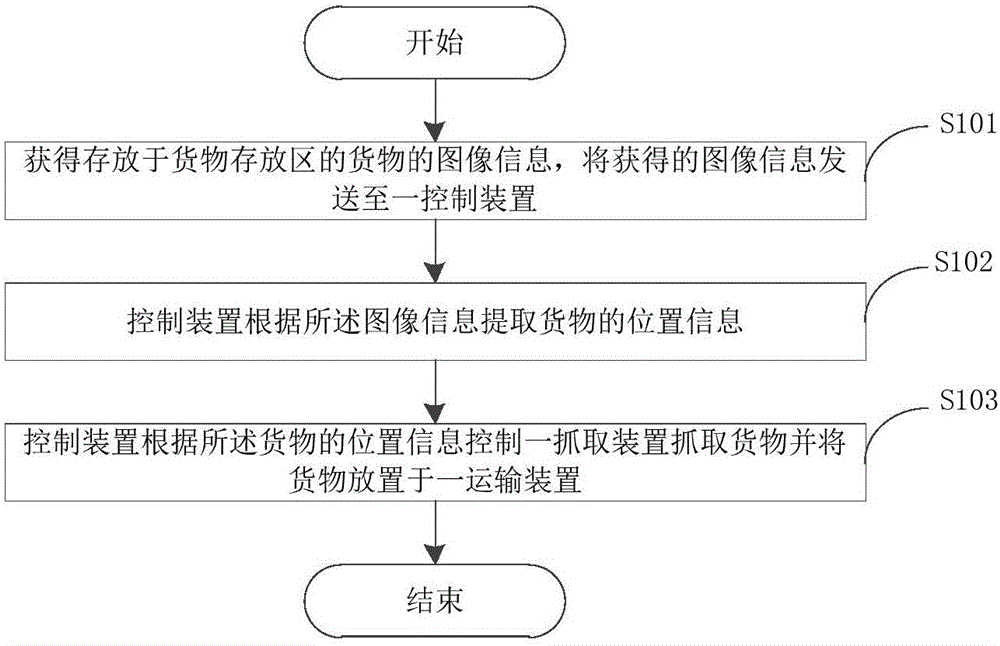

Goods sorting system and method

InactiveCN105728328AImprove efficiencyImprove accuracySortingComputer scienceInformation acquisition

The present invention provides a cargo sorting system and method. The cargo sorting system includes an information acquisition device, a control device, a grabbing device and a transport device. The image information of the goods stored in the goods storage area is acquired by the information acquisition device and sent to the control device. The control device extracts the position information of the goods according to the image information, and at the same time, the control device controls the grabbing device to grab the goods according to the position information of the goods and places the goods on the transportation device, and transports the goods to the weighing platform through the transportation device. The weighing table is used to facilitate the sorting work later. The goods sorting system provided by the embodiment of the present invention controls the grabbing device to grab the goods in the goods storage area through the control device, which replaces the manual sorting in the traditional sorting platform, and improves the efficiency and accuracy of goods sorting. The labor cost is reduced, and the operation is convenient, fast and effective.

Owner:HANGZHOU YAMEILIJIA TECH CO LTD

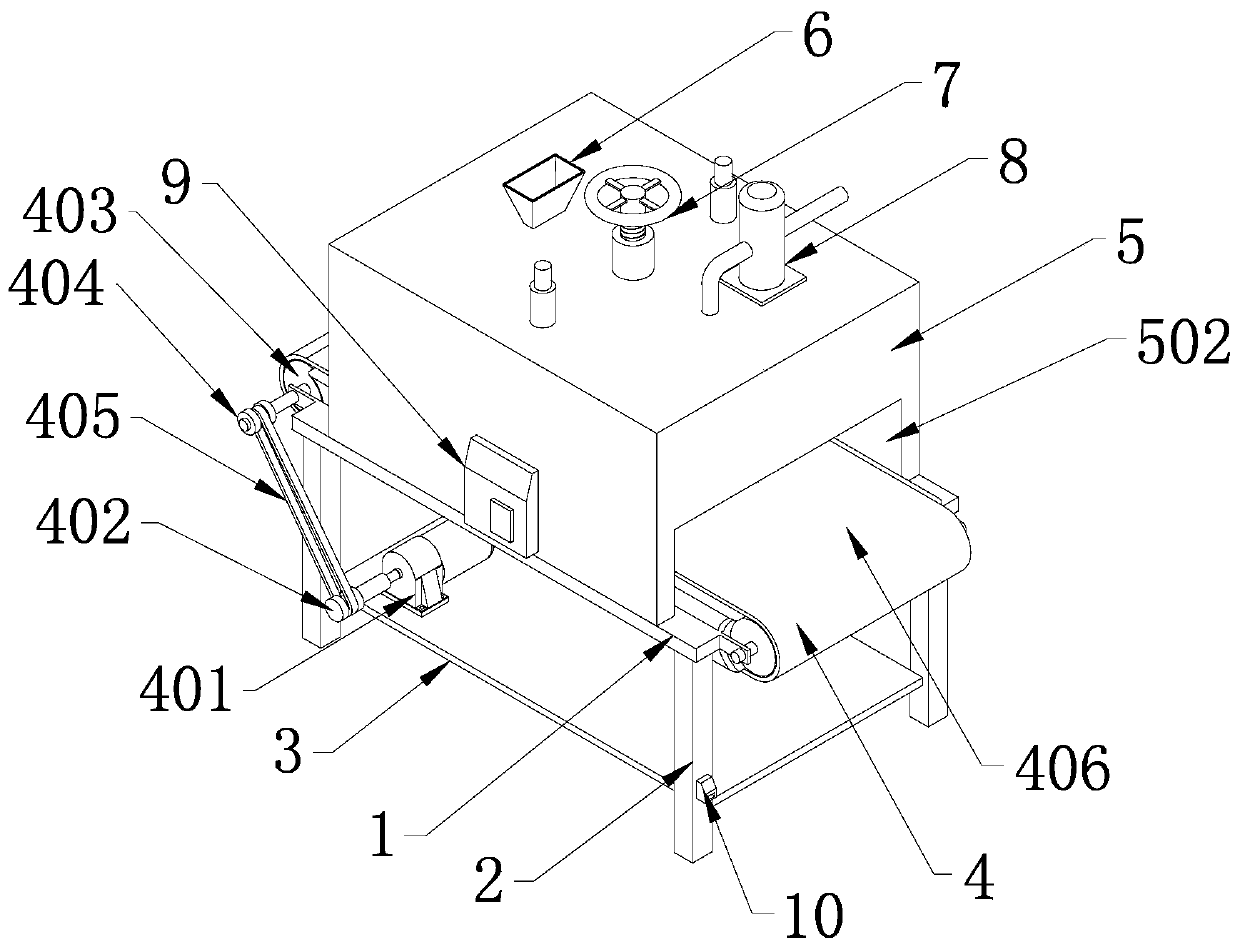

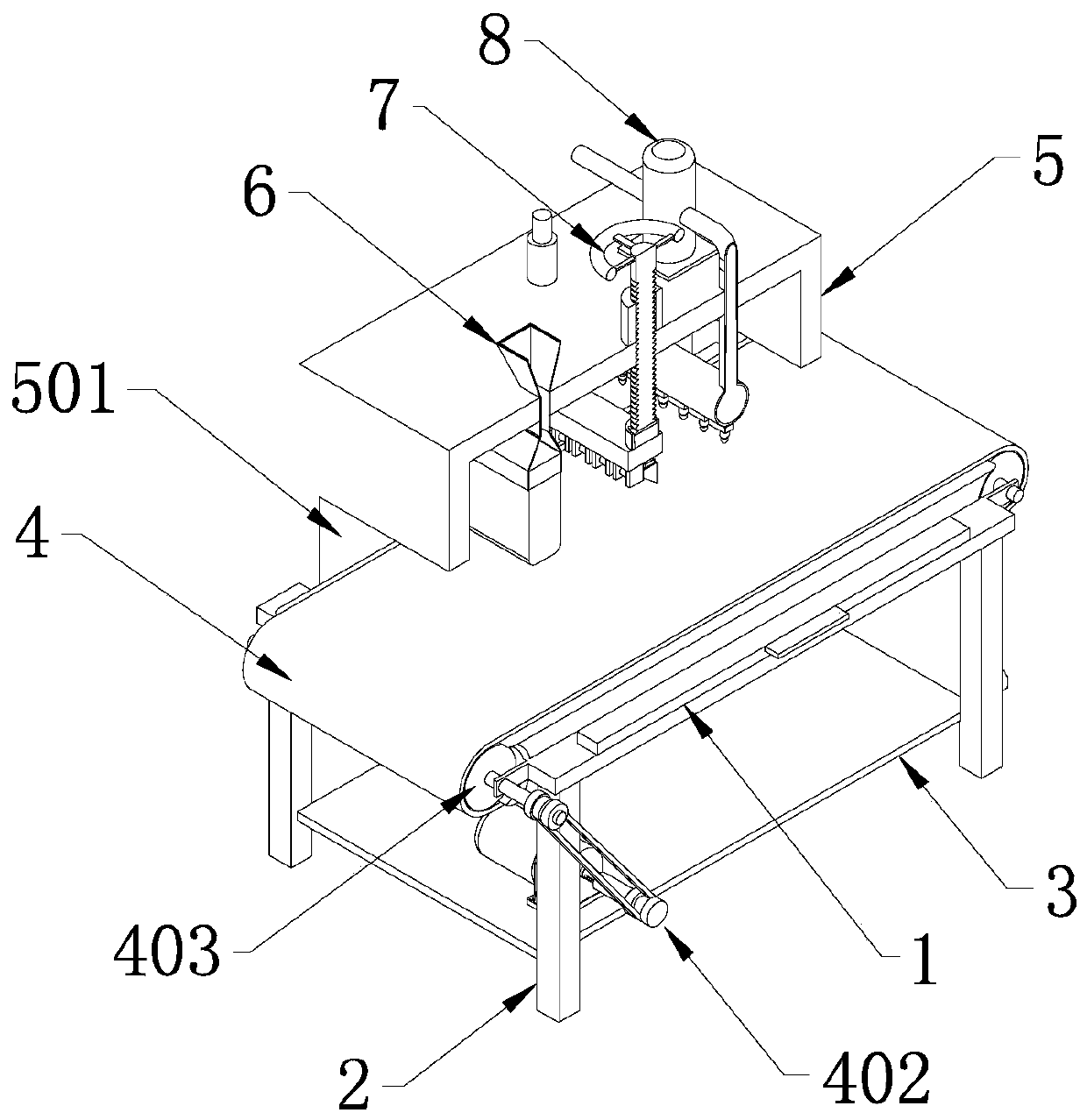

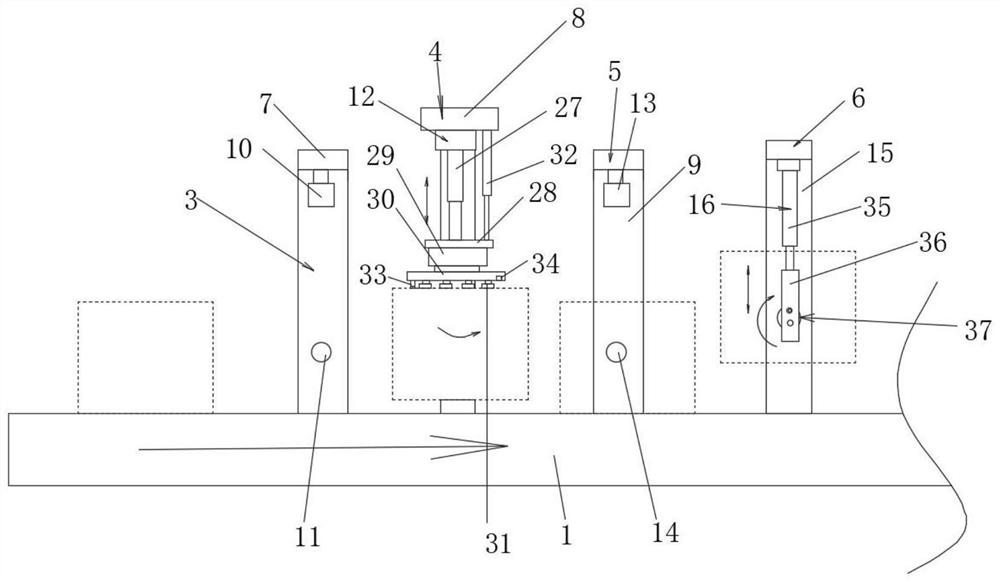

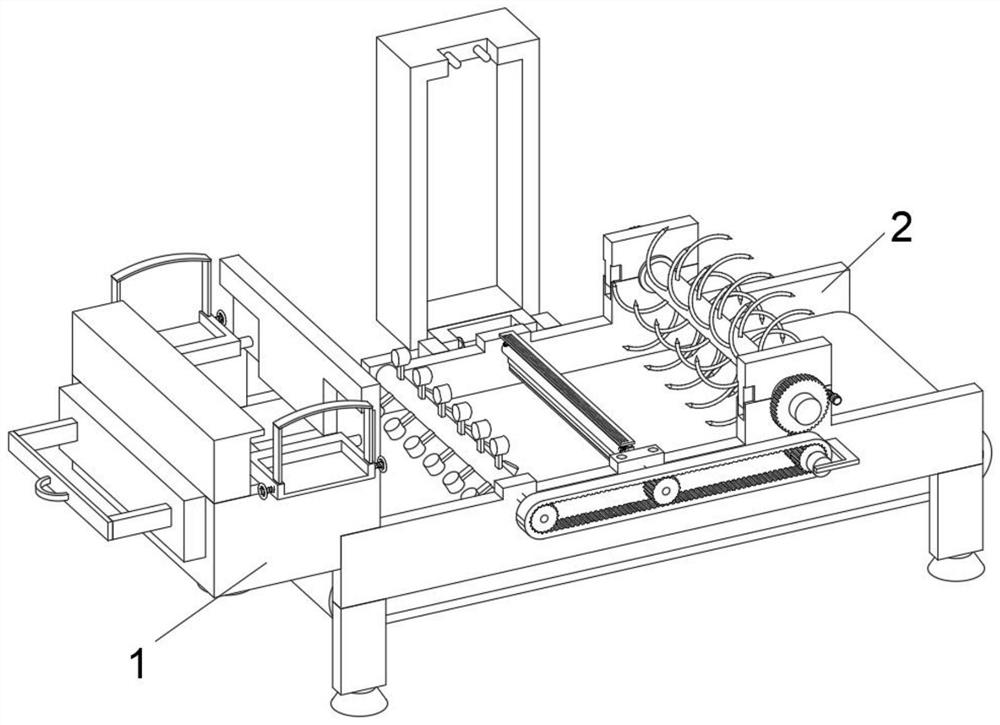

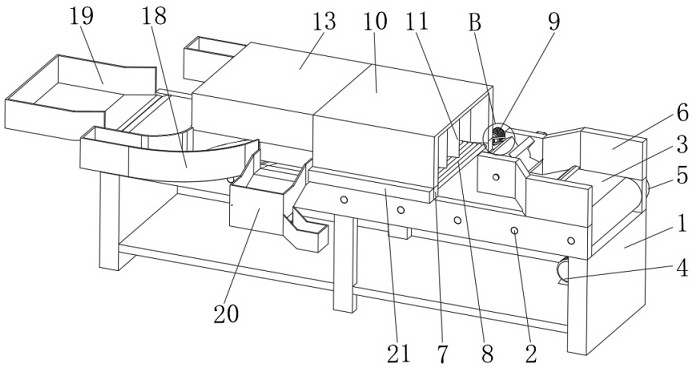

Flatness detection equipment for machine tool parts

InactiveCN110631542AImprove the efficiency of flatness inspectionConvenient sorting workLiquid surface applicatorsMeasurement devicesMachine partsEngineering

The invention discloses flatness detection equipment for machine tool parts, belongs to the technical field of mechanical part detection and aims at solving the technical problem of how to improve theflatness detection efficiency of the machine tool parts and the sorting efficiency of uneven parts. The flatness detection equipment for the machine tool parts comprises a workbench, wherein supportcolumns are fixed at the lower end of the workbench; a transverse diaphragm is fixed on the support columns; a power interface is fixed at the side part of each support column; a housing is fixed on the workbench; a feeding hole is formed in one end of the housing and a discharge hole is formed in the other end of the housing; a conveying mechanism, a lubricating mechanism, a detection mechanism and a marking mechanism are arranged in the housing; and an electric cabinet is fixed at the side part of the housing. Through the detection mechanism, a plurality of workpieces of a machine tool can be detected at the same time, so that the flatness detection efficiency of the workpieces is greatly improved; and furthermore, the workpieces with uneven surfaces can be marked by adopting the markingmechanism, so that subsequent sorting work of workers is facilitated and the sorting efficiency of the uneven workpieces is improved.

Owner:胡峥

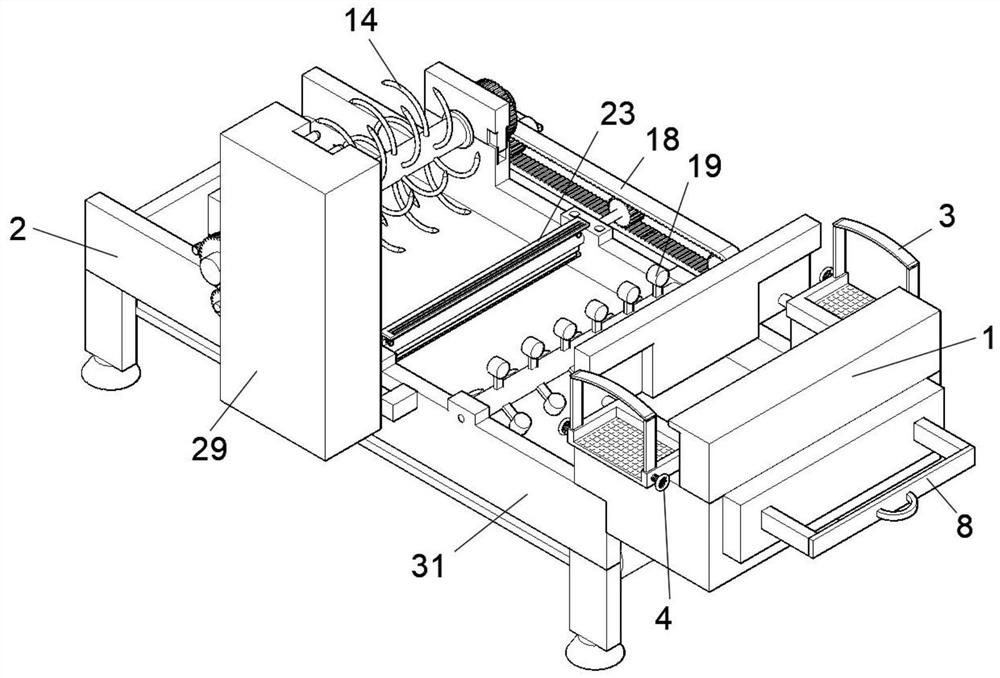

Sorting device and sorting method for gear machining

The invention discloses a sorting device and a sorting method for gear machining. The sorting device comprises a supporting rack and a motor. A bottom plate is mounted on the outer surface of the supporting rack, a top plate is fixedly mounted at the top end of the supporting rack, a notch is formed in the top plate, a feeding plate is fixedly mounted at the left end of the top plate, a discharging plate is fixedly mounted at the right end of the top plate, side plates are fixedly mounted on the top surfaces of the top plate, the feeding plate and the discharging plate, a fixed plate is fixedly mounted on the top surface of each side plate, a rotating shaft is mounted on each fixed plate, the rotating shaft is fixedly connected to the output end of the motor, the motor is fixedly mounted on each fixed plate, and a connecting gear is mounted on the outer surface of the rotating shaft. According to the sorting device for gear machining, a gear on the sorting device can be poked by a pushplate to move, so that a phenomenon that the gear stands still in the moving process is avoided, the gear sorting work efficiency is improved, and the gear moves stably on the sorting device conveniently.

