Unmanned logistics express platform system

A platform and logistics technology, which is applied in the field of unmanned logistics express platform system, can solve problems such as low work efficiency, high error rate, complex and large structure, etc., to reduce sorting costs, reduce sorting errors, and improve sorting efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

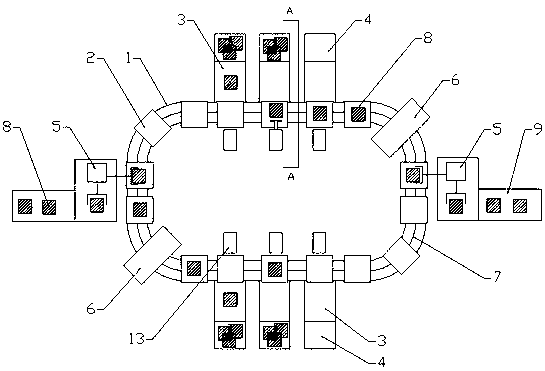

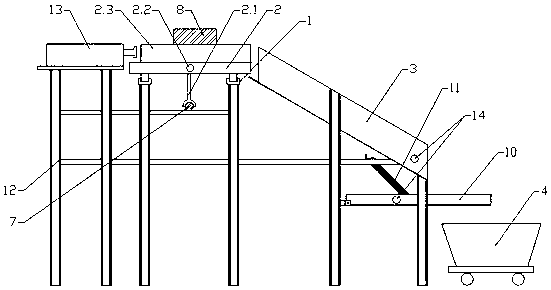

[0023] Embodiment one: if figure 1 As shown, an unmanned logistics express platform system includes a bracket 12, on which an annular track 1 and a power belt 7 are arranged, and a certain number of power units with their own driving devices that can place express parcels 8 are distributed on the annular track 1. Trolley 2, the bottom of the power trolley 2 is equipped with a power connection device 2.1 to connect with the power belt 7, the power belt 7 provides the power to make the power trolley 2 move on the circular track 1, and a number of slideways 3 are provided on the outside of the straight section of the circular track 1. The lower end of the road 3 is provided with a courier storage device 4, and a cylinder structure 13 is provided to make the courier package 8 on the power trolley 2 fall into the slideway 3; at least one multi-arm robot platform 5 is provided on one side of the arc section of the circular track 1, One side of the multi-arm robot platform 5 is provi...

Embodiment 2

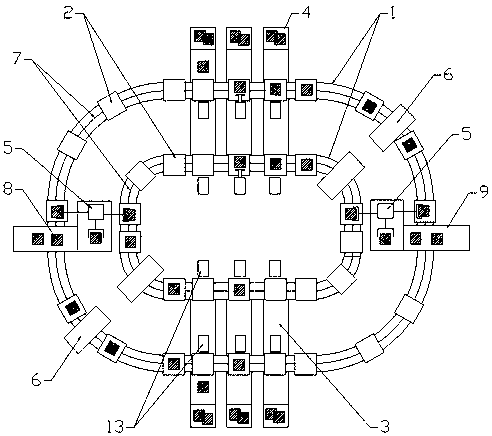

[0025] Embodiment two: as image 3 As shown, the difference from Embodiment 1 is that the annular track 1 and the power belt 7 are two different perimeters, and are concentric structures. Select the position where the express parcel 8 is placed in the situation, which improves the sorting efficiency.

[0026] In the above two embodiments, the cylinder structure 13 can have multiple different installation methods:

[0027] The first one can be installed horizontally on the support 12 on the inner side of the straight section opposite to the slideway 3. During operation, the movable end of the cylinder structure 13 directly pushes the express package 8 to make it fall into the slideway 3.

[0028] The second type can be installed vertically on the bracket 12 at the bottom of the straight section opposite to the slideway 3. During operation, the movable end of the cylinder structure 13 lifts the inner side of the power trolley 2, and after turning it over at a certain angle, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com