Patents

Literature

53results about How to "Control ingress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centrifugal compressor

InactiveCN103047190AIncrease the water content of the inletImprove compression efficiencyPump componentsPumpsAutomatic controlCentrifugal compressor

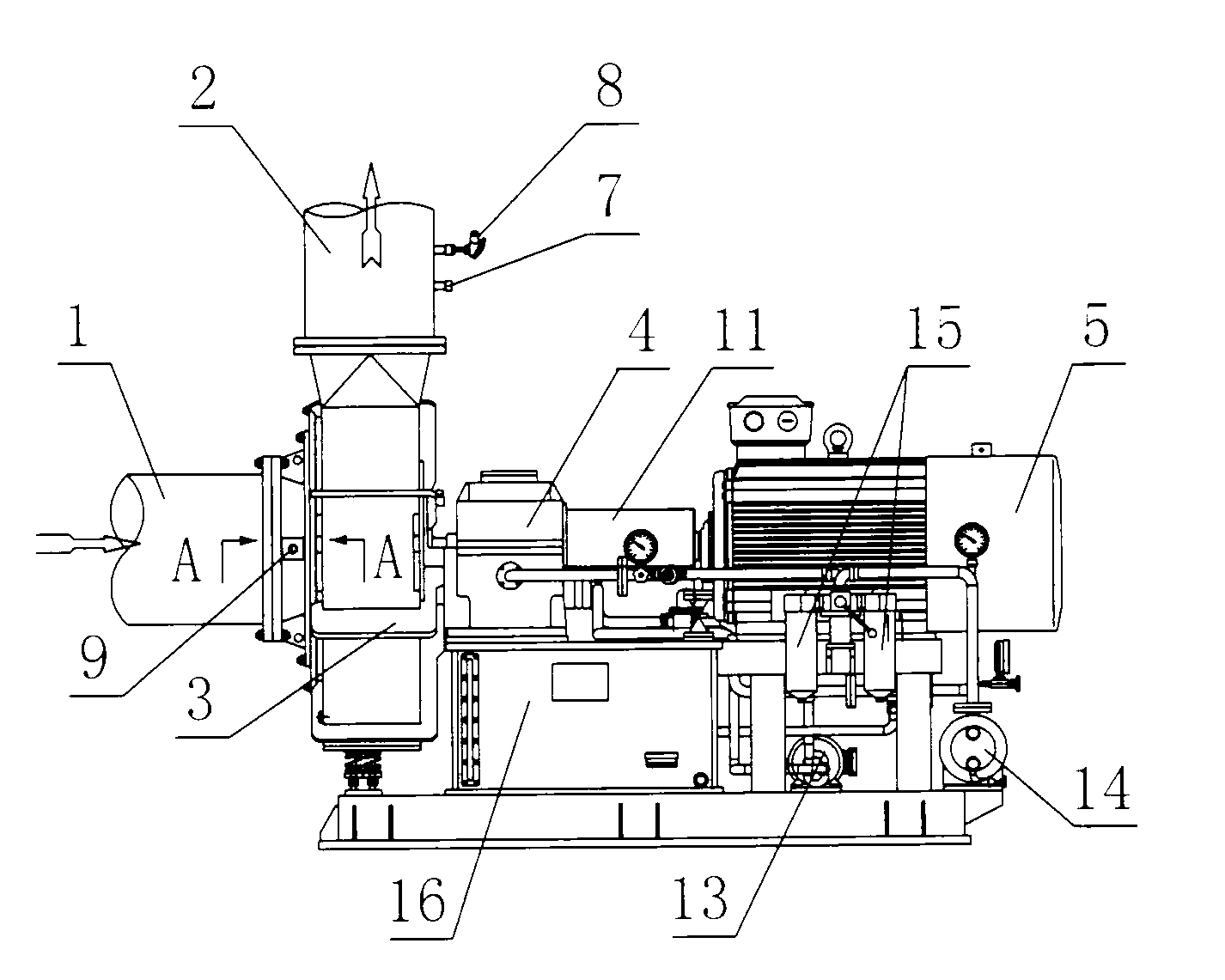

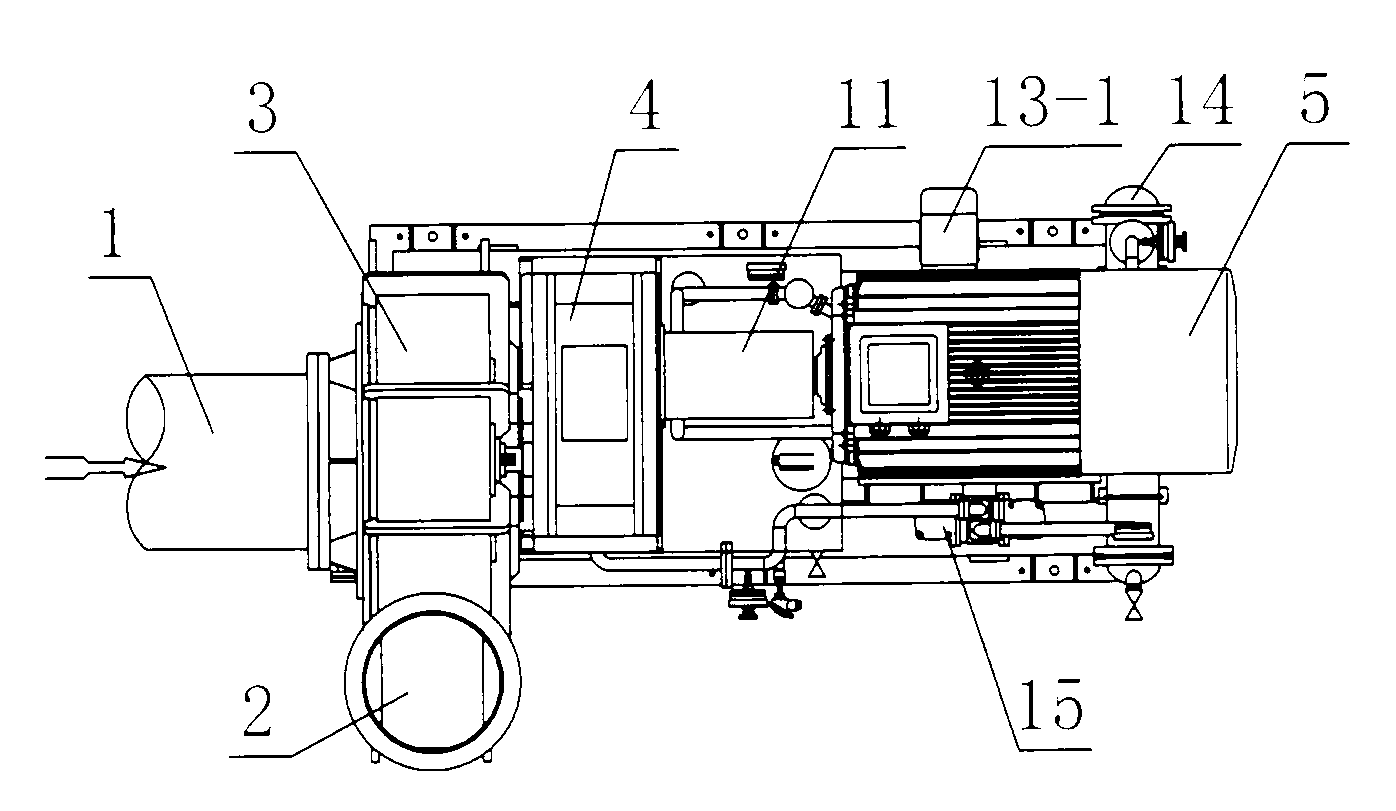

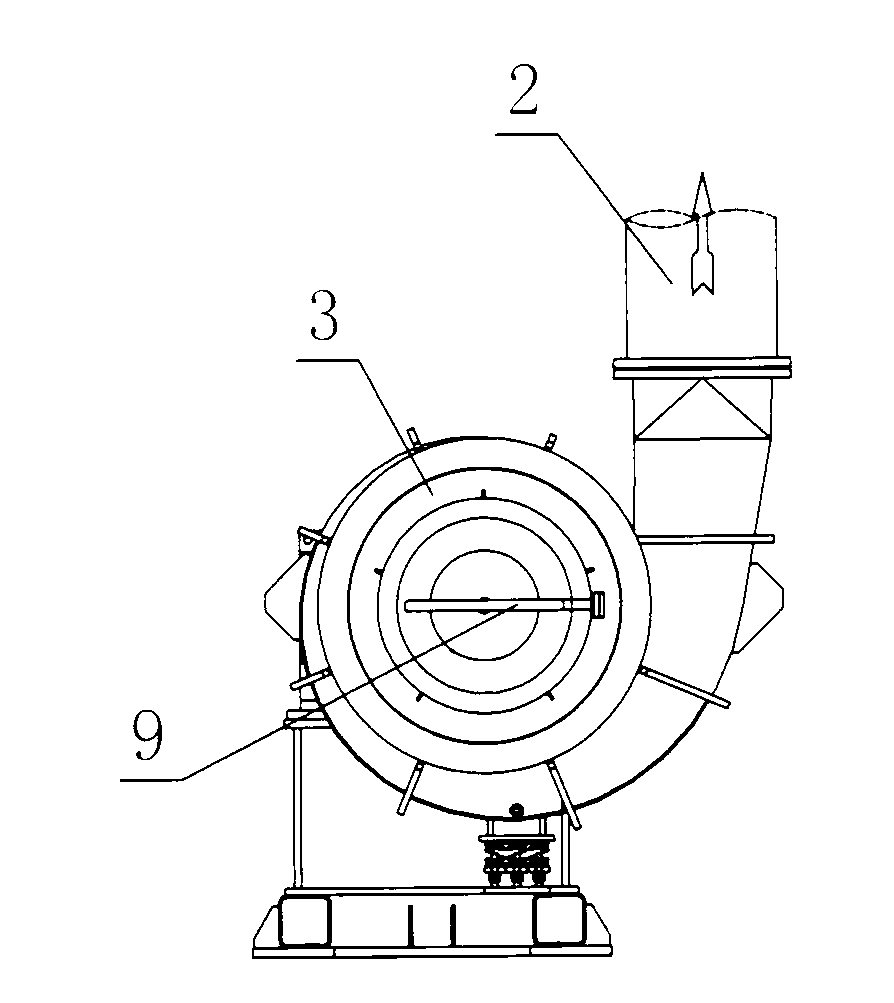

The invention relates to a compressor, in particular to a centrifugal compressor. The centrifugal compressor is mainly applicable to compression of steam and comprises a volute (3) connected with a steam inlet pipe (1) and a steam outlet pipe (2), an impeller (10) and a motor (5). The impeller (10) is arranged in the volute (3), and a power output end of the motor (5) is connected with the impeller (10). The centrifugal compressor is further provided with a water spraying pipe (9) comprising a sprayer (901), the water spraying pipe (9) is arranged on the steam inlet pipe (1), or the water spraying pipe (9) is arranged on the volute (3), and the water spraying pipe (901) faces an inner cavity of the volute (3). By means of the technical scheme, the compression efficiency is high, compression cost is low, performance is stable, reliability is good, and service life is long. The centrifugal compressor achieves automatic control of the pressure and temperature.

Owner:溧阳德维透平机械有限公司

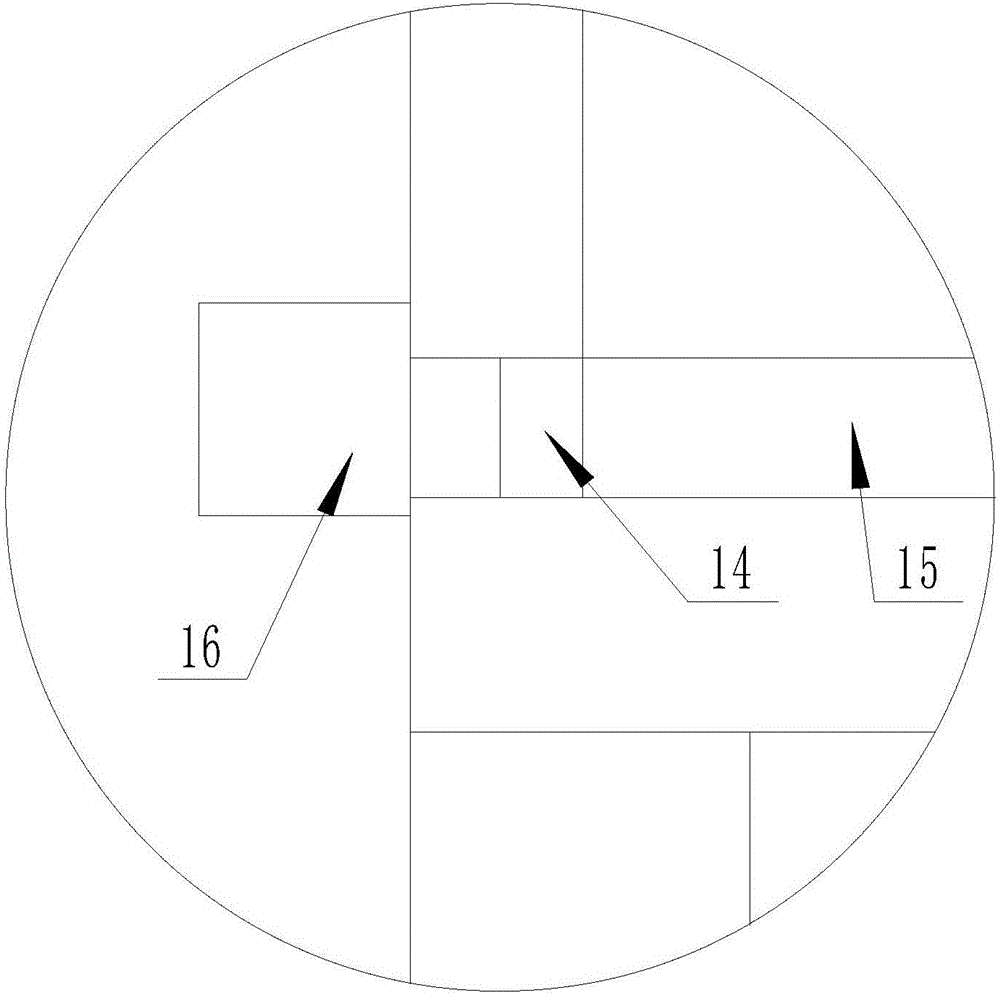

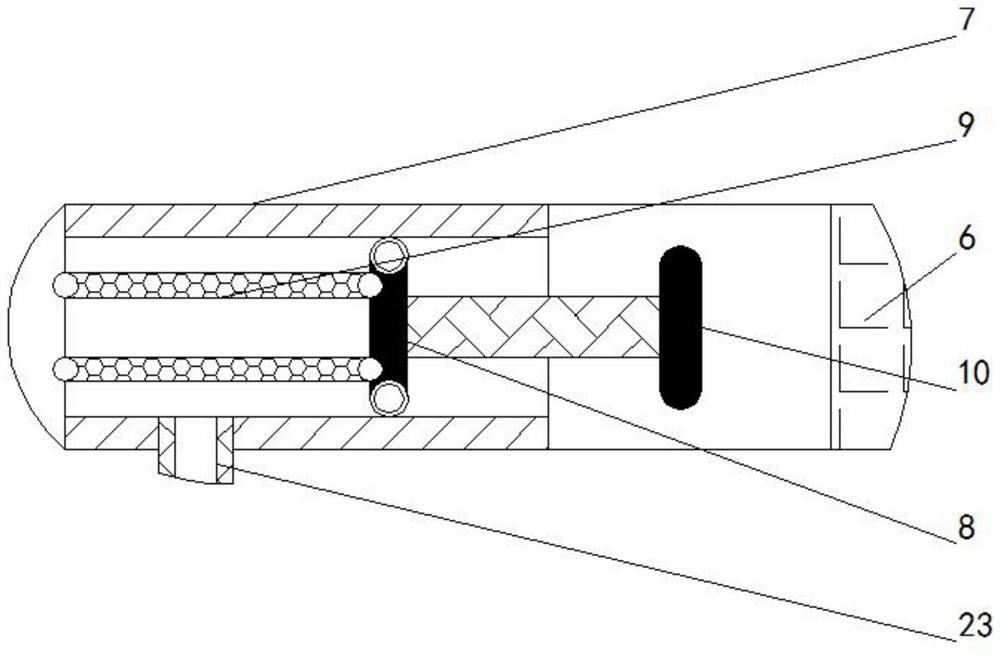

Internal mixing type steam atomization nozzle

InactiveCN106861960ASafe to useGood atomization qualityLiquid spraying apparatusFuel oilMixing chamber

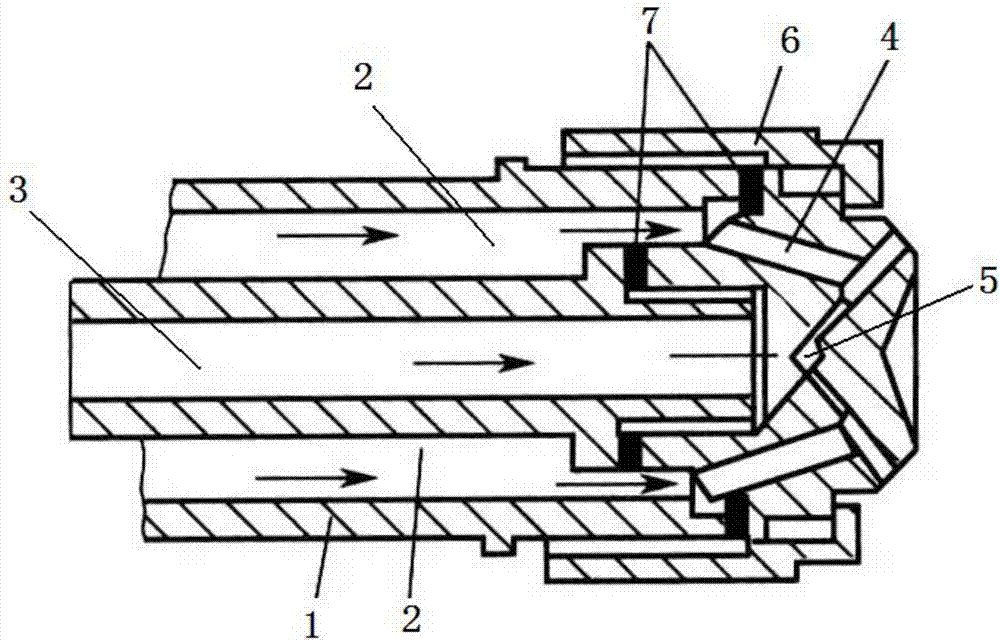

The invention discloses an internal mixing steam atomizing nozzle, which includes a nozzle body, and is characterized in that it also includes an oil inlet passage, a steam inlet passage, an oil nozzle and a mixing chamber, and a ring of oil inlet passages is arranged in the nozzle body. There is a circle of steam inlet passage in the oil inlet passage, and an oil nozzle is arranged at the end of the oil inlet passage. The oil inlet passage sends fuel into the mixing chamber through the oil nozzle for mixing, and the steam is sent into the mixing chamber through the steam inlet passage for mixing. , the diameter of the steam inlet passage is greater than the diameter of the oil inlet passage. The invention provides an internal mixing steam atomizing nozzle with simple structure, convenient use, good atomizing effect and fast spraying speed.

Owner:包光华

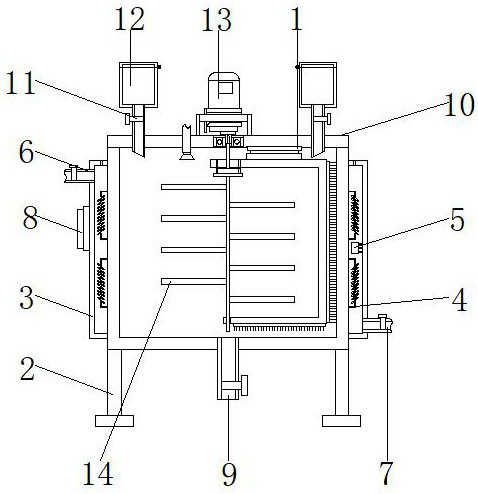

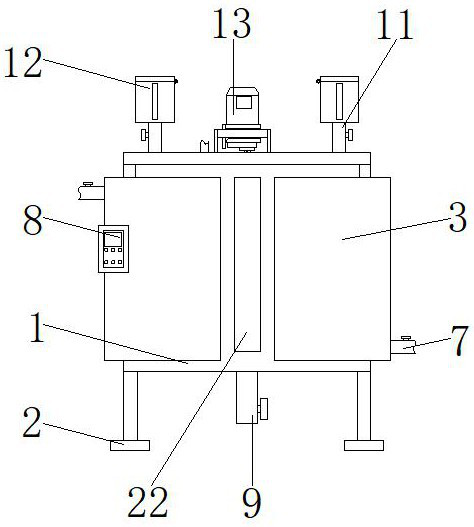

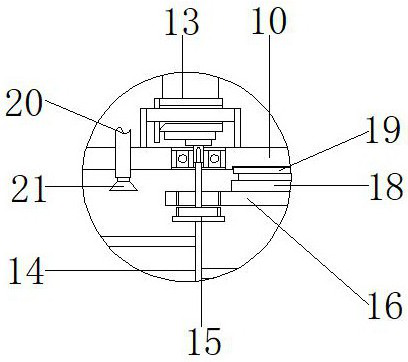

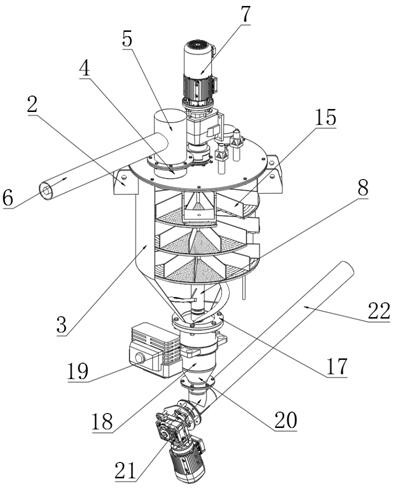

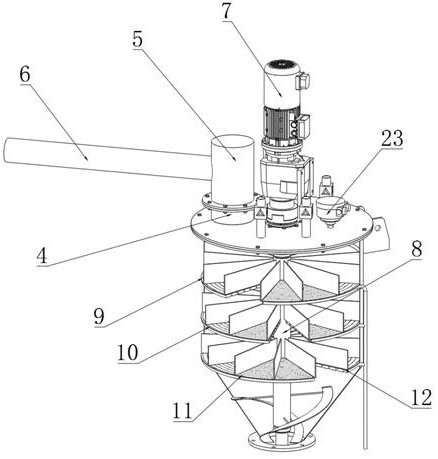

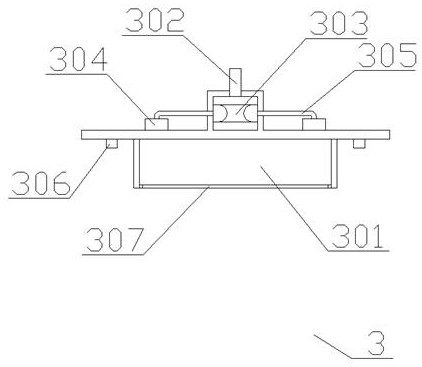

Method and device for fast preparing white activated rice hull ash

InactiveCN102730702AAccelerated dissipationControl ingressSilicaSolid waste disposalTemperature controlEngineering

The invention relates to method and device for fast preparing white activated rice hull ash. The method comprises the following steps: (1) carrying out diluted acid pretreatment on rich hulls for 2-24 hours; (2) washing the rice hulls subjected to diluted acid pretreatment for many times, and removing impurities in the rice hulls; and (3) directly placing the washes rice hulls into an incineration basket, and incinerating in a furnace body, controlling the grate temperature of the furnace body at the temperature of 600-800 DEG C, and preparing rice hull ash with 50 nanoscale particles, wherein the content of amorphous silica achieves more than 90%, the amorphous silica is white and evenly distributed, and the rich hull ash is loosely stacked. The device comprises an insulating furnace body, the incineration basket, a temperature controller, a thermocouple temperature sensor, a resistance wire, an adjustable air inlet and an adjustable air outlet. The method and the device can be used for fast producing white activated rice hull ash capable of substituting silica fume.