Owner:盐城永安科技有限公司

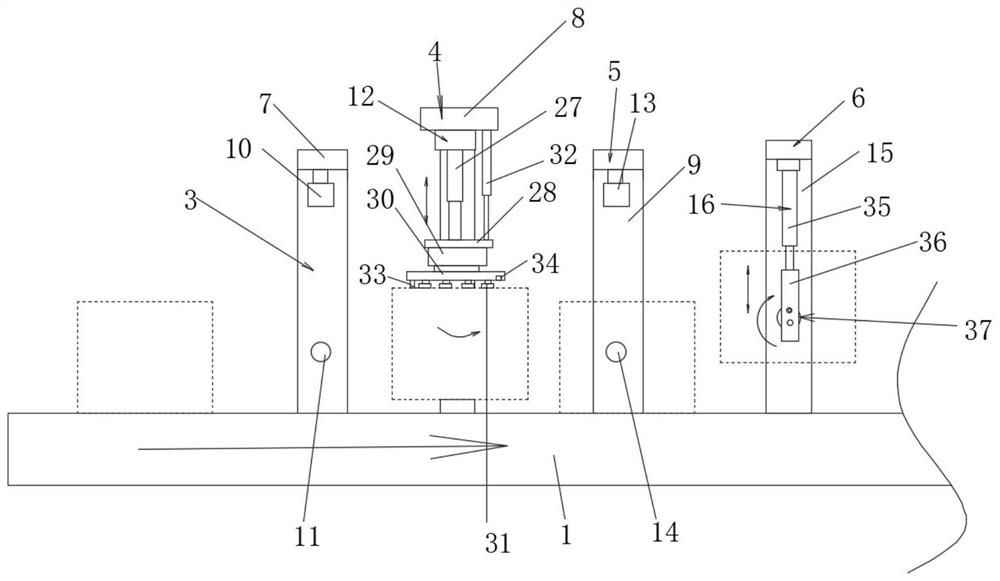

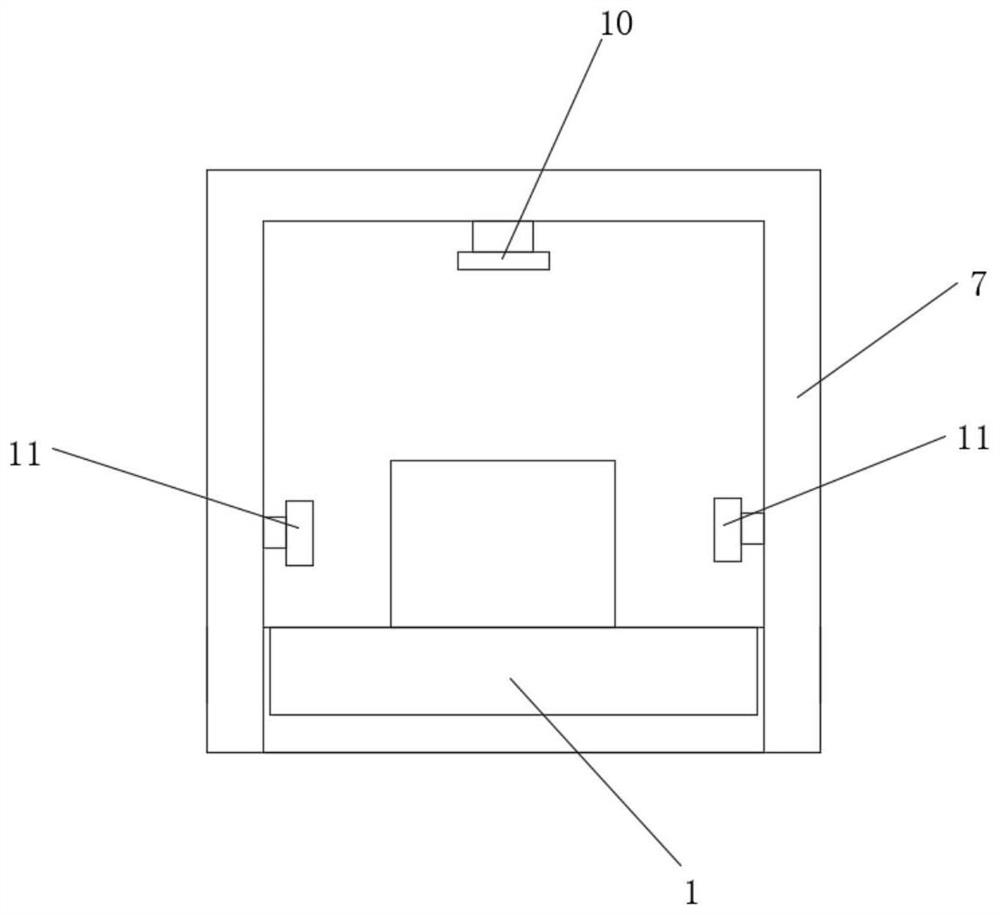

Goods sorting device for intelligent logistics

PendingCN111632849AImprove sorting efficiencyConvenient sorting workSortingLogistics managementEngineering

The invention disclsoes a goods sorting device for intelligent logistics. The device comprises a first frame body, wherein a first scanning mechanism is arranged on the upper surface of the first frame body, a first mounting groove is formed in the upper surface of the first frame body, a first conveying device is connected into the first mounting groove, a mounting opening which is formed in an up-down penetrating mode is formed in the top of the first conveying device, a concentric-square-shaped mounting plate is arranged in the mounting opening, the mounting plate is rotationally connectedwith the inner side wall of the first mounting groove, and a plurality of rotating rollers are rotationally connected to the inner side wall of the mounting plate. According to the device, an adjusting device is used for driving the mounting plate to incline, so that parcels slide to an overturning plate along the mounting plate, then the overturning plate moves to drive the parcels to be overturned to enable an express sheet to face upwards and transferred to a second conveying device, a first code scanner can carry out supplementary code scanning, no manual adjustment is needed, the sortingefficiency is improved, and convenience is brought to sorting work.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

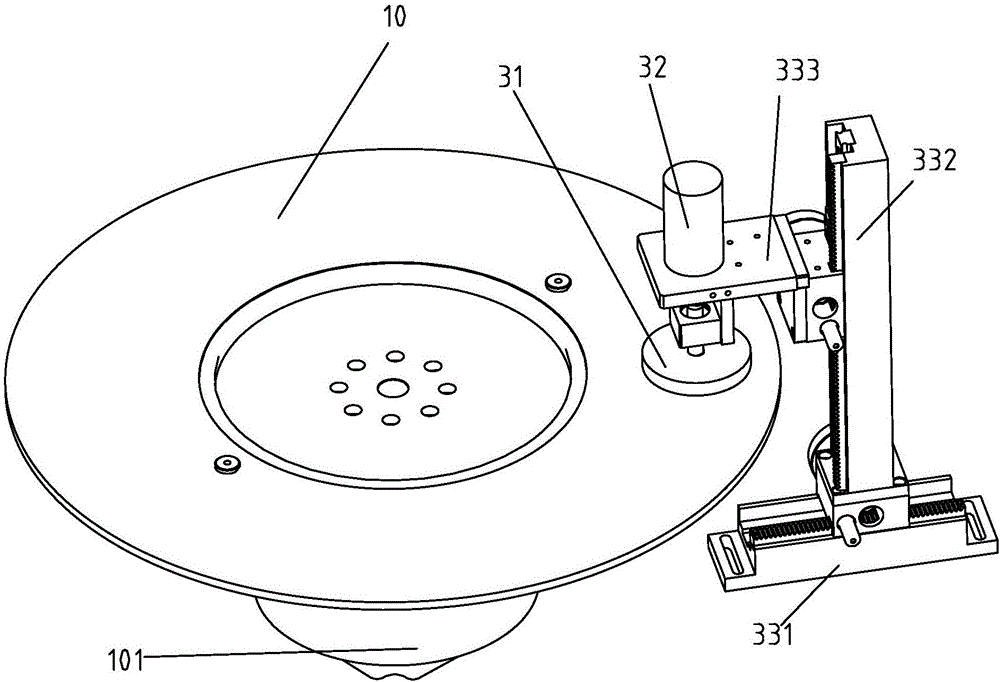

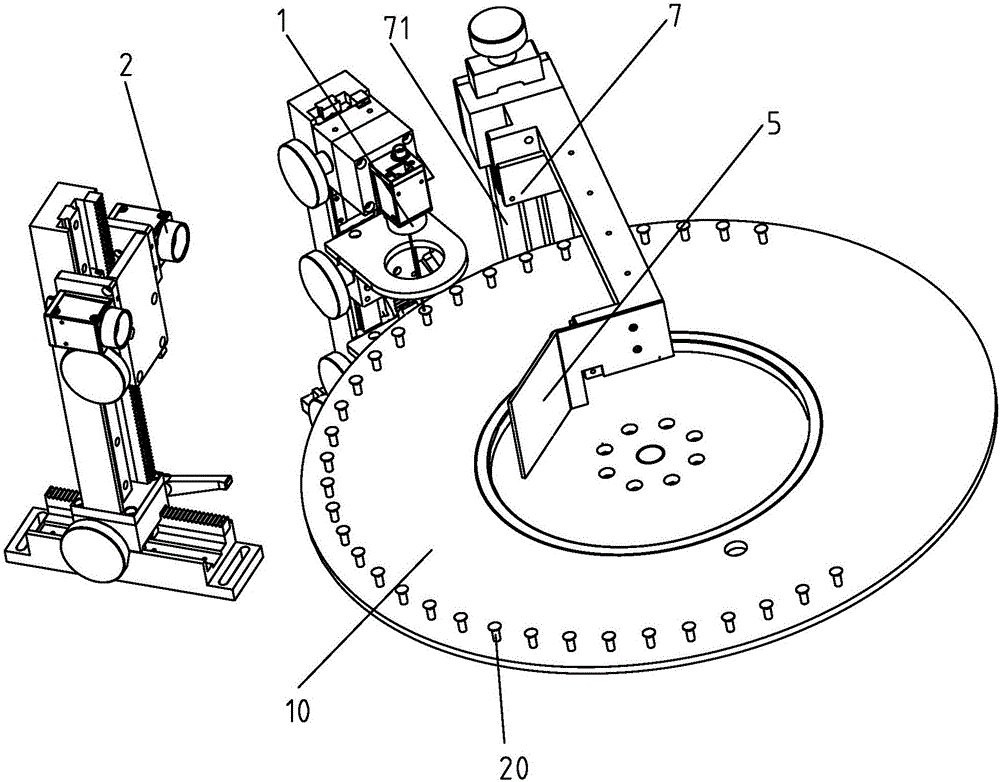

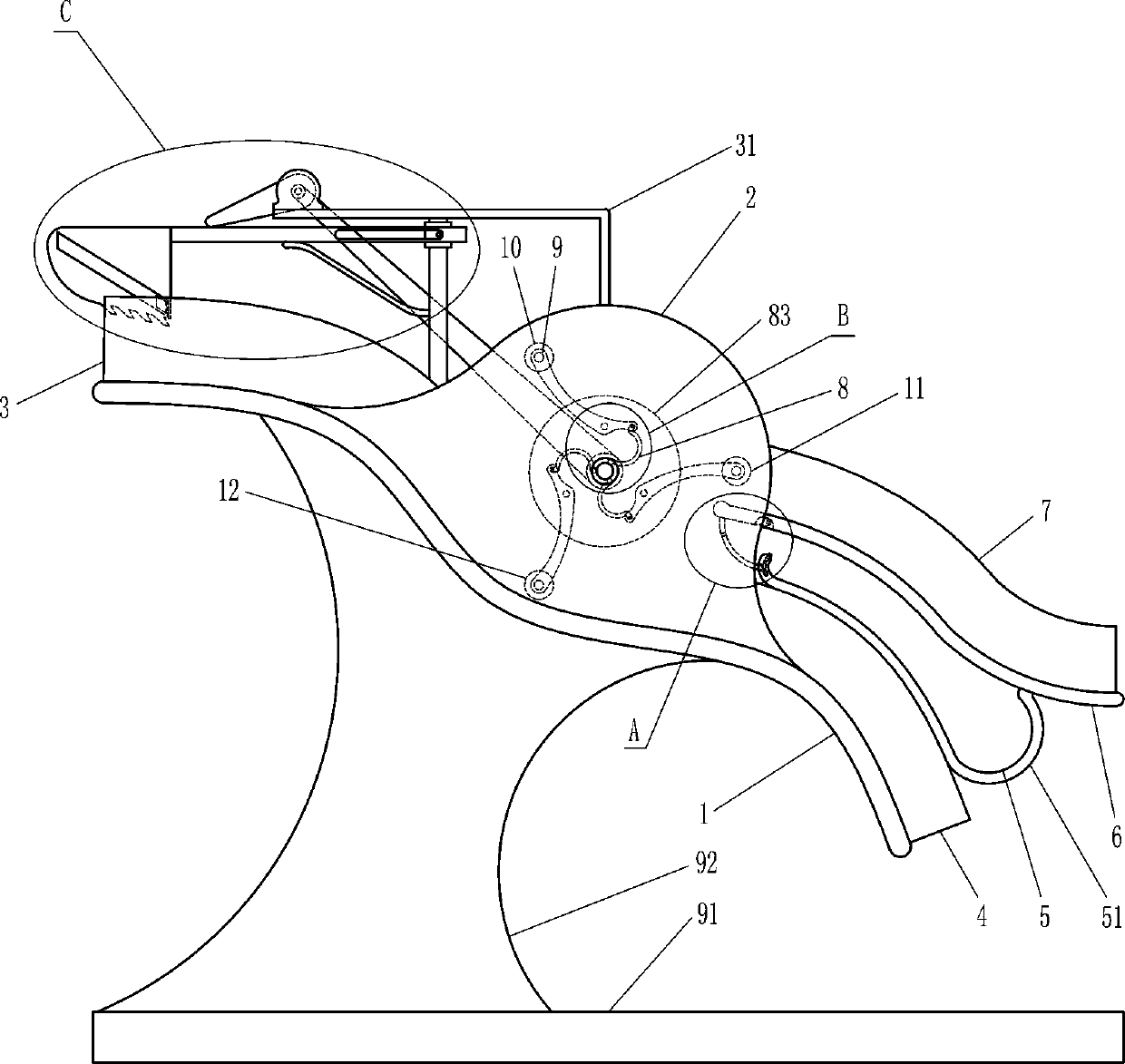

Sorting machine and work method thereof

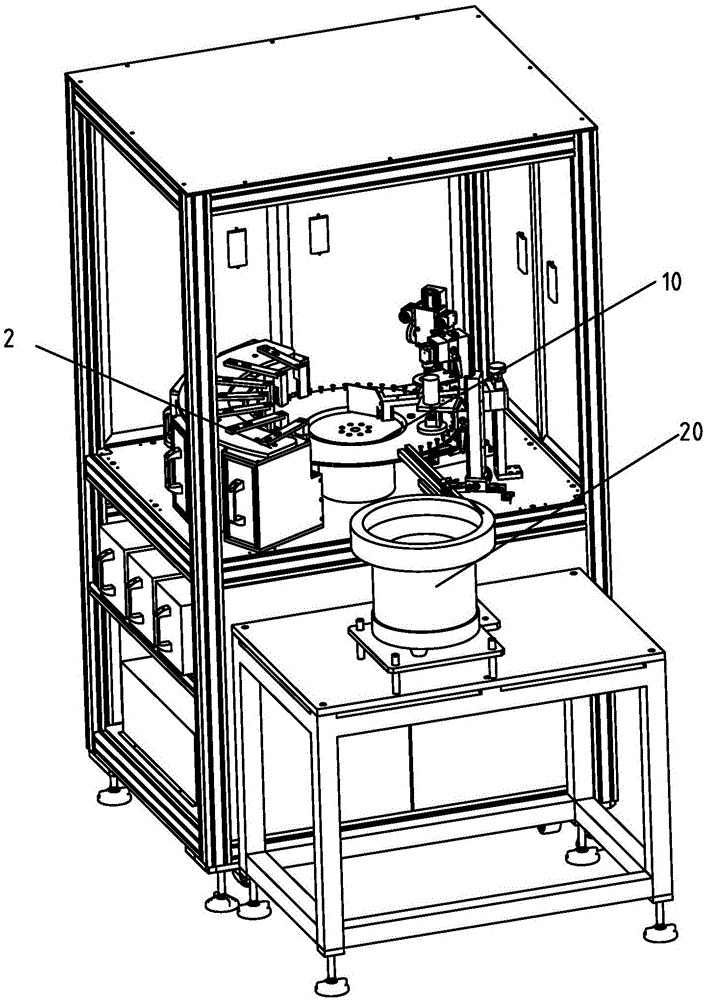

The invention discloses a sorting machine and a work method thereof. The sorting machine comprises a fastening piece station conveying device, an imaging device, a sorting device and an upper computer; the fastening piece station conveying device comprises a rotating disc drive component and a transparent rotating disc which is connected with the rotating disc drive component and driven by the rotating disc drive component to rotate, the sorting device comprises an unqualified product receiving device, a leakage detection receiving device and at least one qualified product receiving device, the imaging device and the sorting device are sequentially arranged in the rotating direction of the transparent rotating disc, the unqualified product receiving device corresponds to an unqualified product receiving station on the transparent rotating disc, the leakage detection receiving device corresponds to the leakage detection receiving station on the transparent rotating disc, and the qualified product receiving device corresponds to the corresponding qualified product receiving station on the transparent rotating disc. The upper computer is connected with the imaging device. The sorting quality of fastening pieces is improved, and the sorting efficiency is improved.

Owner:JIANGSU LEILI MOTOR +1

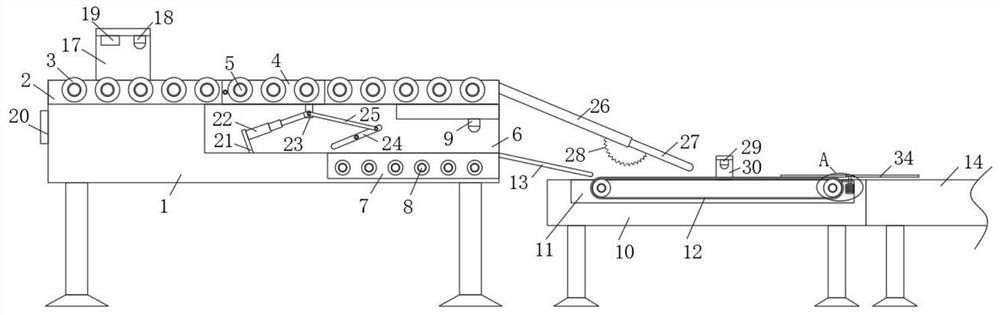

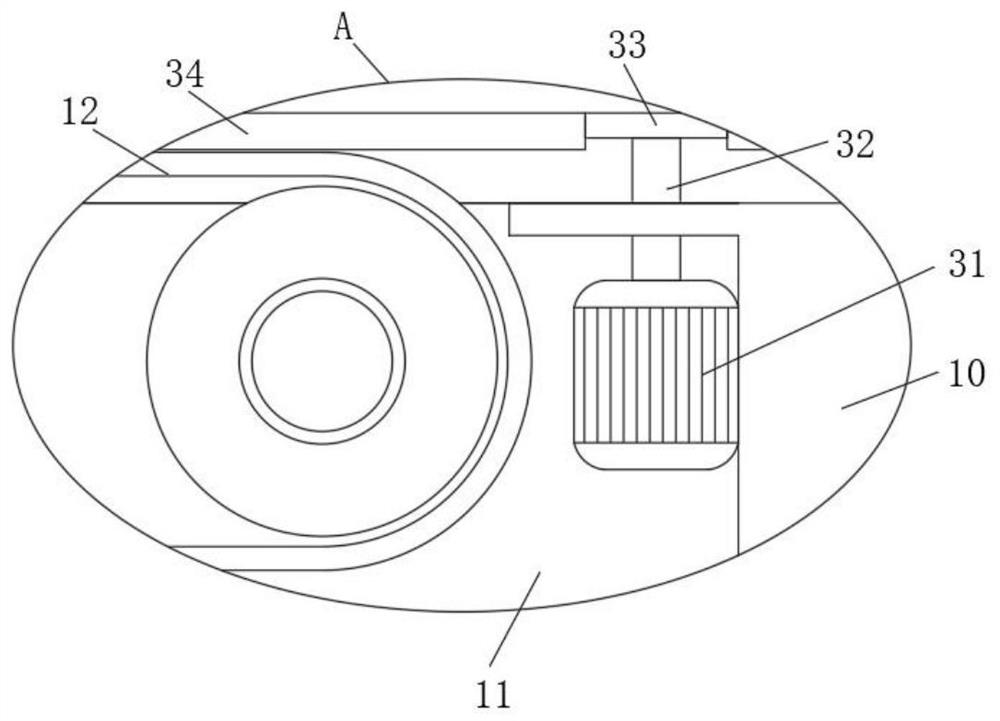

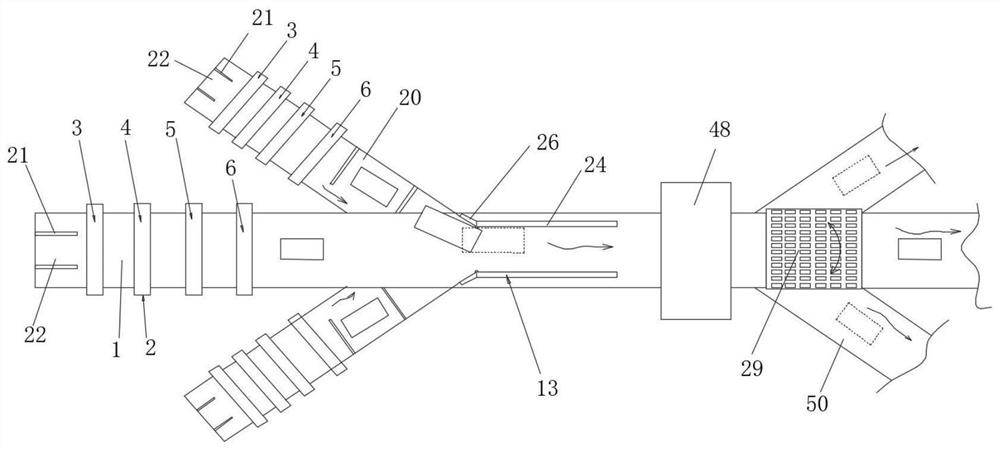

Logistics transportation sorting device for coping with emergency situations

ActiveCN112845111ASimplify work intensityConvenient sorting workSortingLogistics managementVisual recognition

The invention discloses a logistics transportation sorting device coping with emergency situations. The logistics transportation sorting device comprises a main conveying belt, a packaging box position correcting mechanism is arranged on the main conveying belt, the packaging box position correcting mechanism comprises a first position visual identification mechanism, a first logistics packaging box flanging mechanism, a second position visual identification mechanism and a second logistics packaging box flanging mechanism, wherein one side of an output end of the main conveying belt is provided with a visual detection mechanism used for scanning and identifying logistics labels, the tail end of the main conveying belt is provided with balance wheel logistics sorting machines, and a plurality of material receiving conveying belts in butt joint with the balance wheel logistics sorting machines are correspondingly arranged at the tail ends of the balance wheel logistics sorting machines. According to the logistics transportation sorting device, the situation that all the side faces, pasted with the logistics labels, of material packaging boxes can be recognized by a visual detection mechanism to read logistics information on the logistics labels after being corrected through the packaging box position correcting mechanism, so that the logistics sorting efficiency is improved.

Owner:NANJING INST OF RAILWAY TECH

Automatic logistics cargo sorting line

InactiveCN111661612ARealize scanningAvoid unrecognized situationsConveyor partsPictoral communicationLogistics managementElectric machinery

Owner:江苏通四海物流有限公司

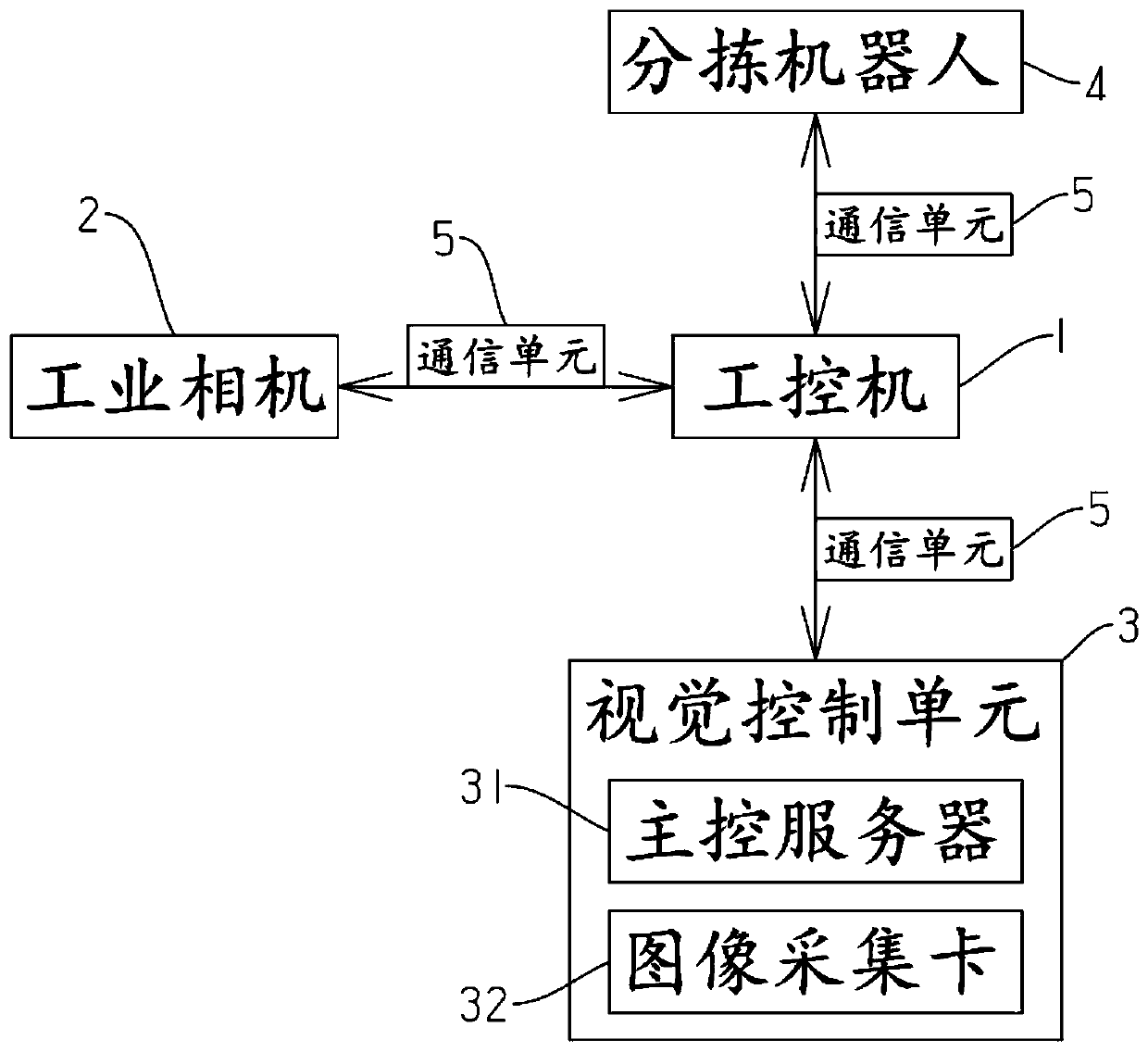

Material sorting method based on machine vision recognition system

The invention discloses a material sorting method based on a machine vision recognition system. The material sorting method includes the following steps: (1) an industrial camera collects the shape, color and position characteristics of materials, and sends the characteristics to an industrial personal machine; (2) the industrial personal machine circularly compares the information with information preset by a visual control unit, and transmits a result to the visual control unit; (3) the visual control unit recognizes the result, and transmits the result back to the industrial personal machine; and (4) the industrial personal machine controls a sorting robot to work according to the transmitted-back result. A manipulator sorting mechanism of an intelligent sorting device based on machinevision has the characteristics of multiple sorting angles, wide coverage range and easy sorting, the production efficiency of enterprises is improved, the intelligent sorting device and system replacemanpower, items can be intelligently sorted automatically, the workload of express personnel is reduced, the enterprise cost is saved, the delivery time of the express items is shortened, and the work efficiency is improved.

