Grape sorting operation platform

An operating platform, grape technology, applied in sorting, food science, application and other directions, can solve the problems of rising raw material cost, grape waste, grape damage, etc., to prevent mutual extrusion damage, improve the quality of raw materials, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

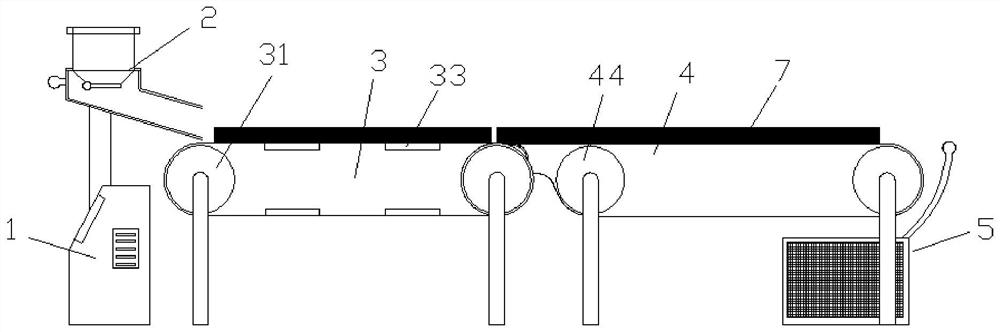

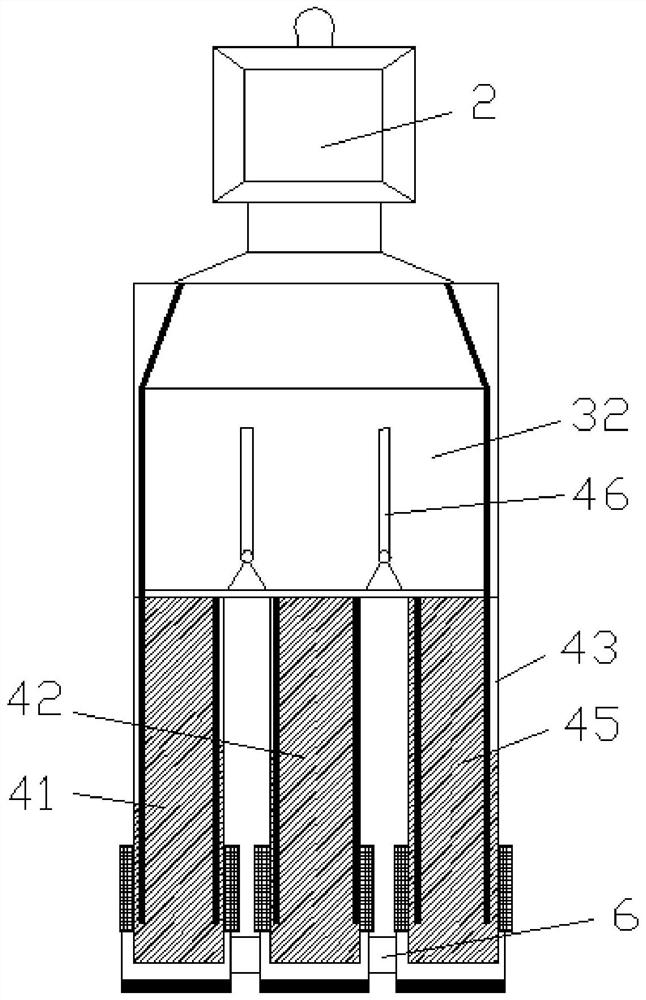

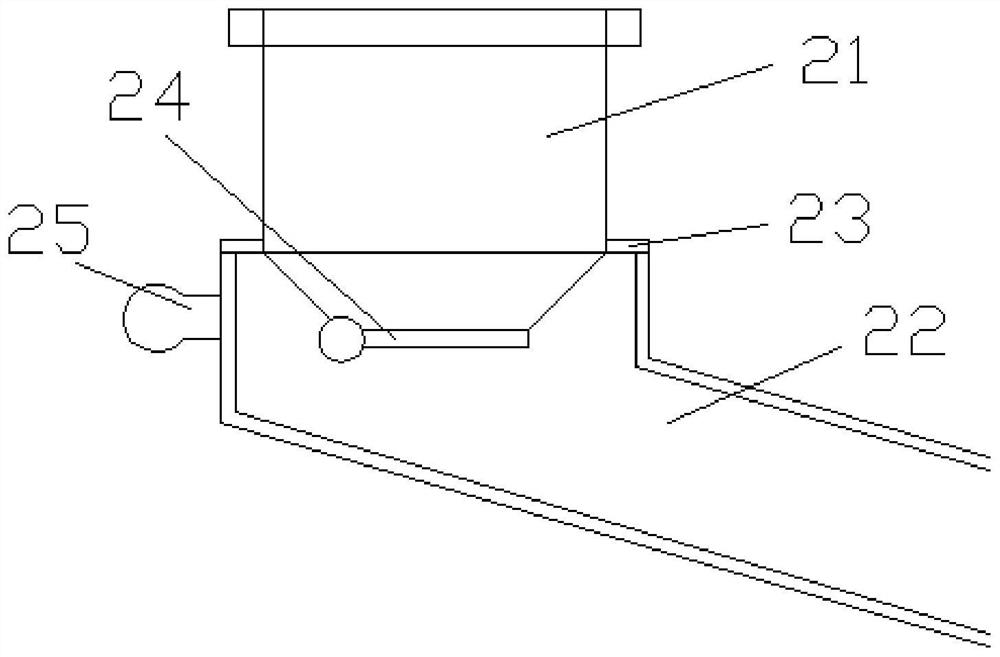

[0022] Embodiment one: Figure 1-Figure 4A grape sorting operation platform is shown, which is mainly composed of: a controller 1, a feeding device 2, a bulk material device 3, a sorting device 4 and a recovery device 5. The feeding The device 2 is arranged at the feed end of the bulk material device 3, the feed end of the sorting device 4 is close to the discharge end of the bulk material device 3, and the recovery device 5 is arranged at the sorting device The lower part of the discharge end of 4, the controller 1 is electrically connected with the feeding device 2, the bulk material device 3 and the sorting device 4, and the controller controls the start and stop of the equipment and the feeding amount to prevent material accumulation. Prevent material damage, high degree of automation; the feeding device 2 is mainly composed of a feeding hopper 21 and a feeding channel 22, the feeding hopper 21 is arranged at one end of the feeding channel 22, the feeding The other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com