Owner:FUZHOU UNIV

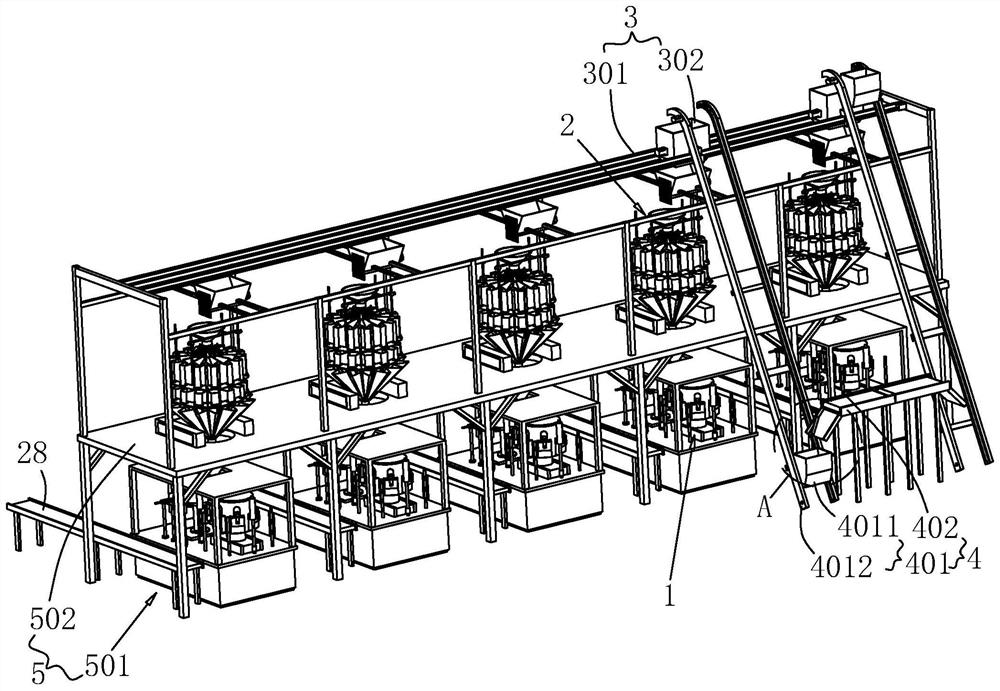

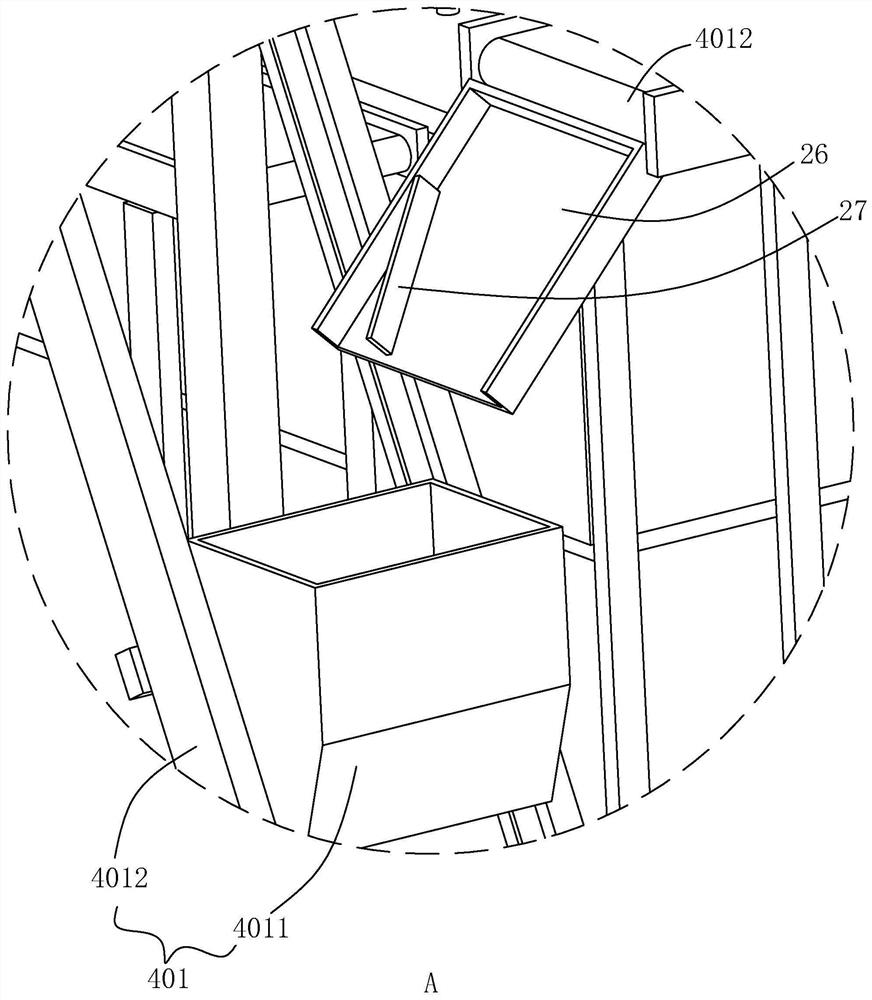

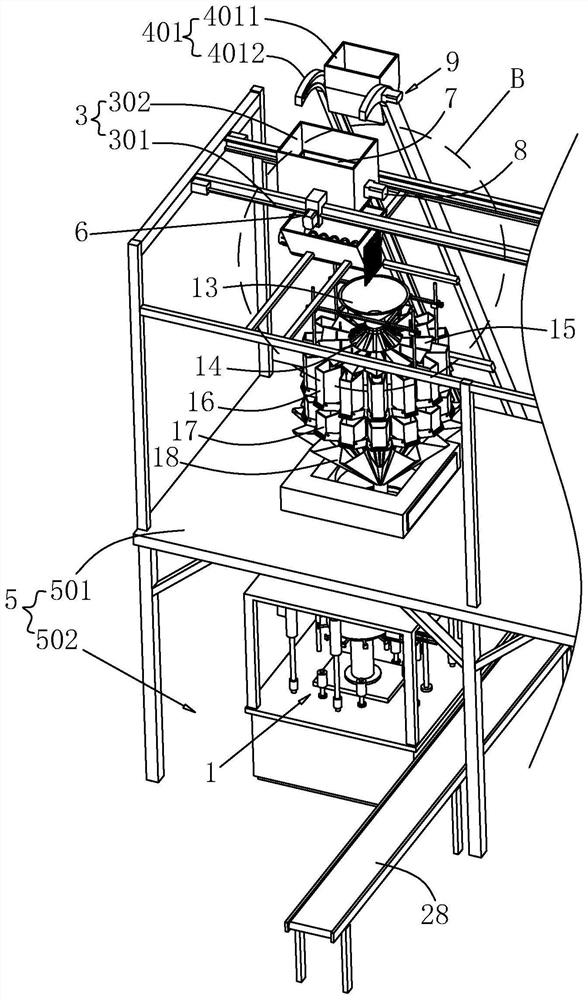

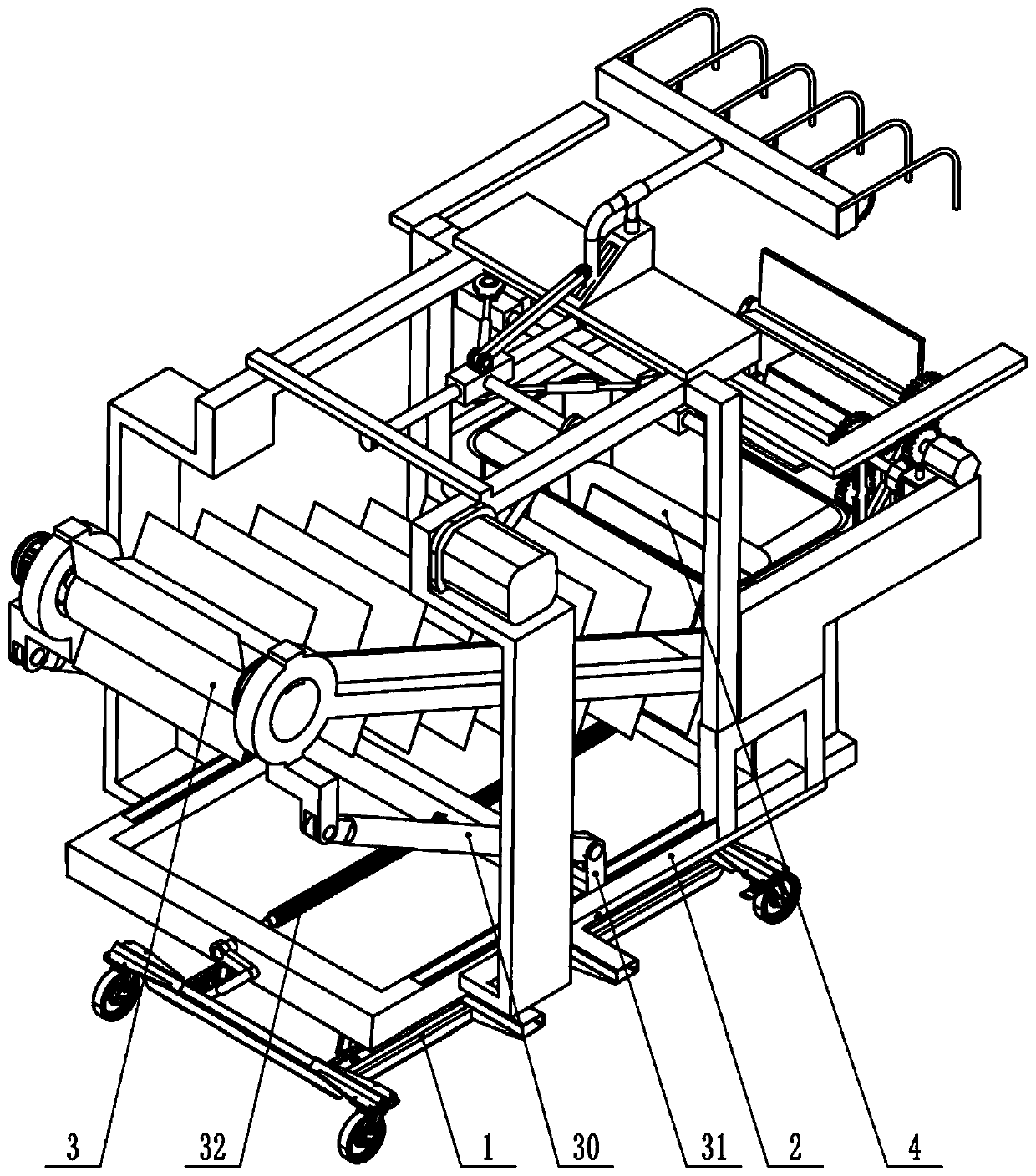

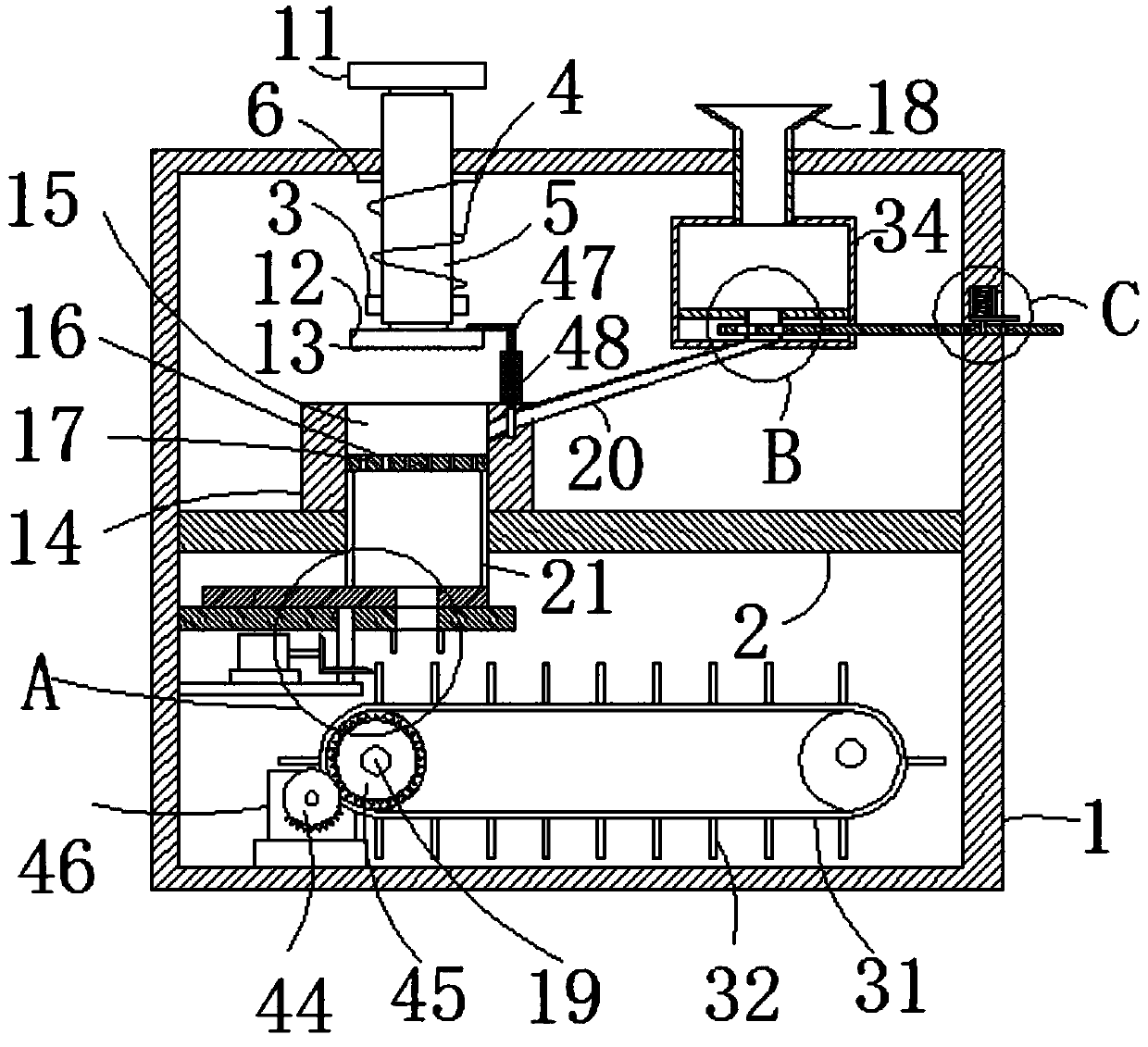

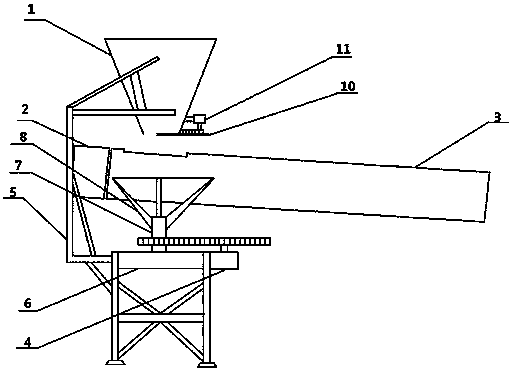

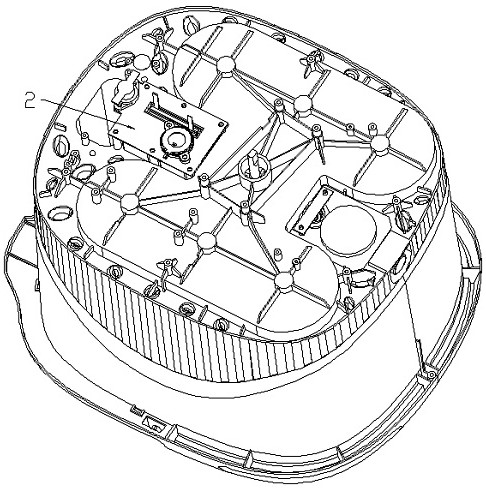

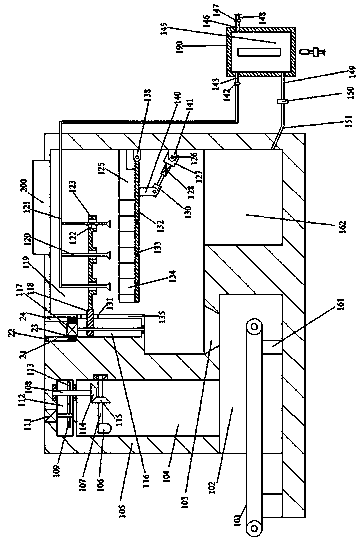

Multi-head scale full-automatic packaging production line

InactiveCN112173191ASave human effortIncrease productivityPackaging by pressurising/gasifyingSolid materialProduction lineProcess engineering

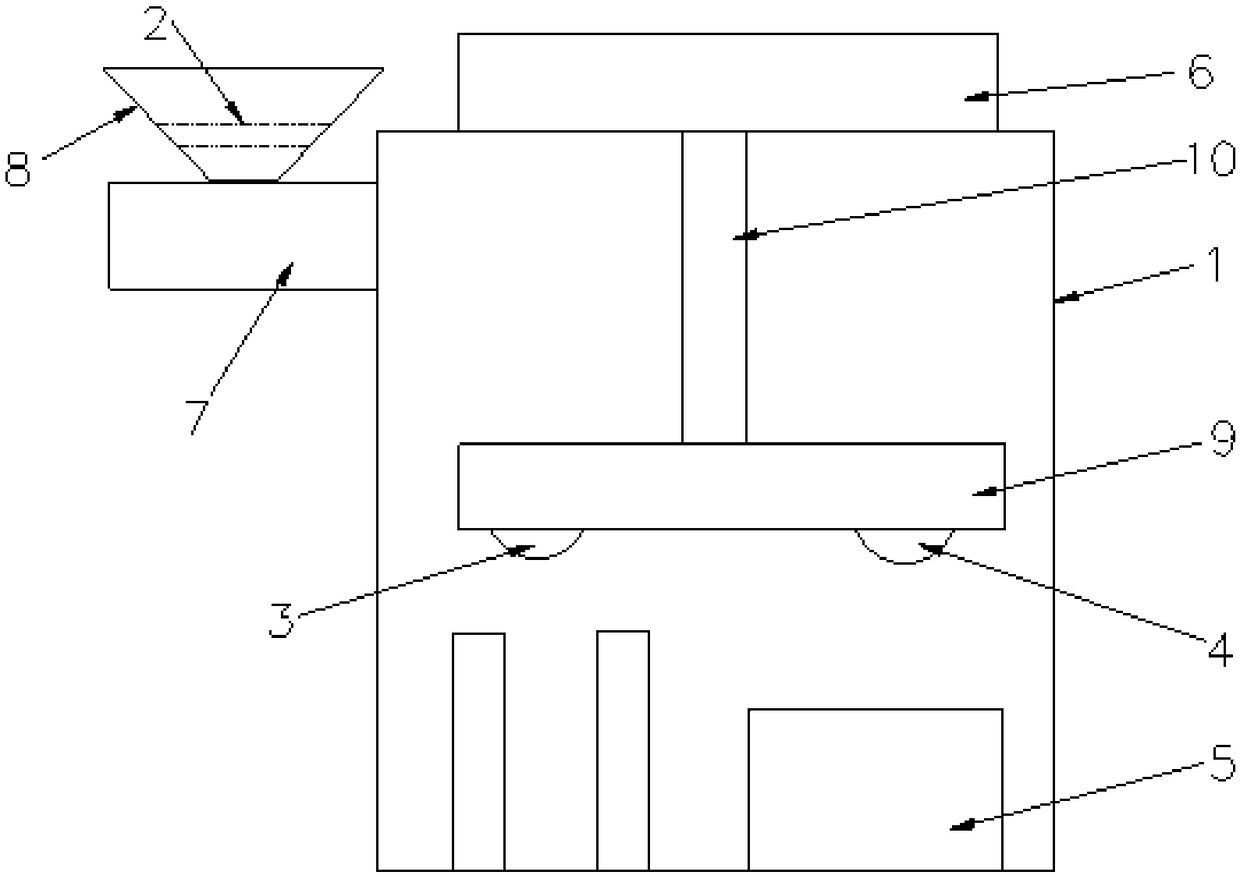

The invention relates to a multi-head scale full-automatic packaging production line. The multi-head scale full-automatic packaging production line comprises a plurality of full-automatic packaging machines, a plurality of multi-head scales, a material distributing and conveying system and a feeding and conveying system, wherein the full-automatic packaging machines are used for packaging weighedmaterials; the multi-head scales are used for quantitatively weighing the materials and then conveying the materials into the full-automatic packaging machines for packaging, and each full-automatic packaging machine is correspondingly provided with one multi-head scale; the material distributing and conveying system is used for distributing and conveying the materials into each multi-head scale for weighing; and the feeding and conveying system is used for feeding the materials into the material distributing and conveying system. Processed vermicelli enters the material distributing and conveying system through the feeding and conveying system, then the vermicelli is sequentially distributed into each multi-head scale through the material distributing and conveying system, and after the vermicelli entering the multi-head scales is weighed to reach the weight needing to be packaged, the vermicelli enters the full-automatic packaging machine correspondingly arranged below each multi-head scale for vacuum packaging. The multi-head scale full-automatic packaging production line has the effects of improving the production efficiency and saving manpower.

