Tea sorting production line device

An assembly line and sorting technology, applied in tea processing before extraction, etc.

Inactive Publication Date: 2014-01-15

李浩

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem that the existing tea sorting machine is expensive and the efficiency of manually sorting tea is low, the present invention provides a tea sorting assembly line device, the assembly line device It can automatically complete tea sorting at one time, with high efficiency, saving manpower and material resources, and the device is simple in structure, low in cost, easy to operate, significantly reduces the cost of tea sorting, and brings great convenience to tea sorting work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

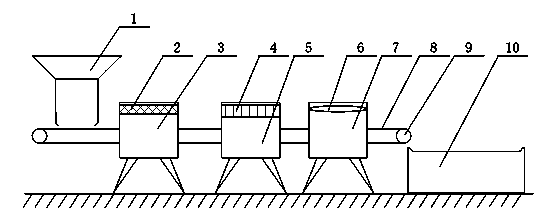

The invention relates to a tea sorting production line device. The tea sorting production line device comprises a feed hopper, an electrostatic generator, a sorting light-matter suction tank, a magnet, a strongly-magnetic adsorption tank, a UV generator, a sterilization tank, a conveyer belt, rotating rollers and a packaging table. The feed hopper is arranged at the upper part in front of the conveyer belt; the conveyer belt passes through the sorting light-matter suction tank, the strongly-magnetic adsorption tank and the sterilization tank in sequence; the electrostatic generator is fixed on the inner wall of the sorting light-matter suction tank; the magnet is fixed on the inner wall of the strongly-magnetic adsorption tank, the UV generator is fixed on the inner wall of the sterilization tank, the packaging table is arranged below the tail end of the conveyer belt, the rotating rollers are arranged at two ends of the conveyer belt; and the rotating rollers are driven by a motor to run. The production line device can automatically complete the tea sorting operation in one step with high efficiency and low labor and material consumptions. Besides, the device has a simple structure and is low in manufacturing cost, is easy to operate, greatly reduces the tea sorting cost, and brings great convenience for tea sorting operation.

Description

technical field [0001] The invention relates to an assembly line device, in particular to a tea sorting assembly line device capable of efficiently and quickly sorting tea leaves. Background technique [0002] Tea sorting is a time-consuming and labor-intensive process in the process of tea processing and packaging, but it is also a very important and key process. The content of impurities in tea directly affects the taste and overall quality of tea, and is related to the economics of tea farmers and tea merchants. Benefits. At present, tea sorting machines on the market are expensive and inconvenient to operate. Therefore, many tea merchants use manpower to sort tea leaves. The efficiency is low and the purity of the sorted tea is poor, which brings difficulties Great inconvenience. Contents of the invention [0003] In order to solve the problem that the existing tea sorting machine is expensive and the efficiency of manually sorting tea is low, the invention provides ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23F3/06

Inventor 李浩李珂

Owner 李浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com