Sorting equipment for green treatment of bulk solid wastes

A solid waste and sorting technology, which is used in solid waste removal, solid separation, grain processing, etc., can solve the problems of garbage sticking together, unable to sort plastic bags, unable to sort hard blocks, etc. Easy to disassemble and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

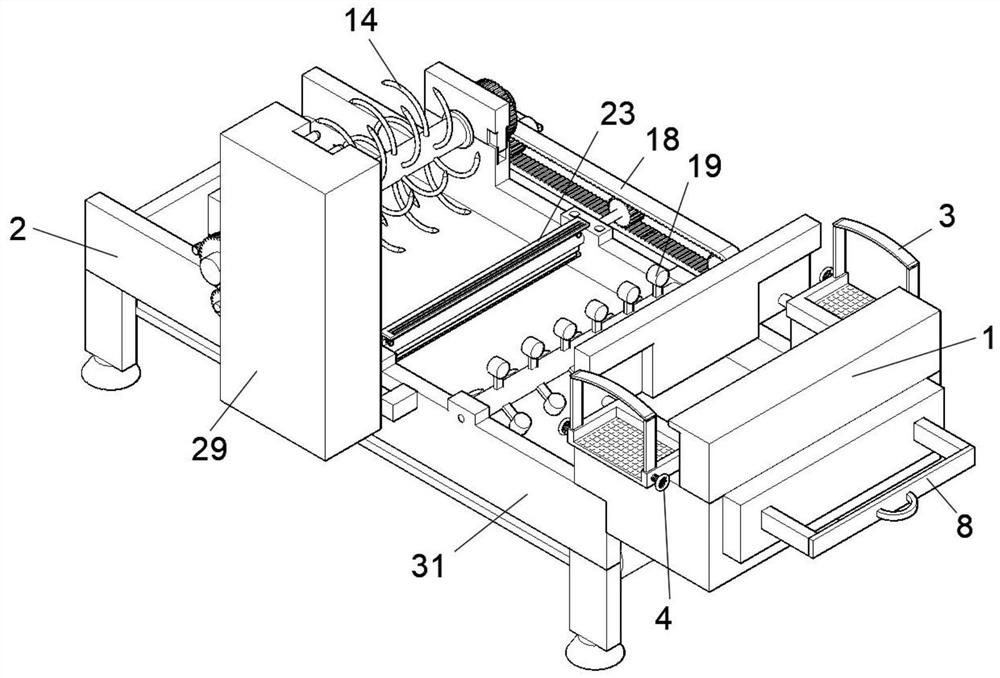

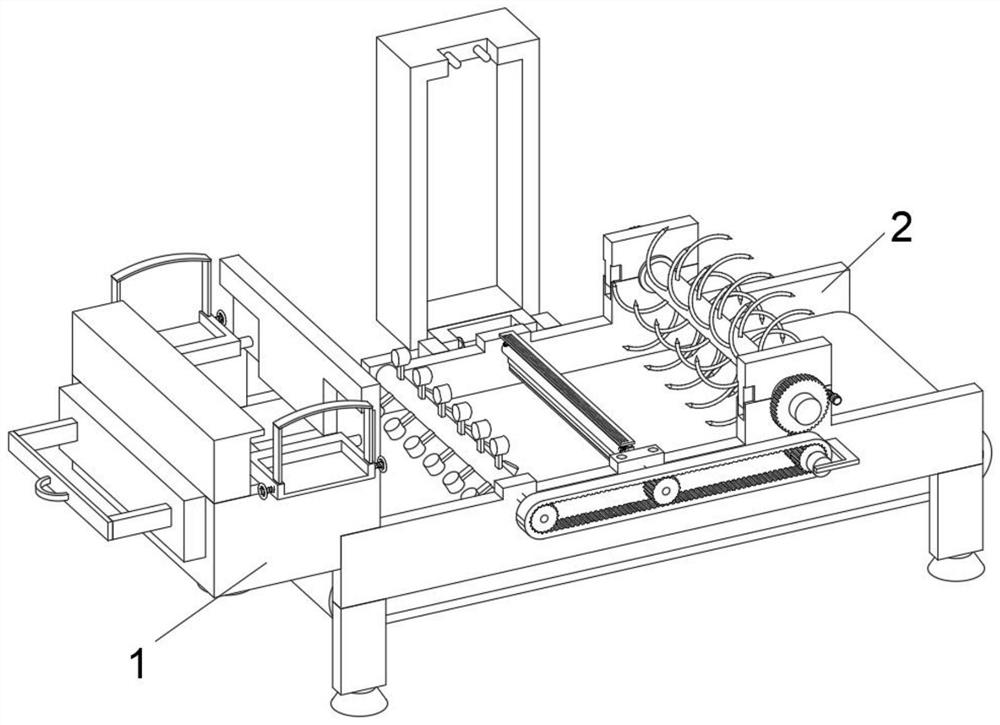

[0035] see Figure 1-2 , an embodiment provided by the present invention: a kind of sorting equipment for green processing of bulk solid waste, including a feeding auxiliary device 1, and a comprehensive sorting device 2 is fixedly connected to the top of one end of the feeding auxiliary device 1;