Owner:四川粮之髓食品有限公司

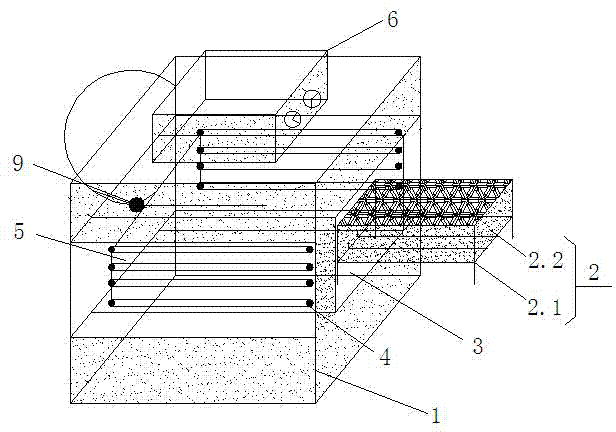

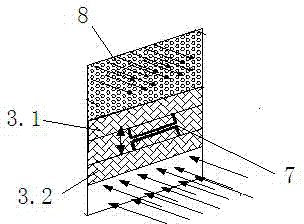

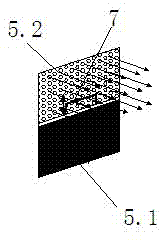

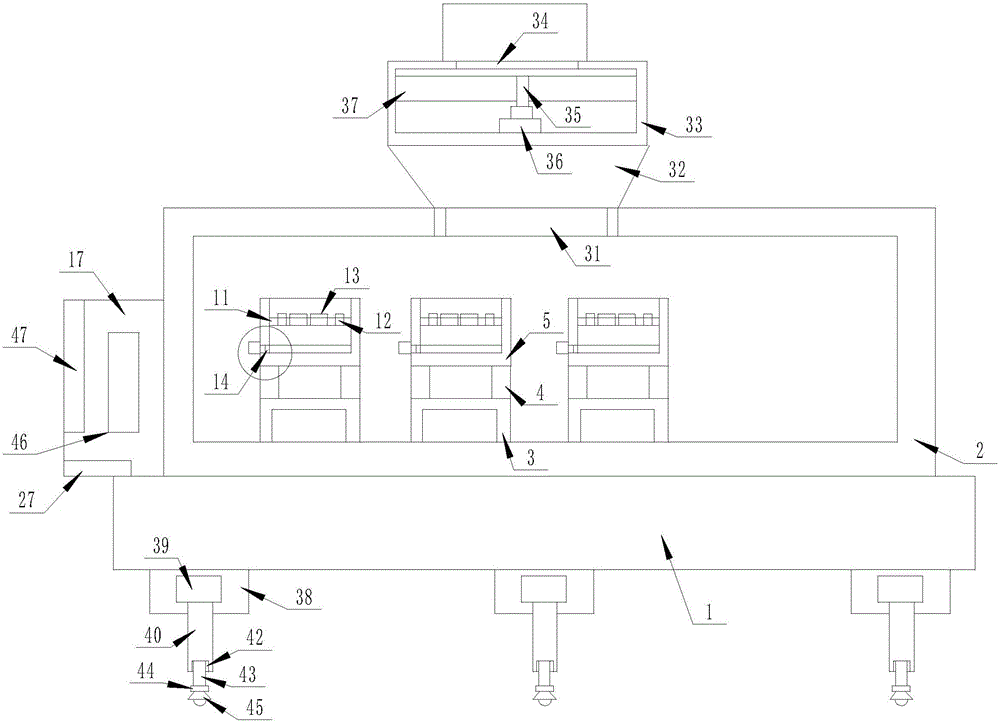

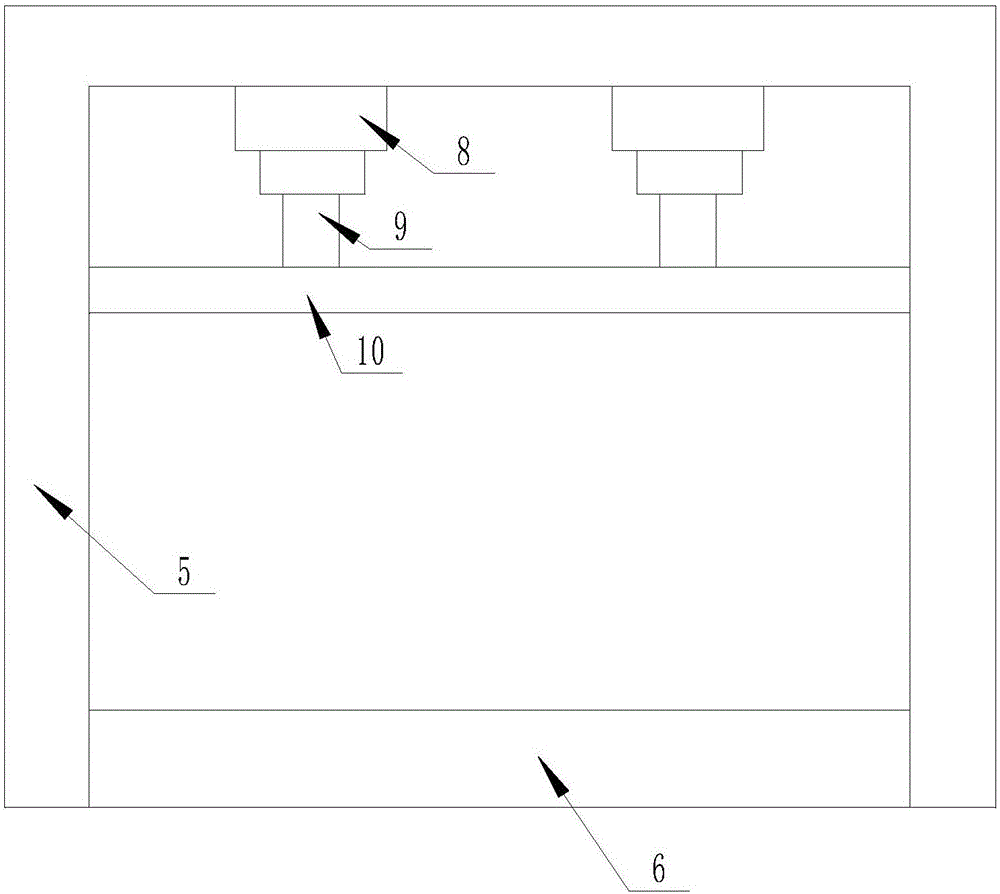

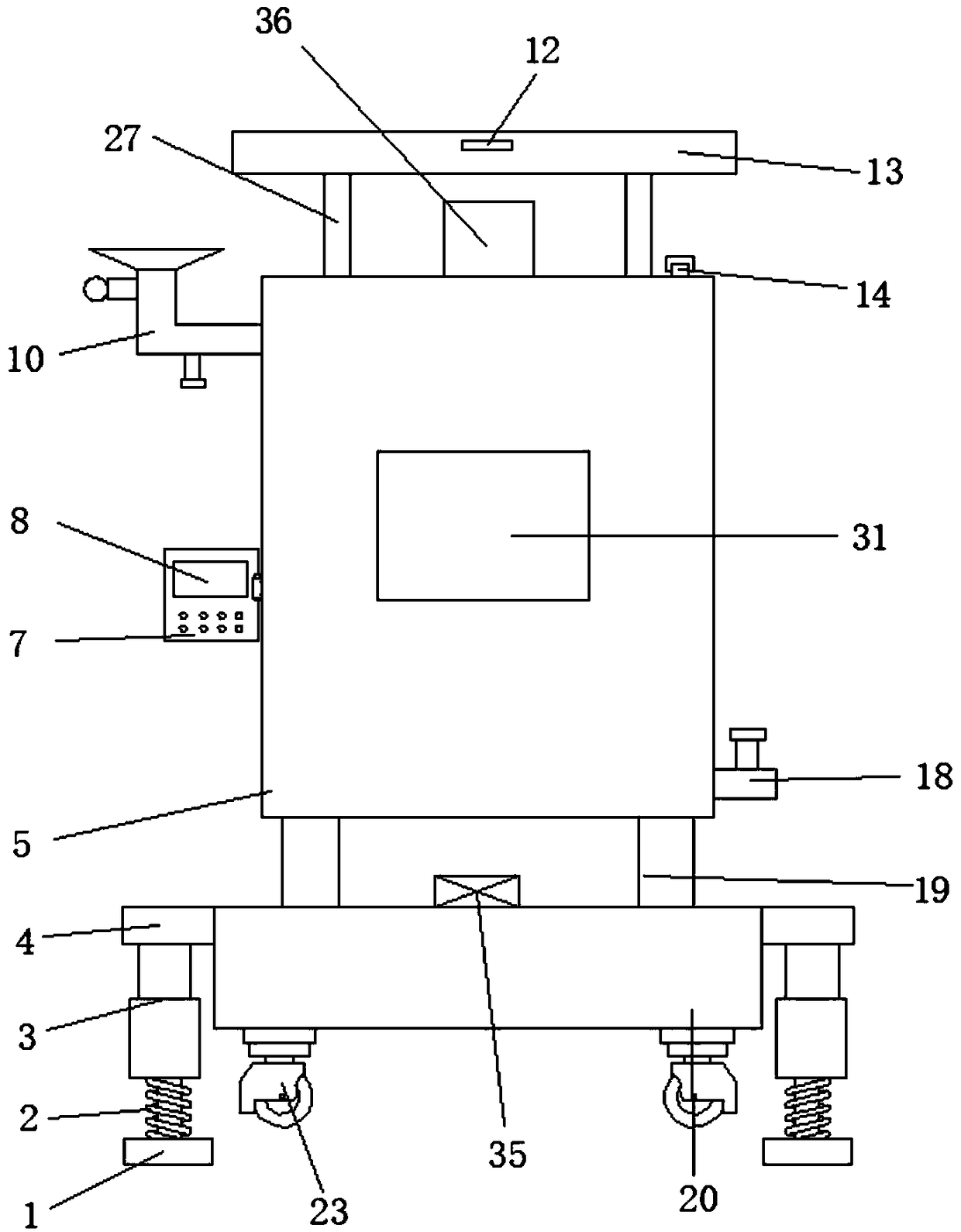

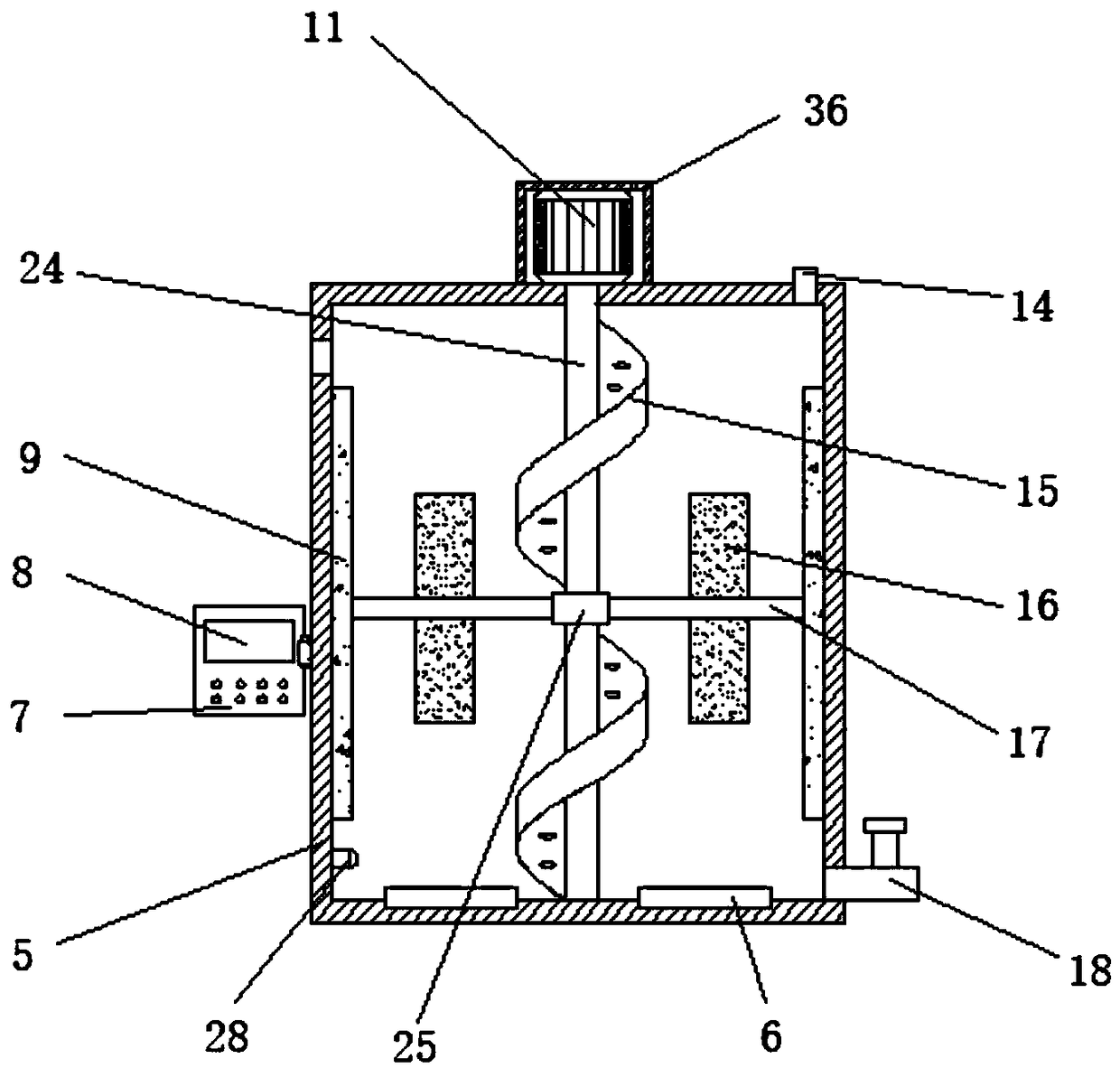

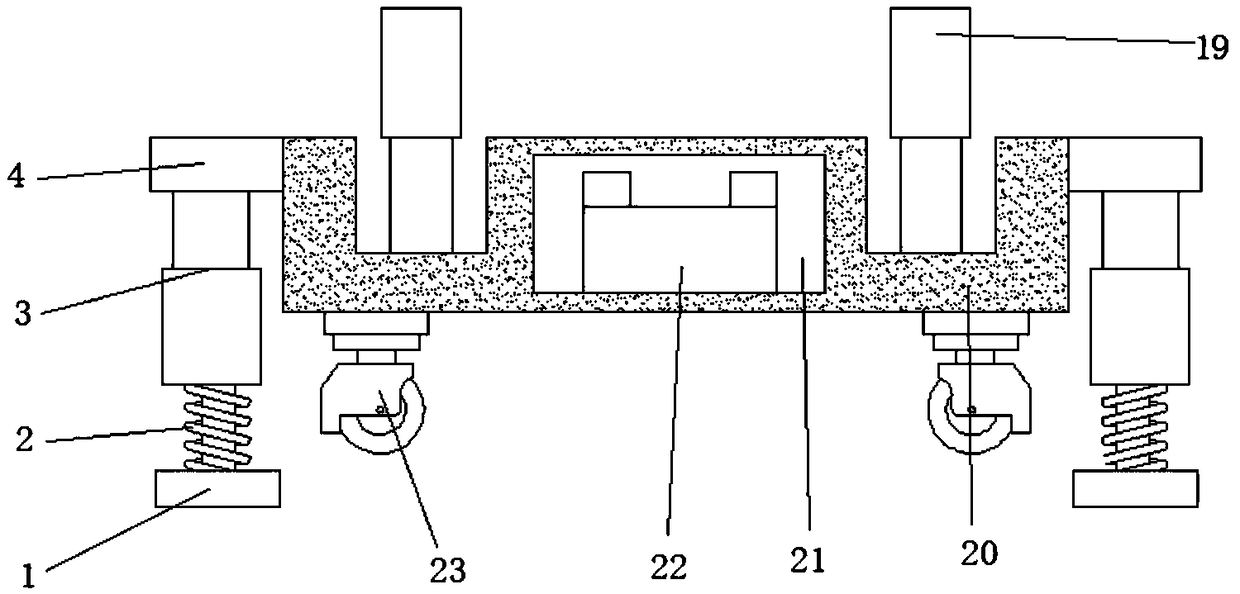

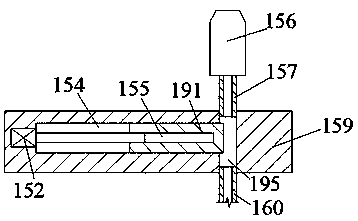

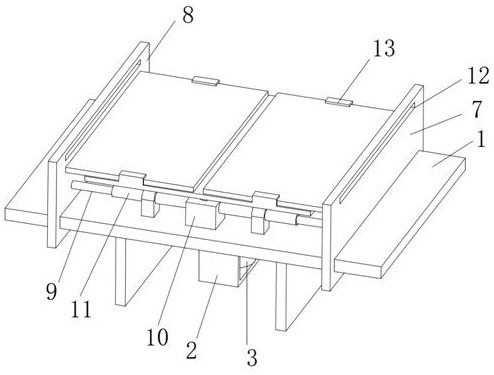

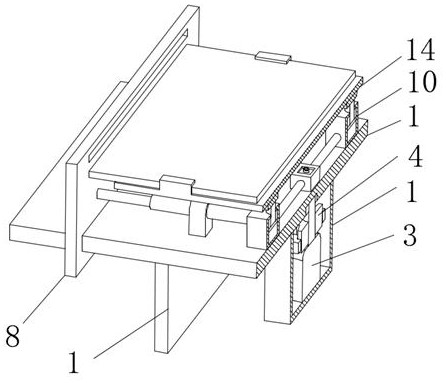

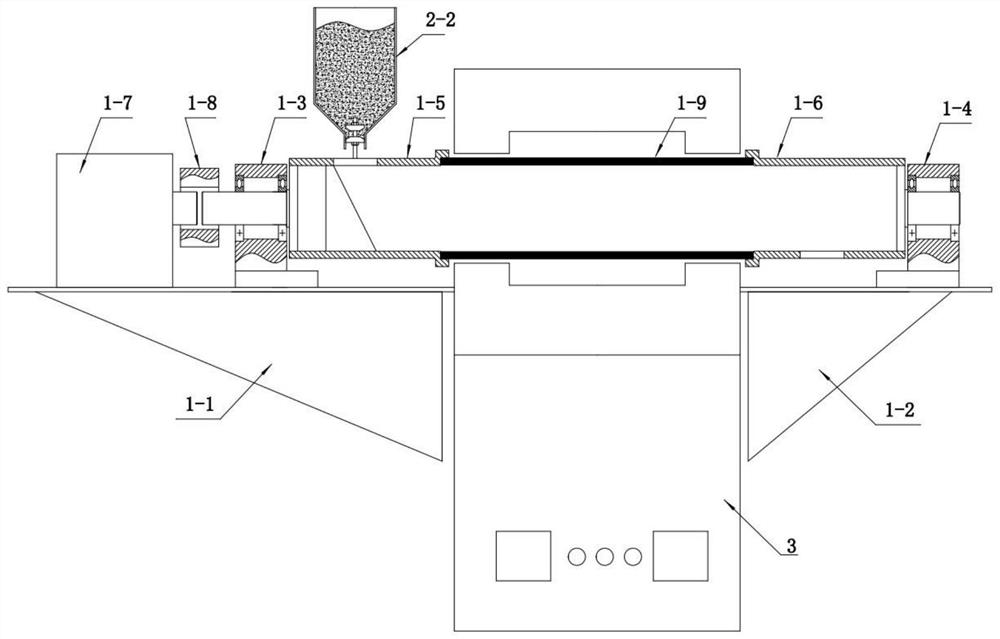

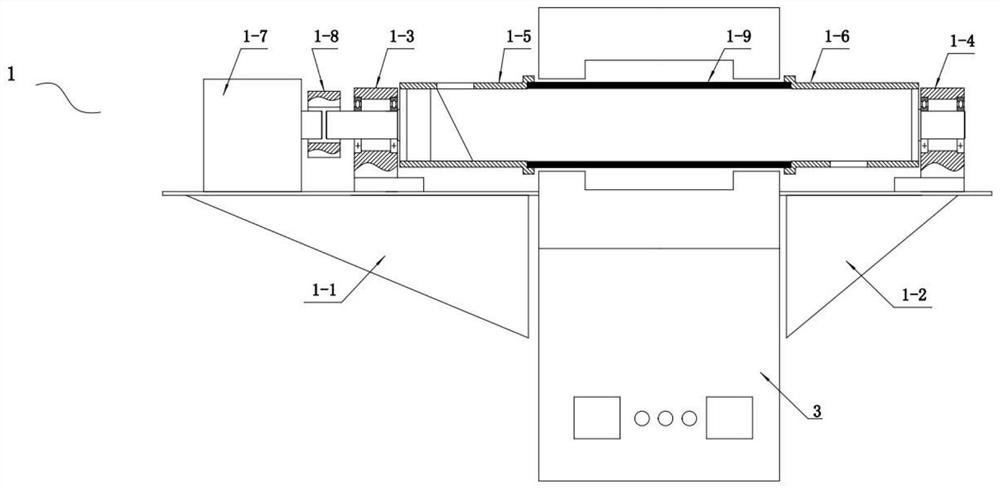

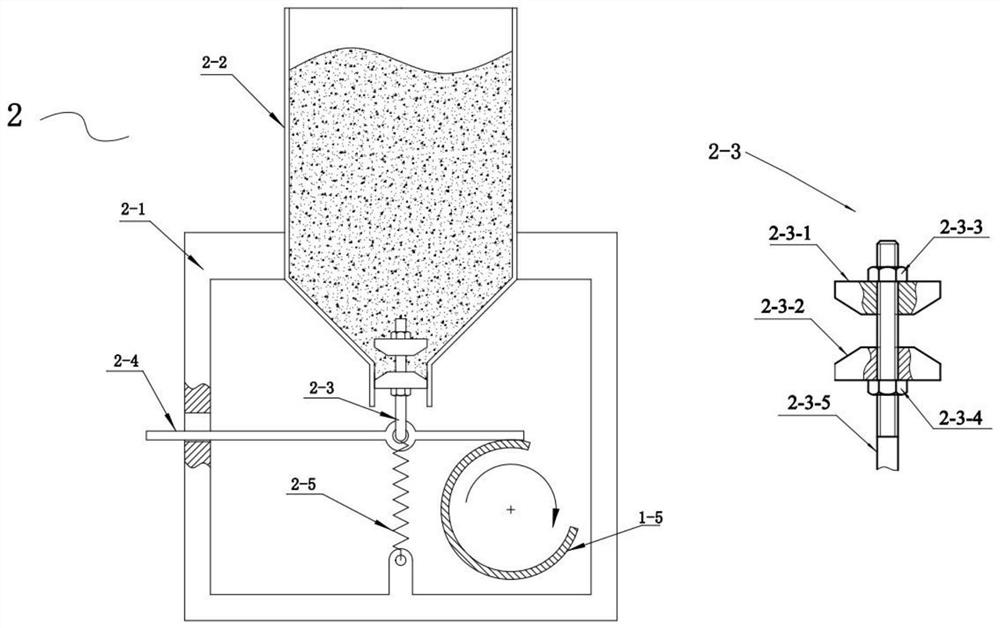

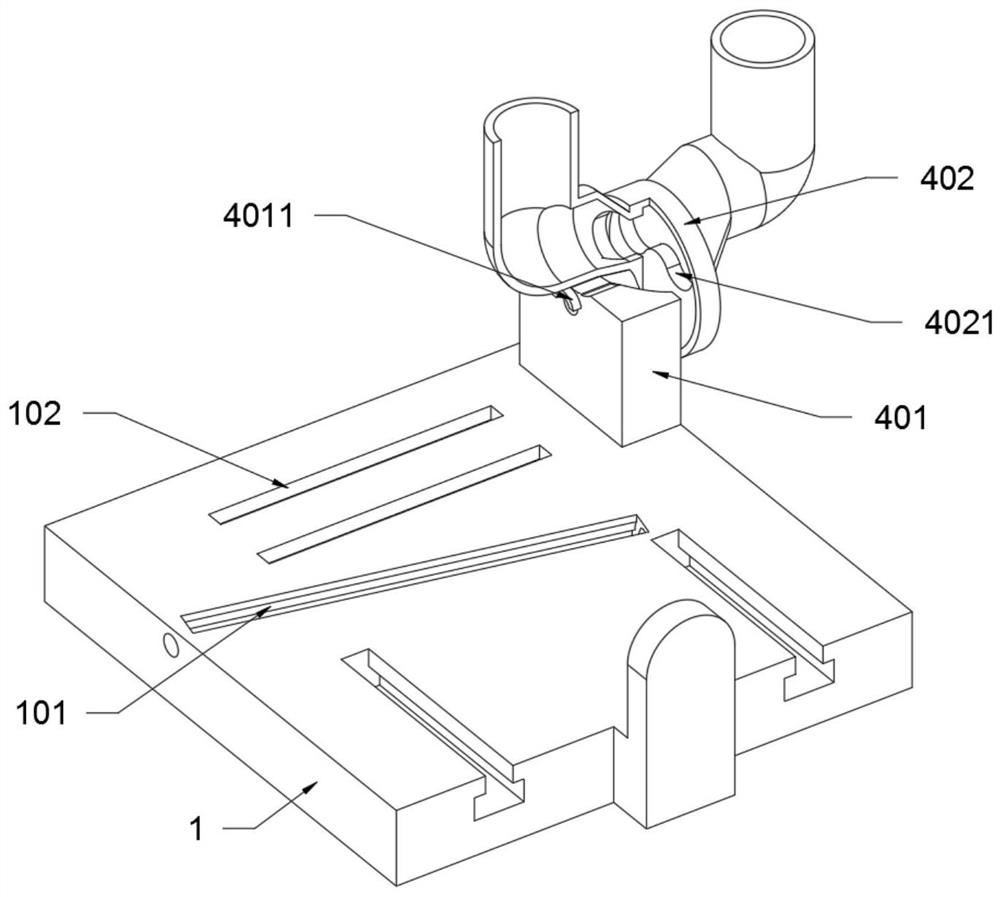

Device for screening seed particles

ActiveCN106622975ASimple structureEasy to operateGradingSeed coating/dressingEngineeringMechanical engineering

The invention discloses a device for screening seed particles. The device comprises a bar-type base. A bar-type workbench is fixedly connected to the upper surface of the bar-type base; the inner part of the bar-type workbench is of a hollow structure; a particle screening mechanism is arranged in the bar-type workbench; a quantitative inflow mechanism is arranged on the upper surface of the bar-type workbench; a carrying mechanism is located under the particle screening mechanism in the bar-type workbench; a moving mechanism is arranged on the lower surface of the bar-type base; and a controller is arranged on the side surface of the bar-type workbench. The device for screening the seed particles provided by the invention has the beneficial effects of simple structure and high practicability.