Owner:OPTIMUS ROBOT AUTOMATION SUZHOU CO LTD

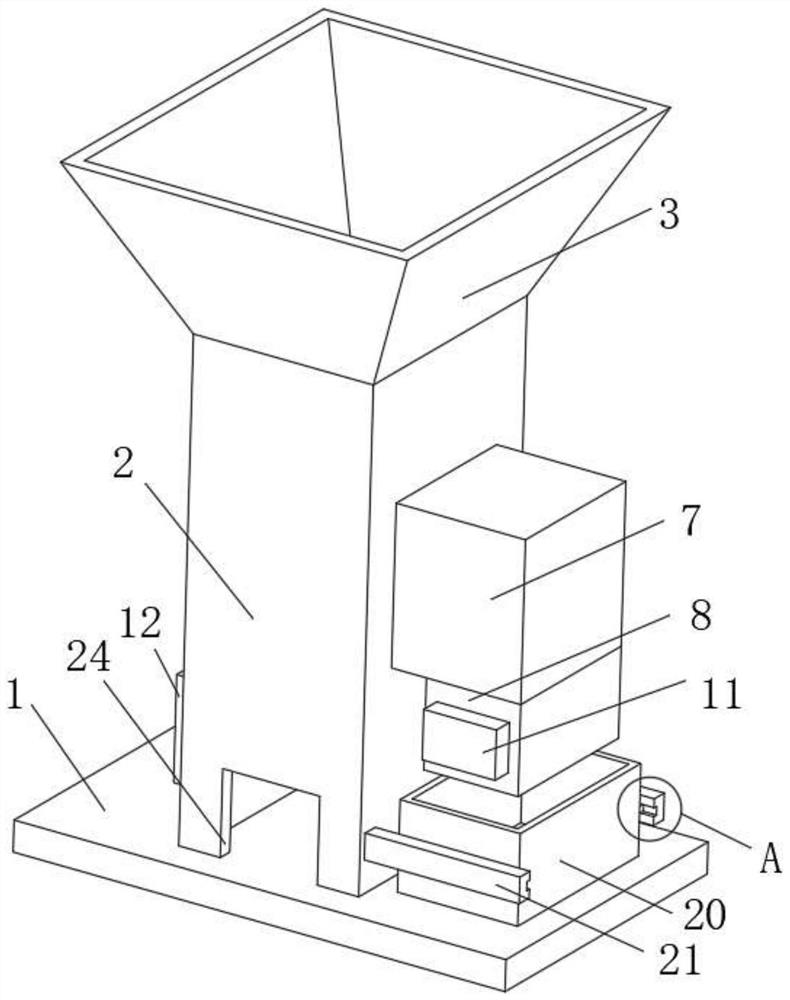

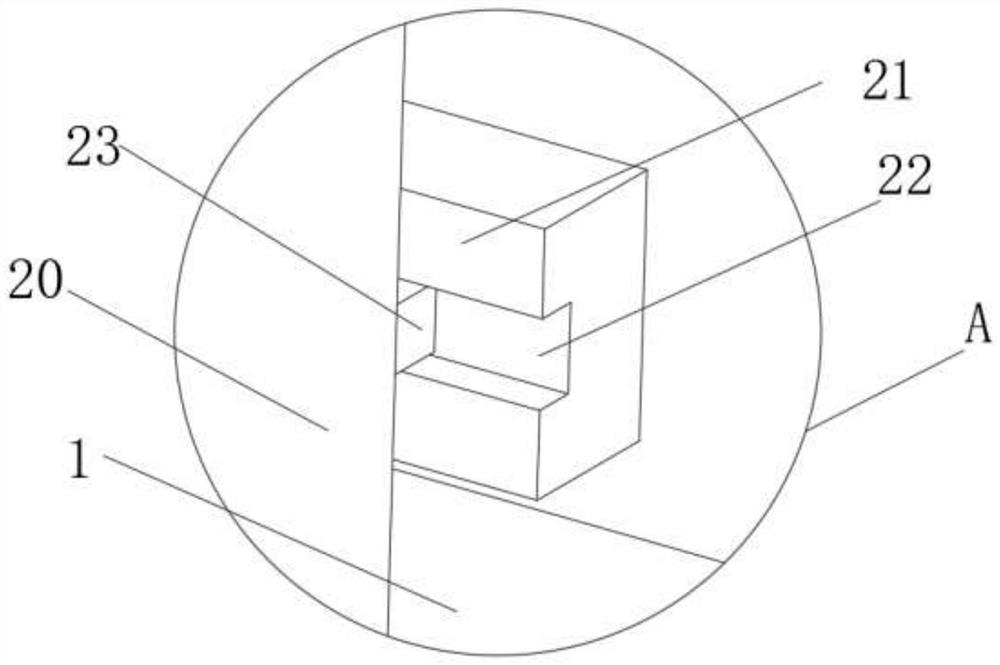

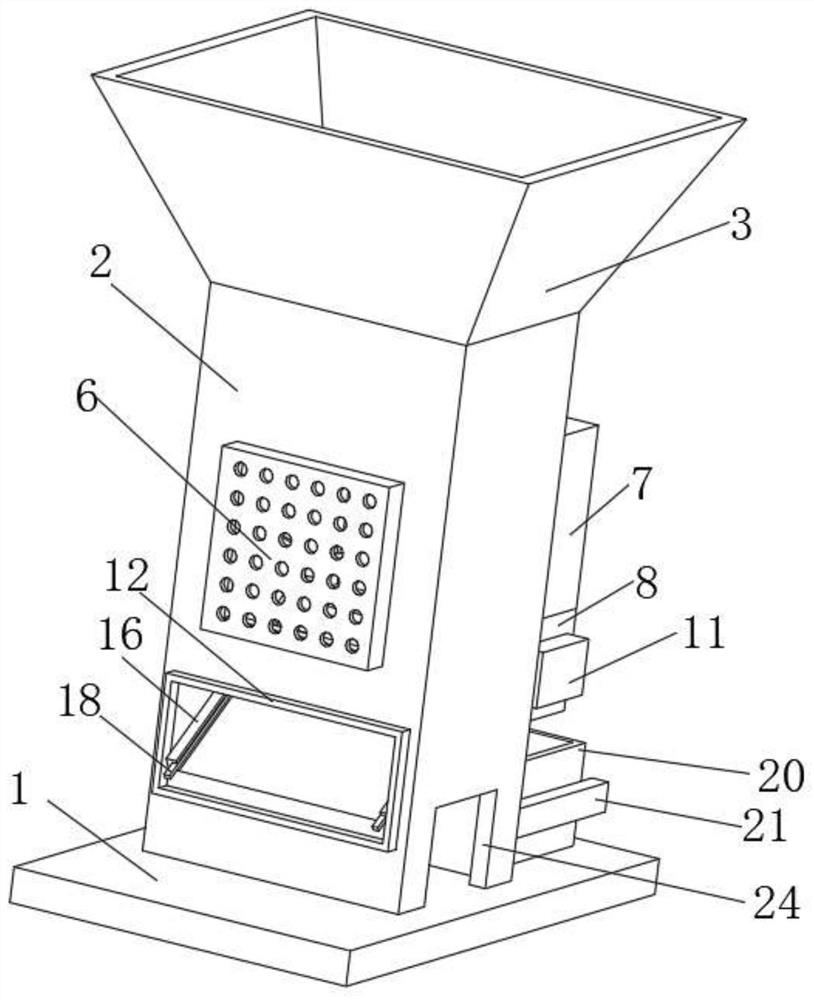

Solid waste sorting device

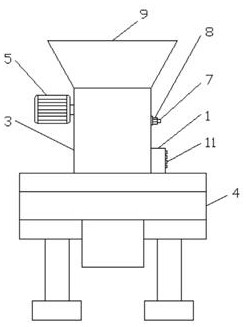

ActiveCN112157112AFunction increaseRealize processingGas current separationUsing liquid separation agentMechanical engineeringWaste management

The invention relates to the technical field of sorting equipment, and discloses a solid waste sorting device. The solid waste sorting device comprises a bottom plate; a vertical pipe is fixedly connected to the top surface of the bottom plate; a feeding funnel fixedly communicates with the top surface of the vertical pipe; a mounting groove is formed in the left side surface of the vertical pipe;and a fan is fixedly mounted on the inner surface of the mounting groove. According to the solid waste sorting device, a discharging box fixedly communicates with the bottom of a feeding box, a rotating shaft is movably sleeved with the discharging box, the rotating shaft is sleeved with a crushing roller, the crushing roller is driven by a power box to rotate, light waste blown into the feedingbox and falling into the discharging box is crushed, the crushed light waste falls into a collecting box, treatment of the light waste is timely and effectively realized, additional collection and transportation of the light waste are avoided, the light waste is transferred to crushing treatment equipment, the treatment process is shortened, the treatment time is shortened, the treatment efficiency is improved, the functions of the sorting device are expanded, and the use effect is good.

Owner:深圳市前海极智创新科技有限公司

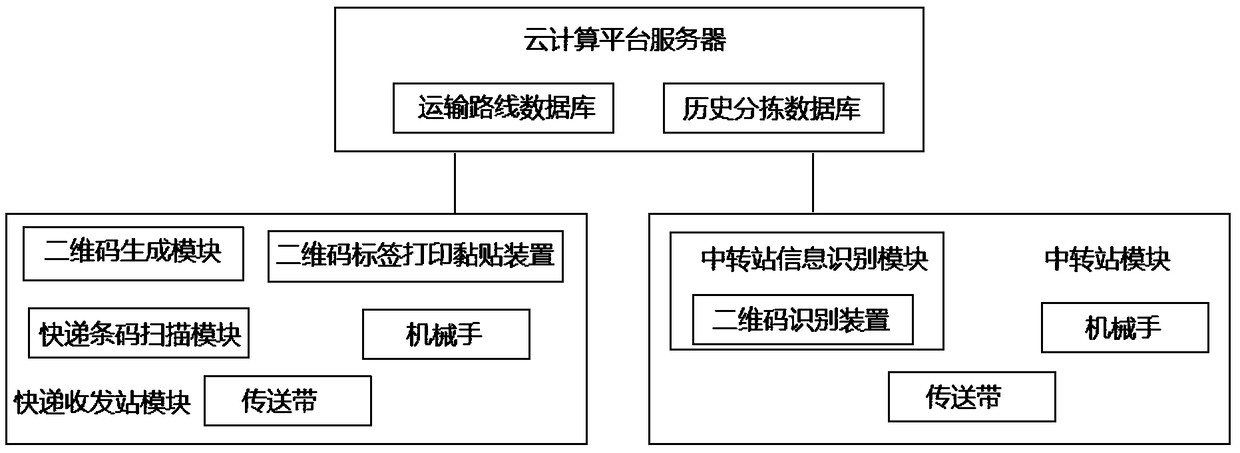

Express sorting system based on cloud computing

InactiveCN109033918ARealize automatic sortingShorten delivery timeLogisticsSensing by electromagnetic radiationWorkloadCloud computing

The invention discloses an express sorting system based on cloud computing, comprising an express bar code scanning module, a cloud computing platform server, a two-dimensional code generation module,a relay station information identification module and an early warning module. The invention realizes automatic sorting of express delivery, lightens workload of staff and shortens delivery time of express delivery. The record of express route information is realized based on two-dimensional code technology, which not only facilitates the follow-up sorting work, but also facilitates the traceability query of express route by scanning two-dimensional code. Through the use of the unique two-dimensional code with the courier document number, the tracking of the courier parcel is realized, so that the missing courier can be found in time.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

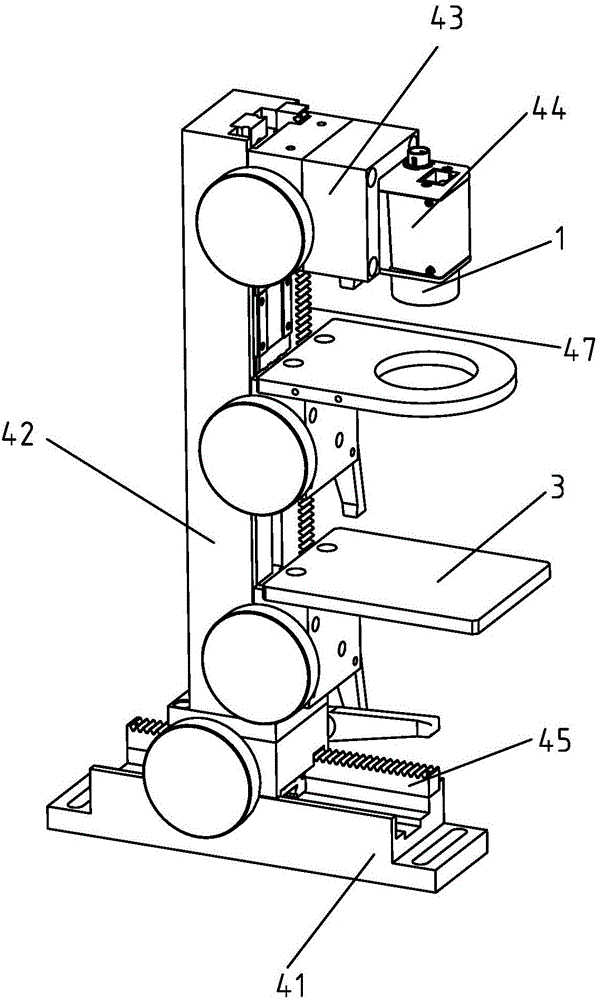

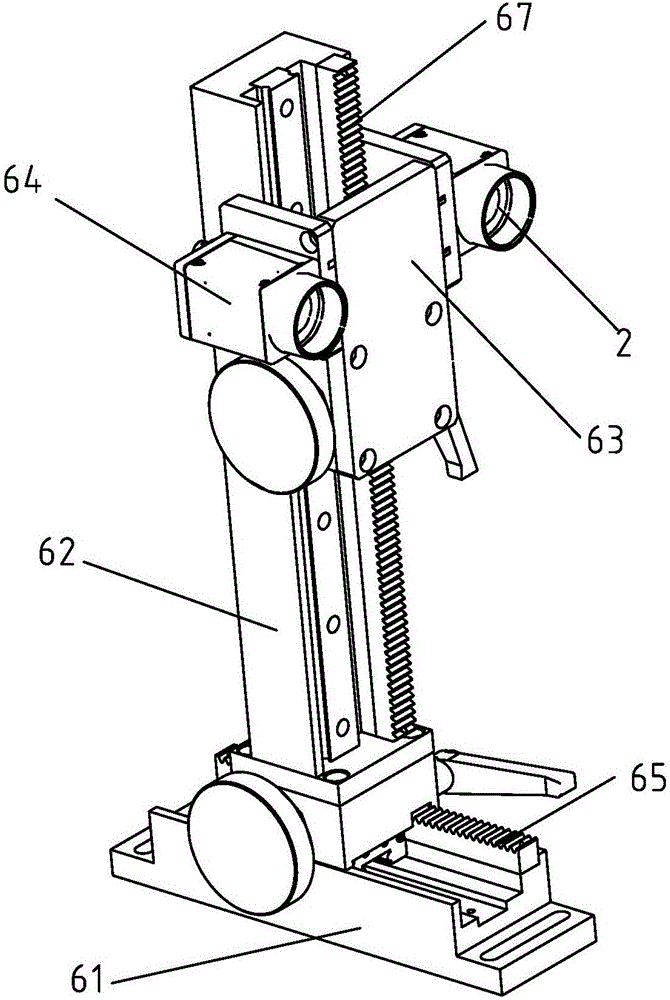

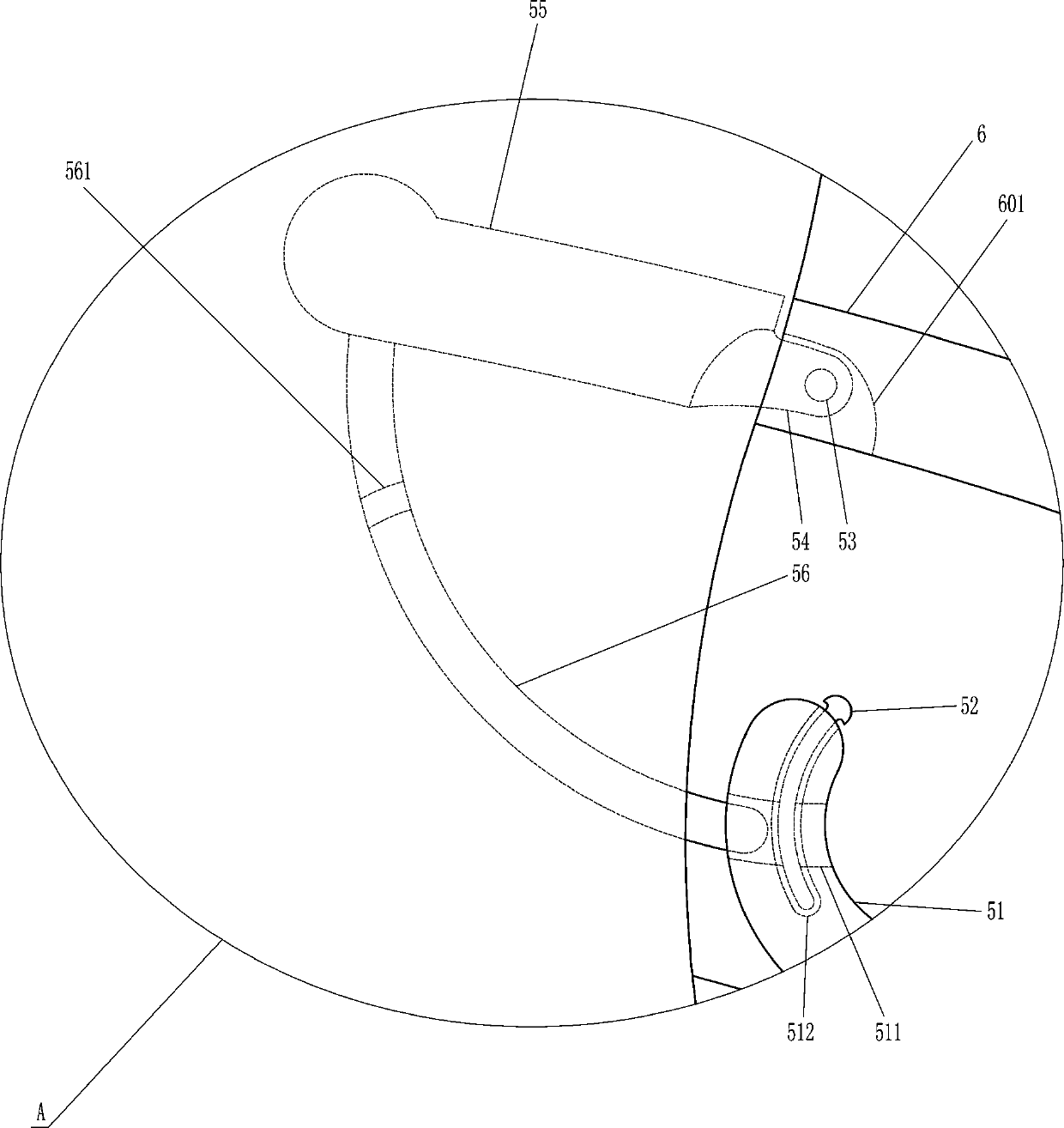

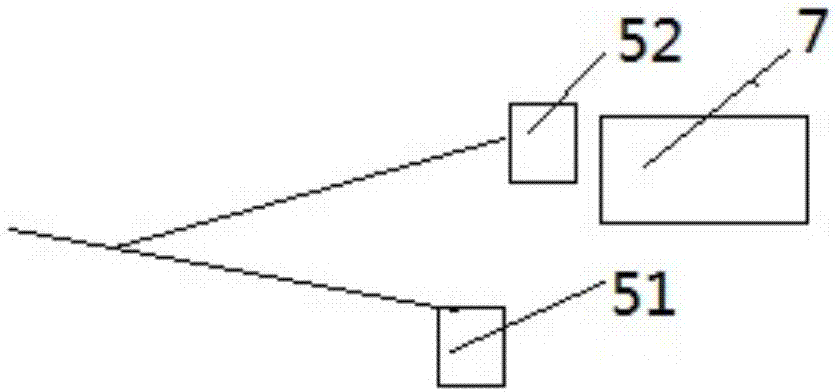

Imaging device for sorting machine

The invention discloses an imaging device for a sorting machine. The imaging device is used for imaging a fastener on a transparent turntable of the sorting machine. The imaging device comprises a vertical imaging part and a horizontal imaging part, wherein the vertical imaging part comprises a vertical imaging camera which is used for shooting an image of the fastener on the transparent turntable along the vertical direction; the horizontal imaging part comprises at least one horizontal imaging camera used for shooting the image of the fastener on the transparent turntable along the horizontal direction; the horizontal imaging part and the vertical imaging part are arranged along the rotating direction of the transparent turntable. According to the imaging device, a camera imaging technique is adopted for imaging the fastener; the size of the fastener can be reasonably collected; the detection precision is promoted.