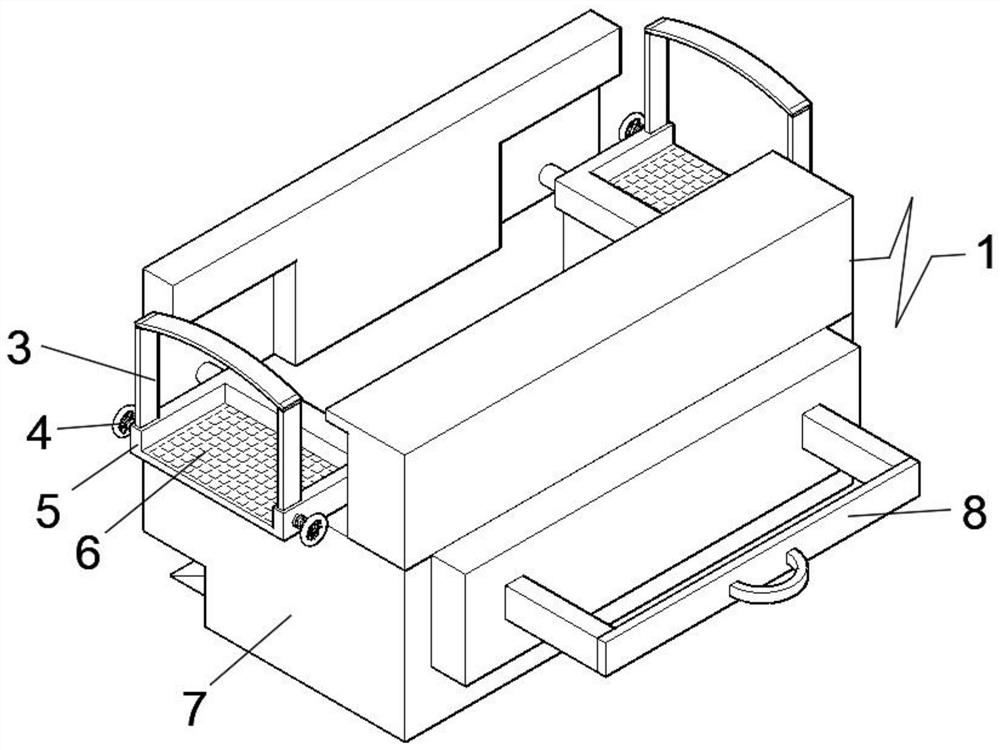

[0036] Such as image 3, the feed auxiliary device 1 includes a fastening limit clip 3, a limit bolt 4, a support and a fixed bottom plate 5, a protective gasket 6, a fixed storage cavity 7 and a toggle push rod 8, and the push push rod 8 slides Inserted inside one end of the fixed storage cavity 7, the support fixed base plate 5 is symmetrically rotatably connected inside the side end of the fixed storage cavity 7, and the fastening limit clip 3 is symmetrically slid and plugged into one end of the support fixed base plate 5, The limit bolt 4 is symmetrically threaded and inserted on the side end of the support and fixed base plate 5, and the protective gasket 6 is symmetrically ...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 8 As shown, the toggle push rod 8 also includes a contact fixing head 32 and an extension protection strip 33, the contact fixation head 32 is fixedly connected to one end of the toggle push rod 8, and the extension protection strip 33 is fixedly connected to the toggle push rod 8 is away from the top of one end of the contact fixing head 32, and the material of the extended protective strip 33 is soft plastic, and the inside of the contact fixing head 32 is arranged in a V shape.

[0045] In the implementation of this embodiment, when the push rod 8 is to contact the fixed head 32 and the extension protective strip 33, it is fixedly connected to the side end of the push rod 8 by contacting the fixed head 32, and the contact fixed head 32 It is set in a V shape to prevent garbage from overflowing upwards. One end of the extended protective strip 33 is fixedly connected to the side end of the pusher rod 8, and the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com