Owner:盐城滨博机械科技有限公司

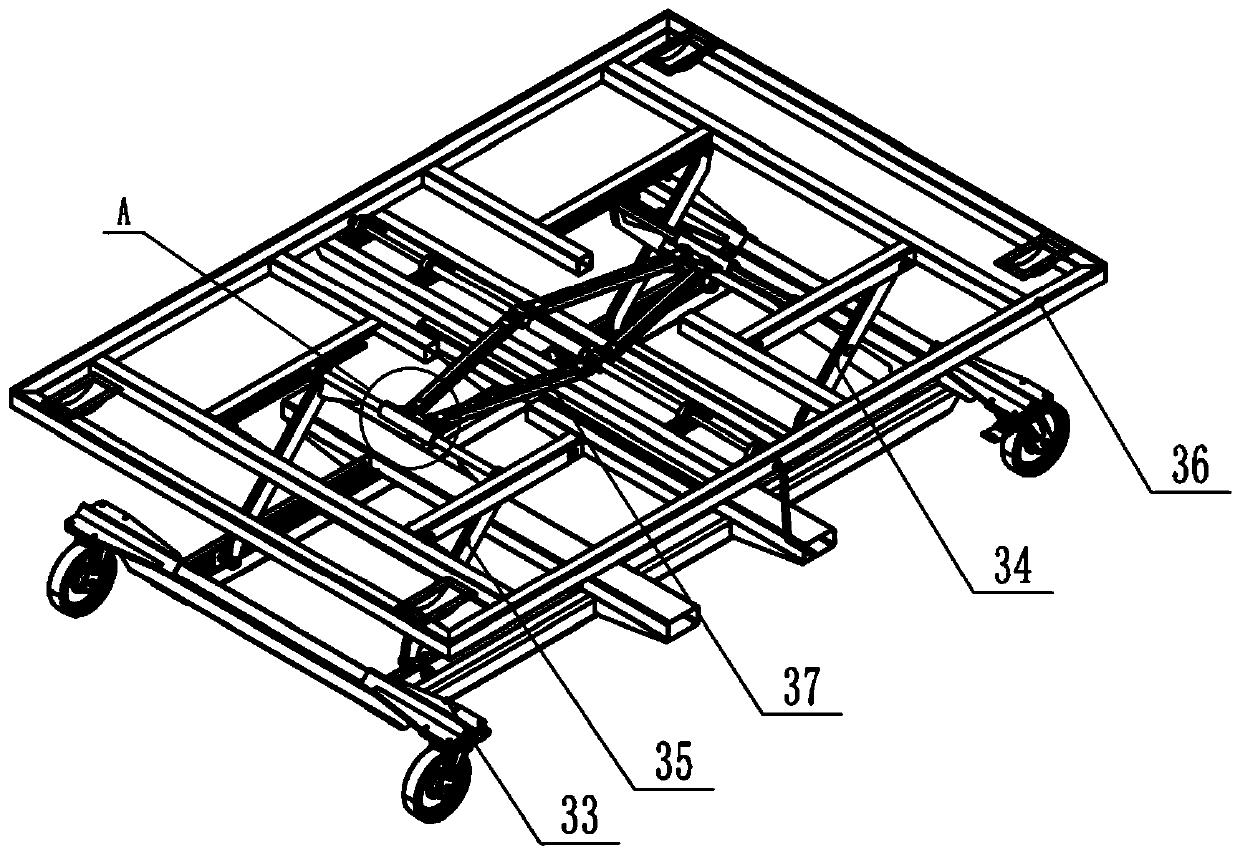

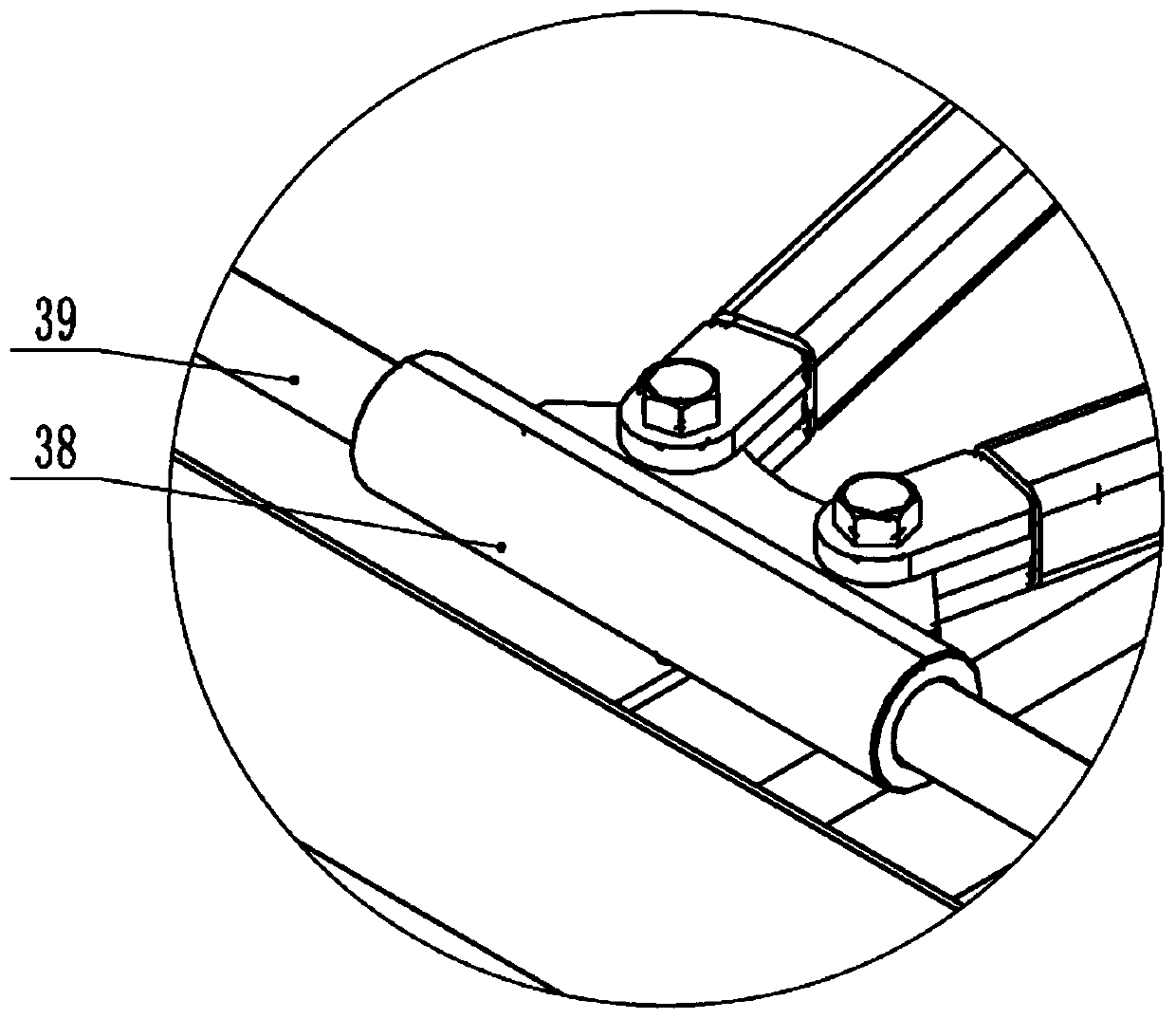

Automatic loading and unloading device for railway goods traffic

ActiveCN110789953AImprove loading efficiency and benefitsReduce labor intensityLifting framesSupporting framesTruckMechanical engineering

The invention discloses an automatic loading and unloading device for railway goods traffic. The problems that working personnel for railway manual loading and unloading is in shortage, when some specific goods are subjected to truck loading, efficiency is low, the manual loading and unloading work amount on a station is large, and truck loading efficiency at the station is directly affected are solved. The automatic loading and unloading device for railway goods traffic comprises a lifting table, a load bearing frame and a conveying device; a material collecting hopper is arranged above the conveying device; a driving block capable of sliding horizontally in a reciprocating manner in the front-back direction is arranged on the load bearing frame; a first adjusting rod, a second adjustingrod and a drive rod are hinged to the drive block; a guide rod is arranged on the right side of the drive block; the guide rod is fixedly connected with the load bearing frame; a first sliding block and a second sliding block capable of sliding in the left-right direction are arranged on the guide rod; fixing frames are fixedly connected to the first sliding block and the second sliding block correspondingly; a ramp is arranged on the load bearing frame and is provided with an L-shaped supporting rod which can slide along the ramp; and a scrabbling claw is fixedly connected to the front end ofthe L-shaped supporting rod. By means of the automatic loading and unloading device for railway goods traffic, the truck loading efficiency and benefits are improved, and the labor intensity of working personnel is relieved.

Owner:刘功利

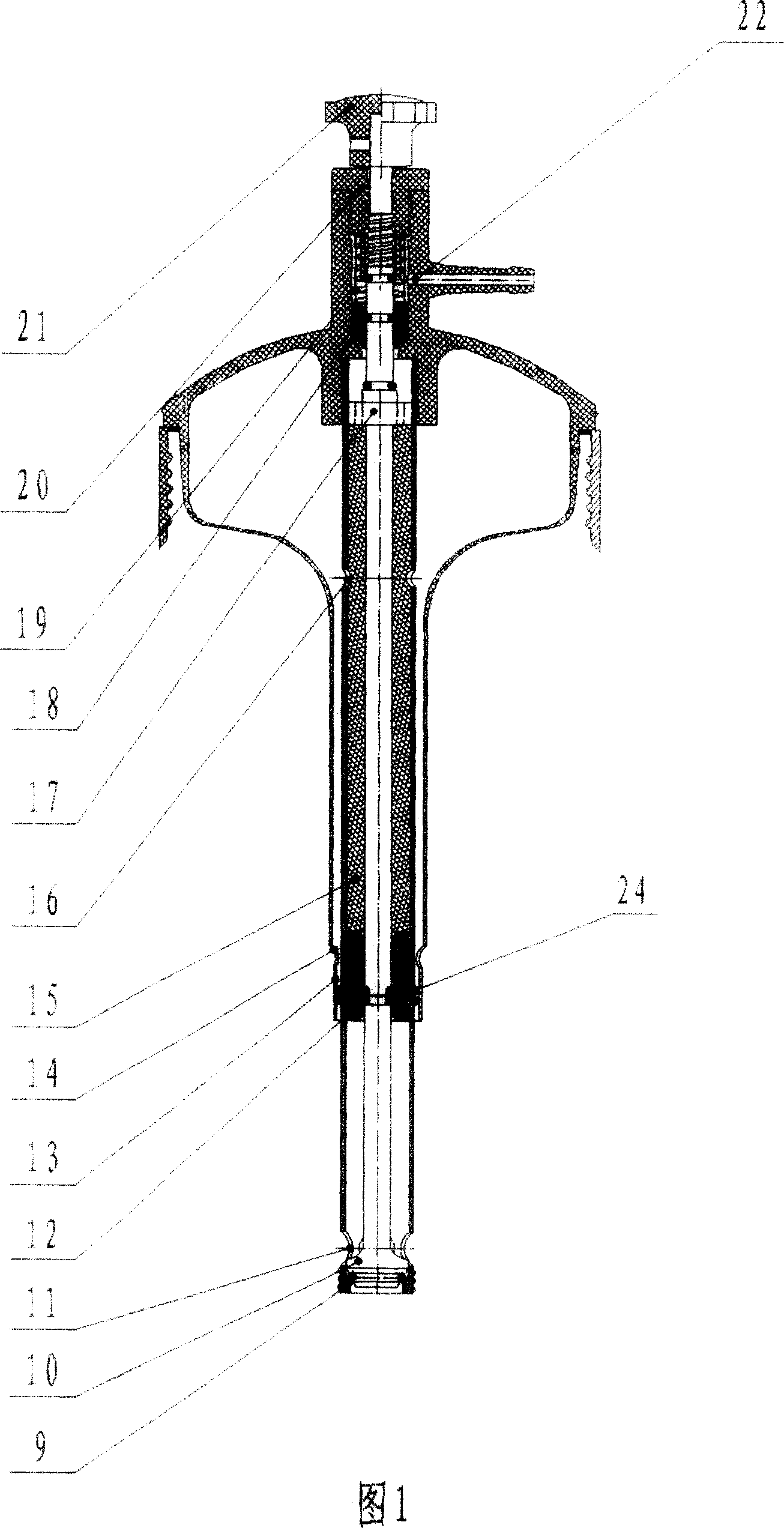

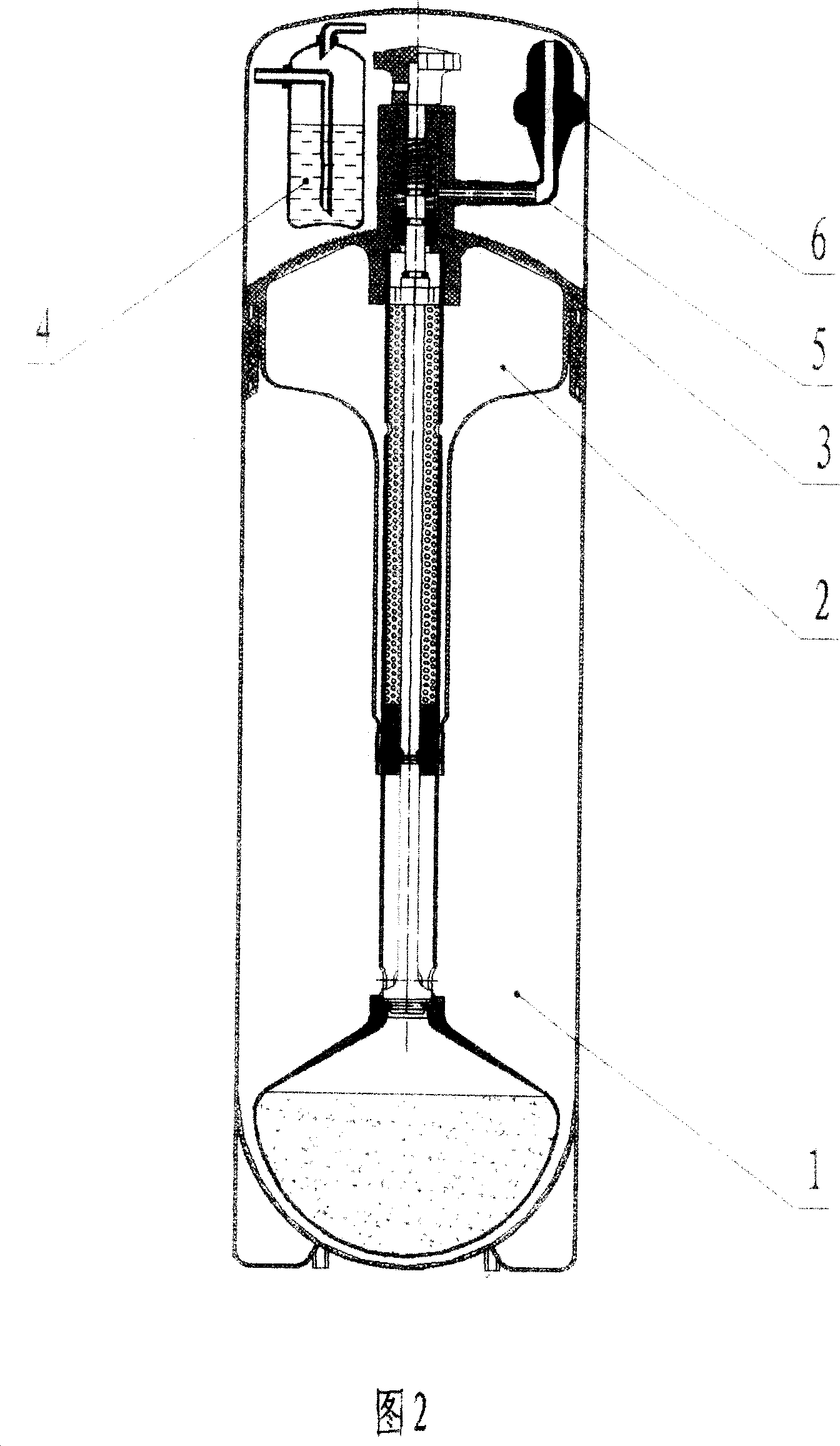

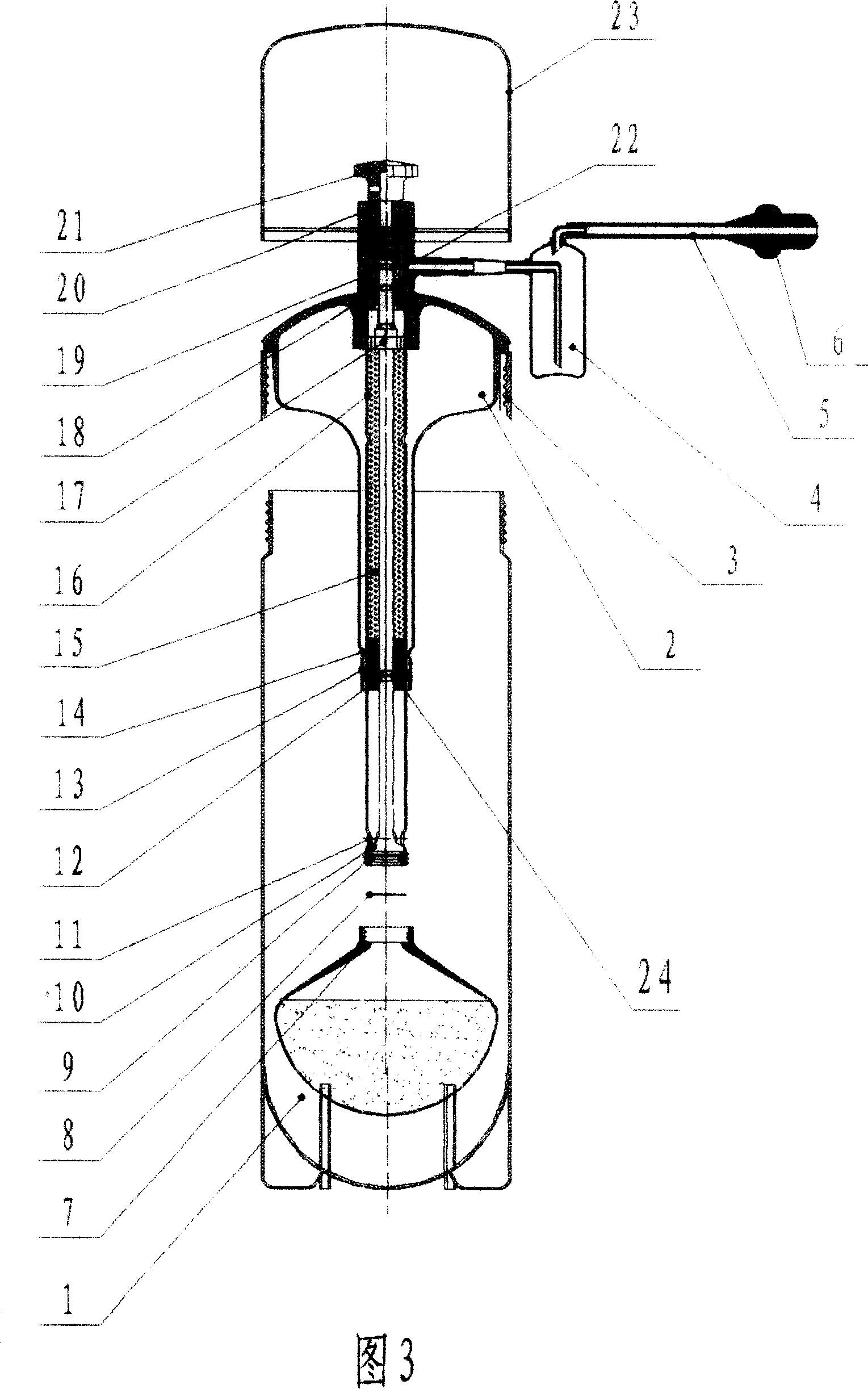

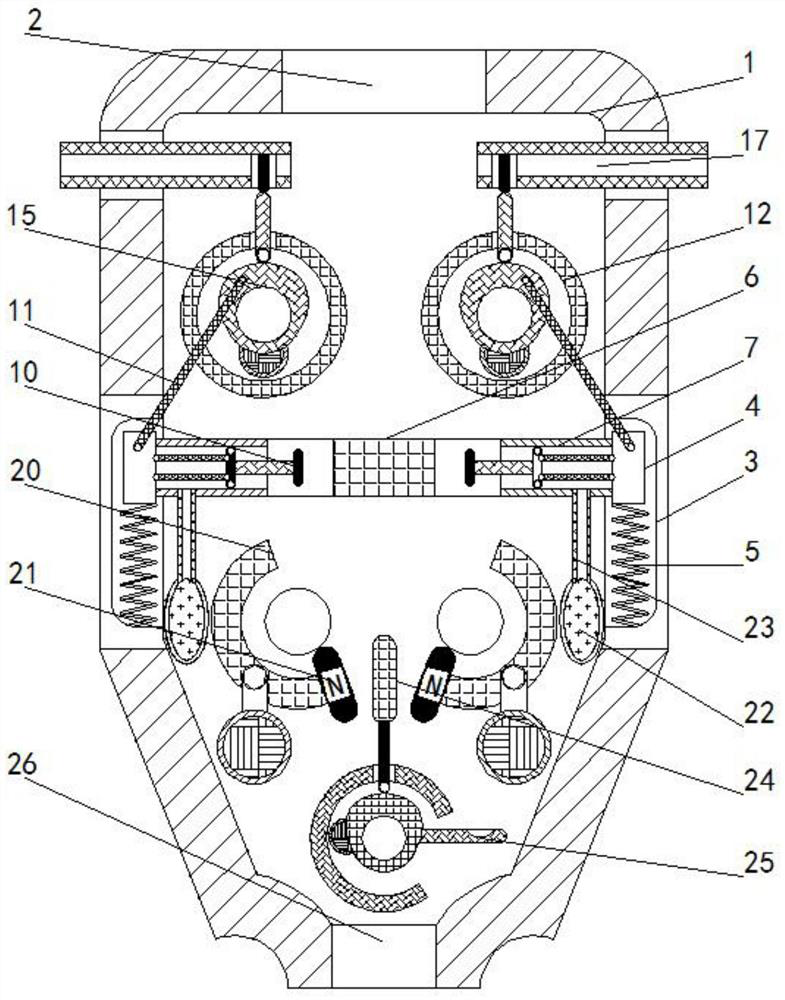

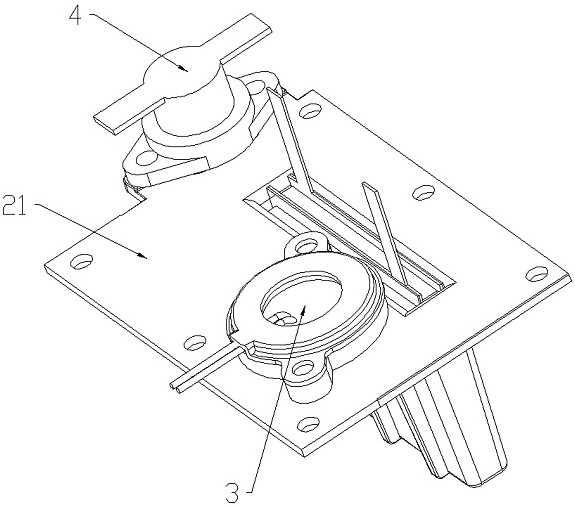

Gas-liquid-solid separation control valve and portable chemical oxygen producer using the same

InactiveCN101012897AControl ingressControl the displacementValve arrangementsOxygen respiratorsNoseOxygen

The invention discloses a gas-liquid-solid separating controlling valve and relative portable chemical oxygen producer, comprising a valve body 3, a water valve element 10, a valve element sheath 9, a compressing cover 20, a valve rod 17 and a button 21. The invention is characterized in that: the invention has a valve rod guide tube 13 whose lower end is arranged with a water inlet 11, a water feeding gas-insulated sealing sheath 12 and a porous filter membrane 15; the wall of the valve rod guide tube is arranged with an air inlet 14 and a filter air inlet 16; the upper chamber of the valve is arranged with a gas valve element 18, a spring 19 and an air outlet 22. The portable chemical oxygen producer is formed by an oxygen-generating room 1, a cover 23, an oxygen inlet tube 5, an oxygen inlet nose plug 6, a gas-liquid-solid separating controlling valve and an agent box 7. The invention can control the separation between liquid and solid, and between the liquid and gas. The invention presets the oxygen agent into the agent box.

Owner:赵祥 +2

Medicine crushing device for pediatric blood tumor nursing

The invention belongs to the technical field of medical instruments and in particular relates to a medicine crushing device for pediatric blood tumor nursing. The medicine crushing device comprises atank body, wherein a partition plate is fixedly connected with the inner side wall of the tank body; the interior of the tank body is divided into a crushing zone and a conveying zone by the partitionplate; an annular plate is fixedly connected with the side wall of the crushing zone; a first spring is fixedly connected with the upper end of the annular plate; a cylinder is inserted into the annular plate; a first spring is arranged on the outer side of the cylinder in a sleeving manner; a baffle plate is fixedly connected with the outer side wall of the cylinder; the lower end of the baffleplate is fixedly connected with the first spring; the upper end of the cylinder penetrates through a through hole in the top plate of the tank body and extends to the upper side of the top plate of the tank body; and an annular limiting plate is fixedly connected with the inner side wall of the cylinder. The medicine crushing device has the advantages that medicines which need to be crushed can beeffectively crushed, meanwhile, the crushed medicines can be quantitatively output outside the tank body, and great convenience can be brought to the nursing process of pediatric blood tumor.