Owner:JIANGSU LEILI MOTOR +1

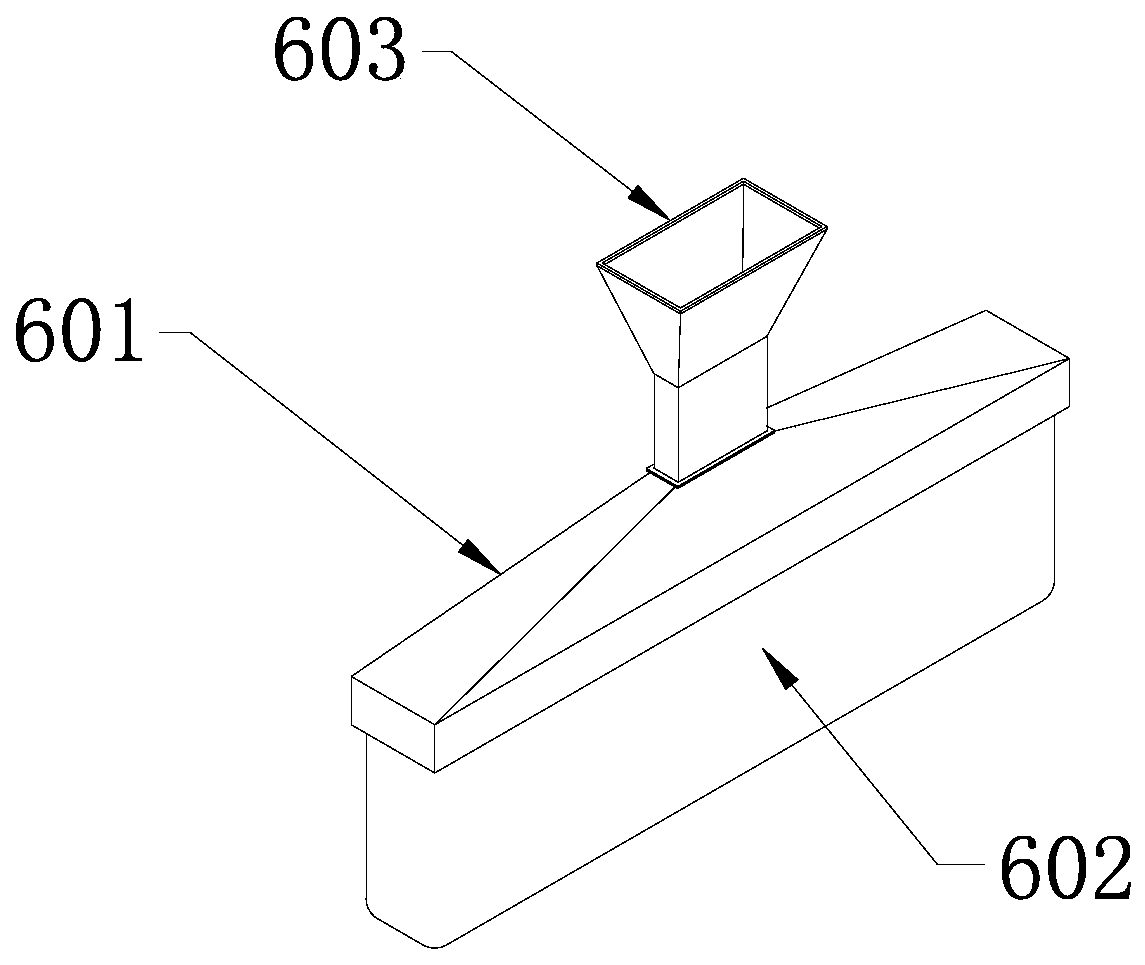

Sorting equipment for green treatment of bulk solid wastes

InactiveCN113399416APrevent fallingInhibit sheddingSolid waste disposalSolid separationStructural engineeringIndustrial engineering

The invention discloses sorting equipment for green treatment of bulk solid waste. The sorting equipment comprises a feeding auxiliary device, the top of one end of the feeding auxiliary device is fixedly connected with a comprehensive sorting device, the feeding auxiliary device comprises fastening and limiting clamping strips, limiting bolts, supporting and fixing bottom plates, protective gaskets, a fixed storage cavity and a stirring material pushing rod, the stirring material pushing rod is inserted to the interior of one end of the fixed storage cavity in a sliding mode, the supporting and fixing bottom plates are symmetrically and rotationally connected to the interiors of the side ends of the fixed storage cavity, the fastening and limiting clamping strips are symmetrically inserted to the interiors of one ends of the supporting and fixing bottom plates in a sliding mode, the limiting bolts are symmetrically inserted into the side ends of the supporting and fixing bottom plates in a threaded mode, and the protective gaskets are symmetrically and fixedly connected to the interiors of the supporting and fixing bottom plates. According to the sorting equipment, through the arrangement of the feeding auxiliary device and the comprehensive sorting device, after garbage is crushed, plastic bags in the interior of the garbage are sorted out.

Owner:赵瑞霞

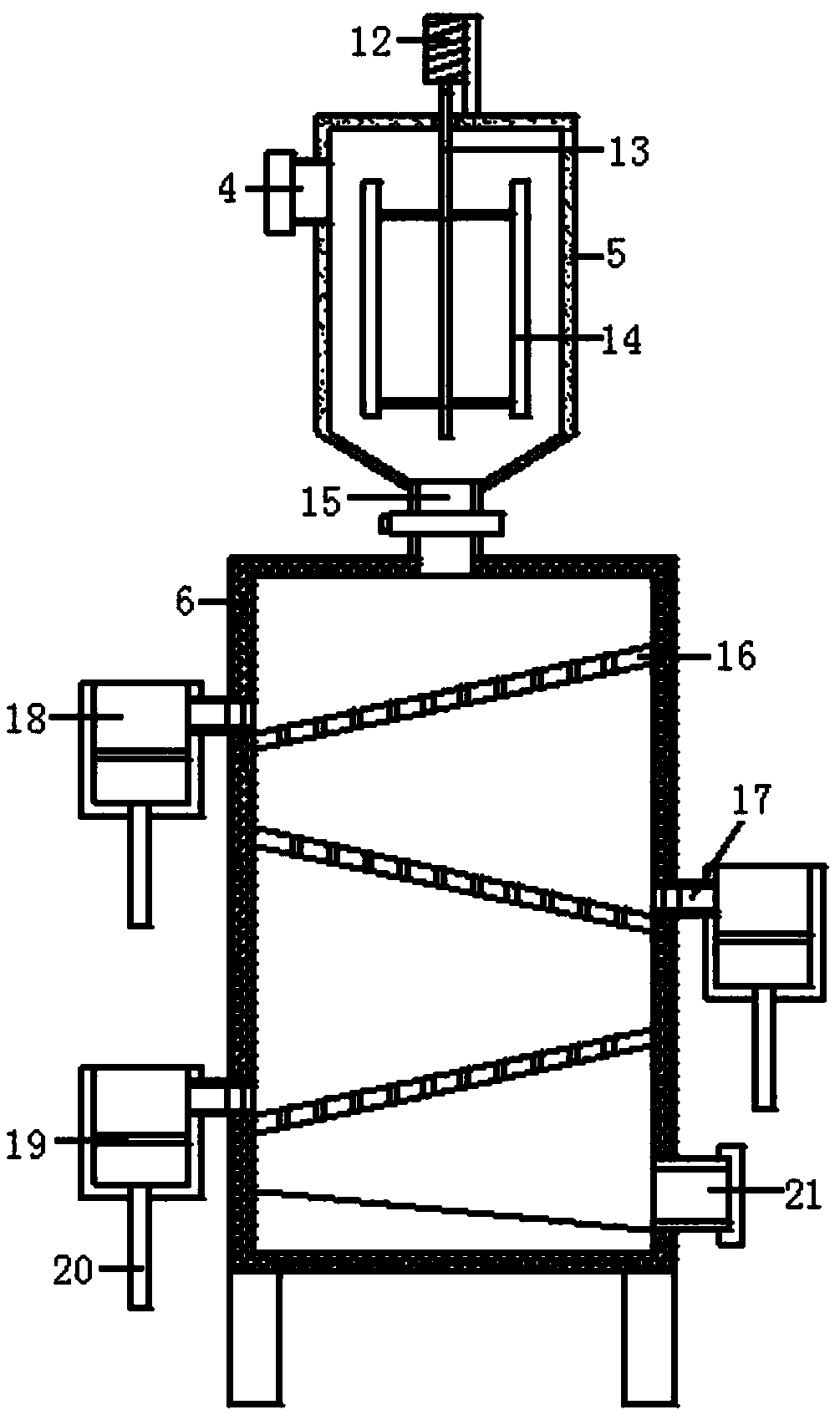

Jigger with multistage separation function and control system thereof

The invention discloses a jigger with a multistage separation function in the technical field of jiggers. The jigger comprises a cabinet, a feeding groove is arranged on the left side of the top of the cabinet, a screen plate is arranged at the top of an inner cavity of the cabinet, an overflow port is arranged on the right side wall of the cabinet and positioned above the screen port, and a stirring tank is arranged on the right side of the overflow port. Compared with existing jiggers, the jigger is simple in structure and convenient in use; mineral aggregate is stirred through the stirringtank, so that the mineral aggregate is stirred and mixed more uniformly, accumulation of the mineral aggregate in the stirring tank is reduced, and more convenience is brought to separation; ore flowing out from the overflow port is screened stage by stage through a multistage separation device, so that granularity of large-particle mineral is graded, and requirements on mineral granularity grading are met; screening is controlled and adjusted through a control system, in this way, liquid overflow is reduced.

Owner:HEBEI JINRUN ELECTRICAL AUTOMATION EQUIP

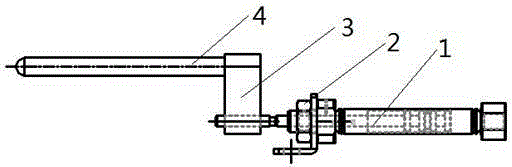

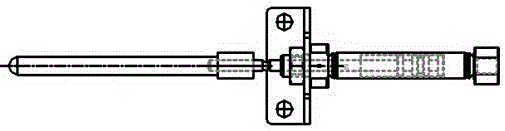

Solar energy detection oiliness marker pen

InactiveCN106559036ASimple structureEasy to manufacturePhotovoltaic monitoringPhotovoltaic energy generationEngineeringAutomation

The present invention discloses a solar energy detection oiliness marker pen. The marker pen comprises a cylinder, a connecting piece, a support body and an oiliness marker pen. The cylinder and the oiliness marker pen are arranged on the support body, the cylinder is directly connected with the support body, the oiliness marker pen is connected with the support body through the connecting piece, and the oiliness marker pen can be moved with the driving of the cylinder. The solar energy detection oiliness marker pen can rapidly and effectively mark an unqualified solar panel to facilitate later sorting work. The device also can be configured for other detection marking systems so as to easily improve the automation level and the production efficiency.

Owner:NANJING UNIV OF SCI & TECH

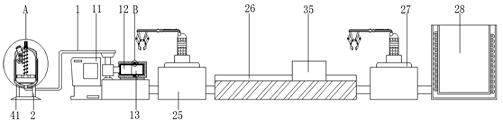

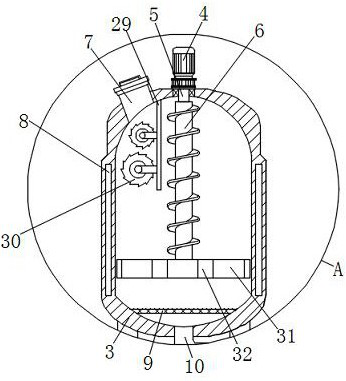

Automatic assembling and detecting equipment for metal packsack pendant

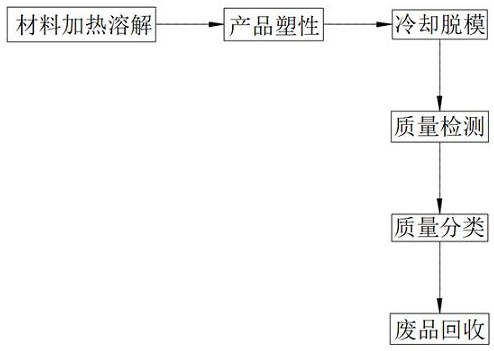

InactiveCN112354627AIncrease the degree of fragmentationStir to dissolve thoroughly and evenlyMachine part testingFoundry mouldsThermodynamicsWaste product

The invention relates to automatic assembling and detecting equipment for a metal packsack pendant. An automatic device body comprises a supporting leg, and the upper surface of the supporting leg isfixedly connected with a dissolving tank. A driving machine is fixedly arranged on the upper surface of the dissolving tank, and the output end of the driving machine is fixedly connected with a rotating rod. The bottom end of the rotating rod penetrates into the dissolving tank and is fixedly connected with a stirring rod. The top, close to the left side of the dissolving tank, of the dissolvingtank is fixedly connected with a feeding pipe, and the inner wall of the dissolving tank is fixedly connected with a temperature-adjustable heating plate. By the coordination of the structures, the dissolution of raw materials is accelerated, and a plastic machine can quickly cool and demold products. Thus, waste recycling work of a user is facilitated, convenience is brought to follow-up productquality screening work of the user, the production efficiency of the product production process is improved, and convenience is brought to the user.

Owner:重庆新禹智能科技有限公司

Automatic agricultural product sorting device for intelligent agriculture

ActiveCN114749363AConvenient and quick sorting distanceEasy to replaceSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural product sorting devices, in particular to an automatic agricultural product sorting device for intelligent agriculture, which comprises a first fixing frame, a second fixing frame is mounted at one end of the first fixing frame, an adjusting structure is mounted on the first fixing frame, and an elastic structure is arranged on the first fixing frame. A discharging structure is installed at the bottom end of the first fixing frame, a screening structure is installed on the second fixing frame, a cleaning structure is arranged on the second fixing frame, and a collecting structure is installed on the cleaning structure. According to the agricultural product sorting device, the adjusting structure is arranged on the first fixing frame, so that the sorting distance between the sorting assemblies can be conveniently and rapidly adjusted, sorting operation can be conducted according to different sorting requirements or different agricultural products, and the use range of the device is widened.

Owner:山东瓦利斯智能科技有限公司

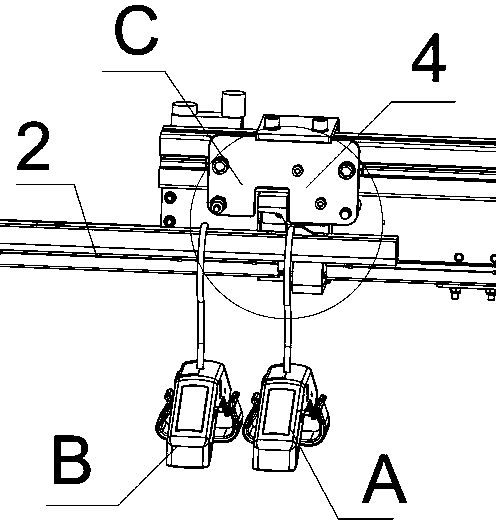

Distribution device suitable for rail transmission and control method thereof

PendingCN111204557AImprove controllabilityIncrease intervalMechanical conveyorsLogistics managementControl engineering

The invention relates to the field of automatic logistics design, and particularly relates to a carrier optimization processing design. The technical purpose of a distribution device is achieved by following technical scheme, the distribution device suitable for rail transmission comprises a rail, the rail sequentially comprises a starting rail, a temporary retaining rail and a transmission trackaccording to the advancing direction of a carrier, the temporary retaining rail is provided with a shifting assembly, the shifting assembly comprises a lower blocking piece and an upper blocking piecemoving relative to the temporary retaining rail, the lower blocking piece is located in front of the upper blocking piece according to the advancing direction of the carrier. The purpose of the distribution device is to provide the distribution device suitable for the rail transmission and a control method thereof, the device can automatically separate the mutually attached carriers, improve theuniformity of each carrier on a conveying line, and can facilitate subsequent sorting work.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

Vegetable logistics distribution automatic sorting device

The invention relates to the technical field of sorting equipment, and discloses a vegetable logistics distribution automatic sorting device. The vegetable logistics distribution automatic sorting device comprises a main body; a movable cavity is formed in the middle of the main body, a supporting rod is movably sleeved with the movable cavity, and the upper end of the supporting rod is movably sleeved with a bearing plate. Through the arrangement of the supporting rod and a current-conducting plate, gravity borne by vegetables can press the supporting rod downwards, the supporting rod drivesthe current-conducting plate to slide downwards along the movable cavity, and when the weight of the vegetables is small, at the moment, the current-conducting plate makes contact with an upper contact plate under the action of a bent spring to switch on a first electromagnet communicating with the upper contact plate; the first electromagnet generates magnetism to repel a permanent magnet above the first electromagnet, a guide ejector rod is pushed to move upwards, the bearing plate deflects towards one side, light vegetables are sorted out from one side, otherwise, for the heavy vegetables,the current-conducting plate makes contact with a lower contact plate, namely, a second electromagnet is switched on to sort out the heavy vegetables from the other side, transported vegetables can beborne and sorted through the bearing springs, and the sorting efficiency is improved.

