Rice freshness preserving gas, preparation method and preparation device thereof

A technology for keeping fresh gas and rice, applied in the direction of gas and gas/steam mixing, mixing methods, chemical instruments and methods, etc., can solve the problems of general fresh-keeping effect of rice, achieve gloss protection, prevent aging deterioration, and good fresh-keeping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

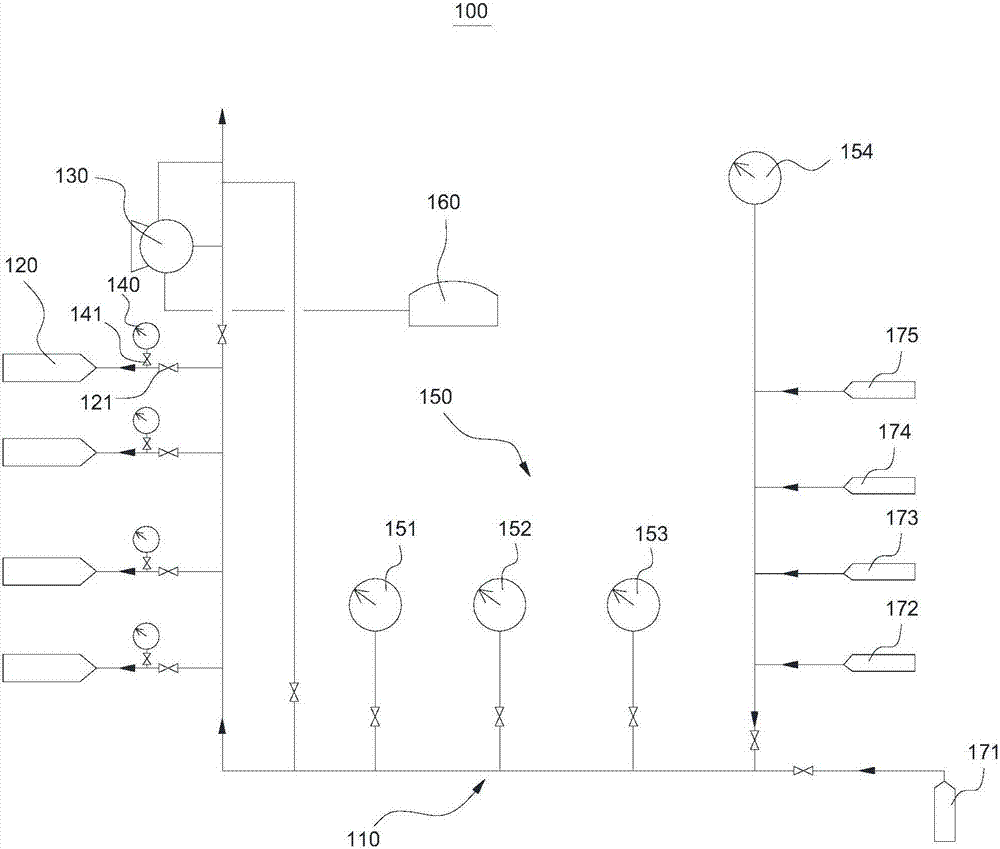

[0046] The nitrogen contained in the first component gas tank 171, the oxygen contained in the second component gas tank 172, the gaseous water contained in the third component gas tank 173, and the carbon monoxide contained in the fourth component gas tank 174 And the carbon dioxide contained in the fifth component gas tank 175 is passed into the vacuum container 120 through the gas supply pipeline 110 one by one. Finally, close the intake valve 121 of the vacuum container 120, start the vacuum pump 130 to evacuate the air supply pipeline 110, then open the valve corresponding to the next component gas tank and the intake valve 121 to feed the next component into the vacuum container 120 Its body, all pass in the vacuum container 120 until all gases, obtain rice fresh-keeping gas. The volume ratio of the functional gas to the dilution gas in the rice fresh-keeping gas is 10:9990, and the ratio of oxygen, gaseous water, carbon monoxide and carbon dioxide is 1:3:10:900.

Embodiment 2

[0048] The nitrogen contained in the first component gas tank 171, the oxygen contained in the second component gas tank 172, the gaseous water contained in the third component gas tank 173, and the carbon monoxide contained in the fourth component gas tank 174 And the carbon dioxide contained in the fifth component gas tank 175 is passed into the vacuum container 120 through the gas supply pipeline 110 one by one. Finally, close the intake valve 121 of the vacuum container 120, start the vacuum pump 130 to evacuate the air supply pipeline 110, then open the valve corresponding to the next component gas tank and the intake valve 121 to feed the next component into the vacuum container 120 Its body, all pass in the vacuum container 120 until all gases, obtain rice fresh-keeping gas. The volume ratio of the functional gas to the dilution gas in the rice fresh-keeping gas is 5:9995, and the ratio of oxygen, gaseous water, carbon monoxide and carbon dioxide is 1:10:20:800.

Embodiment 3

[0050] The nitrogen contained in the first component gas tank 171, the oxygen contained in the second component gas tank 172, the gaseous water contained in the third component gas tank 173, and the carbon monoxide contained in the fourth component gas tank 174 And the carbon dioxide contained in the fifth component gas tank 175 is passed into the vacuum container 120 through the gas supply pipeline 110 one by one. Finally, close the intake valve 121 of the vacuum container 120, start the vacuum pump 130 to evacuate the air supply pipeline 110, then open the valve corresponding to the next component gas tank and the intake valve 121 to feed the next component into the vacuum container 120 Its body, all pass in the vacuum container 120 until all gases, obtain rice fresh-keeping gas. The volume ratio of functional gas to diluent gas in the rice fresh-keeping gas is 6:9994, and the ratio of oxygen, gaseous water, carbon monoxide and carbon dioxide is 2:5:12:850.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com