Owner:北京享云智汇科技有限公司

Intelligent injection molding on-line visual inspection system

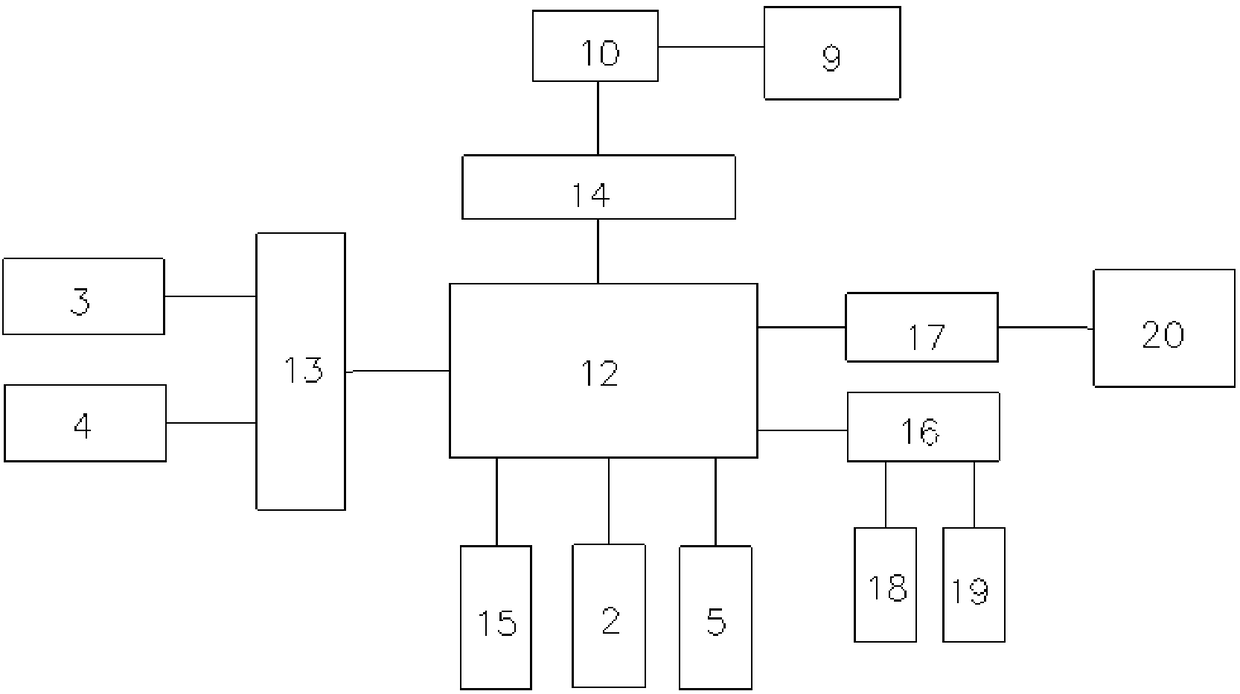

InactiveCN108226169AControl ingressRealize traceability of weighing measurement resultsOptically investigating flaws/contaminationVisual inspectionElectric machinery

The invention discloses an intelligent injection molding on-line visual inspection system including an injection molding machine, a weight type metering instrument, a plurality of cameras, a weighingsystem and a controller. The injection molding machine is provided with a feeding pipe, and the feeding pipe communicates with a hopper; the weight type metering instrument is arranged in the hopper;the injection molding machine is internally provided with a control manipulator, a driving motor, an injection molding mold and a weighing system; the plurality of cameras are arranged on the controlmanipulator respectively; the controller is mounted outside the injection molding machine. The system is simple in structure principle, convenient to use and high in intelligence degree, can realize the inspection control of the quality of products, traces the results of weighing and metering of a material, achieves contrast and linear relation calibration on the finished product after injection molding and metering data, monitors the injection-molded product quality, material usage amount, product weight and injection molding period of the injection molding machine in real time, and providesoriginal and accurate production large data for managers or customers.

Owner:上海熙视光电科技有限公司

Anti-blocking paper machine treatment box for quantitatively and automatically treating broken paper

InactiveCN112620309AControl ingressAvoid cloggingSievingSolid waste disposalControl theoryWaste paper

The invention relates to the technical field of paper machine waste paper treatment, and discloses an anti-blocking paper machine treatment box for quantitatively and automatically treating broken paper. The anti-blocking paper machine treatment box comprises a treatment box main body, a rotating wheel is movably mounted in the treatment box main body, a magnet is fixedly mounted at the bottom of the rotating wheel, and air bags are fixedly mounted on the inner walls of the left and right sides of the treatment box main body; and the tops of the air bags are fixedly connected with air guide pipes, a baffle is fixedly installed at the top of an ejector rod, and a water bearing plate is fixedly installed at the right side of a rotary disc. After a water solution does not fall onto the water bearing plate any more, the balance of the water bearing plate is damaged, so that the rotary disc deflects, the ejector rod drives the baffle to vertically move downwards, under the action of magnetic force of two magnets, the air bags restore to the initial shape, an extrusion plate moves towards the inner side of an air cylinder, through holes in a filter plate are enlarged, and the conduction area of the filter plate is increased, so that after the filter plate is blocked, the permeable area of the filter plate is automatically increased, and the effect of preventing the filter plate from being blocked is achieved.

Owner:温州熠虹贸易有限公司

Aluminum chip drying system

InactiveCN106017045AReasonable structural designEasy to useIncinerator apparatusHeating arrangementEngineeringExhaust pipe

The invention discloses an aluminum chip drying system. The aluminum chip drying system comprises an incineration furnace, a rotary drying furnace and a conveyor; a natural gas feeding device is mounted at the top end of the incineration furnace; one side of the tail end of the incineration furnace is communicated with the rotary drying furnace through an exhaust pipe a; the other side of the tail end is connected with an exhaust pipe b; the exhaust pipe a extends into the rotary drying furnace; a circulating pipe communicated with the incineration furnace is arranged above the left end of the rotary drying furnace; a circulating fan is mounted on the circulating pipe; an aluminum chip feeding pipe is arranged near the circulating pipe; an aluminum chip outlet is formed below the right end of the rotary drying furnace; and the conveyor is mounted at the tail end of the aluminum chip outlet. The aluminum chip drying system has the beneficial effects of reasonable structure design and convenience for operation and use; preheat in the incineration furnace is recovered through the rotary drying furnace for drying aluminum chips; meanwhile, afterheat can be recycled through the circulating fan, so that the energy is saved; the emission of waste gas is reduced; the product quality is improved; the operation cost is reduced; the working efficiency is improved; and the application range is wide.

Owner:昆山中能工业设备有限公司

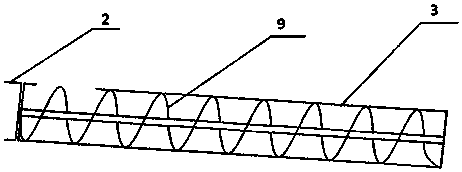

Rotary pushing type feeding device

The invention discloses a rotatable pushing type feeding device, which comprises a hopper, a pushing mechanism, a transport pipe, a rotating mechanism, a motor and a fixed frame; the rotating mechanism includes a rotating motor; the rotating motor is arranged on the fixing machine on the frame; the hopper is arranged on a fixed frame; the frame is provided with a bearing; the inner ring of the bearing is provided with a rotating shaft; the rotating motor and the rotating shaft are connected through gears; It is arranged on a fixed frame; the rotating shaft is connected to the transport pipe through a support rod; the push mechanism includes a push motor; the push motor is arranged on the transport pipe; the push motor is provided with a screw push shaft . The invention can avoid the trouble of secondary transportation, improve work efficiency, reduce workload, and effectively prevent materials from falling during transportation.

Owner:李金盛

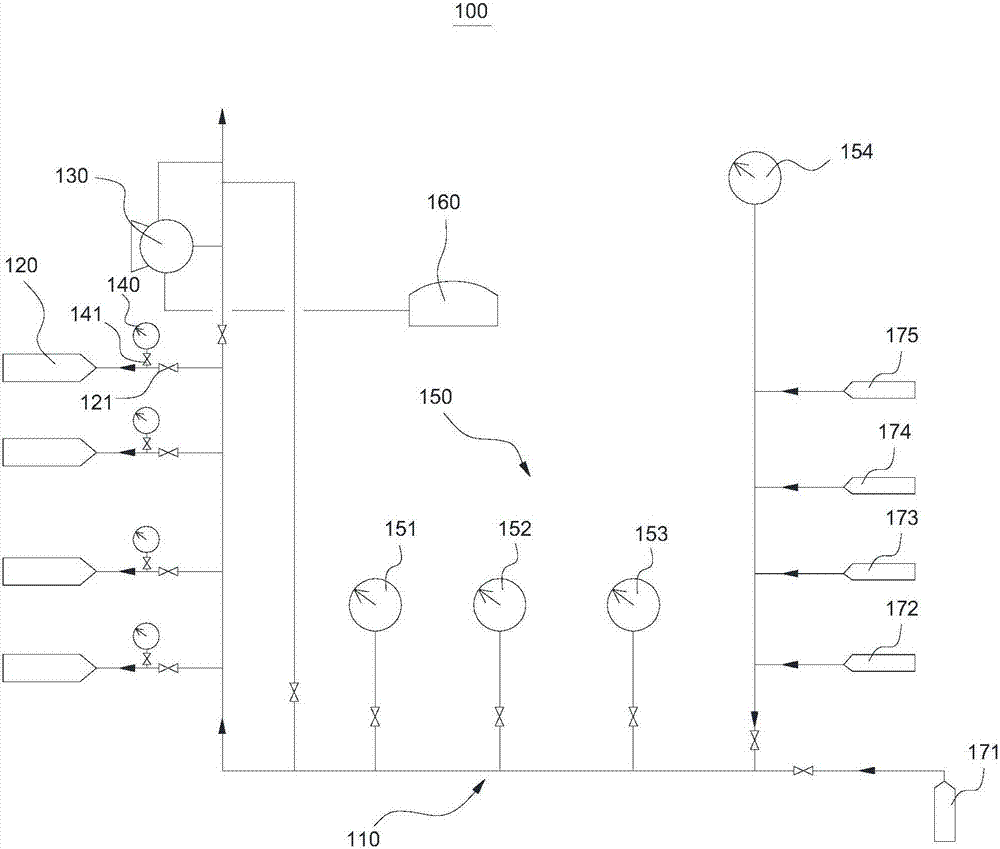

Rice freshness preserving gas, preparation method and preparation device thereof

ActiveCN107261968APrevent spoilageDelay agingTransportation and packagingMixer accessoriesInlet valveOxygen

The invention relates to the field of freshness preserving gases, and provides a rice freshness preserving gas. The rice freshness preserving gas comprises a diluent gas and functional gases. The functional gases include oxygen, vaporous water, carbon monoxide and carbon dioxide. The diluent gas refers to an inert gas. The invention further provides a preparation method and a preparation device of the rice freshness preserving gas. The preparation method used for preparing the rice freshness preserving gas is simple and includes the step of mixing the diluent gas, the oxygen, the vaporous water, the carbon monoxide and the carbon dioxide. The preparation method used for preparing the rice freshness preserving gas comprises a gas feeding pipeline, vacuum containers, a vacuum pump and first pressure gauges, the first pressure gauges are connected with the vacuum containers which are provided with gas inlet valves and connected with the gas feeding pipeline, and the vacuum pump is communicated with the gas feeding pipeline. The preparation device of the rice freshness preserving gas is simple and easy to operate, and obtained freshness preserving gas is high in precision.

Owner:贵州省科创气体有限公司

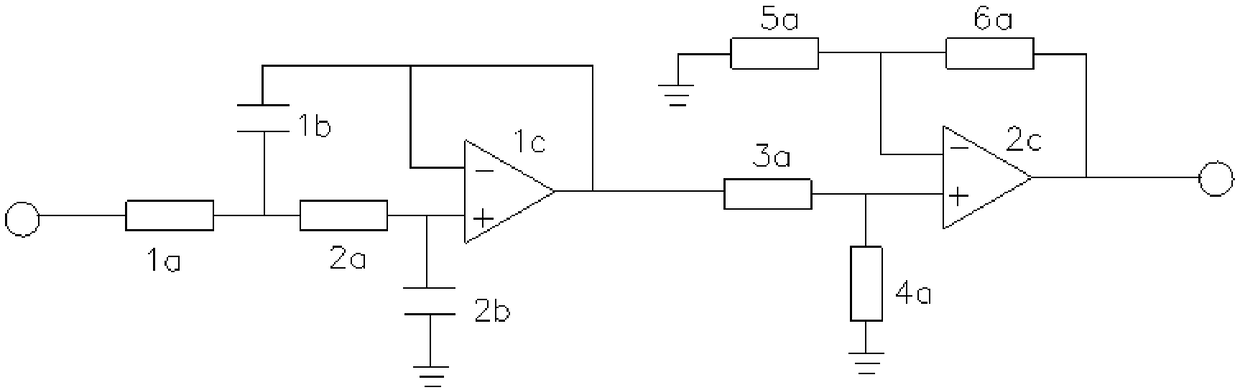

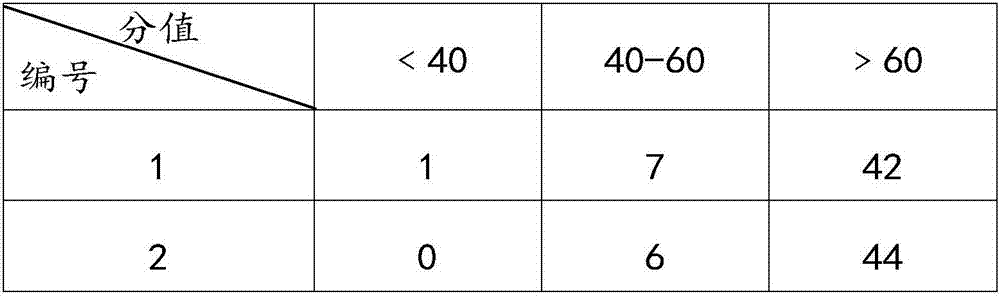

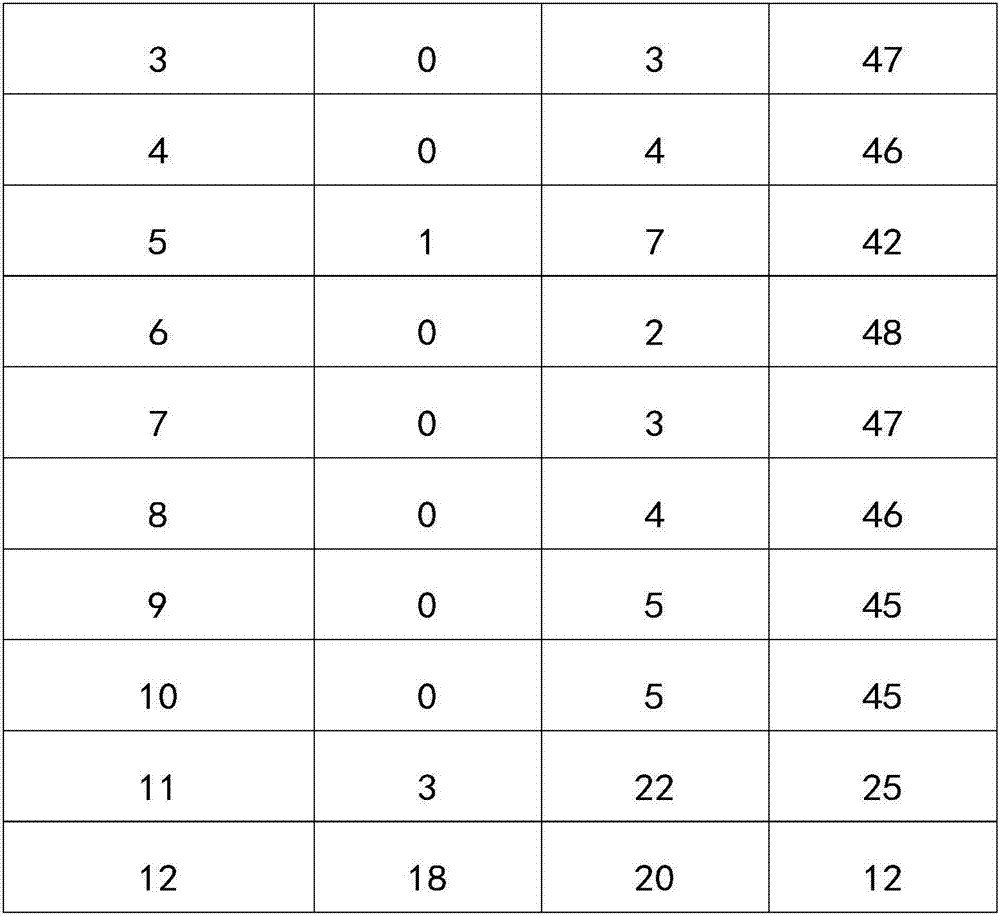

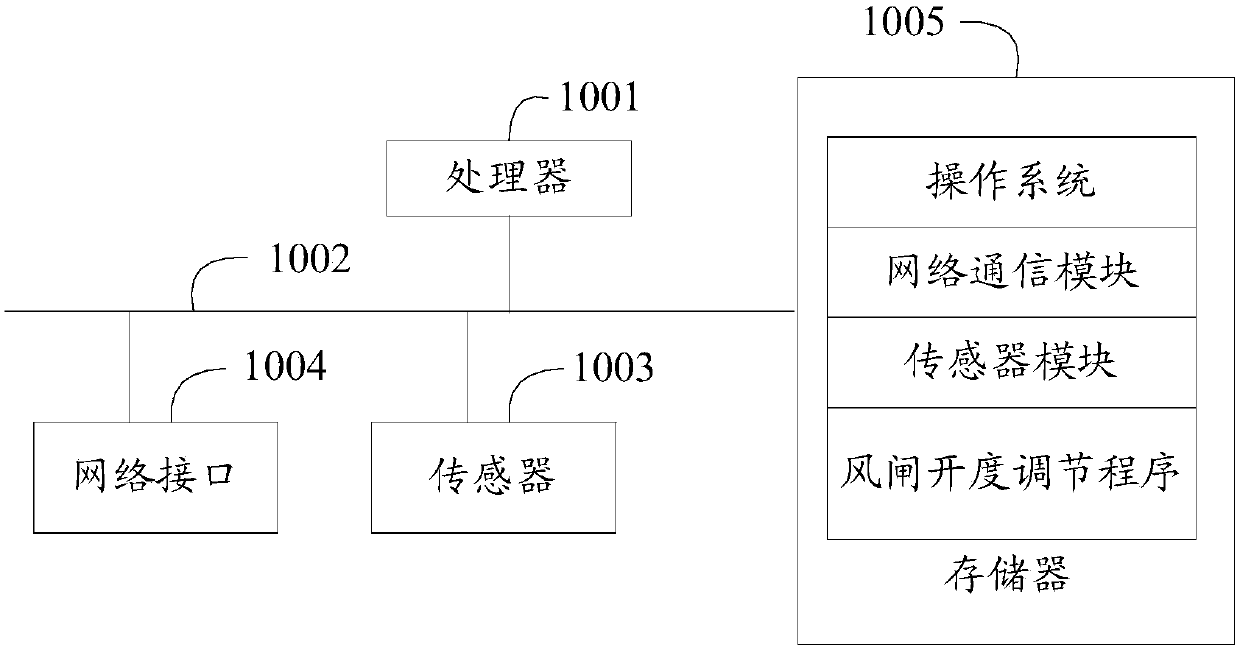

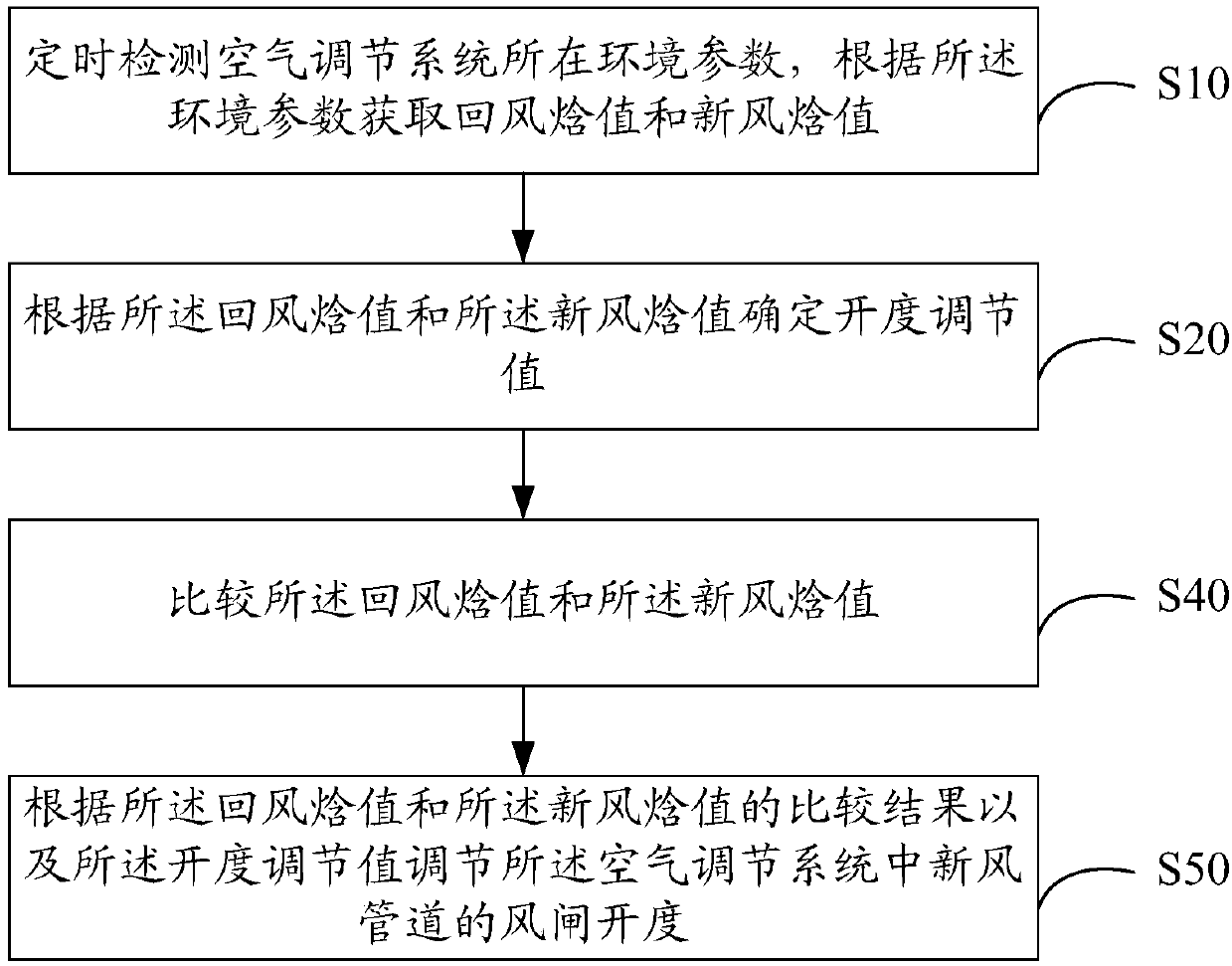

Method and device for controlling opening degree of air brake, and storage medium in air conditioning system

InactiveCN107726570AReduce workloadControl ingressMechanical apparatusElectric energyHeat regulation

The invention discloses a method for controlling the opening degree of an air brake in an air conditioning system. The method comprises the steps of detecting environmental parameters of the air conditioning system on time, and acquiring a return air enthalpy value and a fresh air enthalpy value according to the environmental parameters; determining the adjustment value of the opening degree according to the return air enthalpy value and the fresh air enthalpy value, and adjusting the opening degree of the air brake in the air conditioning system according to the adjustment value of the opening degree so that the supply air volume of the air conditioning system is adjusted. The invention also discloses a device for controlling the opening degree of the air brake, and a storage medium in the air conditioning system. The supply volume of outdoor air can be controlled effectively by adjusting the opening degree of the air brake in a fresh air pipeline according to indoor and outdoor air heat, and the workload of the air conditioning system and the power consumption are reduced.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Color mixing equipment for water-soluble chitosan textile processing

InactiveCN112426968AControl ingressControl precisionRotary stirring mixersTransportation and packagingThermodynamicsEngineering

Disclosed color mixing equipment for water-soluble chitosan textile processing comprises a box body, supporting legs are fixed to the four corners of the bottom of the box body through bolts, a temperature rising chamber is welded to the outer wall of the box body, electric heating wires distributed at equal intervals are fixed into the temperature rising chamber, and a temperature sensor is installed in the temperature rising chamber; and the top of the outer wall of one side of the temperature rising chamber communicates with a water inlet pipe, the bottom of the outer wall of the other sideof the temperature rising chamber communicates with a drainage pipe, a controller is fixed to the outer wall of the temperature rising chamber, and the inner wall of the bottom of the box body communicates with a discharging pipe. When raw materials enter the box body, a servo motor is used for driving a stirring rod to continuously rotate, so that the raw materials can be mixed more uniformly, and when the temperature of the raw materials is too low and the raw materials are condensed, cold water in the temperature rising chamber is heated through an electric heating wire, so that the raw materials in the box body are heated, and the fluidity of the raw materials is greatly improved, so that the raw materials are mixed more uniformly, and color mixing is more accurate.