Owner:安徽汇力农业发展股份有限公司

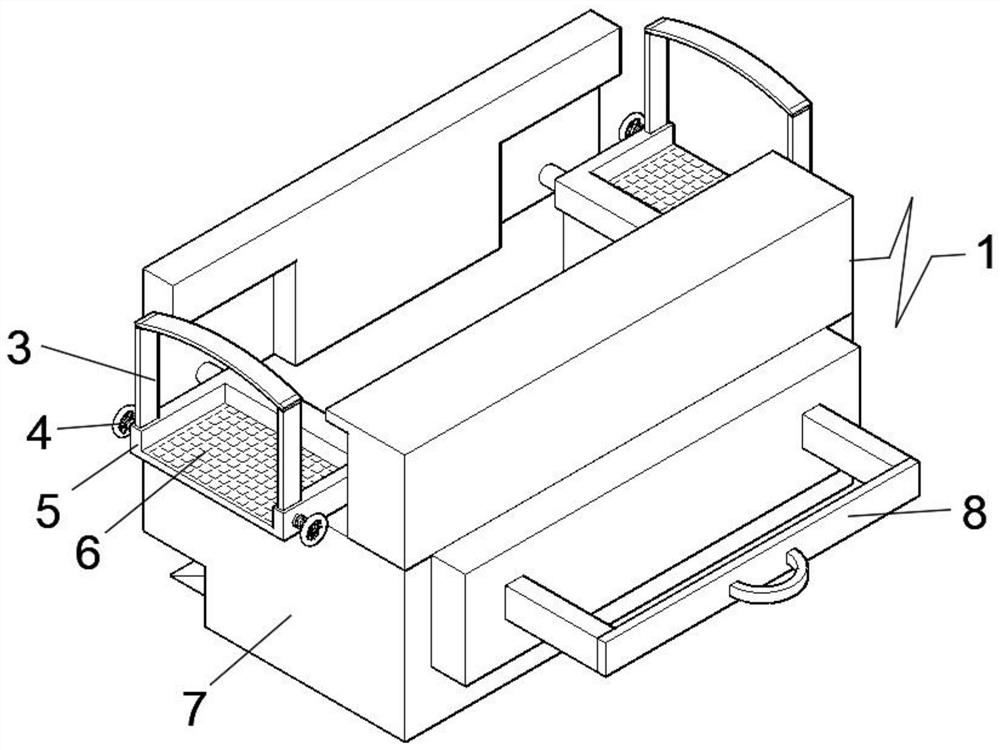

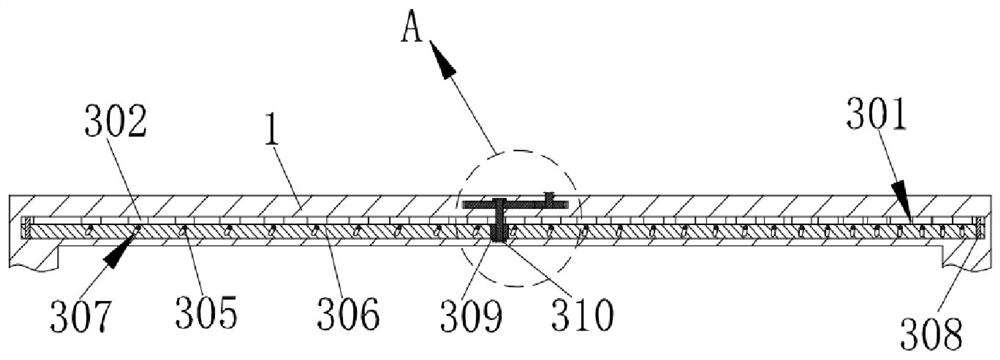

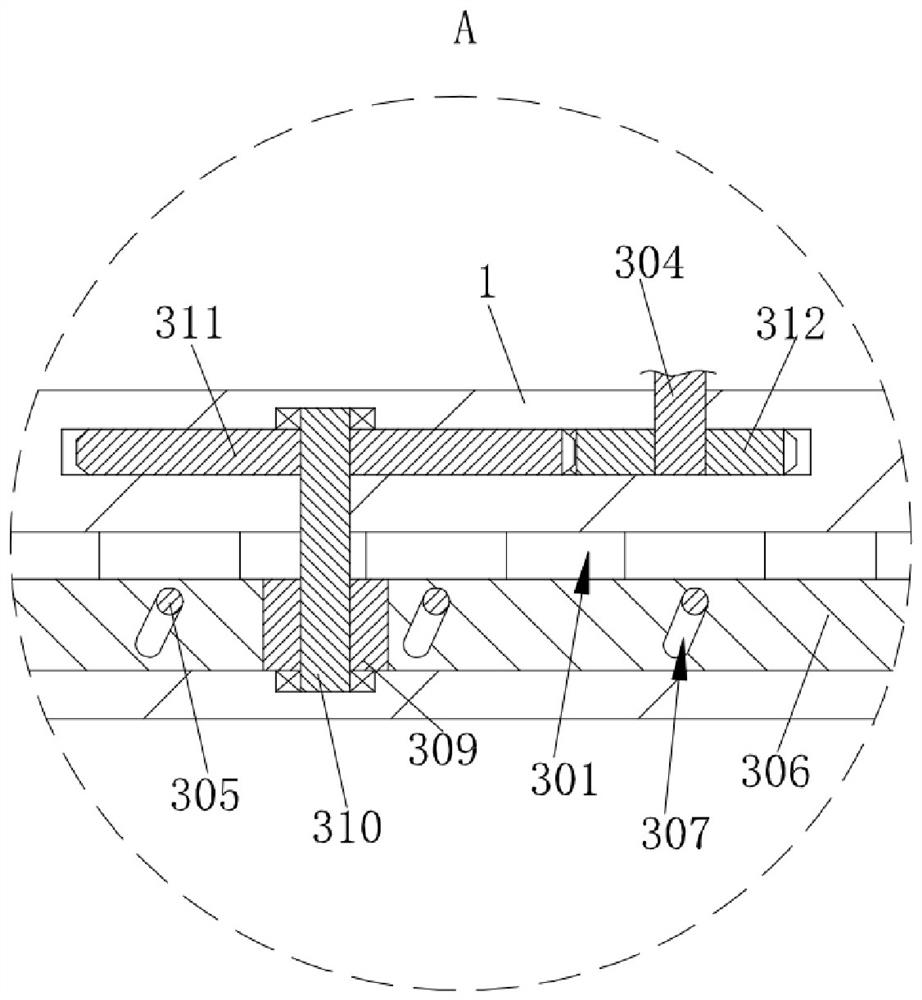

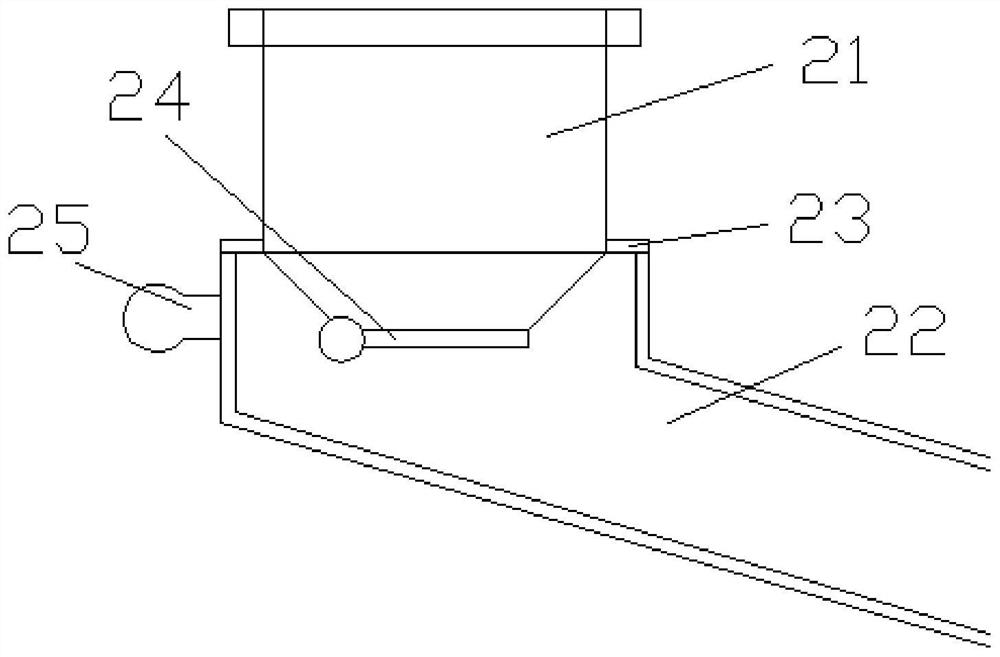

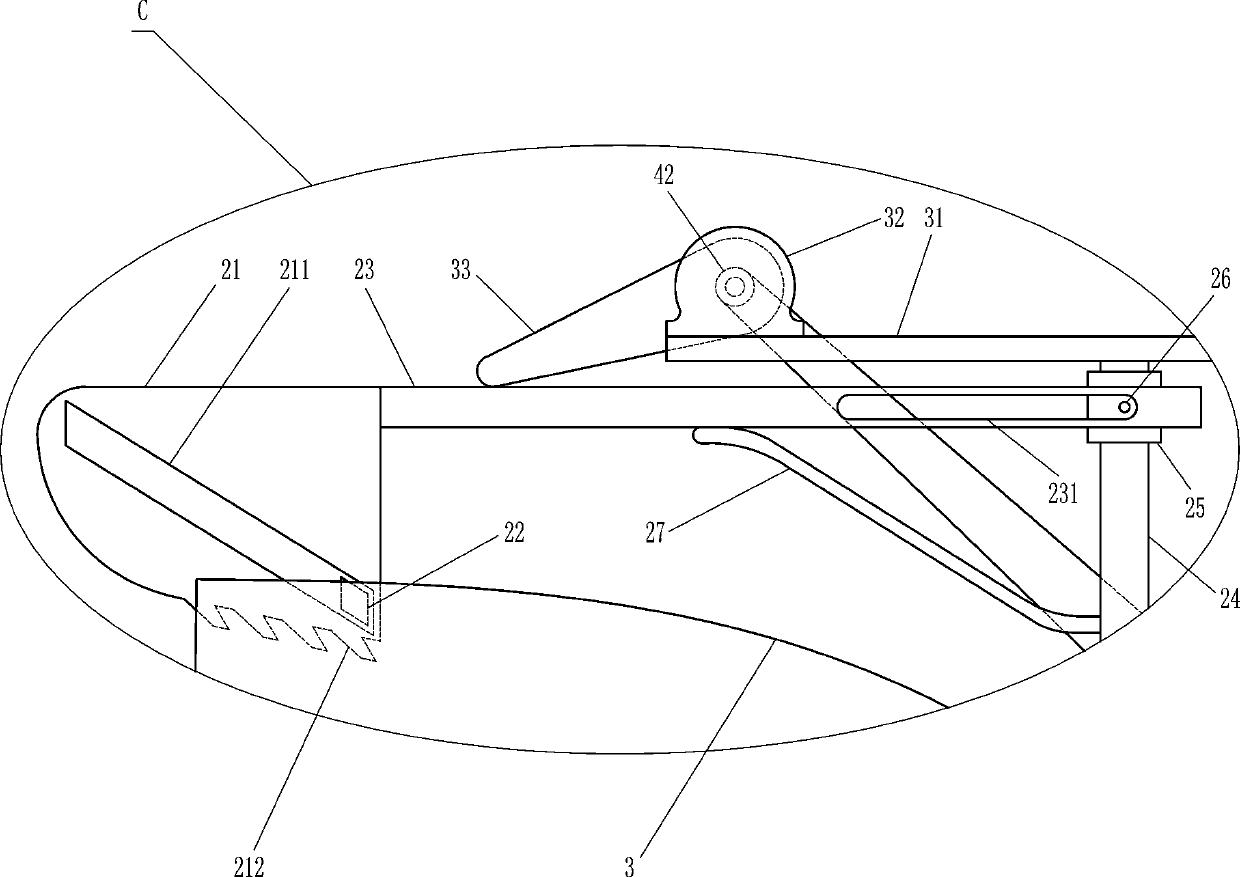

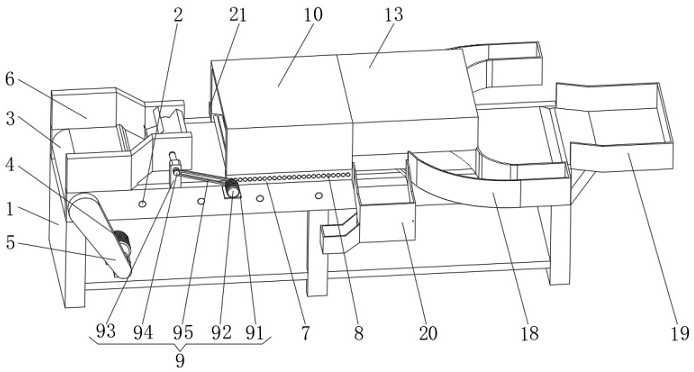

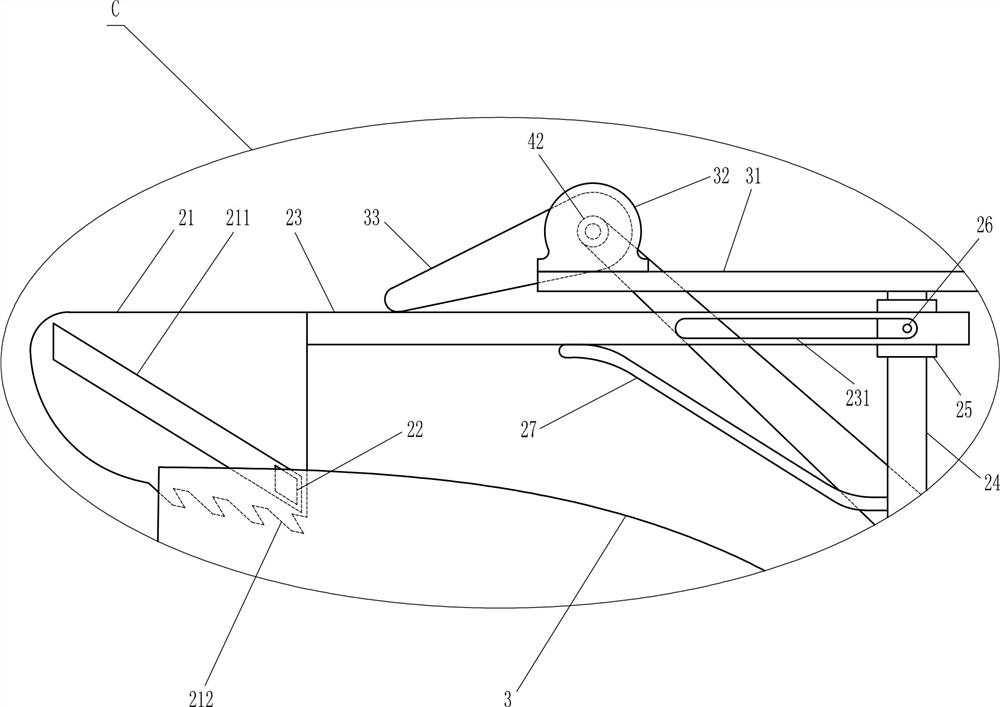

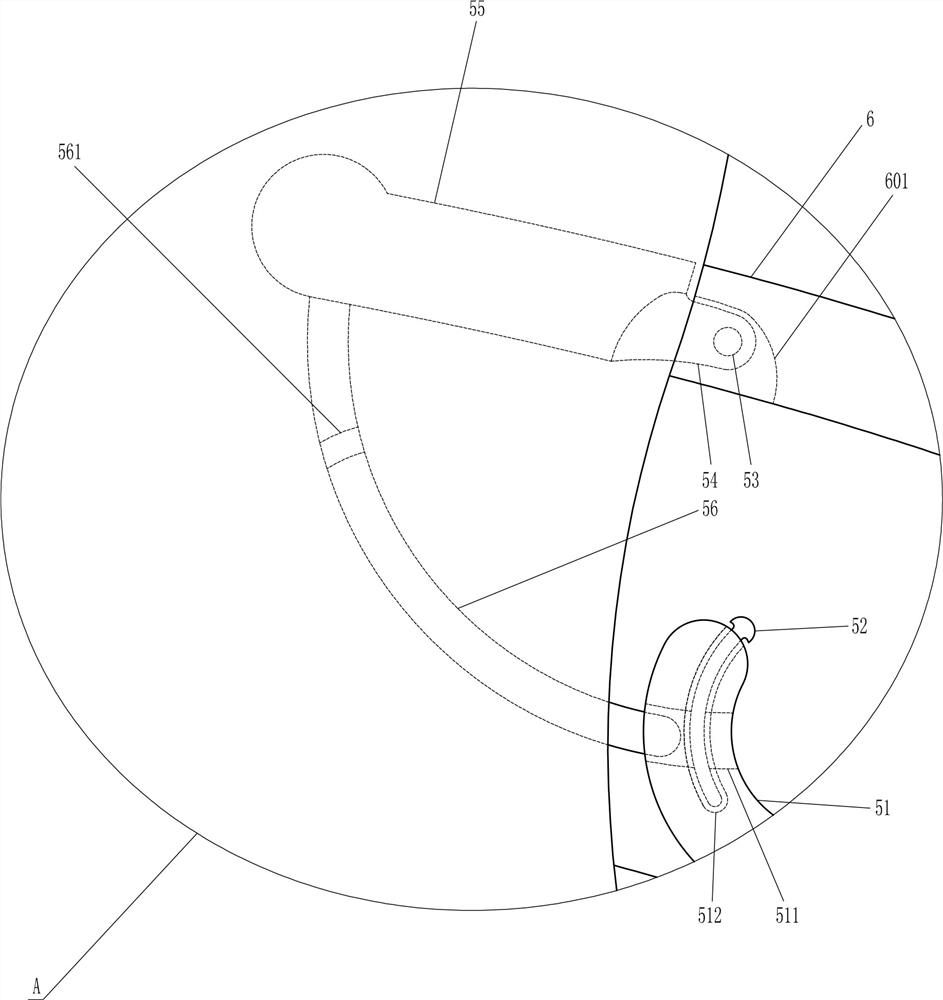

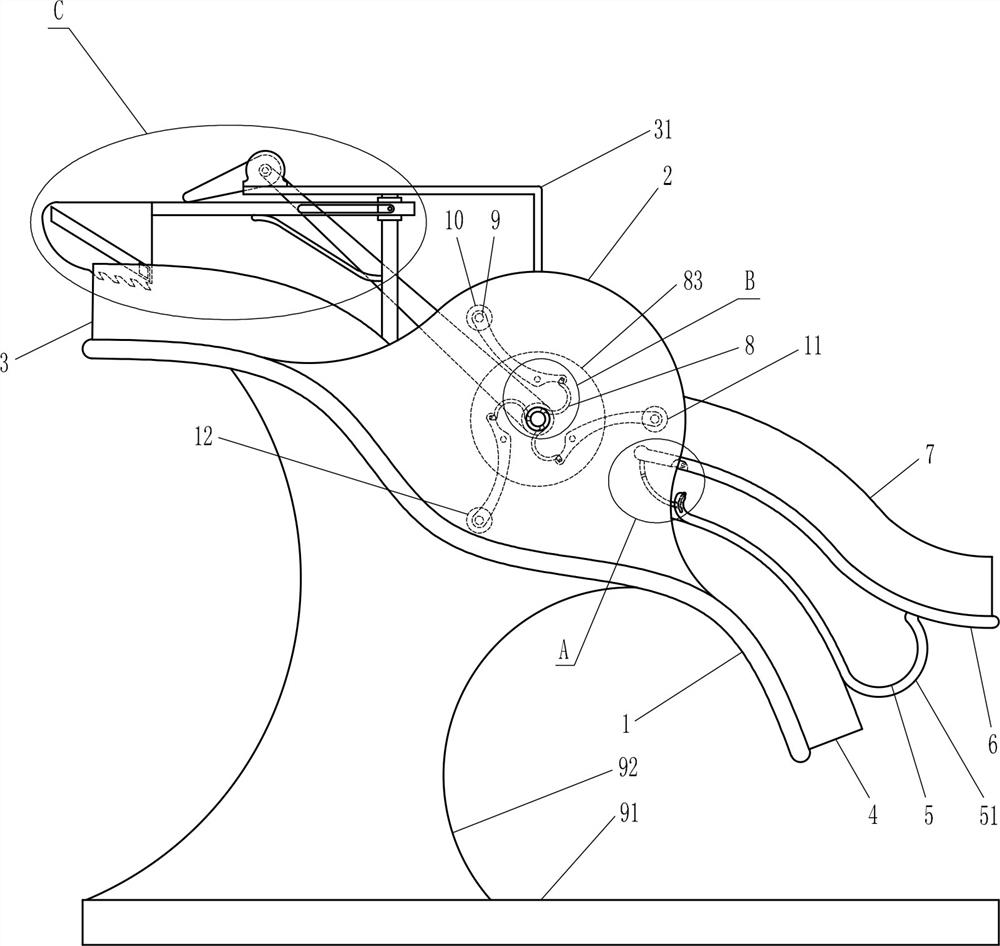

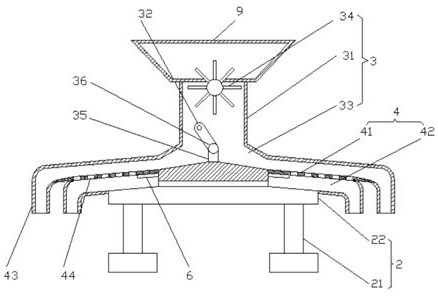

Grape sorting operation platform

InactiveCN114472233AControl ingressAvoid damageSortingFood treatmentAgricultural engineeringProcess engineering

The invention discloses a grape sorting operation platform which is mainly formed by combining a controller (1), a feeding device (2), a material dispersing device (3), a sorting device (4) and a recycling device (5). According to the grape sorting operation platform, the feeding amount of grapes each time can be effectively controlled through a weighing device, a warning lamp and an electric control bin gate, the grapes are prevented from being damaged at a feeding port section, and the working efficiency is improved. The material dispersing device can disperse grapes entering in piles through vibration and flatly lay the grapes on a material dispersing belt, it can be ensured that the grapes are kept in a flatly-laid state when entering the sorting device, the grapes are prevented from being squeezed and damaged by one another, on the other hand, sorting work of workers is facilitated, the sorting device is divided into three parts for flow division, and the sorting efficiency is improved. A worker sorts one sorting device independently, grape damage caused by mutual influence of the workers is prevented, the device is simple in structure and convenient to operate, the utilization rate of raw materials is effectively increased, the quality of the raw materials of the grape wine is improved, and the production cost is reduced.

Owner:湖南唯楚果汁酒业有限公司

Anti-blocking ore raw material sorting device

ActiveCN110653061AAvoid foulingConvenient sorting workMagnetic separationMetallurgyMechanical engineering

The invention relates to an ore sorting device, in particular to an anti-blocking ore raw material sorting device. With the anti-blocking ore raw material sorting device avoided, a straight-up and straight-down feeding mode can be avoided; and smooth sorting work can be facilitated. The anti-blocking type ore raw material sorting device comprises a large arc-shaped material guide plate, large arc-shaped mounting plates, a left arc-shaped baffle and a right arc-shaped baffle; the two large arc-shaped mounting plates are fixedly connected to the upper side surface of the large arc-shaped material guide plate; and the two large arc-shaped mounting plates are arranged in a front-back symmetrical mode. According to the anti-blocking ore raw material sorting device of the invention, the large arc-shaped material guide plate is adopted; ore raw materials can be fed through the weight of the ore raw materials; the straight-up and straight-down feeding mode can be avoided; the ore raw materialsare prevented from being deposited and blocked; frequent shutdown for cleaning is not needed; sorting work is facilitated; a rotary sorting device can stir the ore raw materials; a blockage problem is prevented; sorting efficiency is high; and a sorting effect is good.

Owner:醴陵金源矿业有限公司

Sorting auxiliary device for manual assembly line small article packaging

ActiveCN112774997AImprove sorting effectRealize the preprocessing functionSortingElectric machineProcess engineering

The invention belongs to the technical field of sorting auxiliary devices, and discloses a sorting auxiliary device for manual assembly line small article packaging. The sorting auxiliary device comprises a workbench, a moving motor and a transmission device, the moving motor is located at the bottom of the workbench, the moving motor is in transmission connection with the transmission device, a rotating column is fixedly installed in the middle of the workbench through a bearing, the rotating column is in transmission connection with a moving motor through a transmission device, and the outer surface of the rotating column is fixedly sleeved with a conveying belt. According to the sorting auxiliary device, secondary sorting is conducted on the small articles with the medium sizes and the large sizes through the moving column and the sorting device, and the small articles with the small sizes, the small articles with the medium sizes and the small articles with the large sizes are sorted into a small collecting device, a first collecting box and a second collecting box through a first drainage device, a second drainage device and a first sorting box correspondingly; compared with the prior art, the sorting auxiliary device can automatically distinguish the sizes of the small articles and complete the sorting function and has the advantage of good sorting effect.

Owner:QINGDAO YILONG PACKAGING MACHINERY

An anti-clogging ore raw material sorting device

ActiveCN110653061BAvoid foulingConvenient sorting workMagnetic separationMining engineeringMechanical engineering

The invention relates to an ore sorting device, in particular to an anti-blocking ore raw material sorting device. With the anti-blocking ore raw material sorting device avoided, a straight-up and straight-down feeding mode can be avoided; and smooth sorting work can be facilitated. The anti-blocking type ore raw material sorting device comprises a large arc-shaped material guide plate, large arc-shaped mounting plates, a left arc-shaped baffle and a right arc-shaped baffle; the two large arc-shaped mounting plates are fixedly connected to the upper side surface of the large arc-shaped material guide plate; and the two large arc-shaped mounting plates are arranged in a front-back symmetrical mode. According to the anti-blocking ore raw material sorting device of the invention, the large arc-shaped material guide plate is adopted; ore raw materials can be fed through the weight of the ore raw materials; the straight-up and straight-down feeding mode can be avoided; the ore raw materialsare prevented from being deposited and blocked; frequent shutdown for cleaning is not needed; sorting work is facilitated; a rotary sorting device can stir the ore raw materials; a blockage problem is prevented; sorting efficiency is high; and a sorting effect is good.

Owner:醴陵金源矿业有限公司

A solid waste sorting device

ActiveCN112157112BFunction increaseRealize processingGas current separationUsing liquid separation agentEnvironmental engineeringMechanical engineering

The invention relates to the technical field of sorting equipment, and discloses a solid waste sorting device, which includes a bottom plate, a vertical pipe is fixedly connected to the top surface of the bottom plate, and a feeding funnel is fixedly connected to the top surface of the vertical pipe. A mounting groove is opened on the left side of the vertical pipe, and a fan is fixedly installed on the inner surface of the mounting groove. The solid waste sorting device connects the bottom of the upper material box with the lower material box, and the rotating shaft is movably connected to the inside of the lower material box. The light waste that enters the upper material box and falls into the lower material box is crushed, and the crushed light waste falls into the collection box, which realizes the treatment of light waste in a timely and effective manner and avoids additional collection and transportation of light waste. The high-quality waste is transferred to the crushing treatment equipment, which shortens the treatment process, reduces the treatment time, improves the treatment efficiency, expands the function of the sorting device, and has a good use effect.

Owner:深圳市前海极智创新科技有限公司

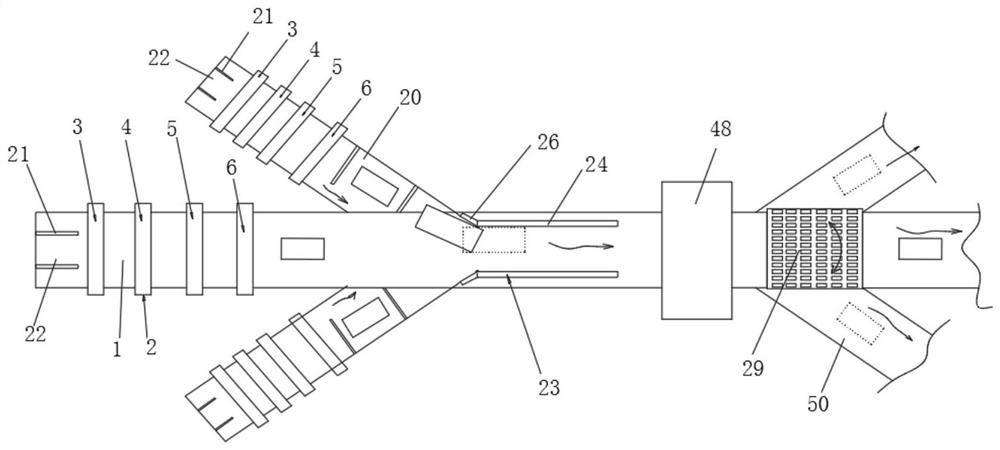

Efficient husking and threshing integrated corn processing equipment and work method thereof

InactiveCN107347371AImprove collection efficiencyAvoid incomplete threshingHarvestersThreshersEngineeringThreshing machine

The invention discloses a work method of efficient husking and threshing integrated corn processing equipment. The efficient husking and threshing integrated corn processing equipment comprises a shell, a husking mechanism, a threshing mechanism and a control device, wherein husking rollers are arranged in the husking mechanism, husk pulling needles are arranged on the husking rollers, and the threshing mechanism is arranged at an outlet of the husking mechanism; cylinders are arranged on the threshing mechanism and internally provided with separating gears used for separating corn from corn pulp, and a corn positioning mechanism is arranged at the position, at the inlet ends of the cylinders, on the shell; the husking mechanism, the threshing mechanism and the corn positioning mechanism are all connected with the control device. A husking machine and a threshing machine are integrated, so that the corn harvesting efficiency is greatly improved, and integration is achieved; meanwhile, the corn positioning mechanism is arranged on the threshing mechanism, so that the threshing precision is greatly improved. The invention further relates to the work method of the efficient husking and threshing integrated corn processing equipment.

