A treatment system for kitchen waste

A treatment system, kitchen waste technology, applied to the removal of solid waste, etc., can solve the problems of large consumption, poor sorting effect, difficult follow-up treatment of garbage, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

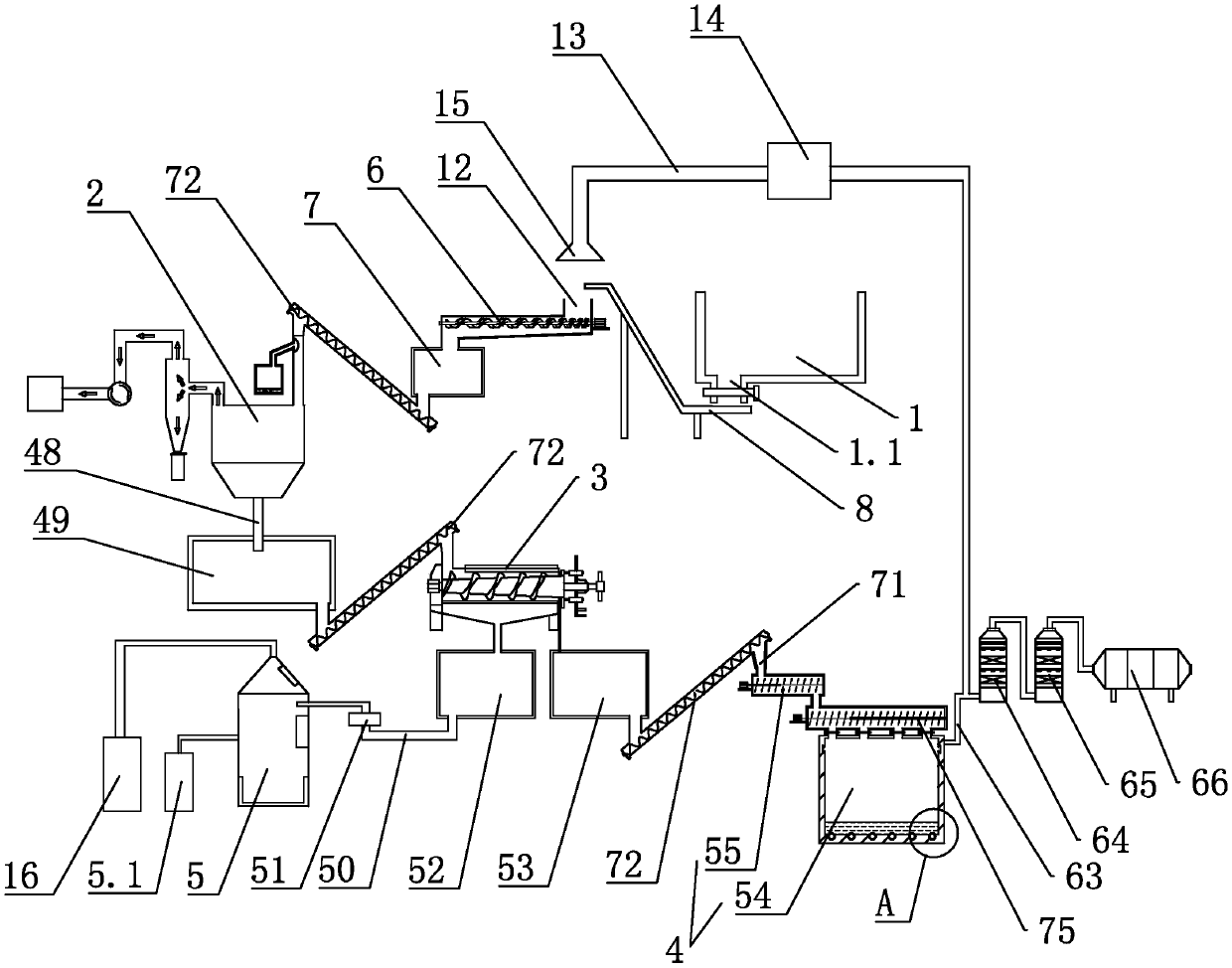

[0055] Such as figure 1 As shown, a treatment system for kitchen waste,

[0056] This in turn includes a feed tank 1 for aggregate;

[0057] Sorting shredder 2 for sorting organic waste and non-decomposable waste;

[0058] A dehydrator 3 for removing moisture from the organic waste sorted out by the sorting and pulverizing machine 2;

[0059] A fermentation device 4 for aerobically fermenting the solid organic matter dehydrated by the dehydrator 3;

[0060] The oil separator 5 is used to separate the oil from the liquid organic matter removed by the dehydrator 3 .