Owner:SUZHOU DEHEYAXIN TEXTILE NEW MATERIAL TECH CO LTD

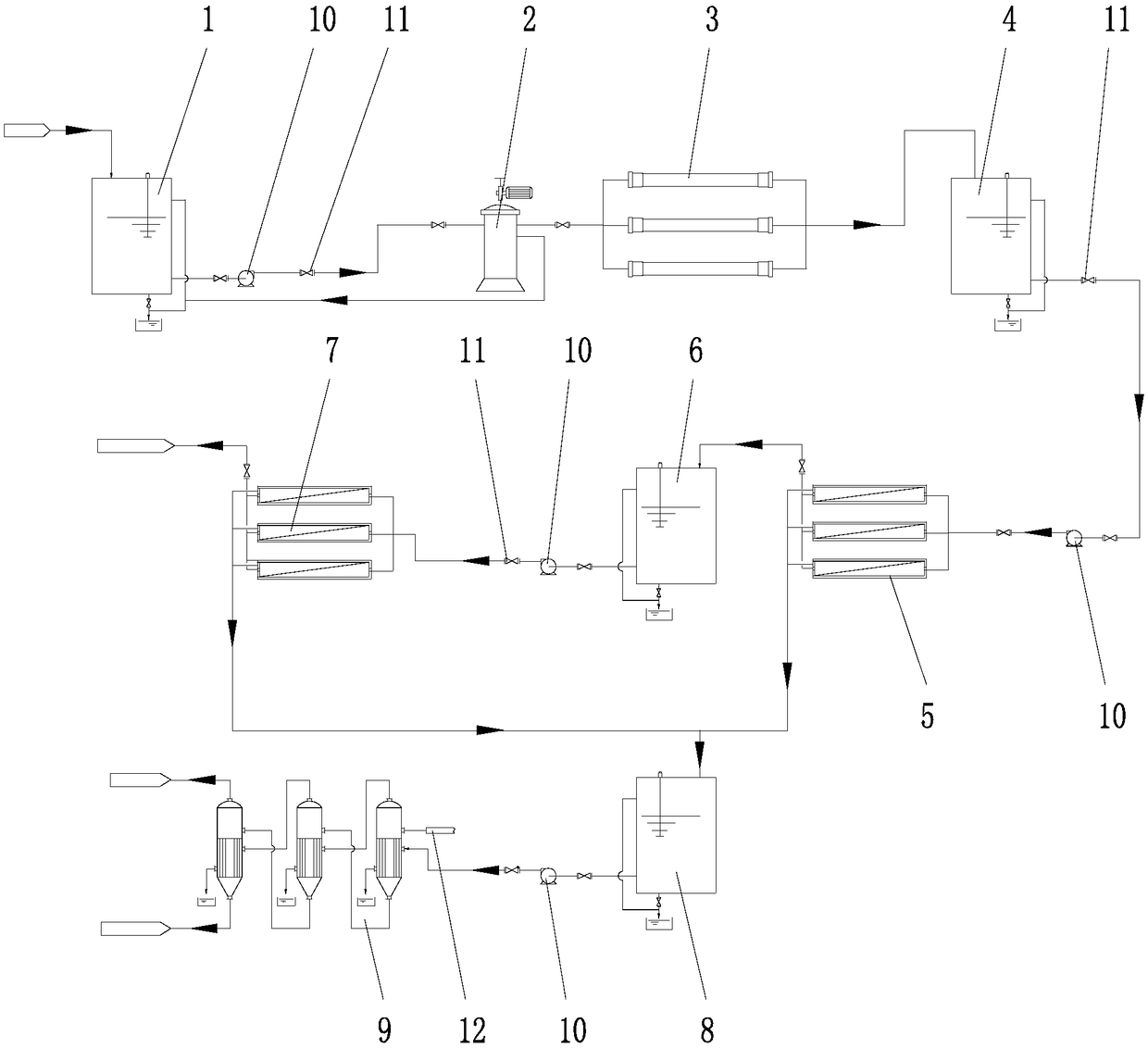

Zero discharge system of garlic processing wastewater

InactiveCN109467274ASolve problems such as wasteEfficient recyclingTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisProduced waterUF - Ultrafiltration

The invention provides a zero discharge system of garlic processing wastewater. The zero discharge system comprises an adjusting tank, a metal self-cleaning filter, a high-capacity ultrafiltration membrane system, a first middle water tank, a primary MS-R membrane system, a second middle water tank, a secondary MS-R membrane system, a concentrate tank and a multi-effect evaporator, wherein the adjusting tank, the metal self-cleaning filter, the high-capacity ultrafiltration membrane system, the first middle water tank and the primary MS-R membrane system are sequentially connected in a communicated way; a wastewater pipe of the metal self-cleaning filter is communicated with the adjusting tank; a concentrated water pipe of the primary MS-R membrane system, the concentrate tank and the multi-effect evaporator are sequentially connected in a communicated way; a produced water pipe of the primary MS-R membrane system, the second middle water tank and the secondary MS-R membrane system aresequentially connected in a communicated way. The zero discharge system solves the problems of secondary pollution, resource waste and the like in the process of garlic producing wastewater treatment, achieves zero organic wastewater discharge of the garlic processing wastewater and efficient recycling of active components, and achieves the recycling rate of 98% or above.

Owner:辽宁莱特莱德环境工程有限公司

Chemical mixing amount control grinding device

InactiveCN111992282AControl ingressQuality improvementCocoaGrain treatmentsElectric machineryEngineering

The invention discloses a chemical mixing amount control grinding device. The chemical mixing amount control grinding device comprises a main machine body, a main motor cavity is formed in the main machine body, a rotating cavity is formed in the lower side of the main motor cavity, chemical inlets are formed in the main machine body in a bilateral symmetry mode, and limiting blocks are arranged on the sides, close to the main motor cavity, of the chemical inlets in a bilateral symmetry and sliding mode. The machine body can perform a preliminary extrusion procedure in a rotating disc, the amount of chemicals entering the machine body can be controlled and the proportion of mixed chemicals can be controlled by controlling forward and reverse operation of a power source, a fine grinding mechanism is arranged to further grind unqualified chemicals in the extrusion procedure, the quality of finished products is improved, and only one power source is used for grinding machining, so that the machining process is finer, and more practical benefits are achieved.

Owner:绍兴上虞宋润化学科技有限公司

Environment-friendly chemical stirring equipment

InactiveCN108889185AReduce vibrationExtended service lifeTransportation and packagingRotary stirring mixersHydraulic cylinderEngineering

The invention belongs to the technical field of chemical equipment and particularly relates to environment-friendly chemical stirring equipment. Aiming at the problem that chemical stirring equipmentdoes not have environmental protection property, the invention discloses the following scheme: the environment-friendly chemical stirring equipment comprises a base, wherein mounting blocks are weldedto the outer walls of two ends of two sides of the base, first hydraulic cylinders are connected to the outer walls of the bottoms of the four mounting blocks through bolts, dampers are connected tothe outer walls of the bottoms of the first hydraulic cylinders through bolts, and rubber cushions are connected to the outer walls of the bottoms of the dampers through bolts; and first mounting slots are formed in the outer walls of four corners of the top of the base, and a second hydraulic cylinder is connected to the inner wall of the bottom of the first mounting slot in one side through a hinge. By arranging a solar cell panel, solar energy can be converted into electric energy, so that an environmental protection effect is achieved; and by arranging an optical sensor, an electric telescopic rod and a processor, the solar cell panel can be adjusted to a proper angle, so that the highest conversion efficiency of the solar energy is realized, and the electric energy is saved.

Owner:刘艳

Instant edible fungus material sterilization device

InactiveCN113951054AOptimizing the High Temperature Sterilization ProcessImprove the efficiency of high temperature sterilizationCultivating equipmentsMushroom cultivationProcess engineeringEdible mushroom

The invention discloses an instant edible fungus material sterilization device. Connecting lifting lugs are welded to the top ends of four mounting supports correspondingly, the connecting lifting lugs are evenly welded to the top of the outer side of a sterilization barrel, a feeding port is formed in one side of the top of the sterilization barrel, and a feeding pipeline is connected to the top end of the feeding port through bolts. In the sterilization process of the fungus material, a fungus material only needs to be added at the feeding end of a feeding auger pipe, automatic high-temperature sterilization can be carried out through each component in the sterilization barrel, and then the sterilized fungus material can be obtained at the discharging end of the discharging auger pipe, so that the high-temperature sterilization process of the fungus material is optimized, and manual participation in the sterilization process is reduced; and meanwhile, an intermittent high-temperature sterilization mode in the traditional sterilization process is changed into continuous sterilization, so that the high-temperature sterilization efficiency of the fungus material is effectively improved, the sterilization device can continuously sterilize the fungus material in a large scale, and the economic benefits of enterprises are effectively improved.

Owner:JIAMUSI UNIVERSITY +1

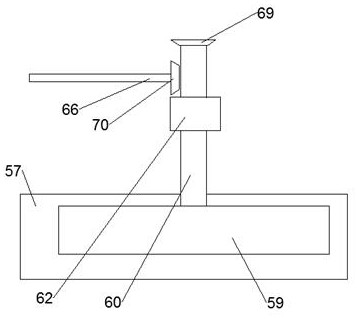

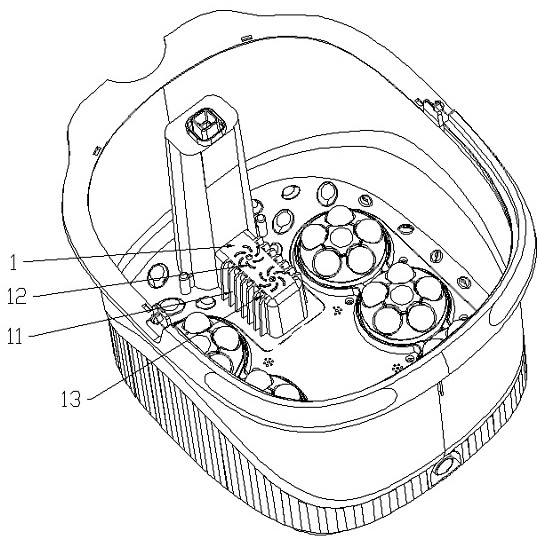

Ultrasonic atomization, fumigating and heating module of foot bath device

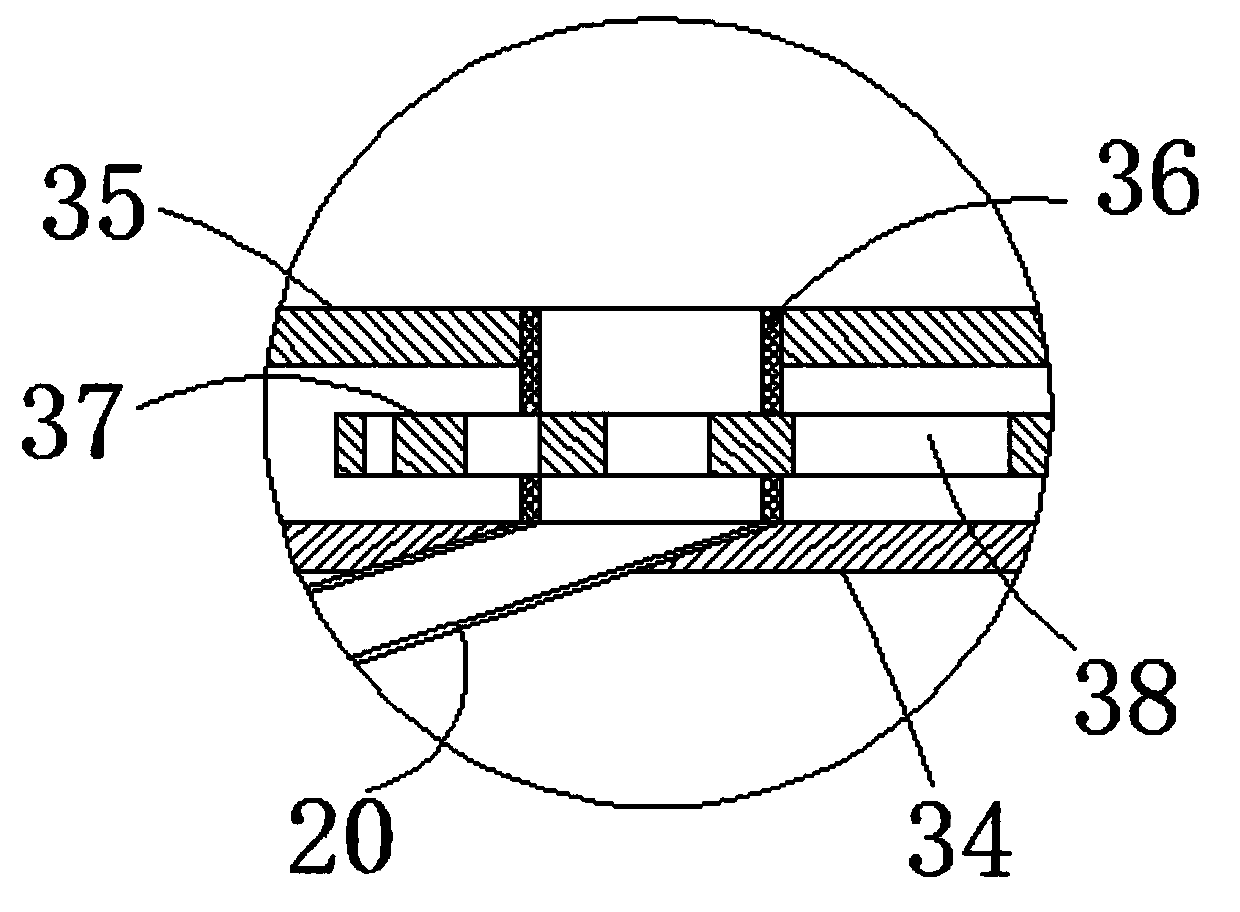

PendingCN113230117AImprove atomization effectIncrease contact areaMedical devicesBathing devicesEngineeringBathinette

The invention relates to the field of foot bath devices, and discloses an ultrasonic atomization, fumigating and heating module of a foot bath device. The module comprises a heating shell and a heating assembly, the heating assembly is used for heating water in the foot bath device, the heating assembly is arranged in the heating shell, and the atomization effect is improved; wherein, the high-frequency oscillation is generated through an ultrasonic ceramic piece, so that water at the ultrasonic ceramic piece is atomized, atomized steam moves upwards and is scattered out through flowing holes, the foot bath tub of the foot bath device is filled with the atomized steam, and the function of steaming and fumigating the feet is achieved; first contact bodies and second contact bodies respectively increase the surface areas of a convex shell and the heating shell, so that the contact area with water is increased, and the heat exchange efficiency is improved; the number of the second contact bodies is greater than that of the first contact bodies, so that the number of the square holes is increased; therefore, the inlet amount of cold water or the outlet amount of hot water in each square hole is controlled, heat exchange is achieved with a small flow amount, and the heat exchange efficiency is improved.

Owner:徐剑

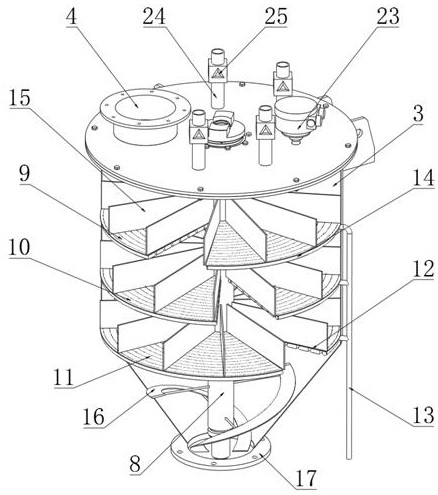

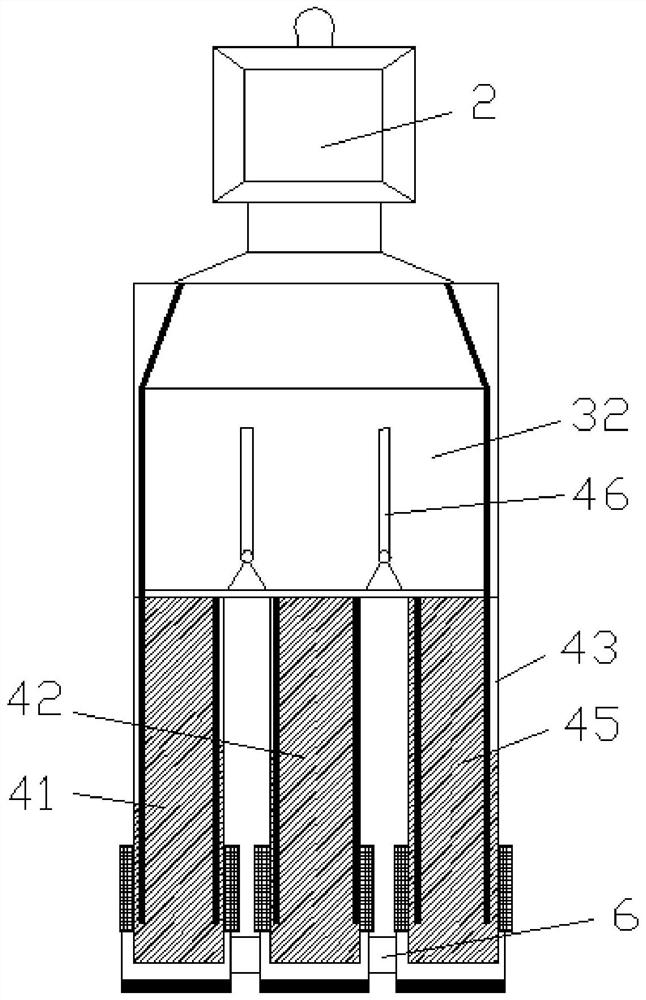

Spray drying device for preparing protein small peptide chelated zinc

ActiveCN114307203AControl ingressControl the amount of atomizationEvaporator accessoriesEvaporation by sprayingSmall peptideChelated zinc

The invention provides a spray drying device for preparing protein small peptide chelated zinc, which comprises a box body mechanism, an upper cover mechanism, a base mechanism and a wall scraping mechanism, the upper cover mechanism and the base mechanism are fixedly connected to the upper end and the lower end of the box body mechanism respectively, and the upper cover mechanism and the base mechanism form a closed container with the box body mechanism; an air heater is fixedly mounted on the side wall of the box body mechanism and is communicated with the box body mechanism; the lower end of the upper cover mechanism is rotationally connected with a rotating mechanism, and atomization mechanisms are installed on the two sides of the rotating mechanism. According to the device, the infrared distance meter fixedly installed on the upper cover body is used for detecting the distance between the wall scraping mechanism and the upper cover body, the feeding amount of materials is controlled according to continuous changes of the shortest distance, then the atomization amount in the box body mechanism is controlled, and the situation that in the drying process, drying is not complete due to too much atomization amount, and drying is not complete can be effectively prevented. The powder which is completely dried is attached to the inner wall of the box body mechanism, so that the drying efficiency of the device is kept to the maximum.

Owner:HUNAN DEBANG BIOLOGICAL TECH CO LTD

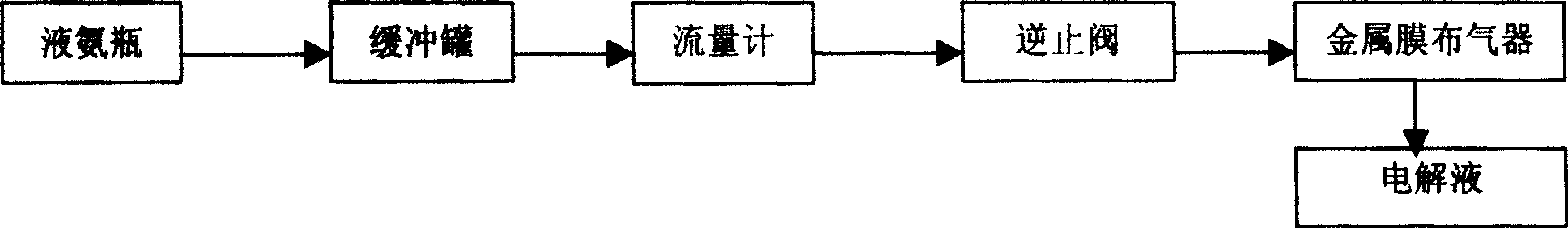

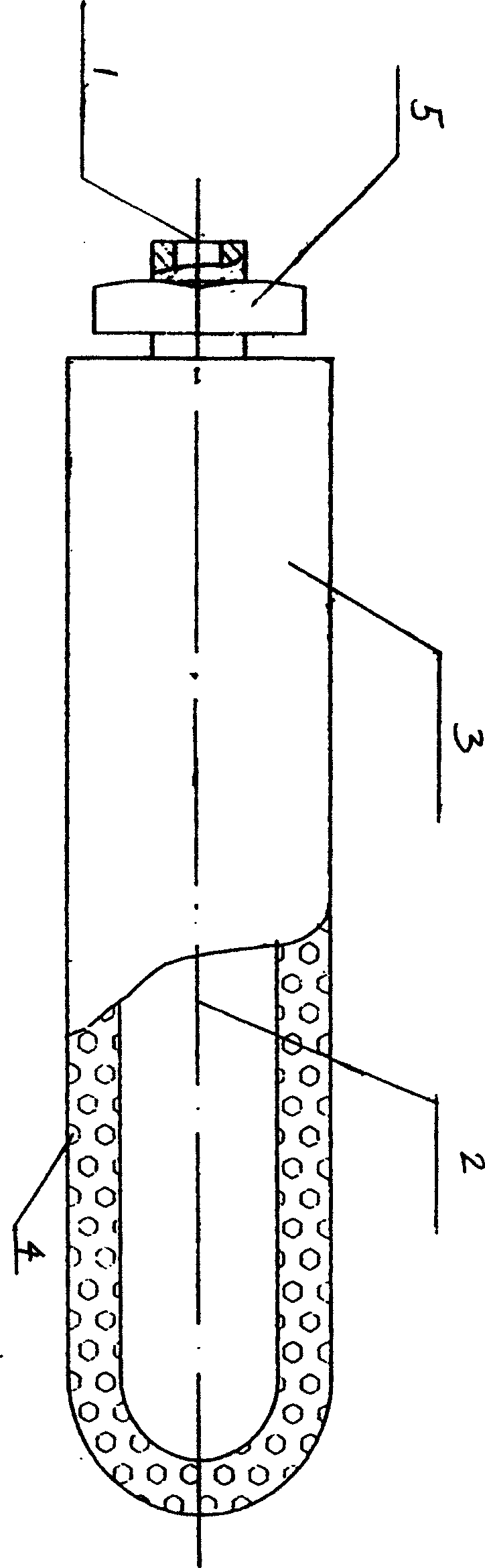

Method for control PH value of nickel powder electrolyte

The invention discloses a method for controlling the pH value of nickel powder electrolyte, relating to a process method for controlling the acidity and alkalinity of electrolyte in the electrolysis process in the production of electrolytic nickel powder. It is characterized in that the ammonia gas at the outlet of the liquid ammonia bottle is first passed into the buffer tank, and then the pH value is controlled through the flow meter, the check valve, the metal film gas distributor, and the electrolyte. In the method of the invention, an ammonia gas flow metering device is added at the outlet of the liquid ammonia bottle, which can effectively control the flow rate of the ammonia gas at the outlet of the ammonia bottle, control the amount of ammonia entering the electrolyte, and achieve the purpose of adjusting the pH value of the electrolyte. And the ammonia gas passes through the metal film gas distributor to make the gas distribution even, eliminate the large number of bubbles, reduce the waste caused by the overflow of ammonia gas, and improve the on-site operating environment.