Owner:TAICANG SAM LVFENG AGRI PROD SPECIALIZED COOP

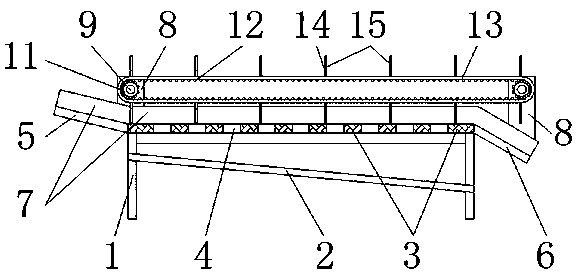

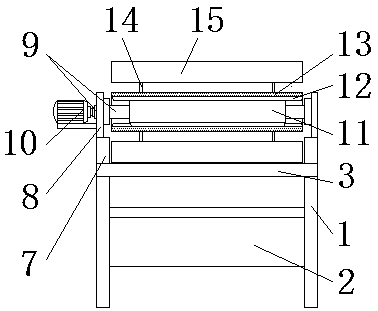

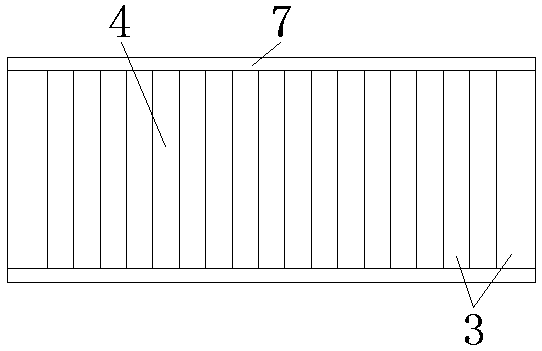

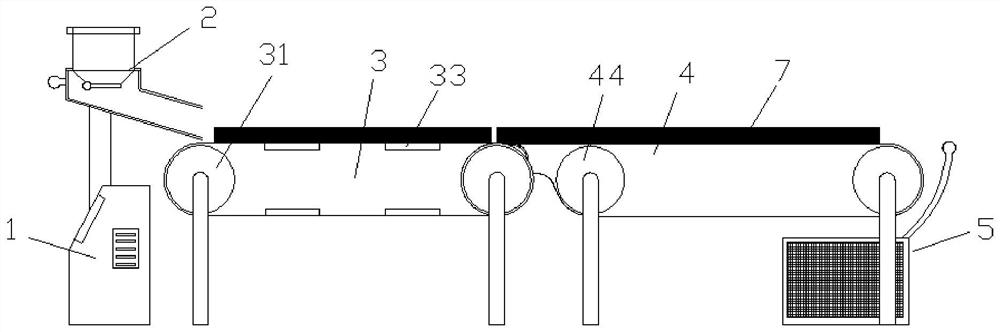

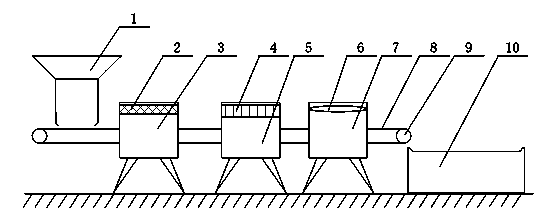

Tea sorting production line device

InactiveCN103504031AReduce sorting costsConvenient sorting workPre-extraction tea treatmentProduction lineElectric machinery

The invention relates to a tea sorting production line device. The tea sorting production line device comprises a feed hopper, an electrostatic generator, a sorting light-matter suction tank, a magnet, a strongly-magnetic adsorption tank, a UV generator, a sterilization tank, a conveyer belt, rotating rollers and a packaging table. The feed hopper is arranged at the upper part in front of the conveyer belt; the conveyer belt passes through the sorting light-matter suction tank, the strongly-magnetic adsorption tank and the sterilization tank in sequence; the electrostatic generator is fixed on the inner wall of the sorting light-matter suction tank; the magnet is fixed on the inner wall of the strongly-magnetic adsorption tank, the UV generator is fixed on the inner wall of the sterilization tank, the packaging table is arranged below the tail end of the conveyer belt, the rotating rollers are arranged at two ends of the conveyer belt; and the rotating rollers are driven by a motor to run. The production line device can automatically complete the tea sorting operation in one step with high efficiency and low labor and material consumptions. Besides, the device has a simple structure and is low in manufacturing cost, is easy to operate, greatly reduces the tea sorting cost, and brings great convenience for tea sorting operation.

Owner:李浩

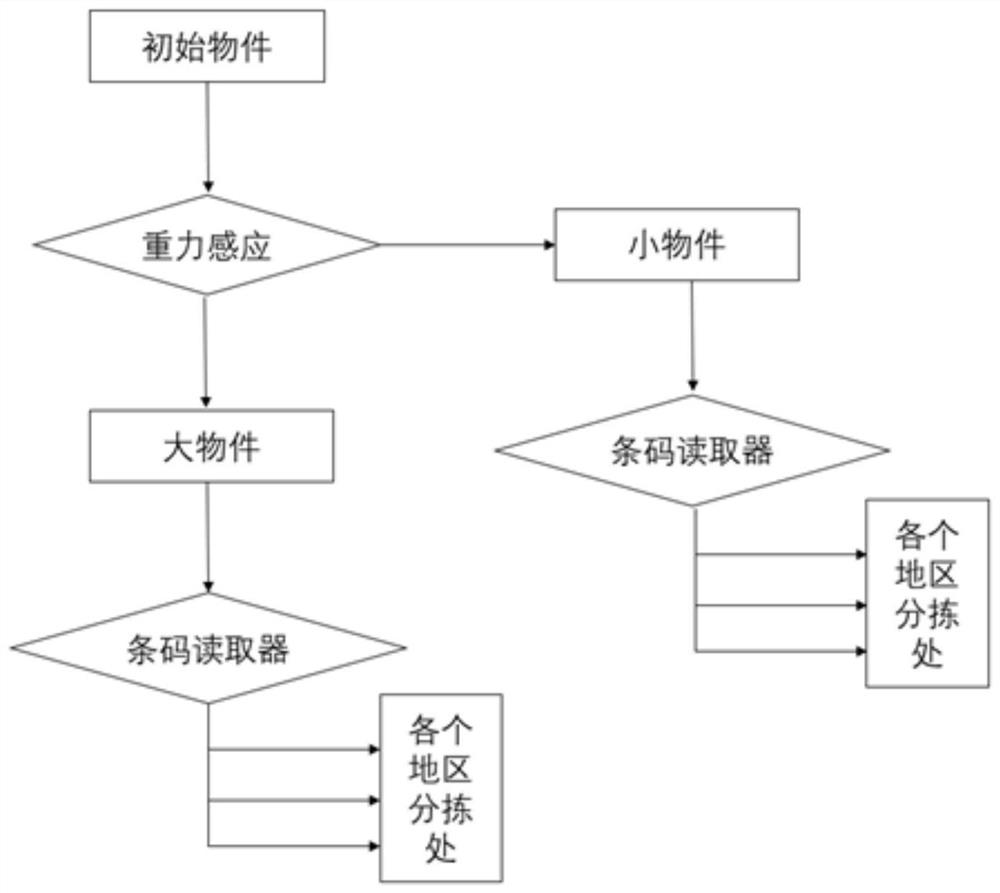

Intelligent emergency material distribution system

ActiveCN114308688AEasy to sortAvoid cumbersomeSortingTotal factory controlLogistics managementEngineering

The invention belongs to the technical field of logistics, and discloses an intelligent emergency material distribution system which comprises a conveying rack, an acceleration belt system and a two-dimensional code recognition assembly are arranged on the conveying rack, a weight sensor is arranged at the position, at the feeding end of the acceleration belt system, of the conveying rack, and a partition plate used for separating large objects from small objects is installed on the conveying rack. The conveying rack is further provided with an object guiding mechanism used for guiding the large objects and the small objects into the two sides of the partition plate correspondingly. In the application, the weight sensor can weigh the weight of an object, the two-dimensional code recognition assembly can scan a two-dimensional code on the object, the two-dimensional code recognition assembly can scan the size of the object, and when the weight sensor cooperates with the two-dimensional code recognition assembly and judges that the object is a large object, the object guiding mechanism starts to act, and the object guiding mechanism can guide the object to move. In this way, the large objects and the small objects enter the acceleration belt systems on the two sides of the partition plate correspondingly, the trouble of manually distinguishing the large objects and the small objects is omitted, and workers can sort the objects of different sizes conveniently.