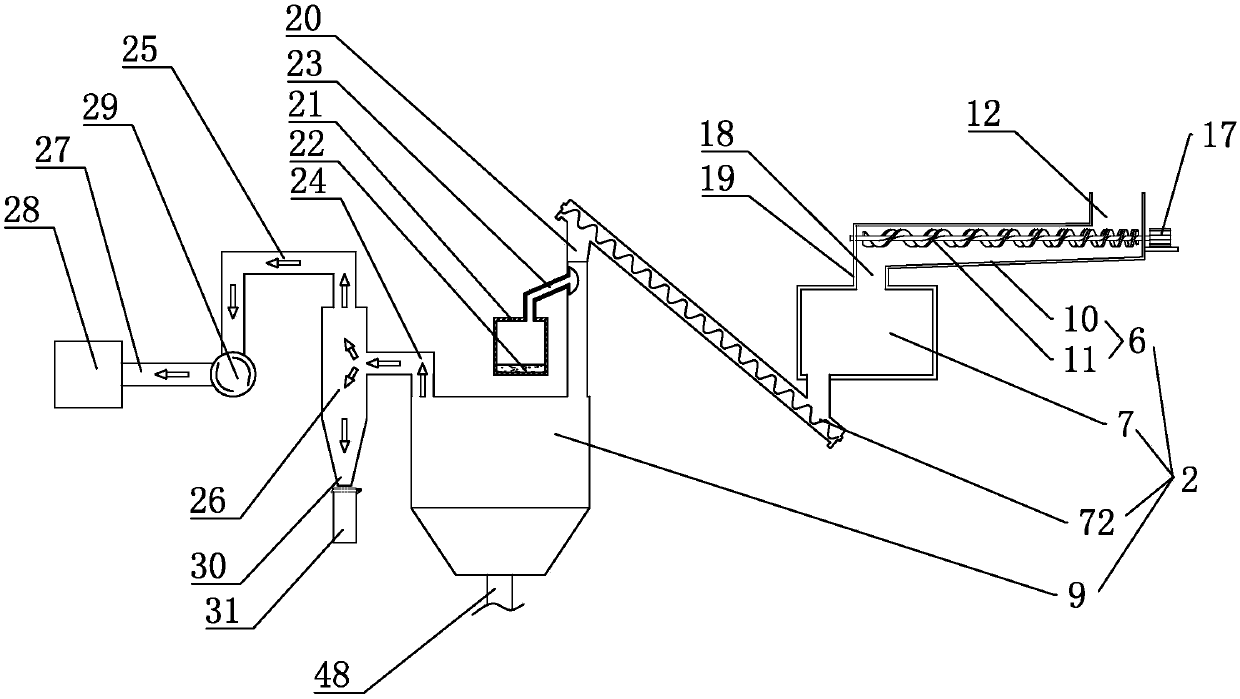

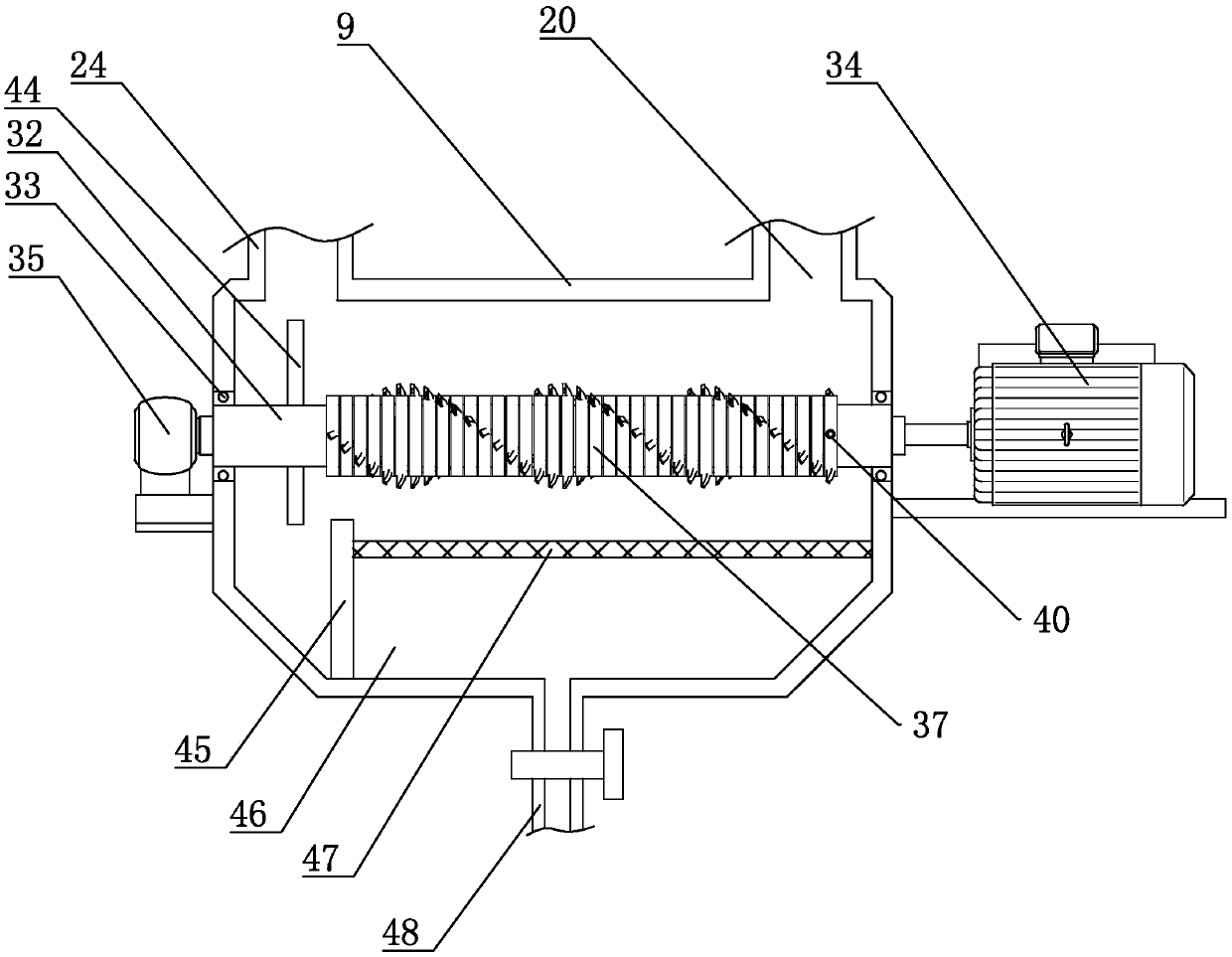

[0061] Such as figure 1 As shown, a bag outlet pipe 1.1 is provided below the feed pool 1, and a valve is provided on the bag outlet pipe 1.1. An elevator 8 is provided between the bag outlet pipe 1.1 and the sorting and pulverizing machine 2 . Such as figure 2 As shown, the sorting and pulverizing machine 2 includes a bag breaking mechanism 6 , an intermediate storage box 7 , a screw feeder 72 and a pulver...

Embodiment 2

[0100] The difference between embodiment two and embodiment one is: as Figure 16 As shown, the bag breaking rod 11 is a variable pitch screw 84 whose pitch gradually increases from the bag inlet 12 to the outlet 18 . There are two bag-breaking bars 11, and the two bag-breaking bars 11 are parallel in the horizontal direction.

[0101]When breaking the bag, two breaking bag rods 11 do an axial stretch to the bag at the same time, and the bag is pulled torn, so that the bag can be broken more fully, and the garbage is more dispersed.

Embodiment 3

[0103] The difference between embodiment three and embodiment three is: as Figure 17 As shown, the bag breaking rod 11 is a variable pitch screw 84 whose pitch gradually increases from the bag inlet 12 to the outlet 18 . Simultaneously, the bag-breaking rod 11 is a variable-diameter screw 84 whose radius gradually decreases from the bag inlet 12 to the outlet 18 .

[0104] When breaking the bag, the two breaking rods 11 stretch the bag in the axial direction at the same time, and the breaking rod has a radial stretching force on the bag, so that the plastic bag can be broken more thoroughly, and the garbage can be more thoroughly dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com