Owner:JINCHUAN GROUP LIMITED

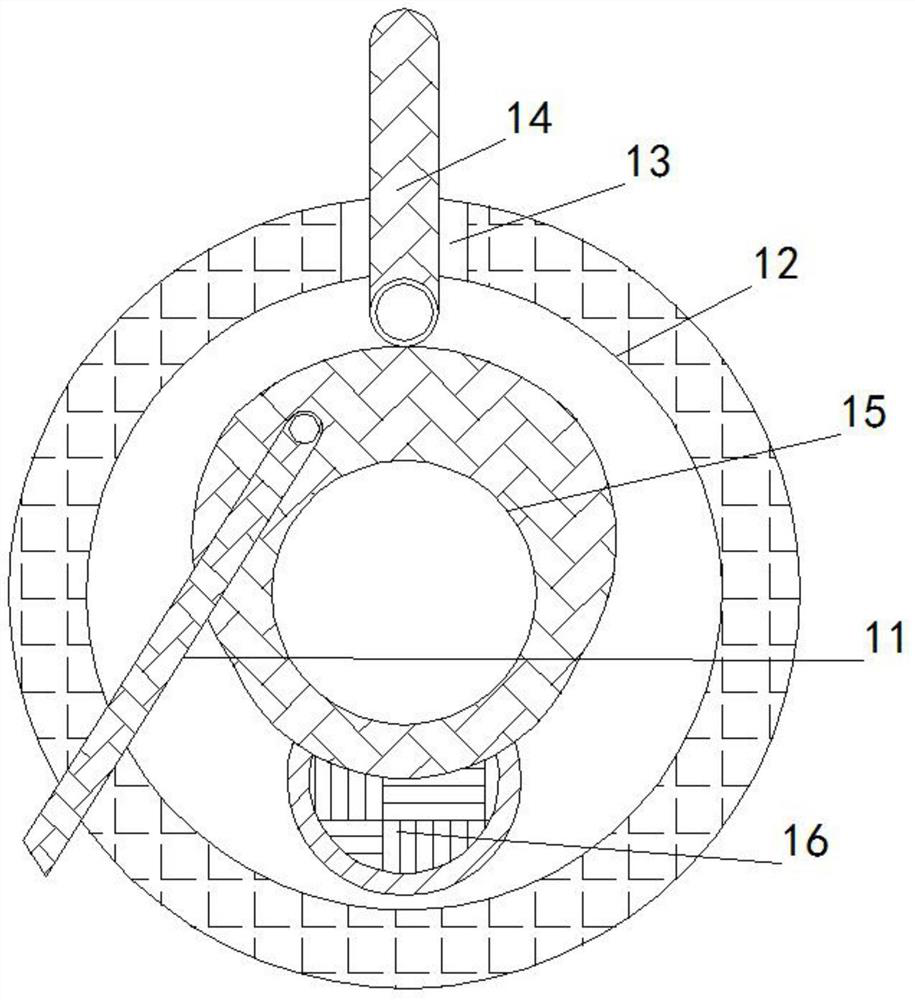

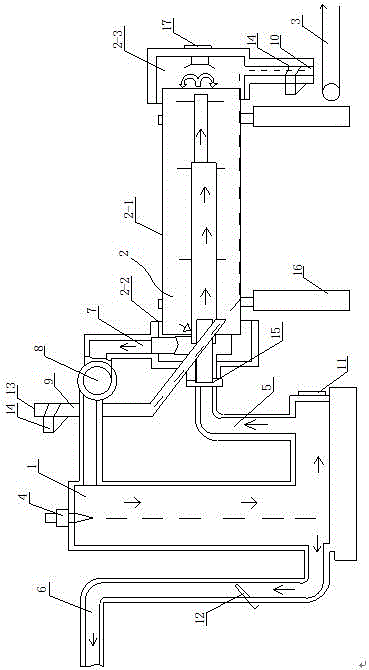

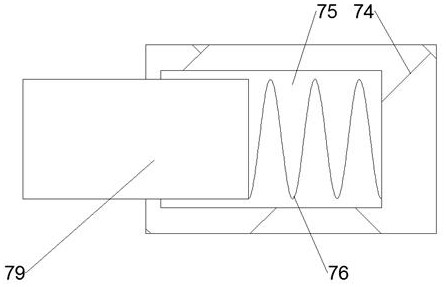

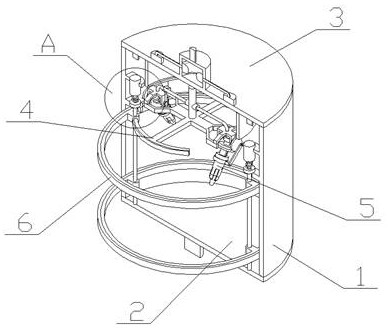

Sterile wort oxygenator

ActiveCN110846162AWell mixedImprove mixing efficiencyWort preparationSustainable biological treatmentProcess engineeringMechanical engineering

The invention discloses a sterile wort oxygenator which comprises a main tube and a mixer. One end of the main tube is communicated with the mixer, a first sealing ring fixedly sleeves the main tube,one side of the first sealing ring is abutted to the outer wall of the mixer, a pressure meter is arranged at one end, far away from the mixer, of the main tube, a filter screen is slidably inserted into one end, close to the pressure meter, of the main tube, one end of the filter screen penetrates the inner wall of the main tube and is fixedly connected with a fixing block, a filter is arranged on one side, far away from the pressure meter, of the filter screen and fixedly inserted into the main tube, two ports communicated with the main tube are formed in the filter, and a plurality of adsorption nets are fixedly inserted into the filter. By the aid of a plurality of filtering mechanisms and stirring mechanisms, the oxygenator can sufficiently filter oxygen and realize mixing of oxygen and other substances, so that beer production quality is improved.

Owner:福建杜尔阀业科技有限公司

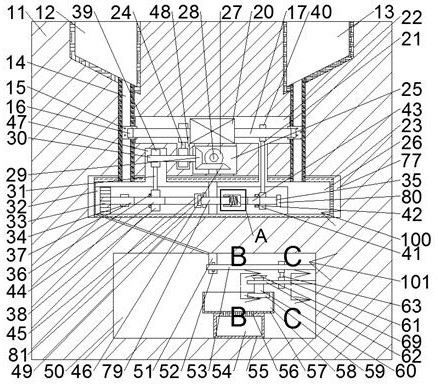

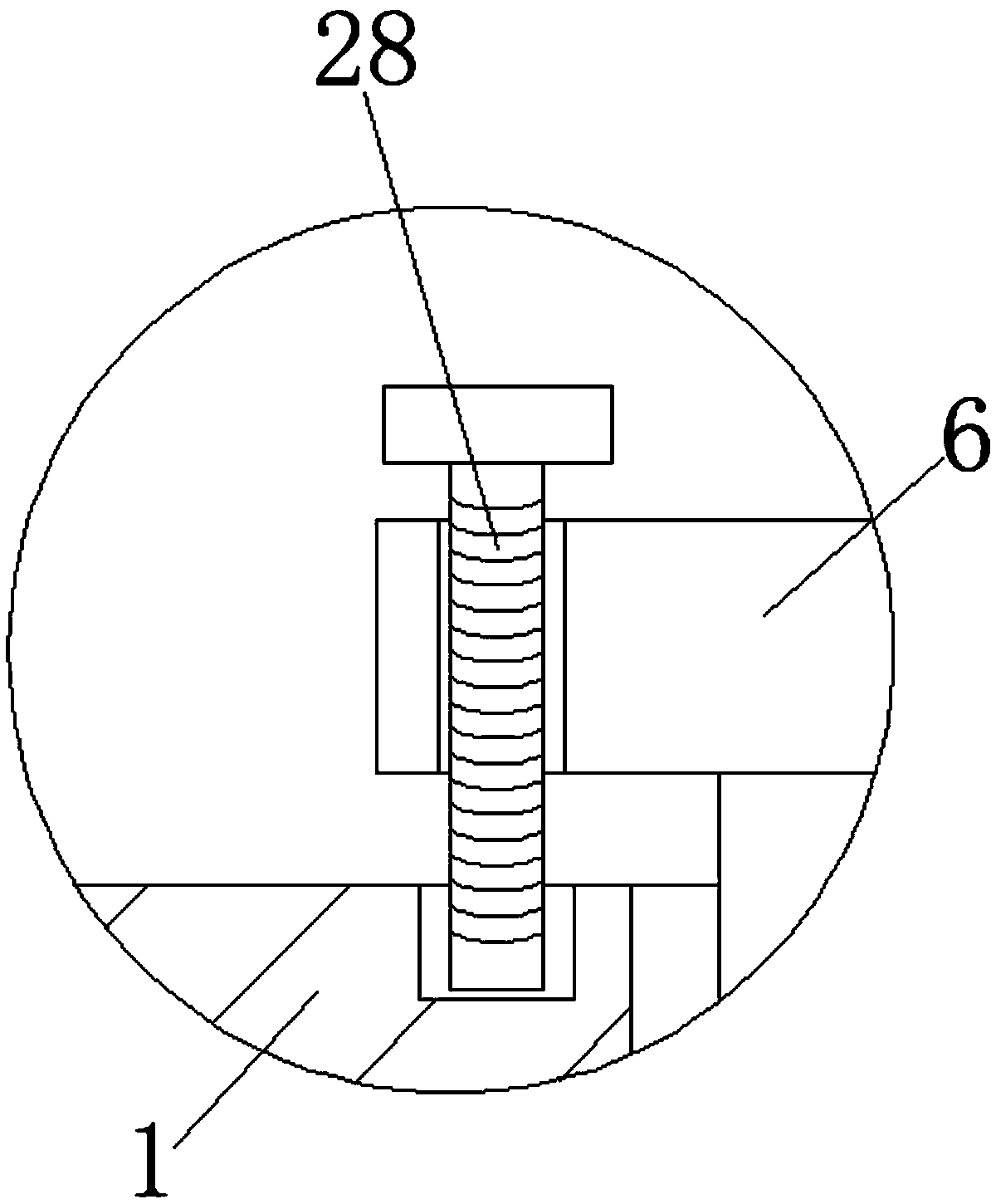

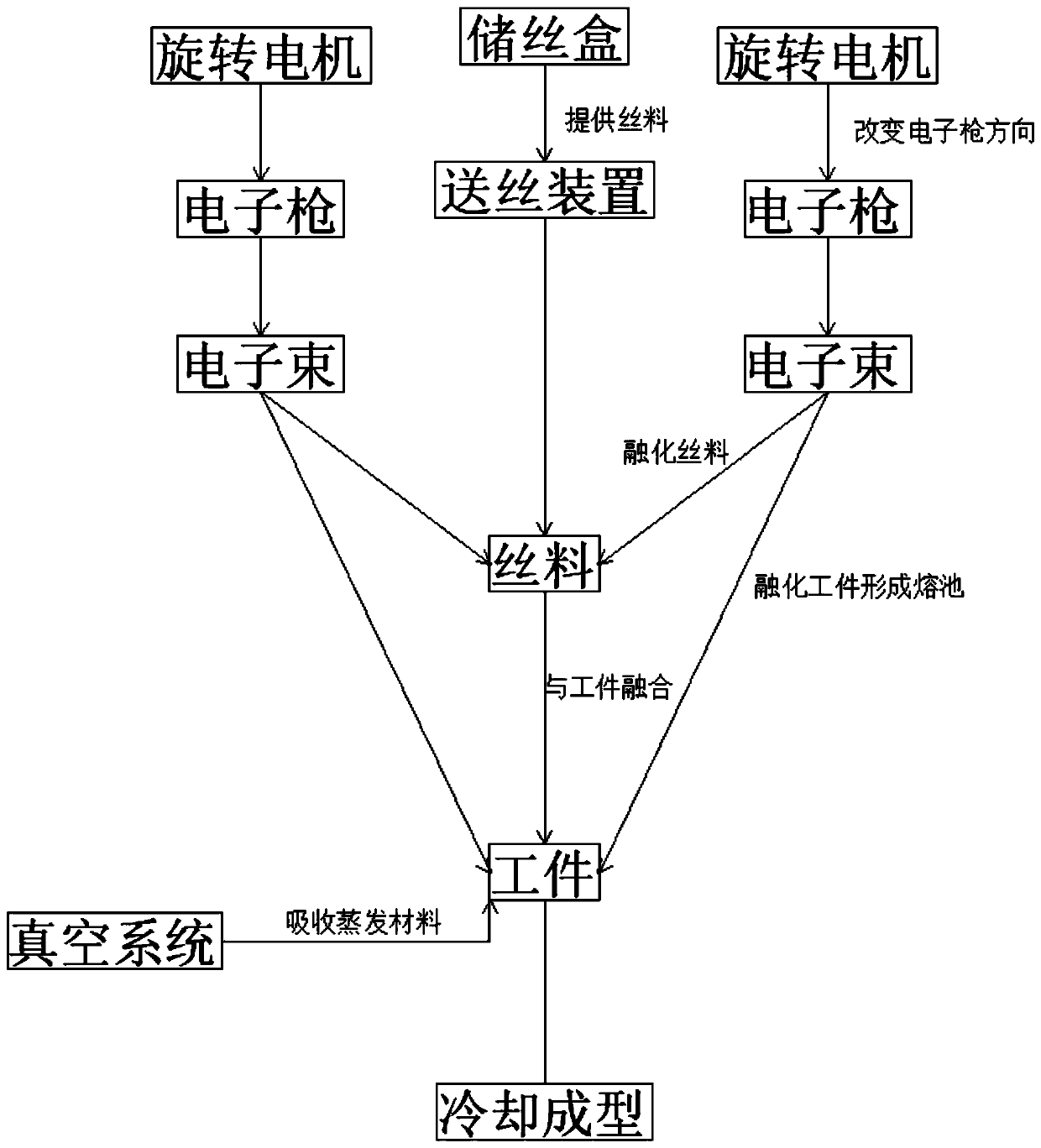

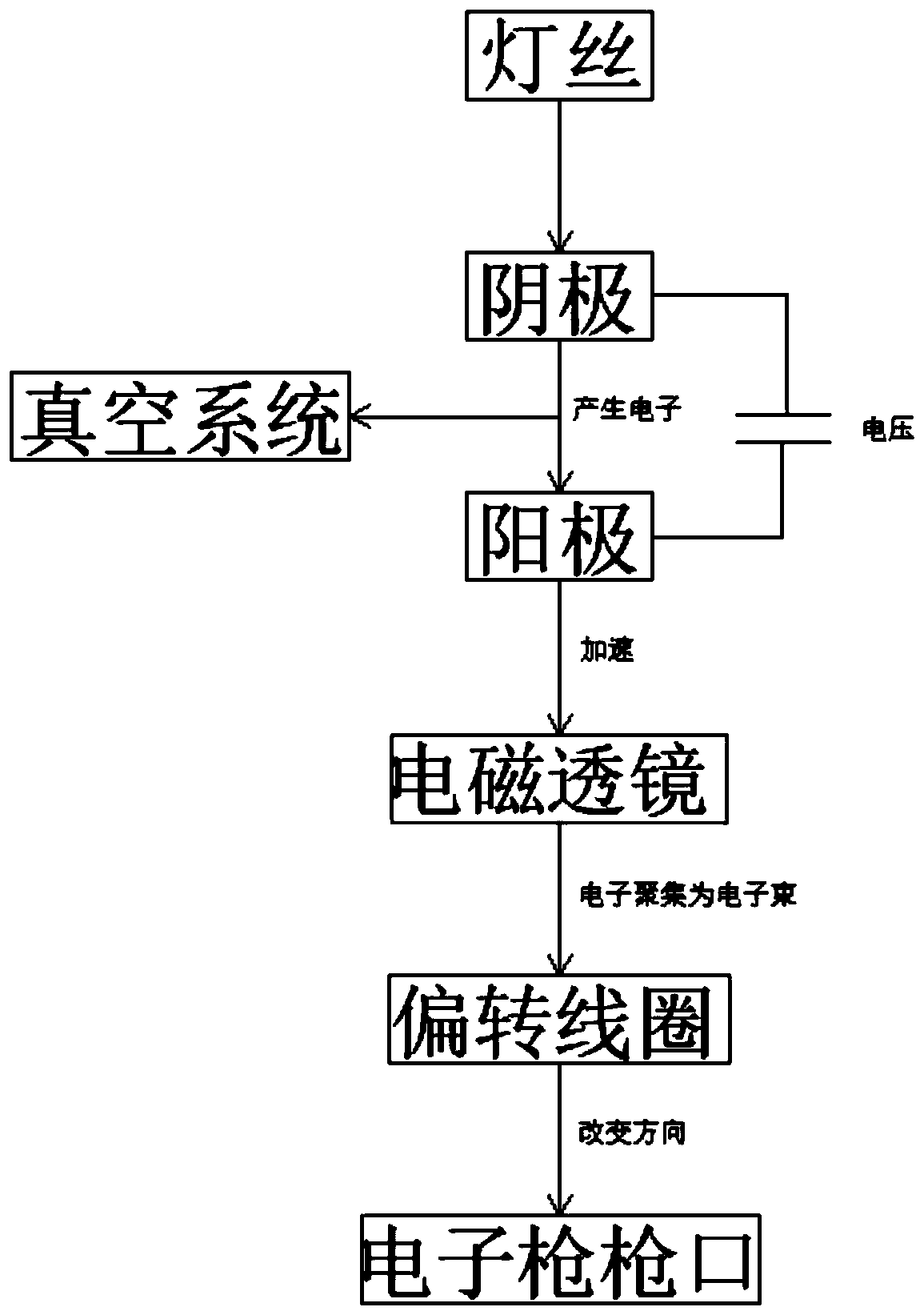

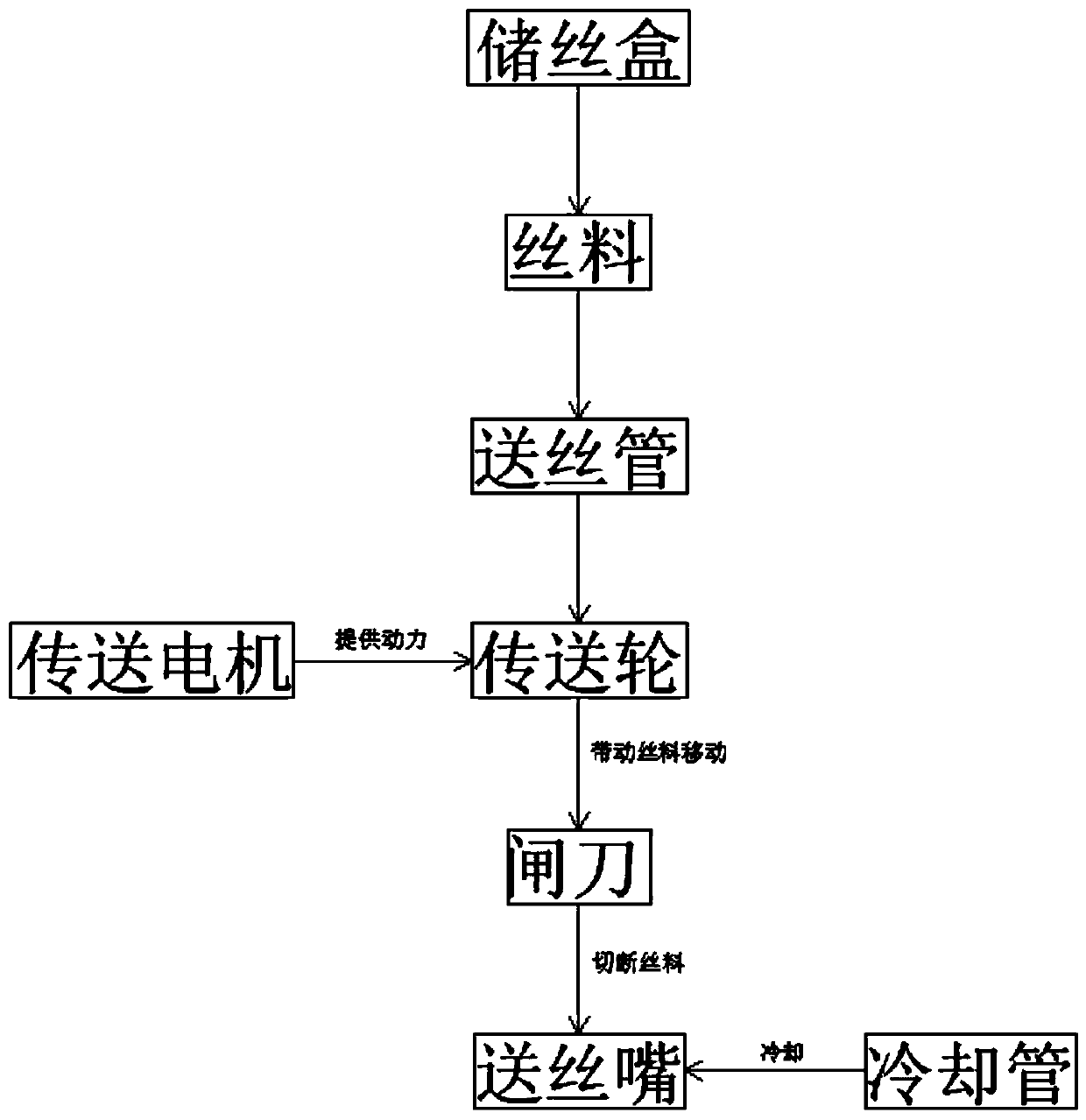

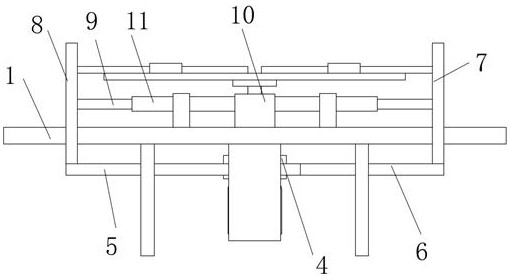

Electron beam processing system capable of realizing multiple electron beam center wire feeding

InactiveCN111250855ASolve the problem of easy adhesion on the productQuality improvementElectron beam welding apparatusElectron beam machiningHigh energy

The invention discloses an electron beam processing system capable of realizing multiple electron beam center wire feeding, and relates to the field of electron beam processing. The electron beam processing system comprises an electron gun and a rotating motor, wherein the electron gun is used for a device generating, accelerating and converging high-energy-density electron beam flows and emits electron beams with certain energy, a certain beam flow, a certain speed and a certain angle, and the rotating motor is used for changing the angle of the electron gun so as to change the illumination angle of the electron beams on a workpiece and used for adjusting the working state. By arranging a diffusion pump, a mechanical pump, an exhaust port and a deposition film, when the electron beams melt the workpiece and wire materials, part of metal is vaporized, at this time, the mechanical pump is firstly started to vacuumize a working chamber, and then oil liquid in the diffusion pump is heatedthrough a heater, so that the oil liquid generates high-speed steam to penetrate through a vacuum extraction opening to extract metal gas generated in a vacuum chamber and exhaust the metal gas fromthe exhaust port, and the problem that metal steam cannot be recovered is solved effectively.

Owner:宁夏中科农副产品辐照中心有限公司

Marine product processing device

InactiveCN108685009AIncrease flexibilityImprove work coordinationFood scienceEngineeringProduct processing

The invention discloses a marine product processing device. The marine product processing device comprises a box body, wherein a processing cavity is fixedly formed in the box body; a power cavity located in the box body is fixedly arranged on the left side of the processing cavity; a sliding cavity which communicates with the processing cavity is formed in the right end wall of the power cavity in a communicating manner; a collecting cavity located in the box body is formed in the lower end wall of the processing cavity in a communicating manner; a side cavity located in the box body is formed in the left side of the processing cavity; a transmission cavity which is located in the box body and of which the opening is leftward is formed in the lower end wall of the side cavity in a communicating manner; and a connecting cavity located in the box body is formed between the transmission cavity and the processing cavity in a communicating manner. The marine product processing device disclosed by the invention is simple in structure and convenient to use; and according to the marine product processing device, steam is used for processing seafood circularly, the seafood is transported in an automatic manner, and condiments are applied in an automatic manner, so that the labor cost is effectively reduced.