Owner:南京工业大学浦江学院

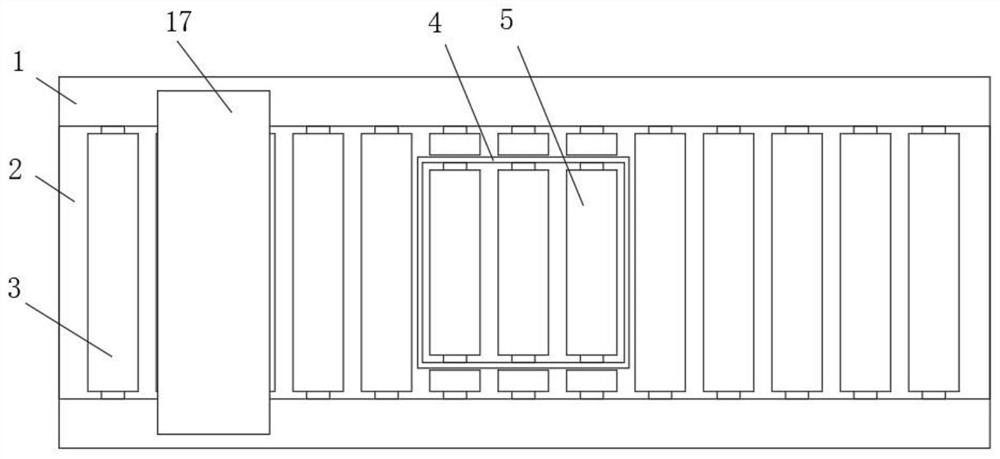

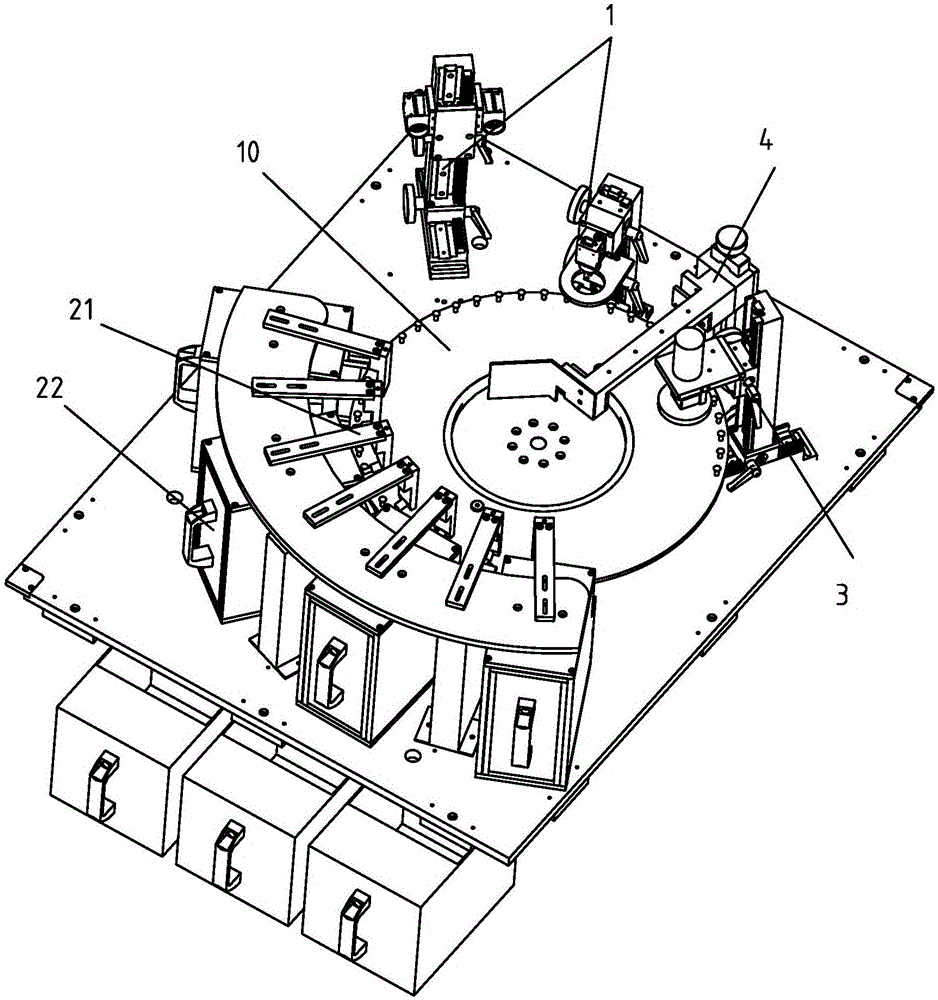

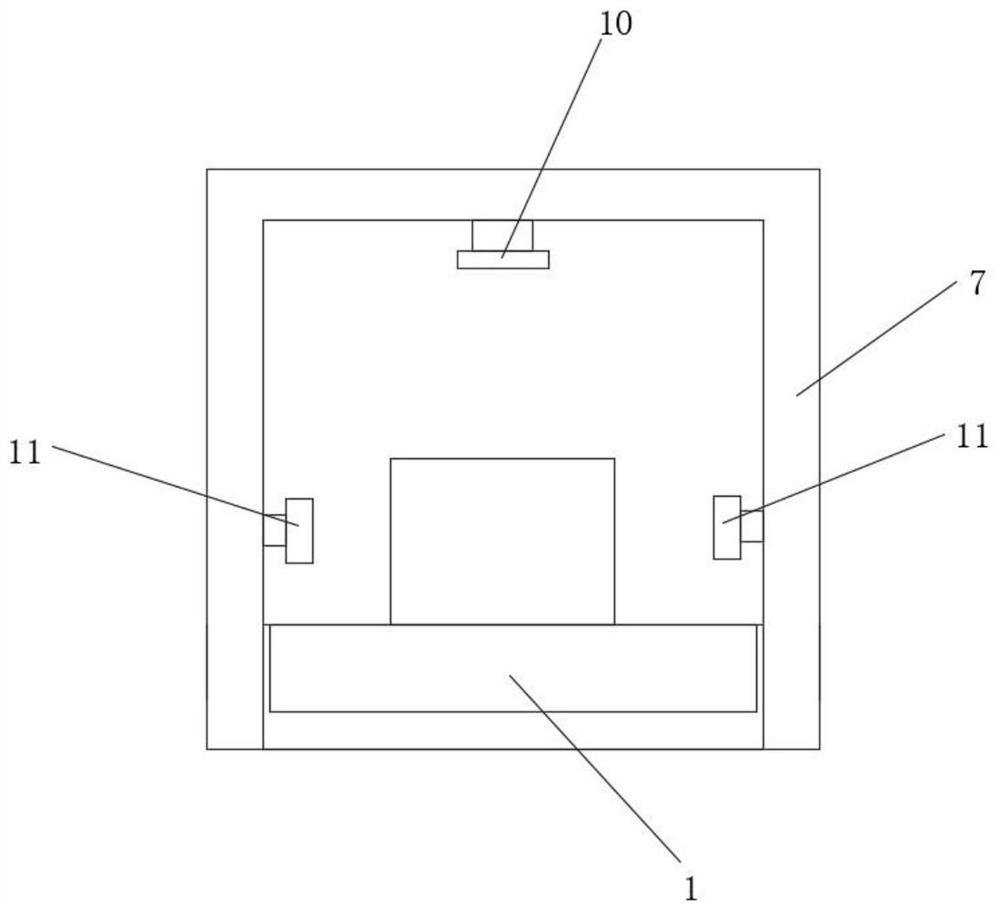

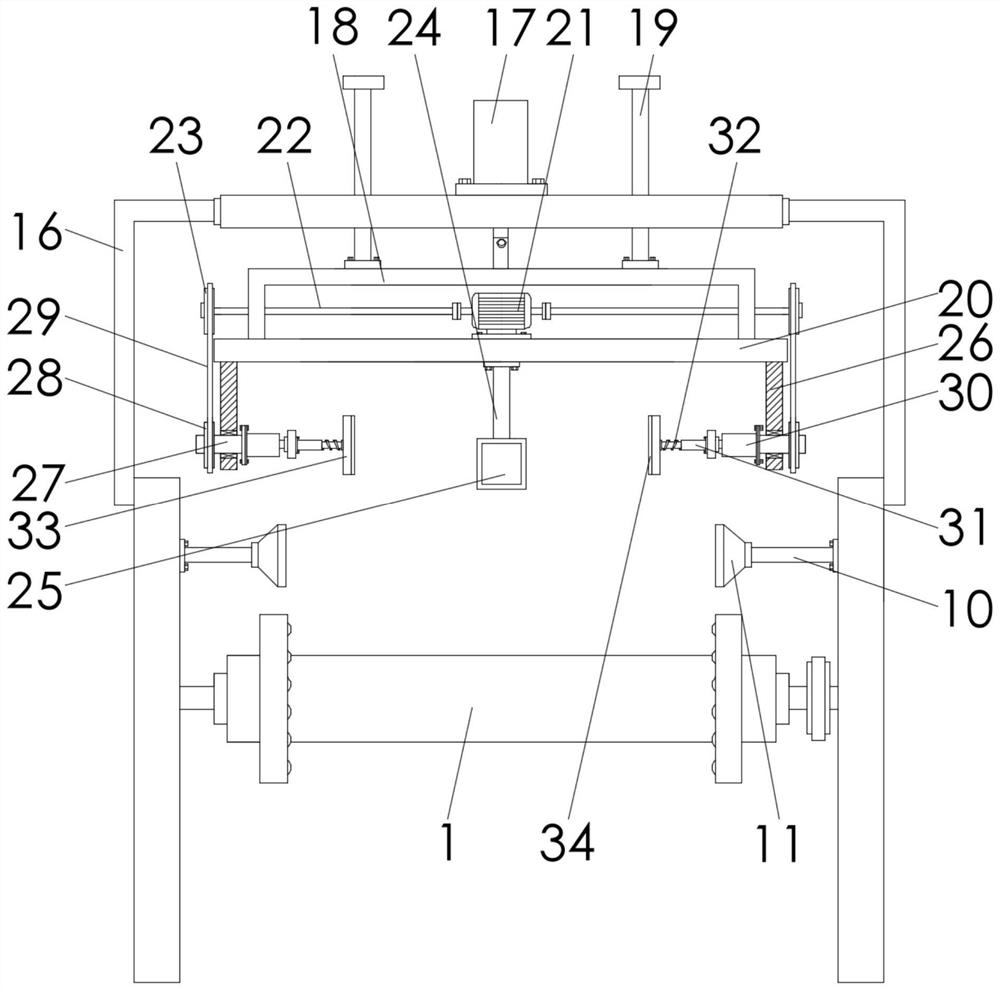

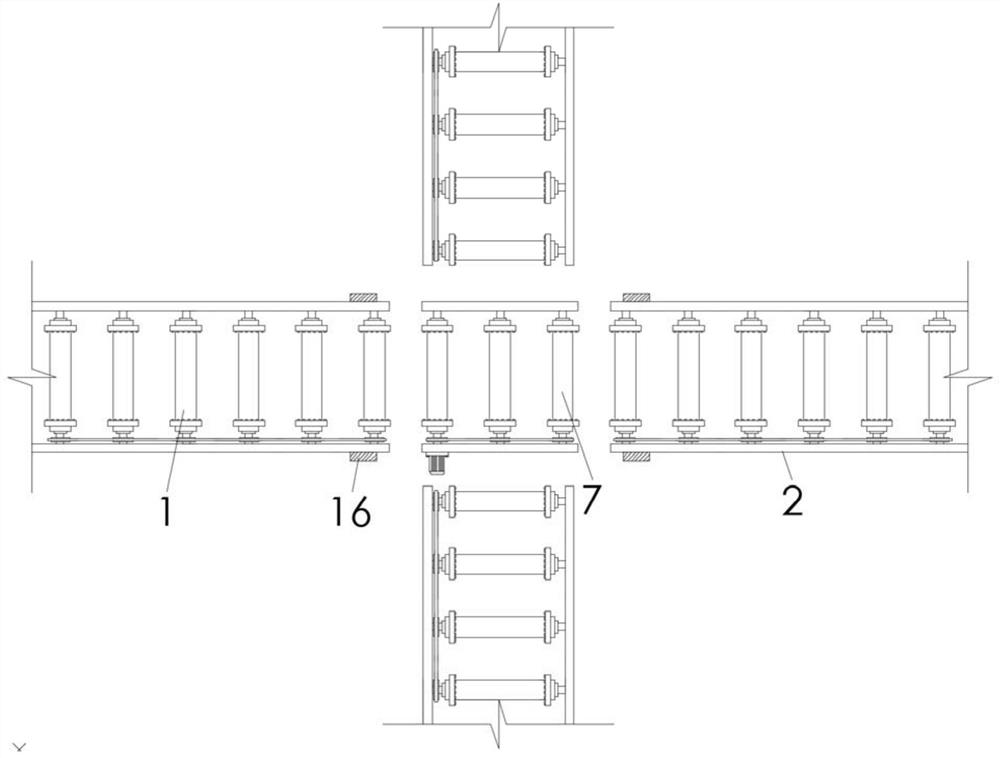

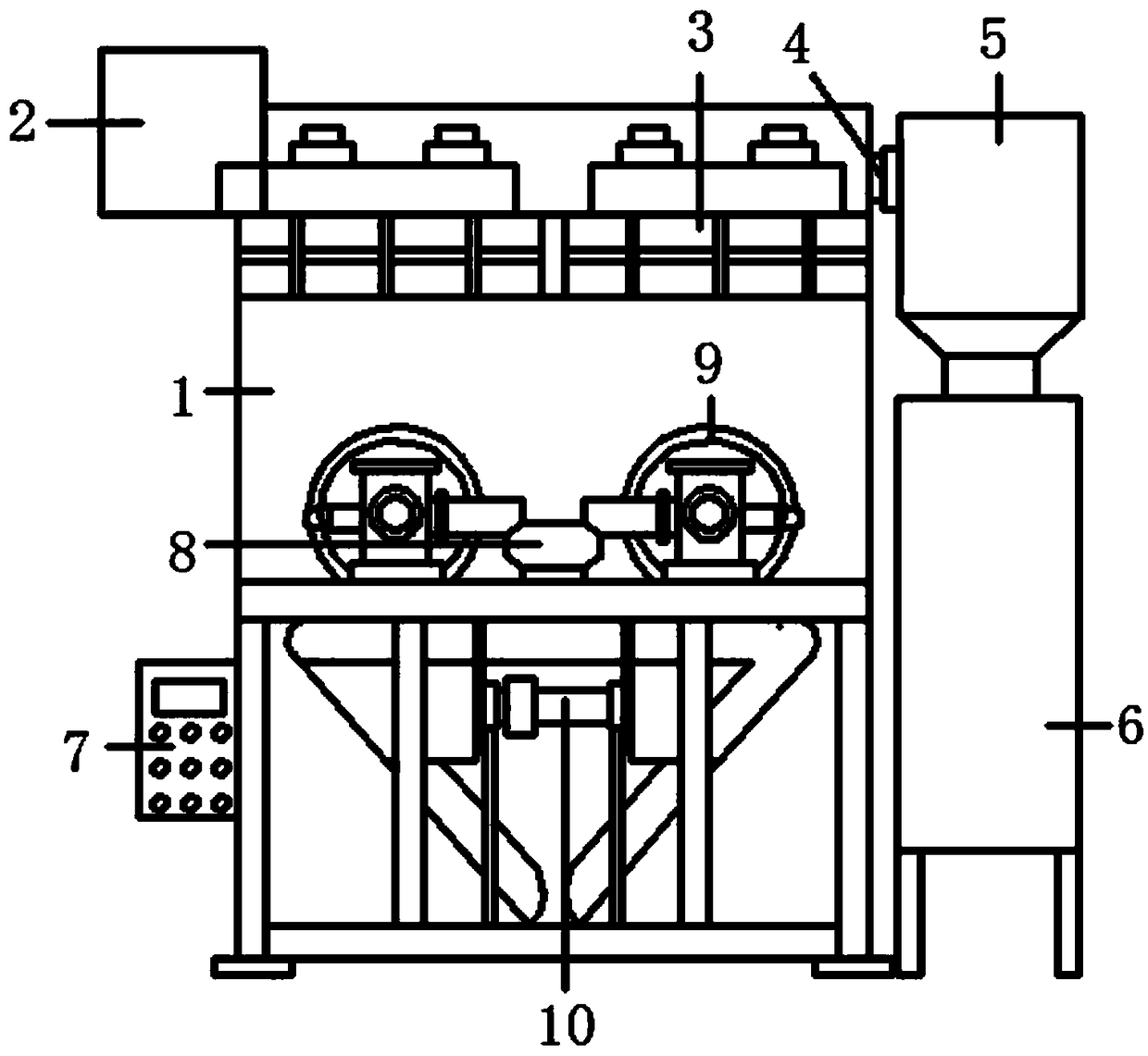

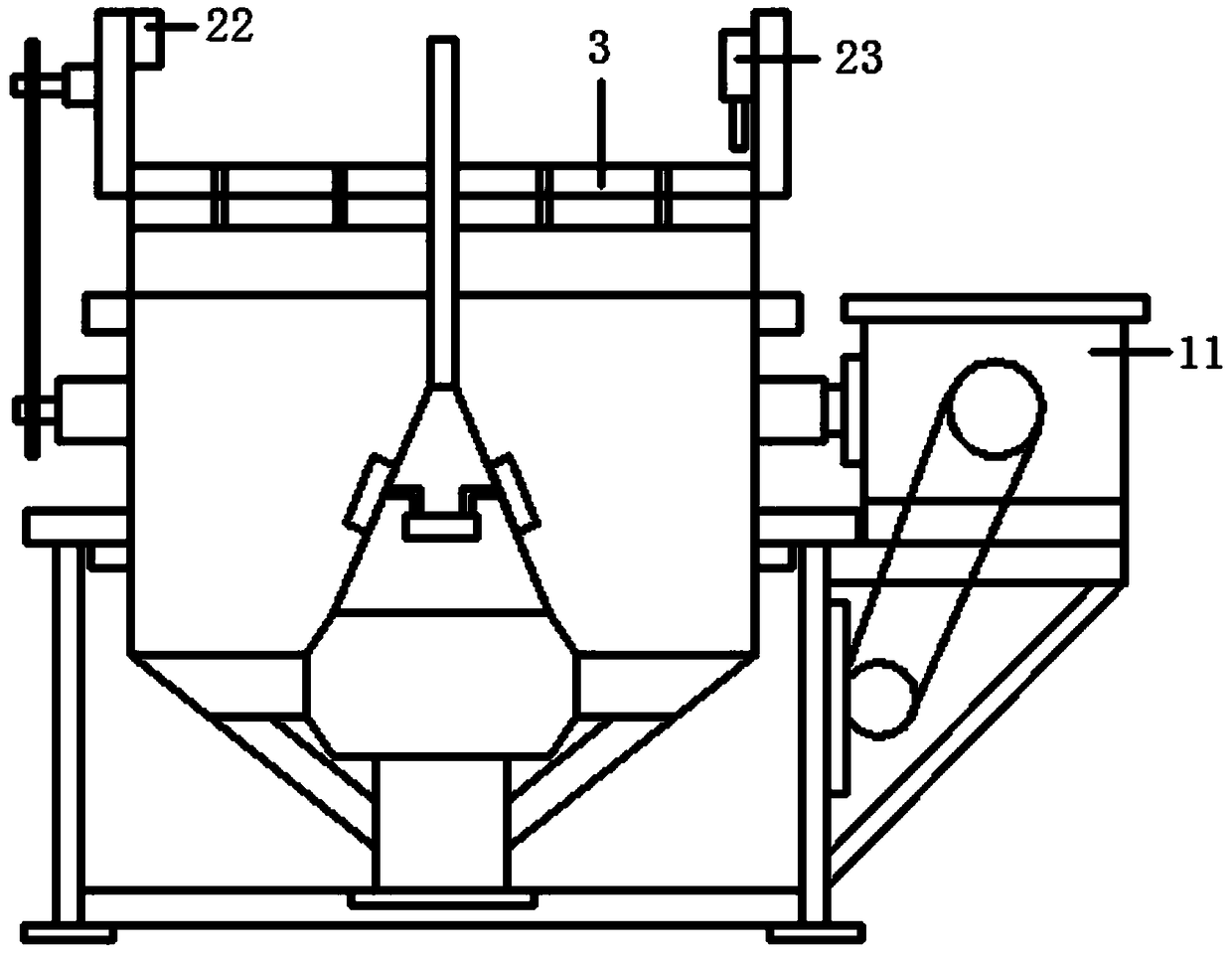

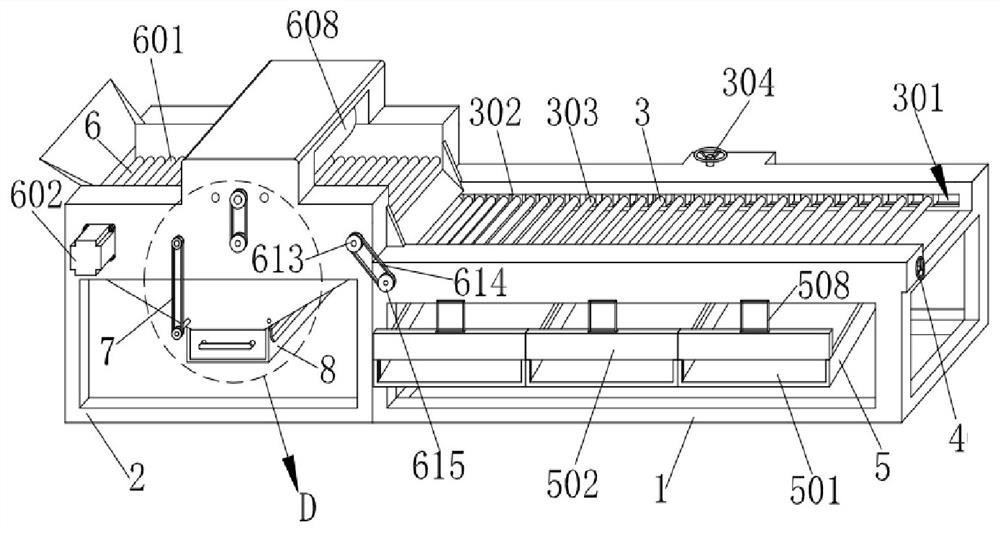

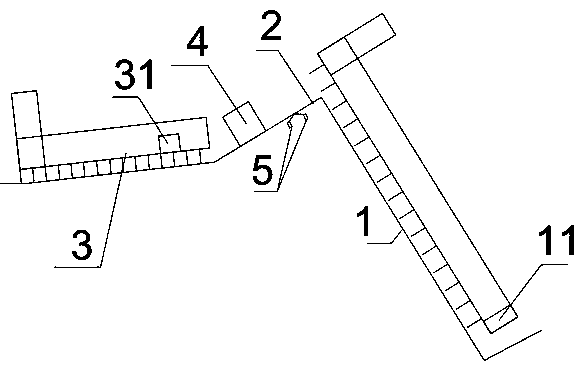

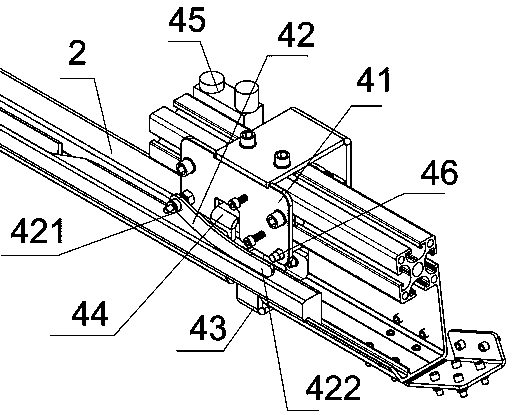

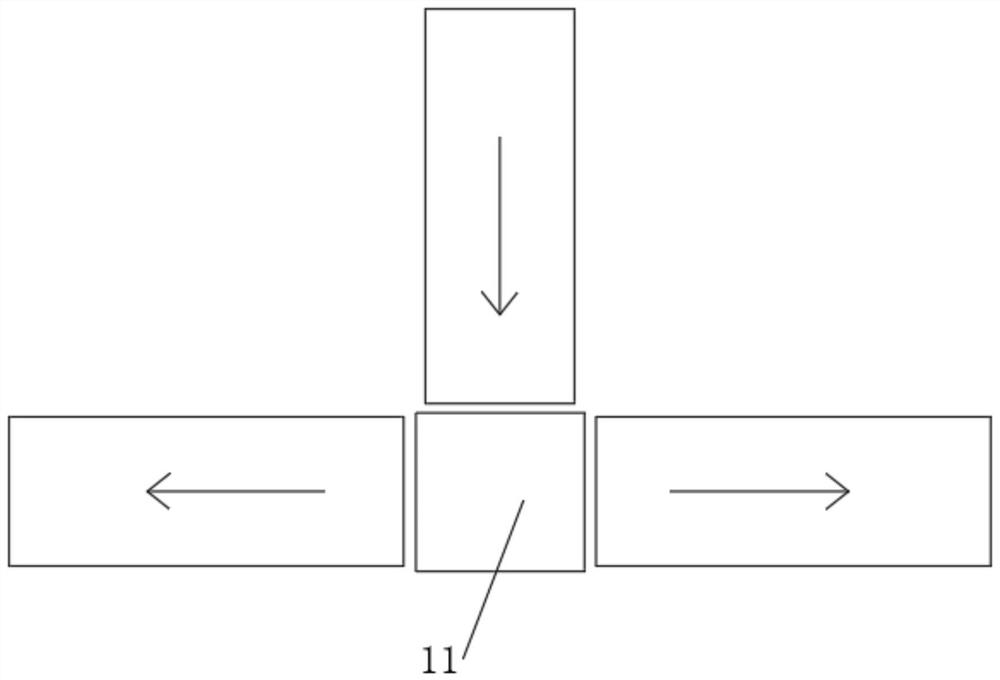

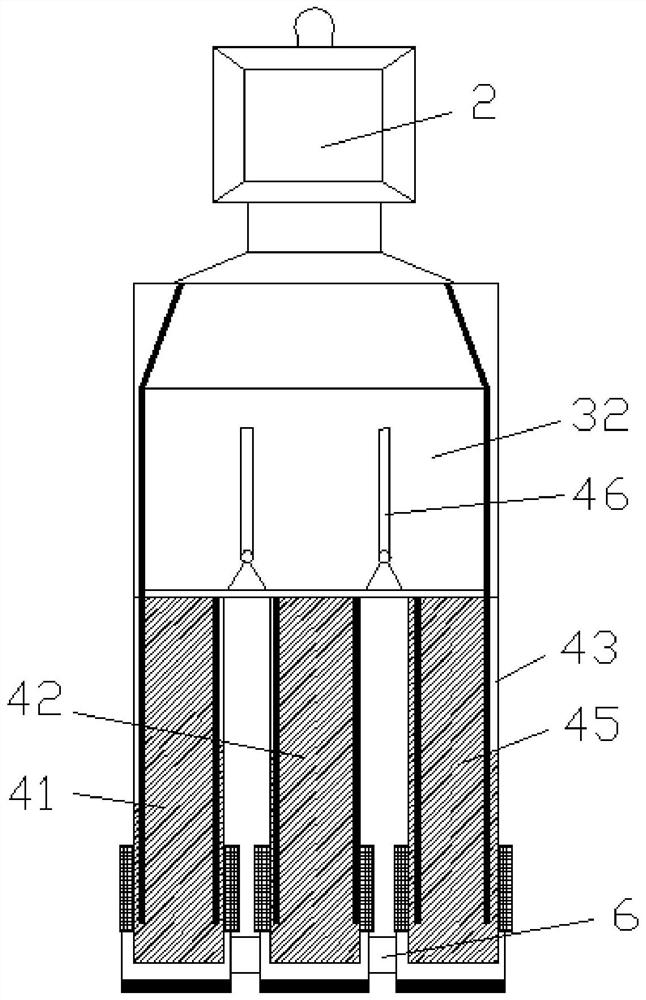

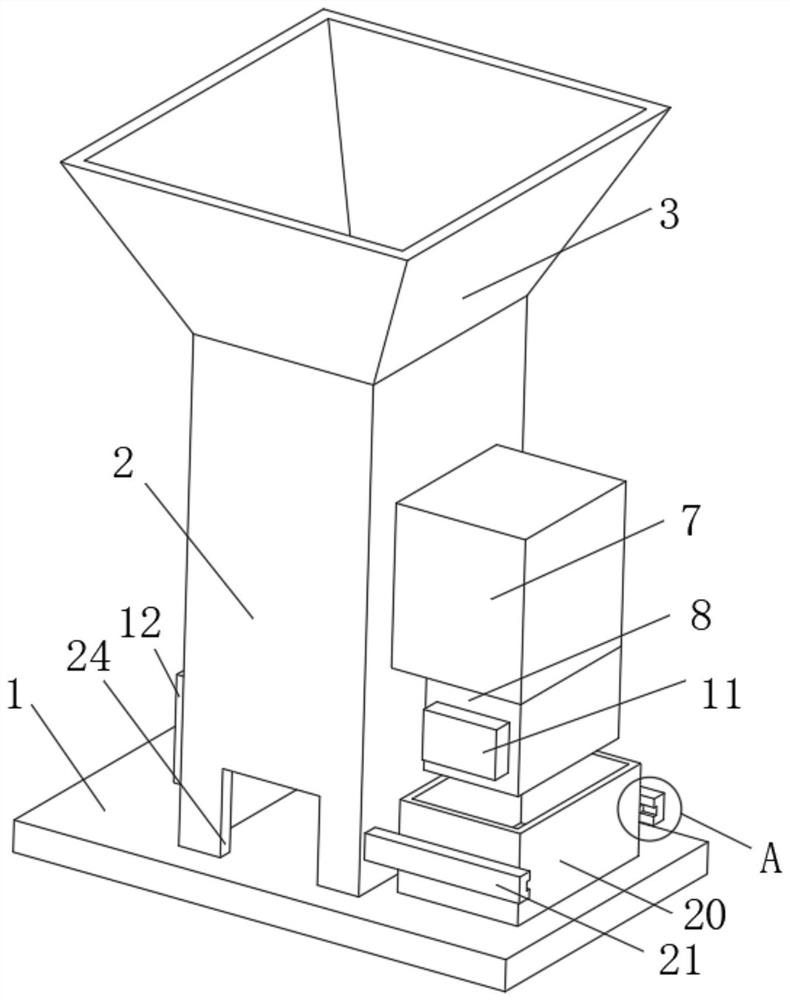

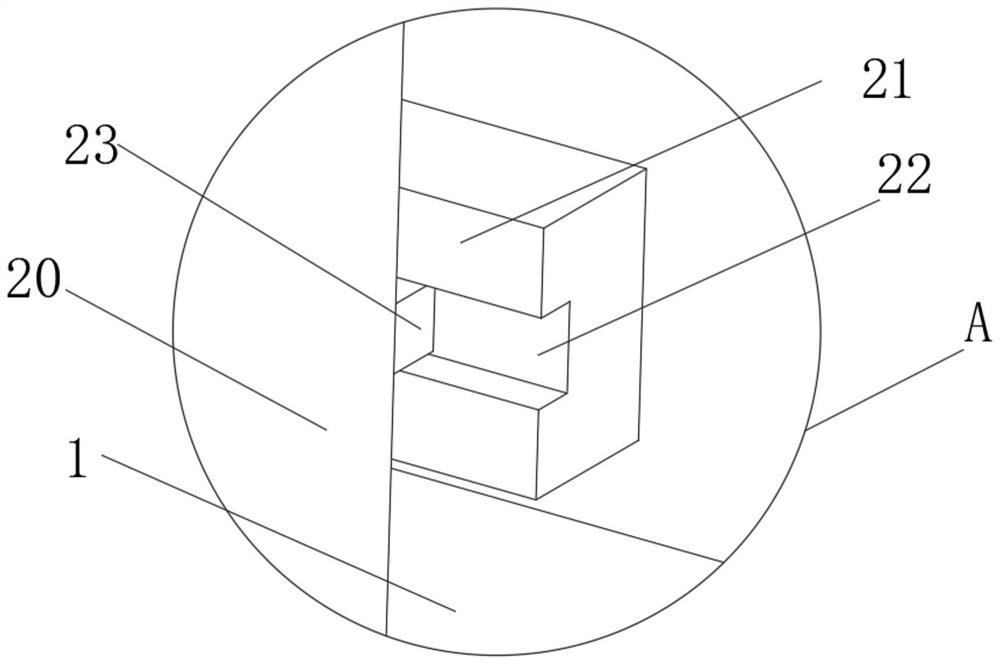

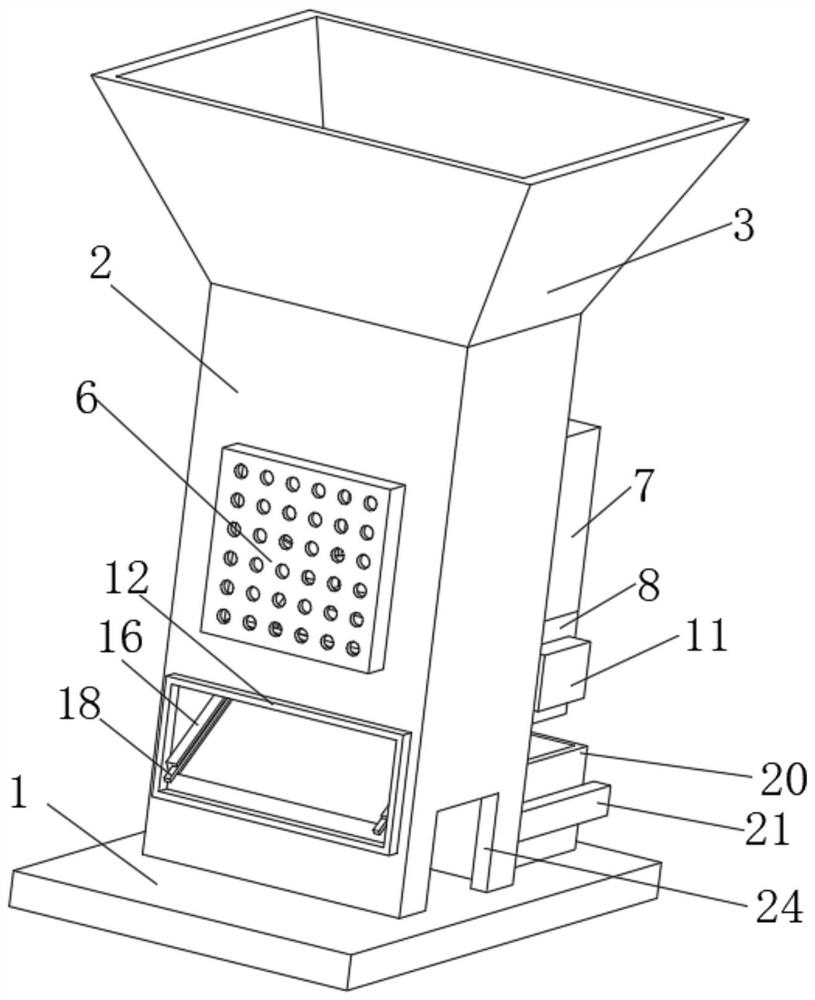

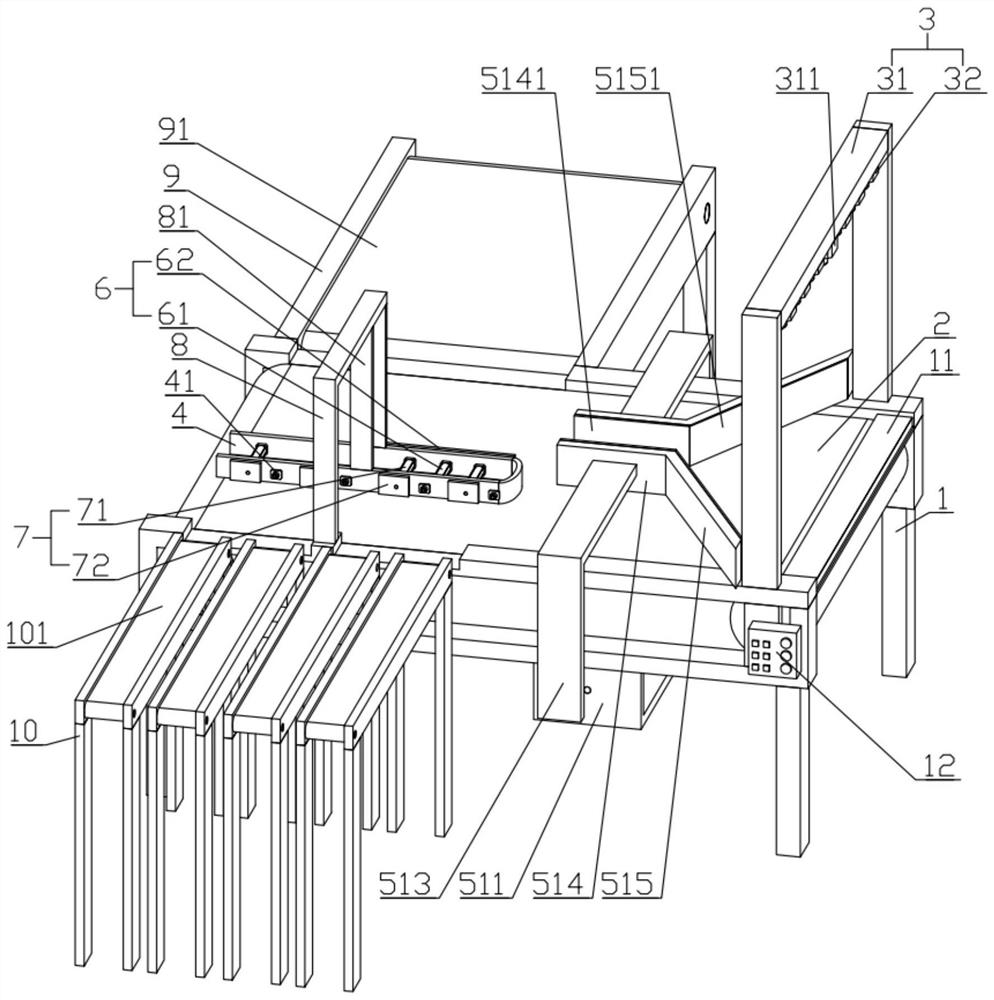

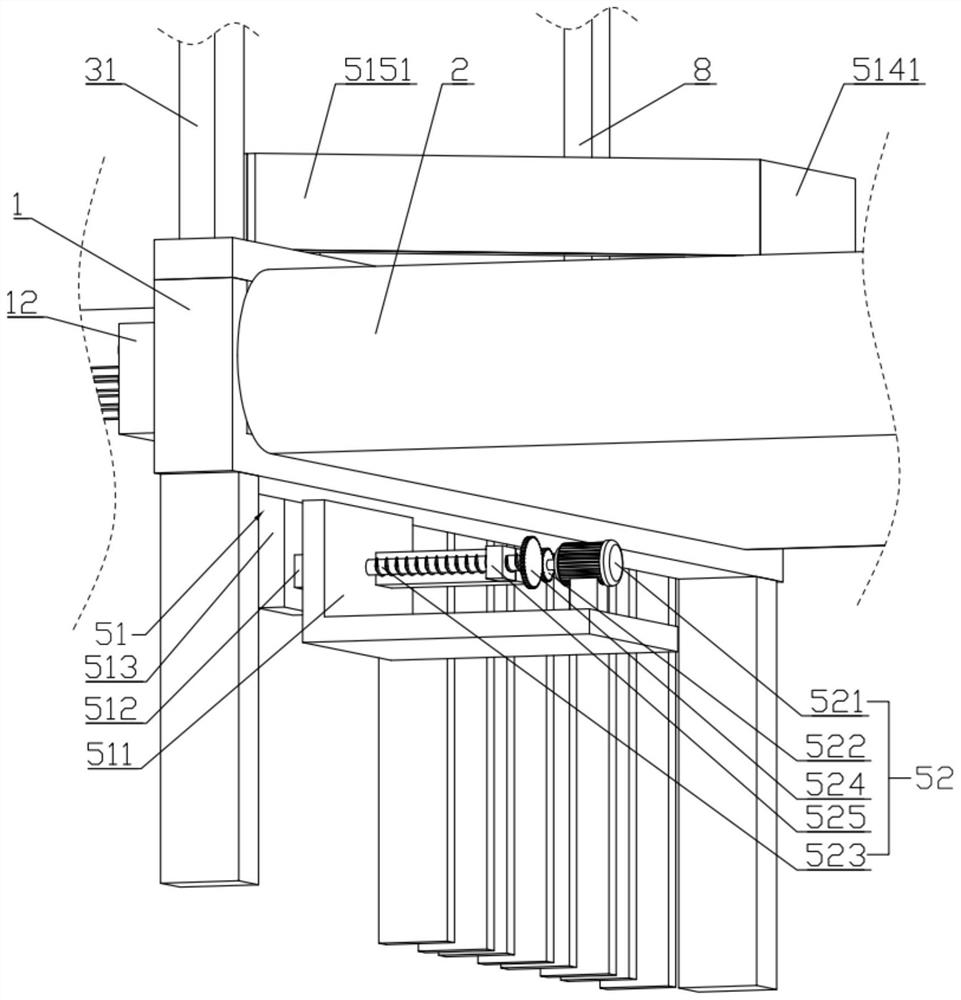

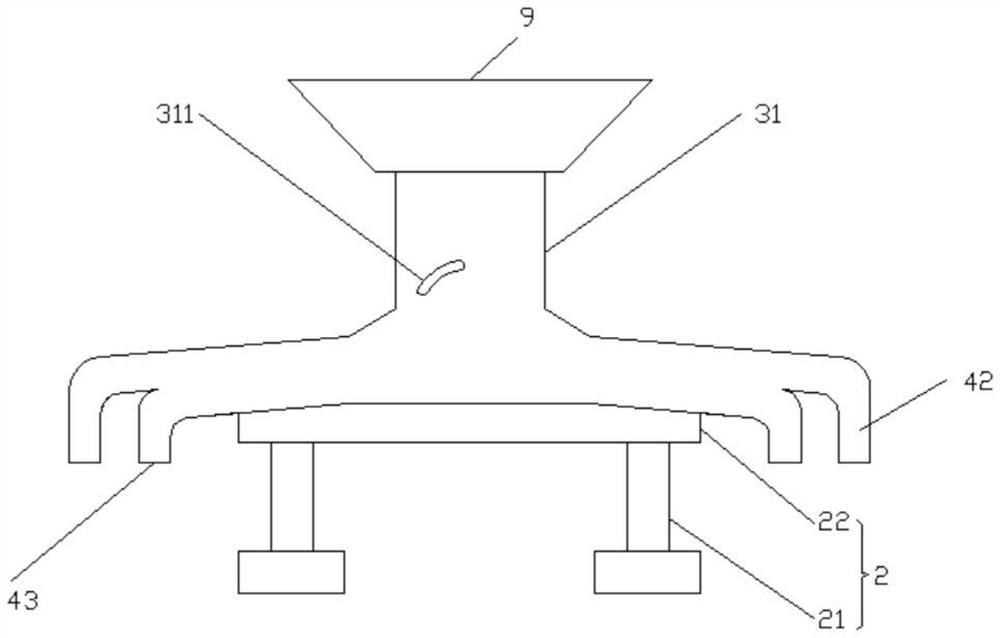

A multi-stage automatic sorting machine for agricultural products

ActiveCN107670996BEasy to sortEasy for secondary sortingSievingScreeningAgricultural scienceAgricultural engineering

The invention discloses an automatic multi-stage sorting machine for agricultural products. The automatic multi-stage sorting machine comprises a control cabinet (1) and a rack (2). The automatic multi-stage sorting machine is characterized in that a first-stage sorting device (3) and second-stage sorting devices (4) are arranged on the surface of the rack (2); the rack (2) comprises support rods(21) and a fixing rod (22); the support rods (21) are fixed below the fixing rod (22); the first-stage sorting device (3) is located at the top of the rack (2); the second-stage sorting devices (4) are symmetrically distributed at the left side and the right side of the first-stage sorting device (3); and the control cabinet (1) is fixed to the side of the rack (2). Through the arrangement of thetwo stages of sorting devices, secondary sorting for the agricultural products is facilitated, so that the working efficiency of the sorting machine is increased, and the sorting quality of the sorting machine is improved.

Owner:扬州和信食品有限公司

A sorting device for logistics transportation in response to emergencies

ActiveCN112845111BSimplify work intensityConvenient sorting workSortingLogistics managementVisual inspection

The invention discloses a sorting device for logistics transportation for responding to emergencies, comprising a main conveyor belt on which a packing box position correcting mechanism is arranged, and the packing box position correcting mechanism comprises the following steps in the order of conveying. The first position visual identification mechanism, the first logistics packaging box flanging mechanism, the second position visual identification mechanism and the second logistics packaging box flanging mechanism are provided, and one side of the output end of the main conveyor belt is provided with a logistics