A three-product hydraulic flotation machine and sorting method for coarse particle recovery

A three-product, flotation machine technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems of continuous separation and recovery of coal slime, complicated coal slime sorting process, and product mismatch content Advanced problems, to achieve the effect of shortening the separation preparation time, improving the quality of clean coal products, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

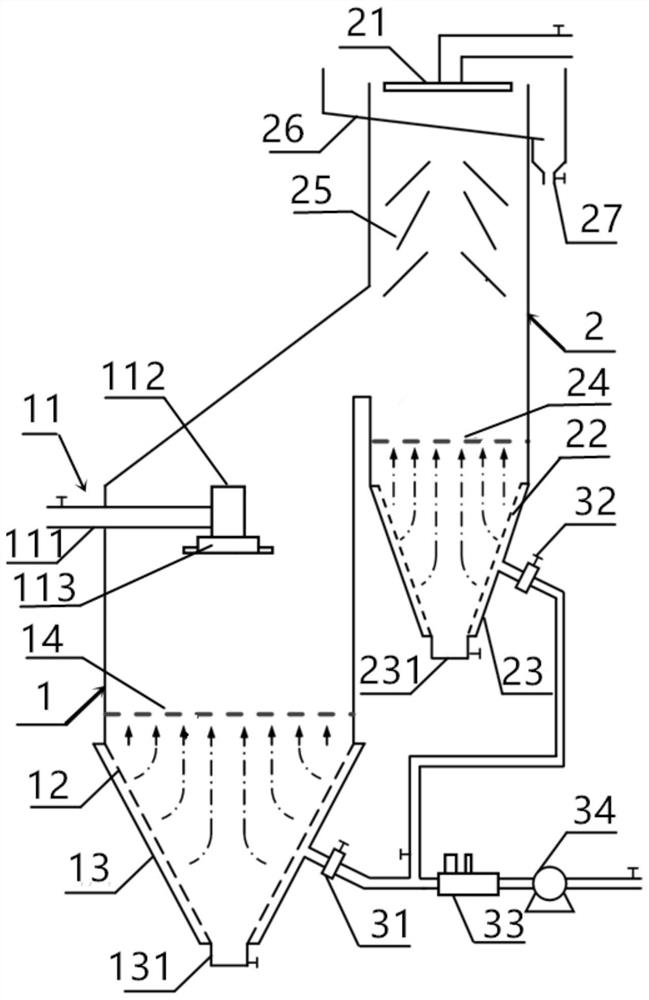

[0038] A specific embodiment of the present invention, such as figure 1 As shown, a three-product hydraulic flotation machine for coarse particle recovery is disclosed, including a first column 1 and a second column 2 connected in parallel at high and low levels, the axis of the first column 1 is connected to the second column 2 The axes are parallel, the bottom of the second cylinder 2 is not higher than the top of the first cylinder 1, the top of the first cylinder 1 communicates with the middle of the second cylinder 2, the first cylinder 1 and the second cylinder 2 The inner diameter ratio is 1.5-3:1, the upper end of the first cylinder 1 is provided with a feeding device 11, the feeding device 11 is connected with the external slurry preprocessor, and the upper end of the second cylinder 2 is provided with a spray water pipe 21, The spray water pipe 21 is connected with the external clean water pipe.

[0039] It should be noted that the heights of the first cylinder 1 an...

Embodiment 2

[0062] Another specific embodiment of the present invention discloses a three-product hydraulic separation method for coarse particle recovery, which is implemented by using the three-product hydraulic flotation machine in Embodiment 1. The steps include:

[0063] Step 1: Open the valves of the first fluidization water port 31 and the second fluidization water port 32, start the booster pump 34, the water flow will inhale air through the bubble generator 18 at a certain pressure, and add a certain amount of water to the water flow through the bubble generator 18 foaming agent.

[0064] The foaming agent is selected from 2-octyl alcohol, methyl isobutyl carbinol, methyl pentanol or dodecyltrimethylammonium bromide, and the consumption is 0.2-2kg / t; in this embodiment, the foaming agent is selected from 2-octyl Alcohol, the dosage is 0.5kg / t. The introduction of air bubbles in the fluidized water expands the difference in specific gravity between different hydrophobic mineral c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com