Owner:潘育素

Device for butt-joint brazing of metal plates

InactiveCN114473126ARealize clamping and fixingPrevent upturningSoldering auxillary devicesGear wheelElectric machinery

The invention discloses a device for butt brazing of metal plates, and belongs to the field of machining, the device comprises a fixed base, the left side and the right side of the fixed base are movably connected with a second abutting plate and a first abutting plate respectively, the lower end part of the fixed base is provided with a supporting plate, the supporting plate is provided with a driving motor, and the upper end part of the driving motor is fixedly sleeved with a gear; an oil storage tank is fixedly installed in the middle of the fixed base, a piston plate is arranged in the oil storage tank, a connecting rod is arranged at the upper end of the piston plate, a balancing weight is connected to the upper end of the connecting rod through threads, and the front side and the rear side of the oil storage tank communicate with transmission cavities through pipelines correspondingly; fixing pipes are symmetrically arranged on the two sides of the transmission cavity, inserting rods are movably inserted into the outer ends of the fixing pipes, a mounting base is arranged at the upper end of the transmission cavity, and limiting plates are symmetrically arranged at the front end and the rear end of the mounting base. The plate machining quality can be improved, the machining efficiency is high, and the automation degree is high.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

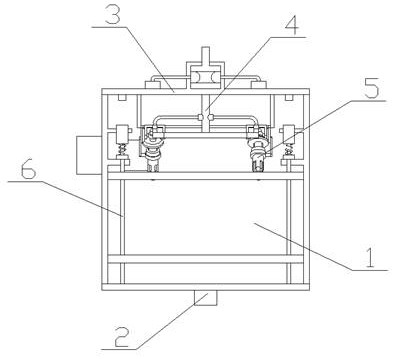

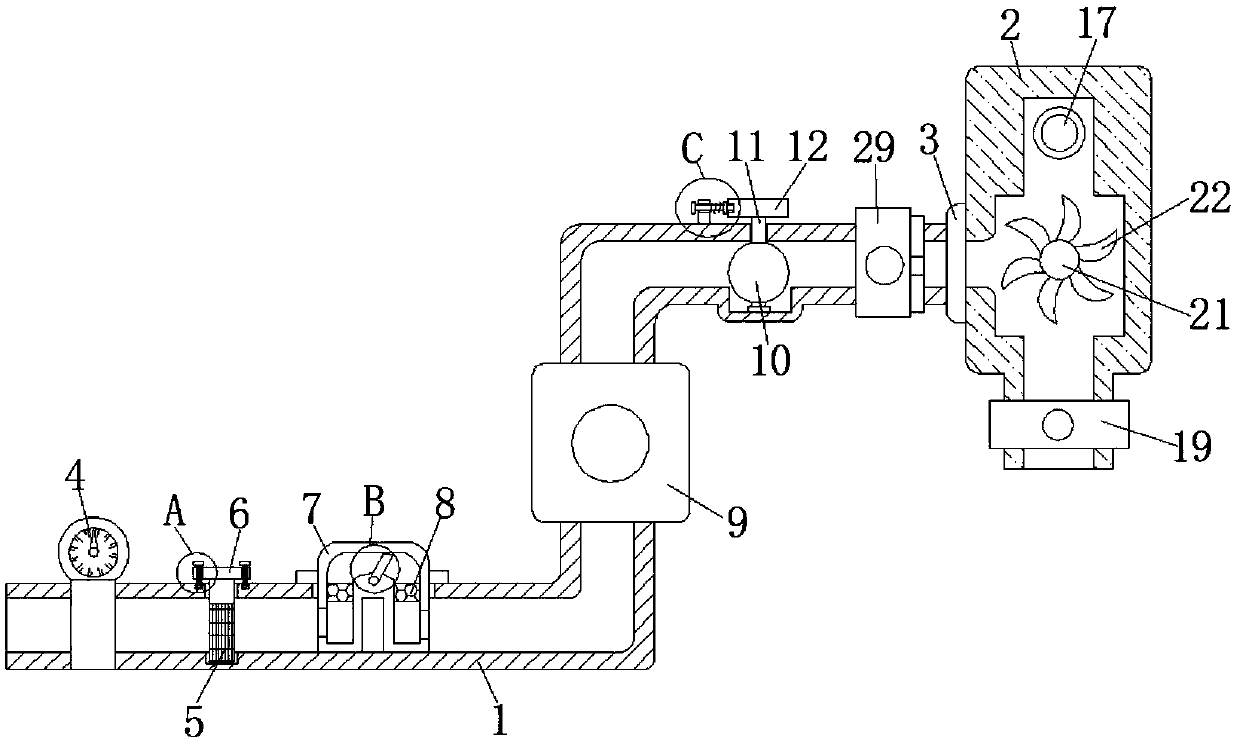

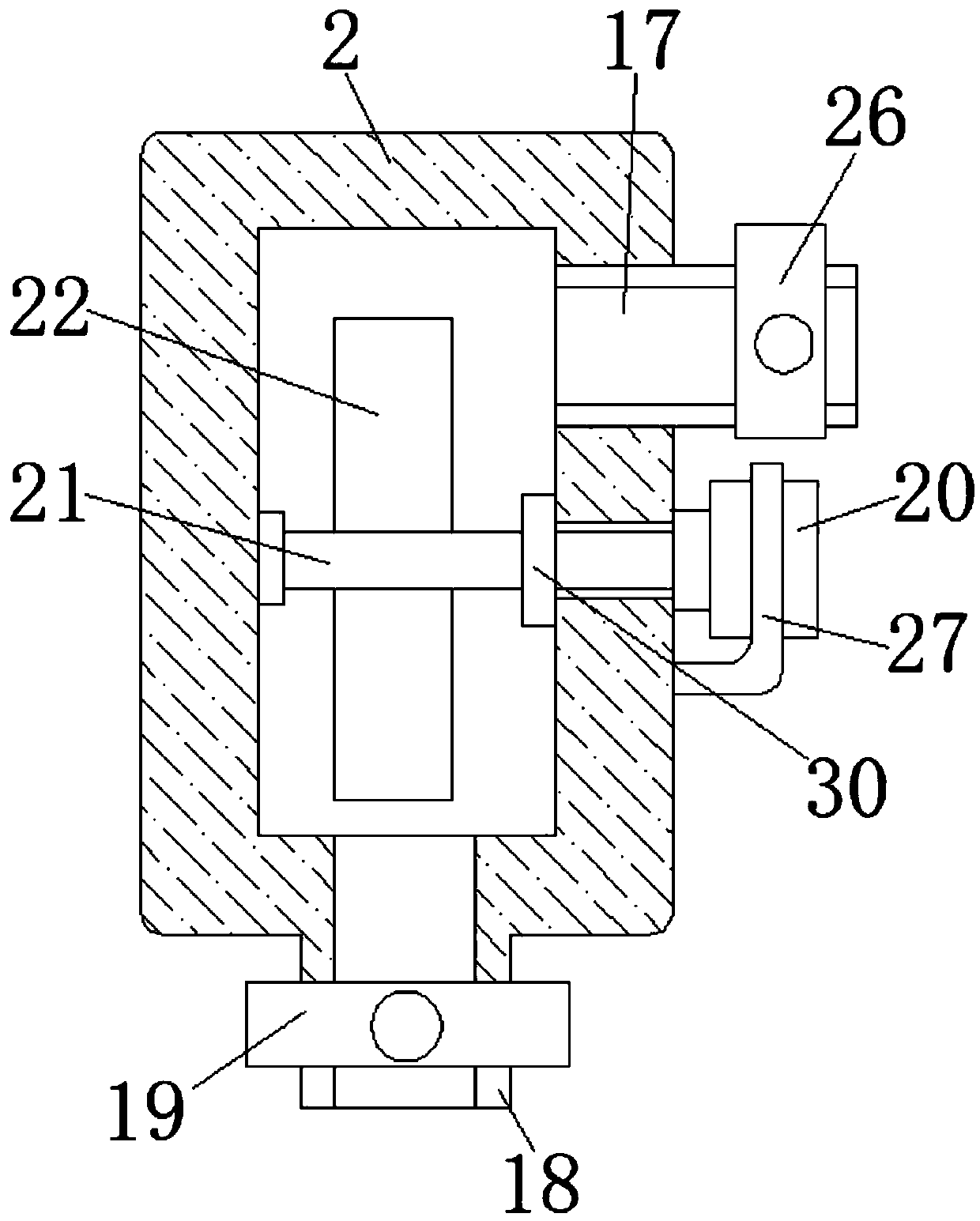

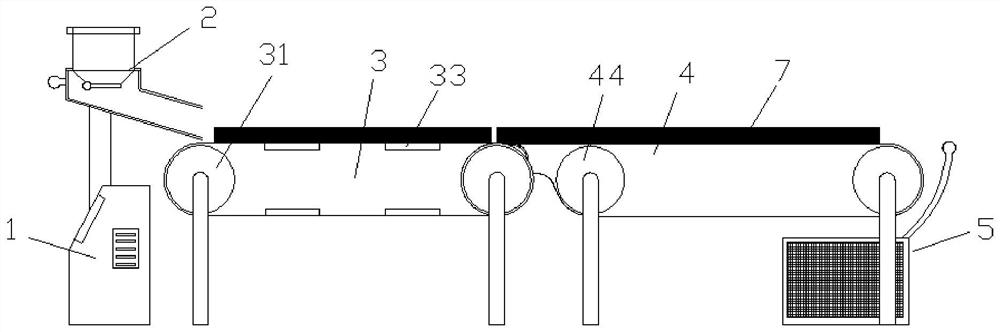

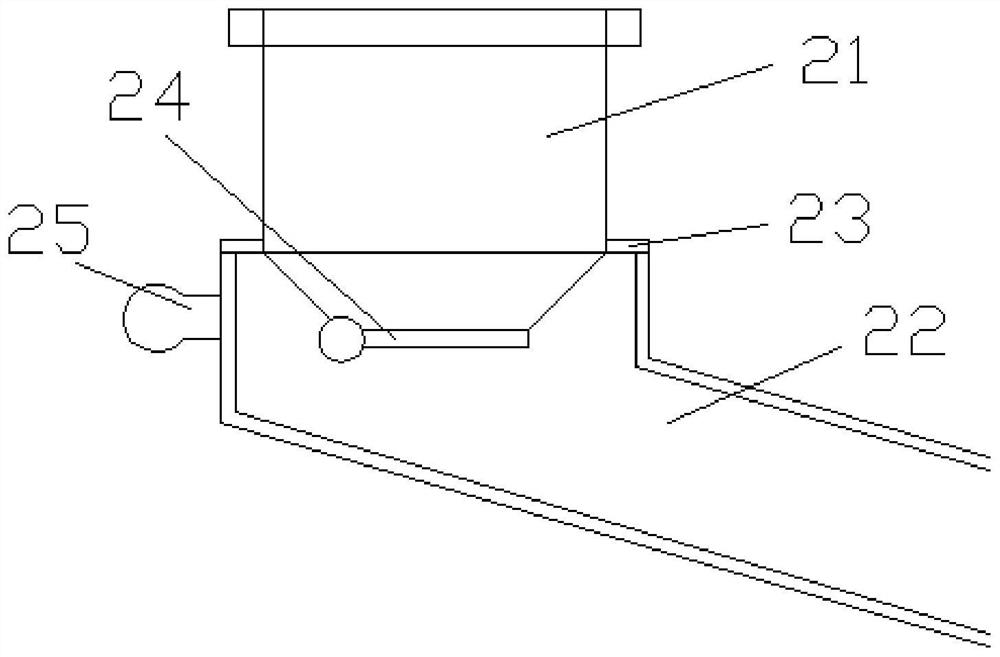

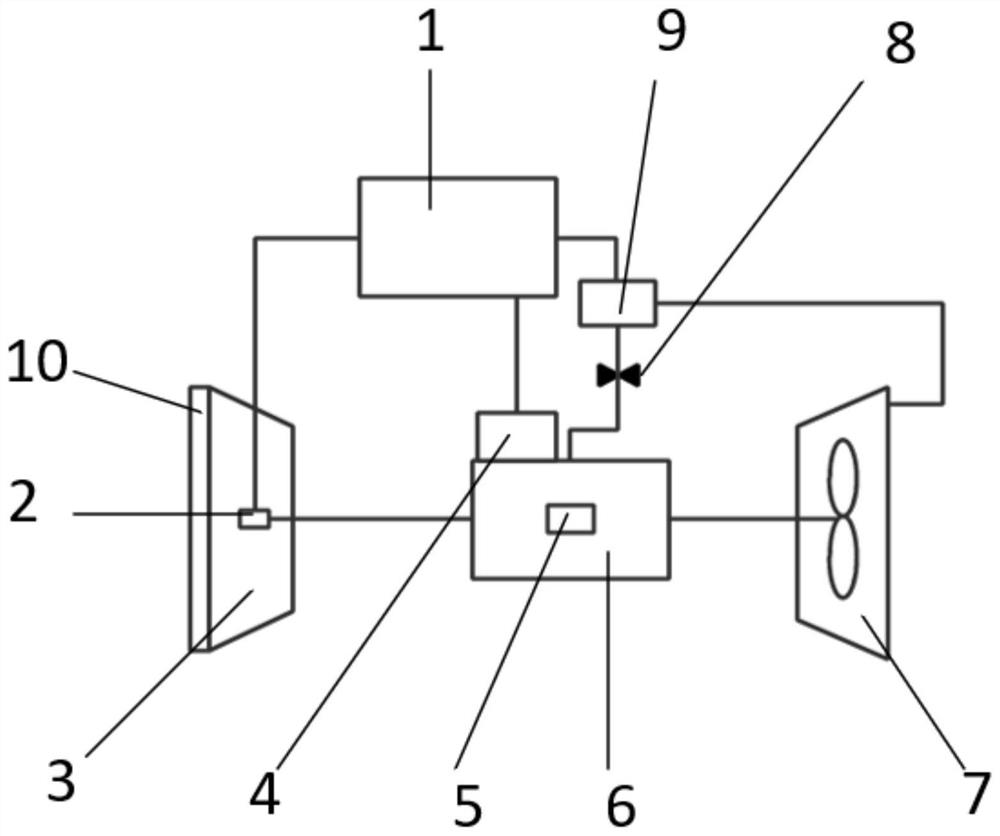

Grape sorting operation platform

InactiveCN114472233AControl ingressAvoid damageSortingFood treatmentAgricultural engineeringProcess engineering

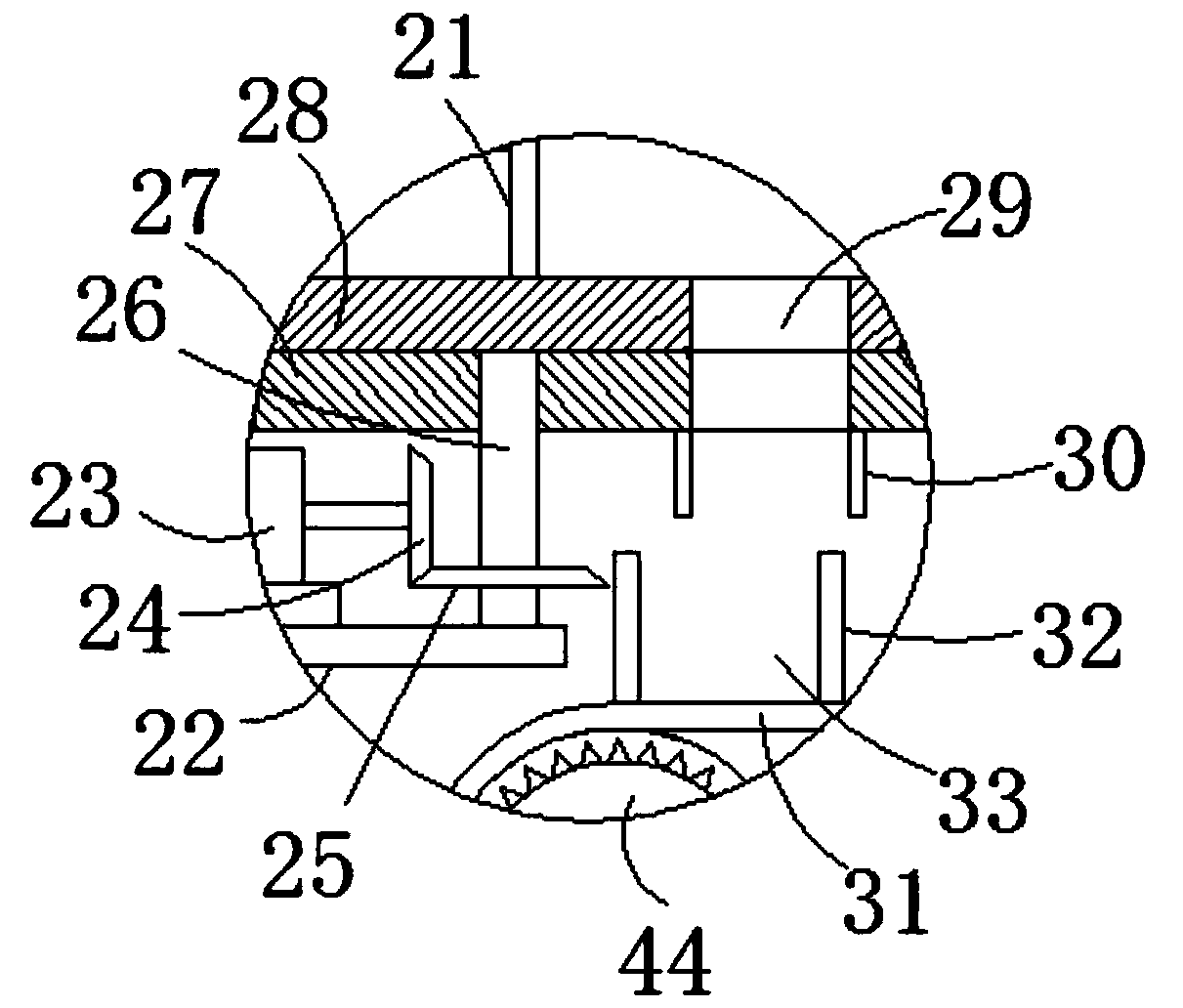

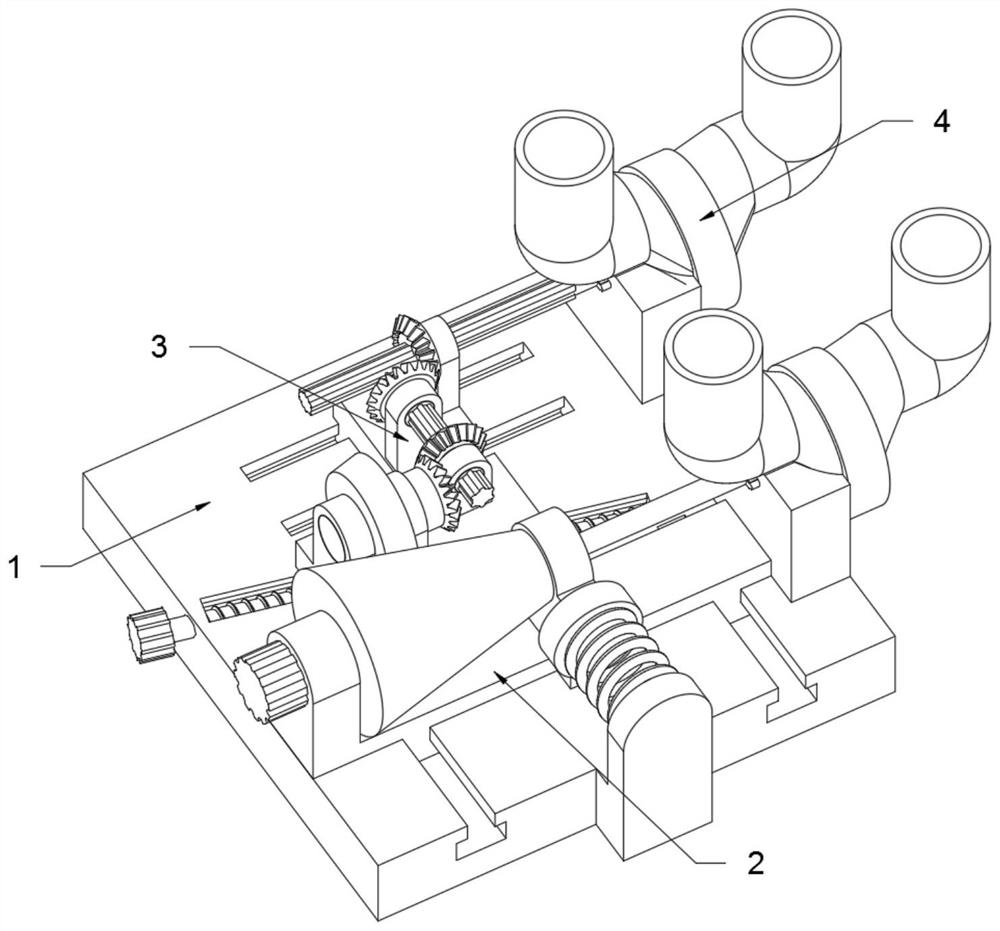

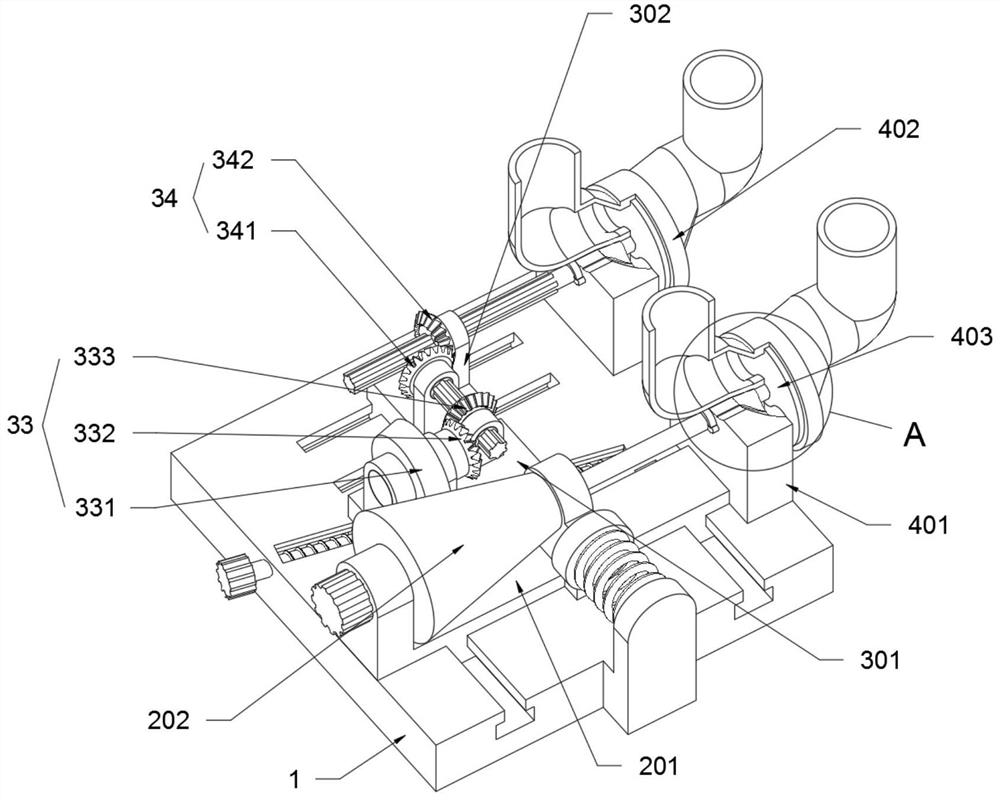

The invention discloses a grape sorting operation platform which is mainly formed by combining a controller (1), a feeding device (2), a material dispersing device (3), a sorting device (4) and a recycling device (5). According to the grape sorting operation platform, the feeding amount of grapes each time can be effectively controlled through a weighing device, a warning lamp and an electric control bin gate, the grapes are prevented from being damaged at a feeding port section, and the working efficiency is improved. The material dispersing device can disperse grapes entering in piles through vibration and flatly lay the grapes on a material dispersing belt, it can be ensured that the grapes are kept in a flatly-laid state when entering the sorting device, the grapes are prevented from being squeezed and damaged by one another, on the other hand, sorting work of workers is facilitated, the sorting device is divided into three parts for flow division, and the sorting efficiency is improved. A worker sorts one sorting device independently, grape damage caused by mutual influence of the workers is prevented, the device is simple in structure and convenient to operate, the utilization rate of raw materials is effectively increased, the quality of the raw materials of the grape wine is improved, and the production cost is reduced.

Owner:湖南唯楚果汁酒业有限公司

Device and method used for continuous material thermal treatment

ActiveCN111895779AAvoid deflectionGuaranteed free expansionRotary drum furnacesLoading/unloadingTube furnaceLap joint

The invention relates to a device used for continuous material thermal treatment. The device comprises a rotary device, a charge device and a tubular type furnace body, wherein the rotary device comprises supporting frames, a supporting barrel and a corundum furnace tube; the supporting frames are positioned at the two sides of the tubular type furnace body; a rotary left supporting barrel and a rotary right supporting barrel are mounted on the supporting frames; the corundum furnace tube is arranged between the supporting barrels; joints of the supporting barrels and the corundum furnace tubeare equipped with aluminum oxide cotton; a charge hole is formed in the left supporting barrel; an inclined guide block is arranged in the left supporting barrel on the lower part of the charge hole;a discharge hole is formed in the right supporting barrel; the charge device comprises a bracket, a collecting barrel, an unloading adjusting template and a guide plate; the collecting barrel is mounted on the supporting frames through the bracket; a loading hole and an unloading hole are formed in the collecting barrel; one end of the unloading adjusting module is inserted into the unloading hole, and the other end of the unloading adjusting module is hinged with the guide plate, and a hinged part is equipped with an elastic element; and one end of the guide plate is inserted into the side wall of the bracket, and the other end of the guide plate is in lap joint on the left supporting barrel. The invention further relates to a method for material continuous thermal treatment.

Owner:YANTAI UNIV

Gas turbine pneumatic control system based on three-dimensional axial flow

ActiveCN112983653AImprove combustion effectImprove work efficiencyTurbine/propulsion fuel controlImpellerComplete data

The invention relates to a gas turbine pneumatic control system based on three-dimensional axial flow. A central control processor is arranged to be connected with an ultrasonic detector, a temperature detector, a rotating speed detector and flow detection equipment and complete data exchange in real time; and meanwhile, the central control processor adjusts the opening and closing degree of an adjusting valve and an guide vane opening and closing angle in real time according to the carbon deposition thickness detected by the ultrasonic detector and the change of the axial flow in a gas compressor, so that the combustion effect in a combustion chamber of a gas turbine is improved; and meanwhile, high-temperature deformation of a gas turbine impeller caused by too high rotation speed of the gas turbine impeller or low efficiency caused by too slow rotation of the gas turbine impeller are avoided, so that the gas turbine is in a stable operation state, and the working efficiency and reliability of the gas turbine are improved.

Owner:山东赛马力发电设备有限公司

Anesthesia concentration adjusting anesthesia device for anesthesiology department

InactiveCN114177466ARealize the ratio of mixed useEasy to useRespiratorsMedical devicesAnesthetic departmentAnesthetic gases

The invention provides an anesthesia concentration adjusting anesthesia device for the anesthesiology department, and relates to the technical field of anesthesia concentration adjusting devices.The anesthesia concentration adjusting anesthesia device comprises a disc valve assembly, a connecting shell is fixedly installed at the top of a connecting base, and a constant-proportion adjusting assembly can fix the proportion of oxygen and anesthetic, so that the anesthetic gas does not need to be proportioned many times in the using process; the device is simple in structure and convenient to use, the two disc valve assemblies can be connected with the inlet and outlet amount of oxygen and anesthetic, so that the two gases are proportionally mixed for use, the anesthetic concentration proportion of the device can be freely adjusted, the device can be suitable for anesthetizing patients under different treatment and operation conditions, the adaptability is extremely high, and the practicability is high. The problems that an existing anesthesia adjusting device cannot fix the proportion concentration of oxygen and anesthetic for use, the air inflow of the oxygen and the anesthetic needs to be adjusted again every time the anesthetic amount is adjusted, and operation is very tedious are solved.

Owner:张萍萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com