label. In the visual inspection mechanism for scanning and identification, the end of the main conveyor belt is provided with a balance wheel logistics sorter, and the ends of the balance wheel logistics sorter are respectively provided with a plurality of connectors for docking the balance wheel logistics sorter. material conveyor belt. The invention ensures that no matter which side the material packing box is affixed with the logistics label, after being corrected by the packing box position correction mechanism, it can be identified by the visual inspection mechanism to read the logistics information on the logistics label, thereby improving the logistics sorting efficiency.

Owner:NANJING INST OF RAILWAY TECH

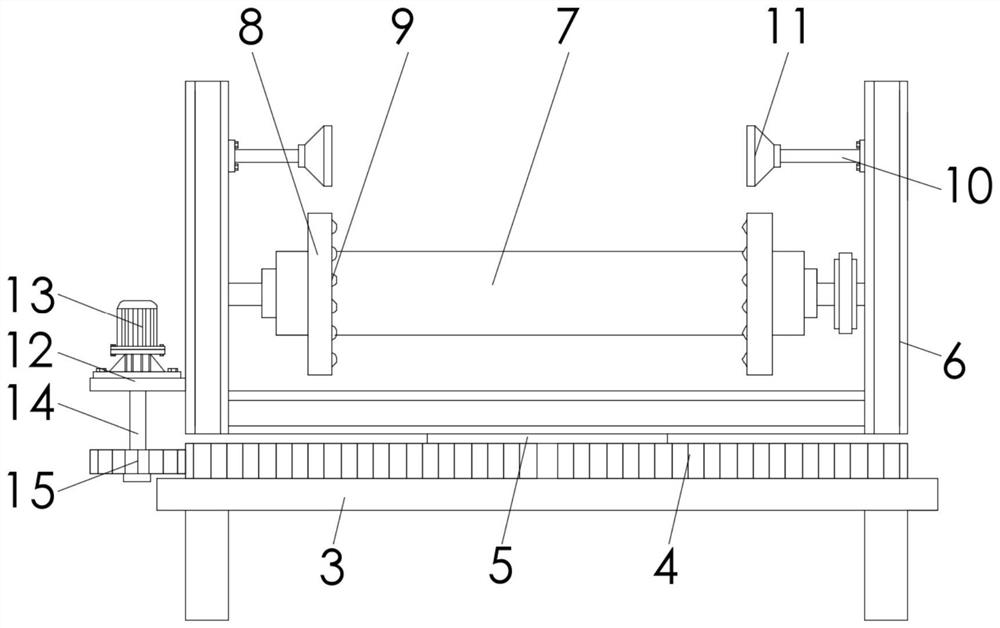

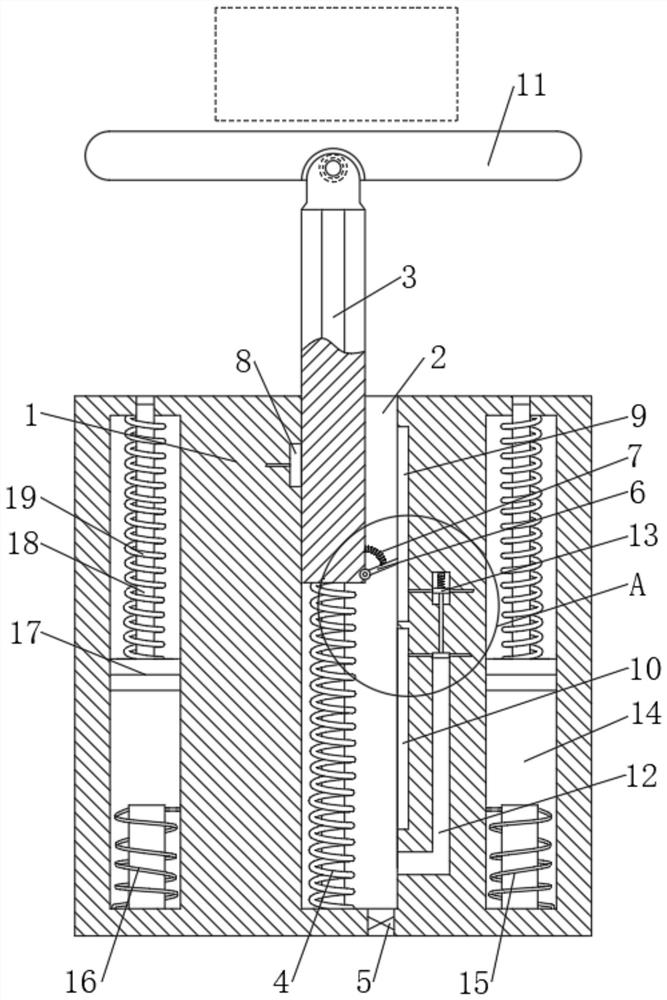

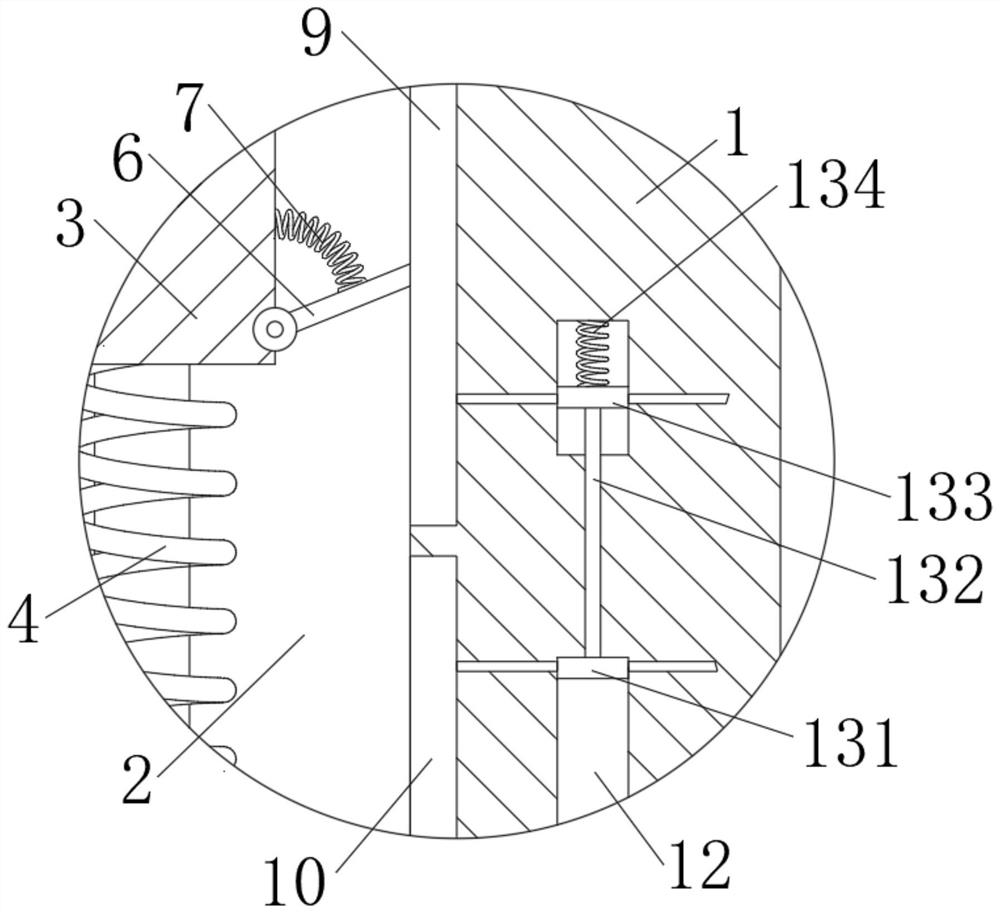

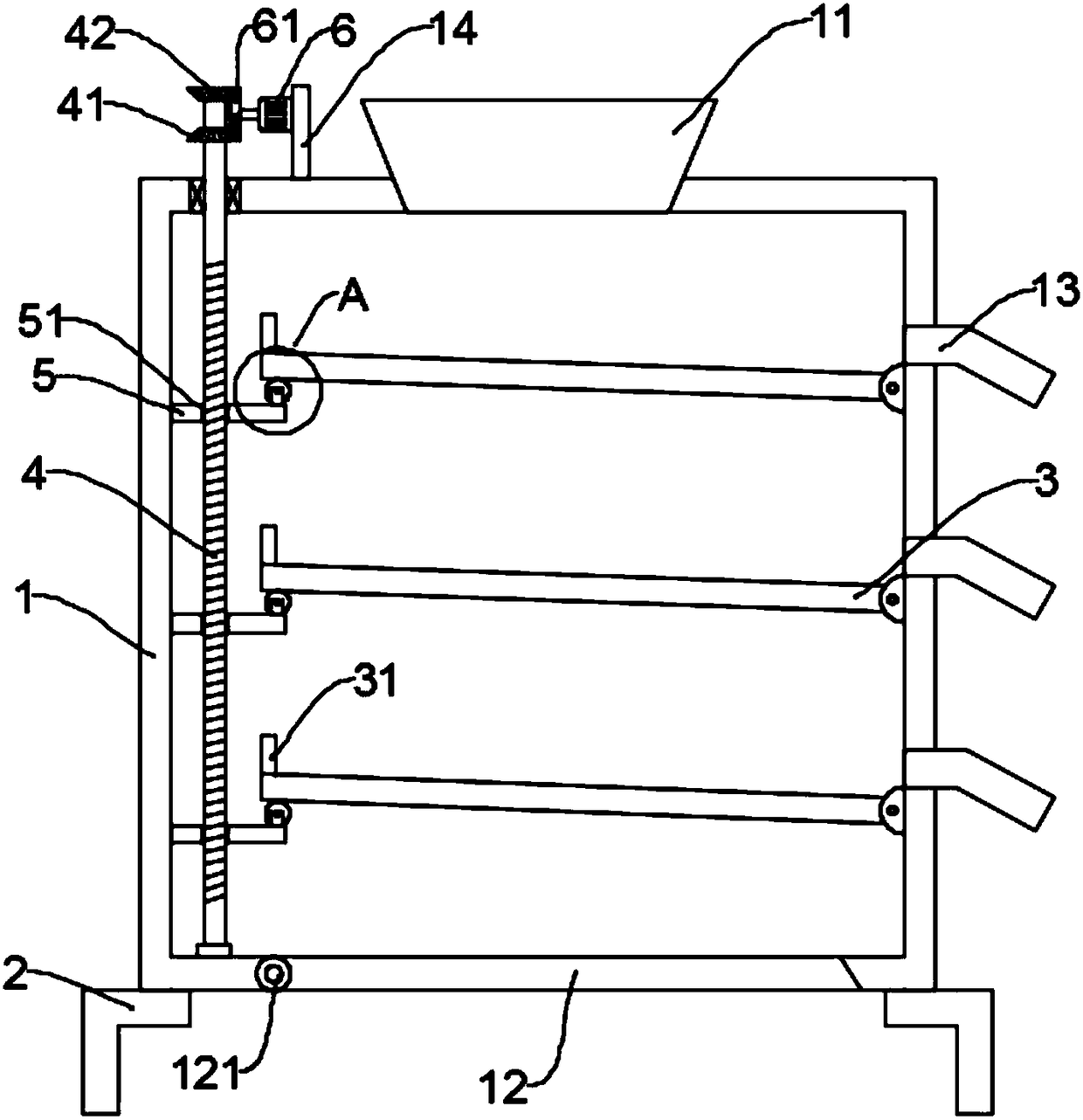

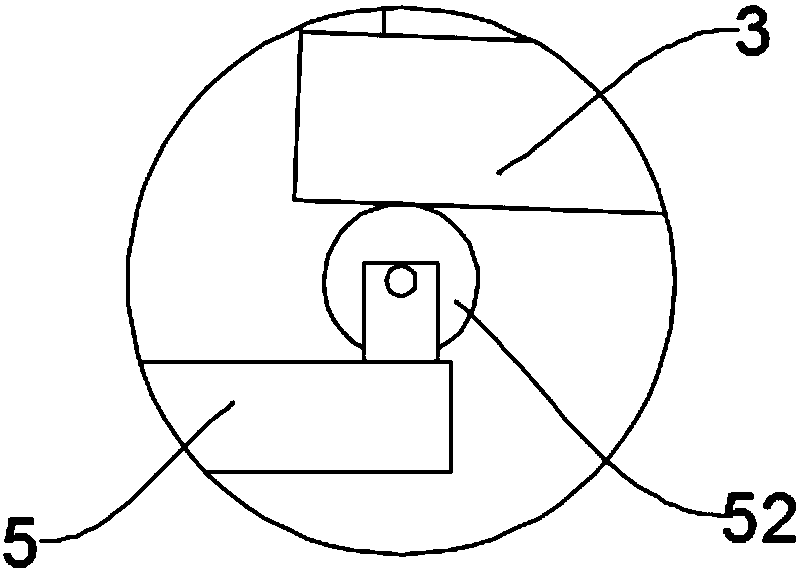

Peanut multi-stage sorting machine with convenient operation

InactiveCN108372110AConvenient sorting workNovel structureSievingScreeningElectric machineryEngineering

The invention discloses a peanut multi-stage sorting machine with convenient operation. The machine comprises a sorting box, screening plates, a screw rod and a motor; multiple screening plates are arranged and equidistantly distributed in an inner cavity of the sorting box from top to bottom, the size of screening holes of the screening plates diminishes sequentially from top to bottom, and the right ends of the screening plates are hinged to the inner cavity wall of the right side of the sorting box; the screw rod is vertically arranged on the left sides of the screening plates, the screw rod is rotatably connected with the sorting box, moving plates corresponding to the screening plates one by one are sleeved with the outer circumference of the rod body of the screw rod, the left ends of the moving plates are slidably clamped on the inner cavity wall of the left side of the sorting box, pulleys are installed on the right sides of the tops of the moving plates, and the outer surfacesof the pulleys are abutted against the lower surfaces of the screening plates. The machine has the advantages of being novel in structure and convenient to operate, by the arrangement of a transmission assembly, multiple screening plates are operated simultaneously through the motor, the manipulating difficulty is reduced, and convenience is provided for peanut sorting operation.

Owner:刘烨

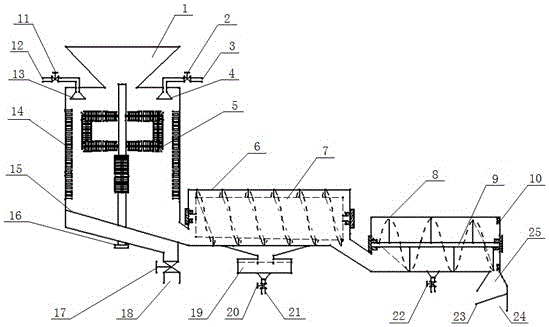

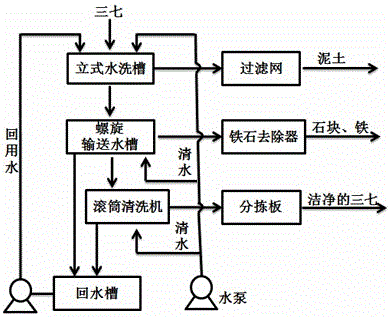

A water-saving type notoginseng tuber cleaning device

ActiveCN104941942BReduce wasteConvenient sorting workCleaning using toolsCleaning using liquidsWater savingSludge

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com